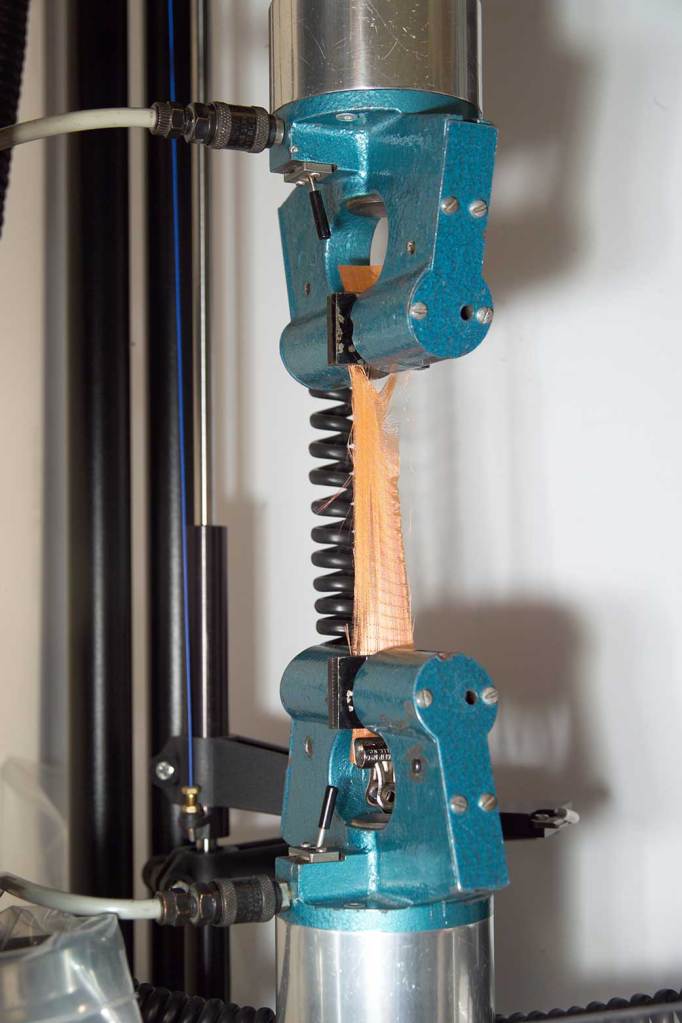

Materials Testing

With over 60 years of experience in meeting the exacting specifications and high tolerances of space flight materials for components, WSTF Materials Testing Group are experts in material identification and characterization, material improvement, acceptance testing, and failure analysis.

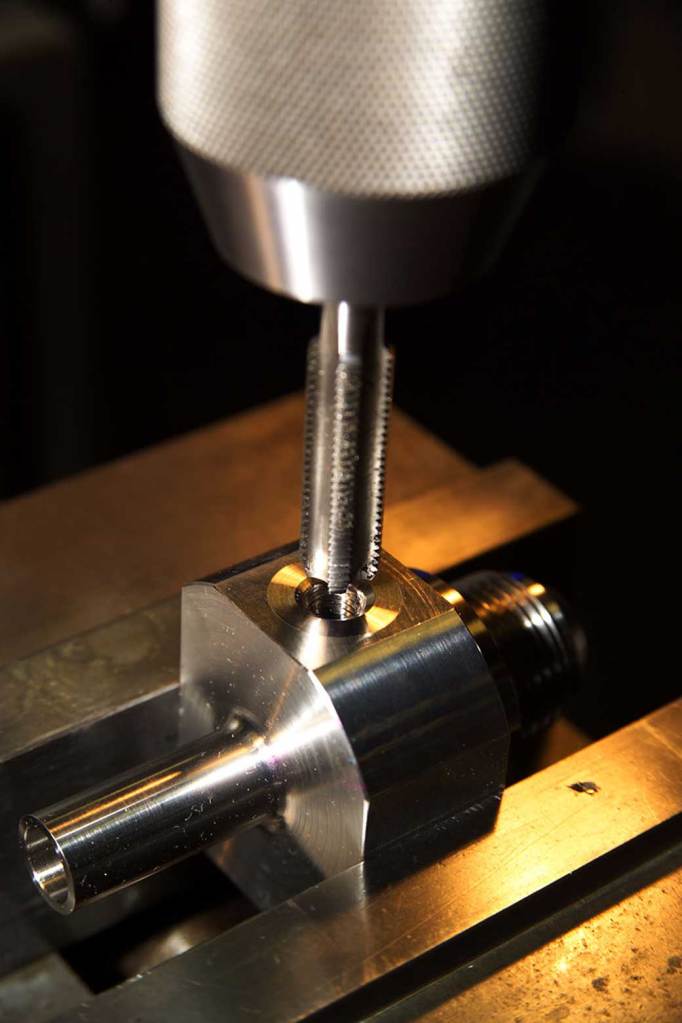

Machining and Fabrication

White Sands Test Facility's Machining and Fabrication craftsmen specialize in the prototype and production of parts used on the International Space Station, ground support equipment, and facility and test hardware

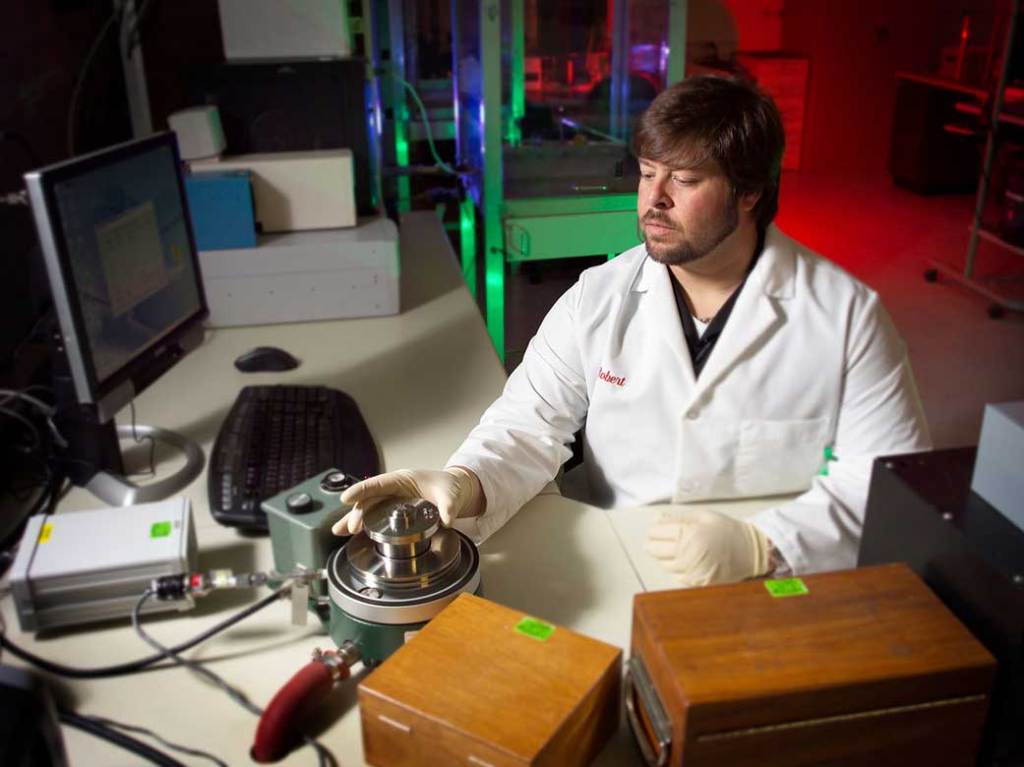

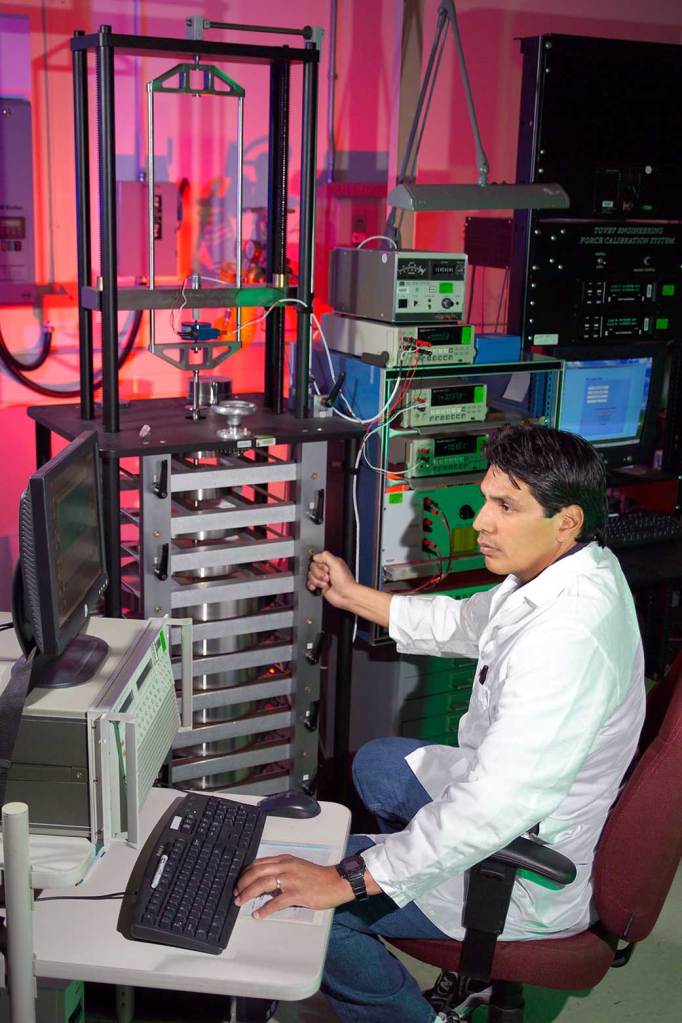

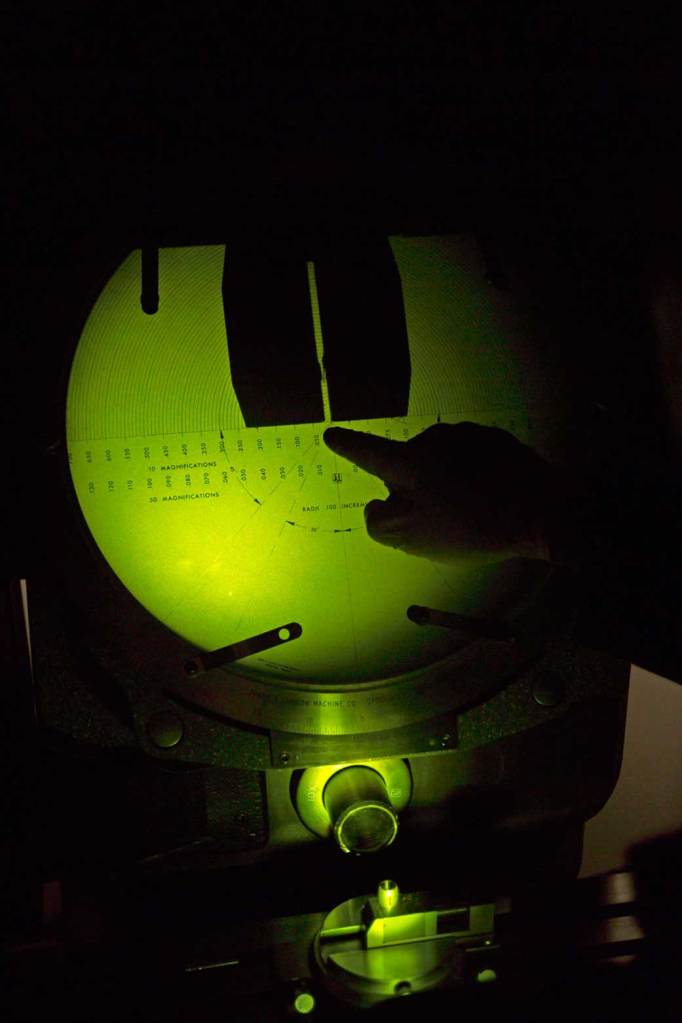

Calibration

WSTF's calibration team supports mission critical testing for the International Space Station and other NASA space exploration efforts, and helps to safeguard the lives and equipment used in these high risk endeavors. Calibration is a critical step for all instrumentation used in our testing and ensures that the data received from calibrated instruments is converted into meaningful and accurate measurements. To minimize measurement uncertainty, calibration processes are performed in an environmentally-controlled laboratory with regulated temperature and humidity when needed according to the National Institute of Standards and Technology (NIST).

Electrical Calibration

Temperature/Humidity Calibration

Pressure Calibration

Mass Calibration

Vacuum Calibration

Torque Calibration

Force Calibration

Flow Calibration

Dimensional Calibration

Component Services

WSTF 's Component Services workforce provides expertise in disassembly, cleaning, maintenance, reassembly, refurbishment, manufacture, and testing of pressure relief and pressure safety valves in compliance with the American National Standards Institute (ANSI) National Board Inspection Code (NBIC)/NB-23.

Operations consist of hardware precision cleaning, component assembly, and component calibration. With a full-service clean room and Valve Repair Facility, this organization has extensive cleaning and refurbishing experience with numerous valve configurations, metal types, and elastomerics.

Learn More about Component Services

Training

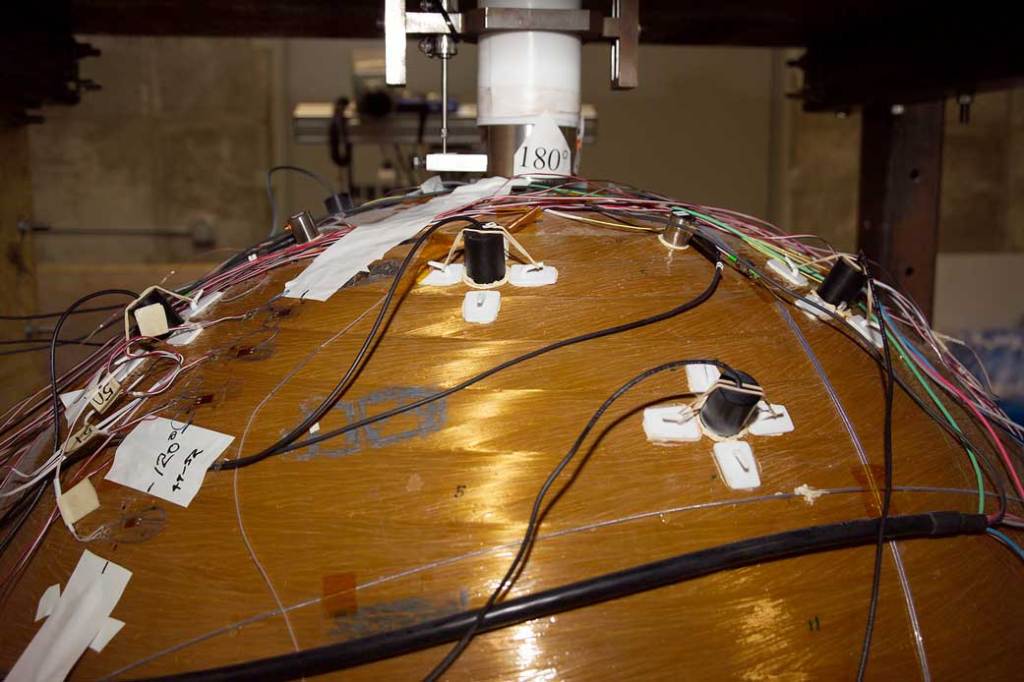

WSTF personnel have developed an extraordinary degree of expertise in composite pressure vessels, oxygen systems, and propellants and aerospace fluids and have partnered with standards organizations, other NASA facilities, government entities, and commercial industry to create world class training. WSTF has conducted extremely comprehensive materials testing and investigations focusing on oxygen and propellant environments and systems for over 40 years. WSTF leads the way for an industry‐wide movement for composite pressure vessel data collection, damage detection, inspection techniques, and impact prevention. This knowledge is passed along to the aerospace and industrial community through training.

Fire Hazards in Oxygen Systems

Oxygen Systems: Operations and Maintenance

Composite Overwrap Pressure Vessel Damage Detection Course

Hypergolic Propellant Handling Training

Hydrogen Handling Training

Totally Encapsulating Suit Training

Blast and Fragmentation Course

Flight Acceptance Standard Testing (NASA-STD-6001) Familiarization Course

Introduction to Precision Cleaning

49 CFR Department of Transportation (DOT) Hazardous Materials (HAZMAT) Training

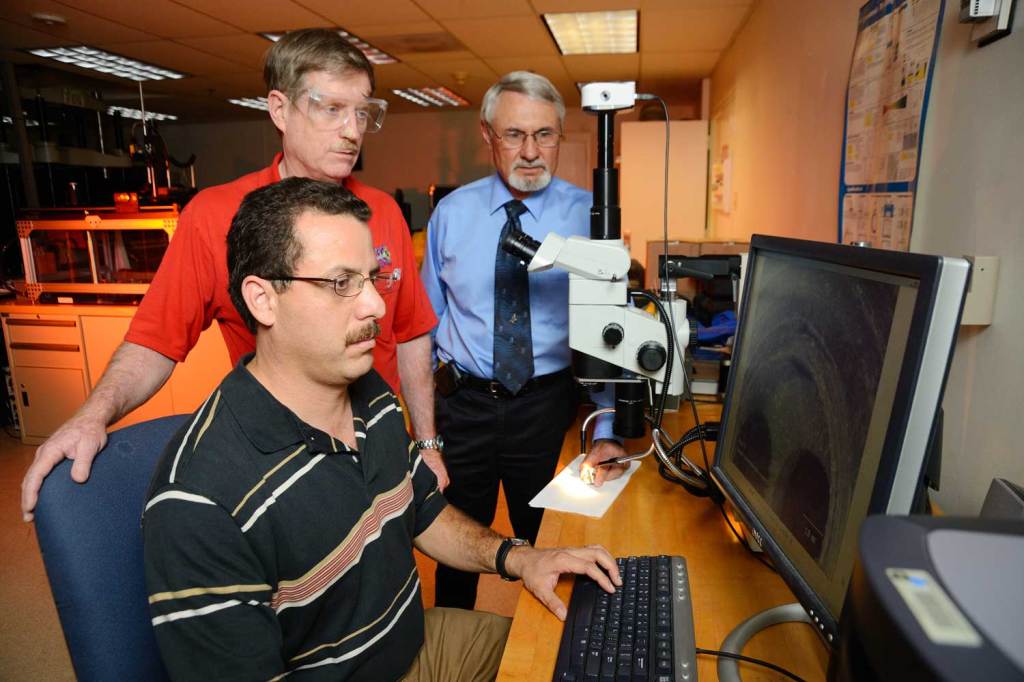

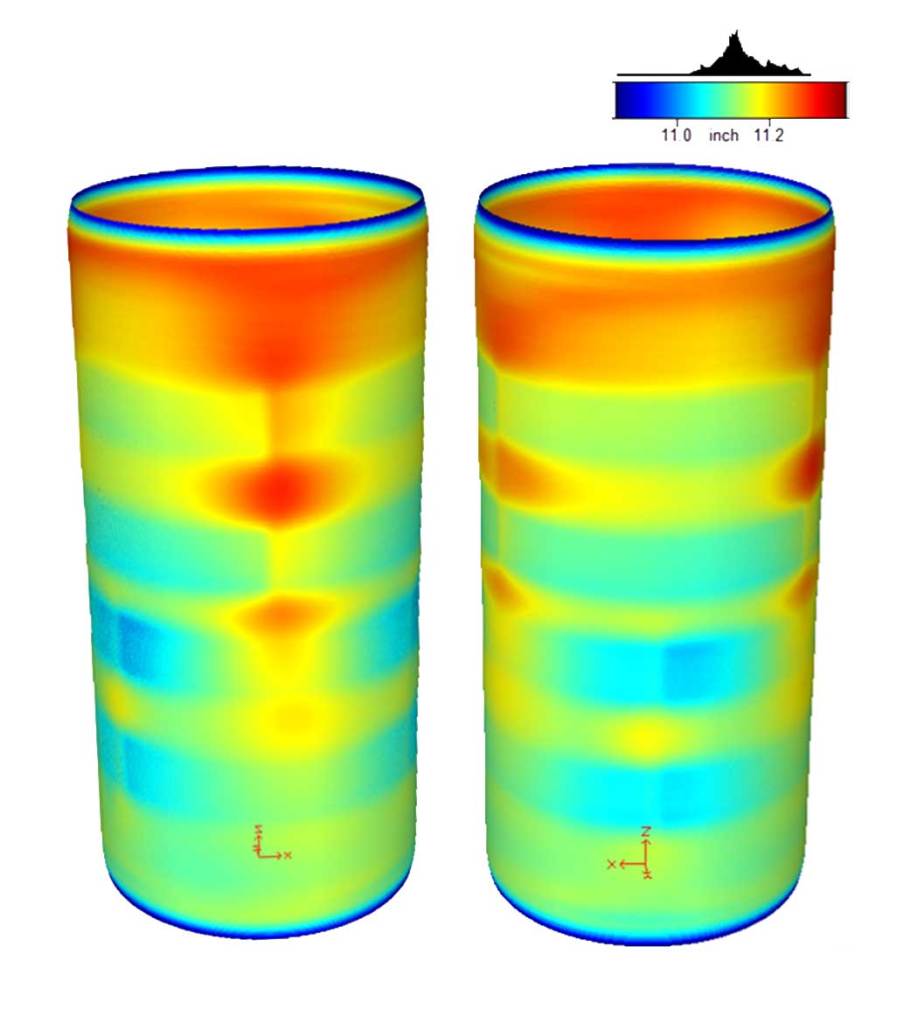

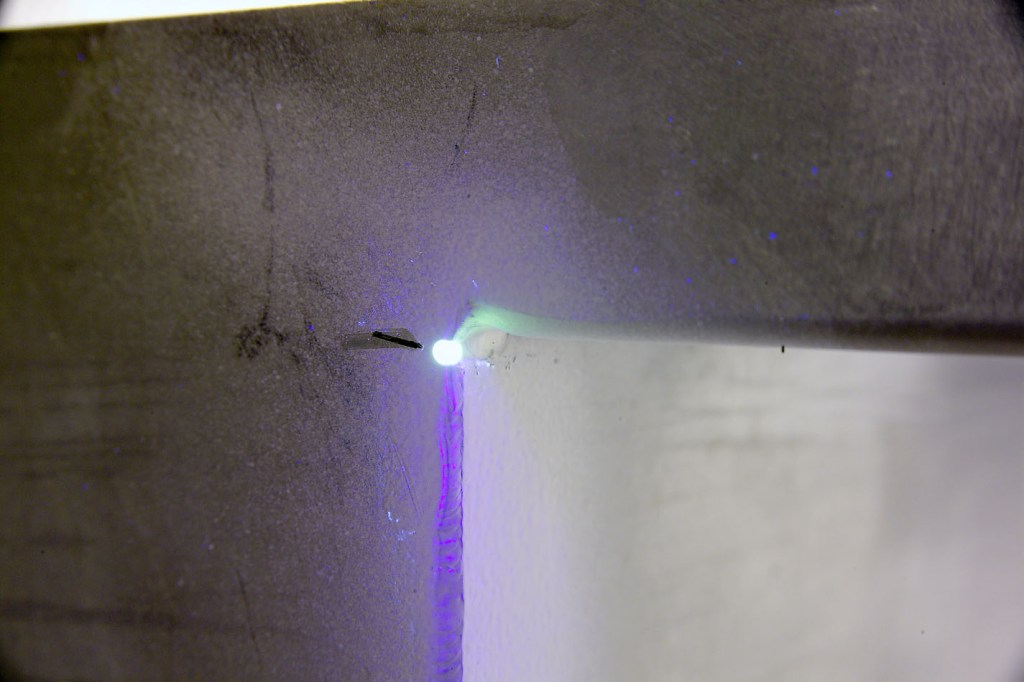

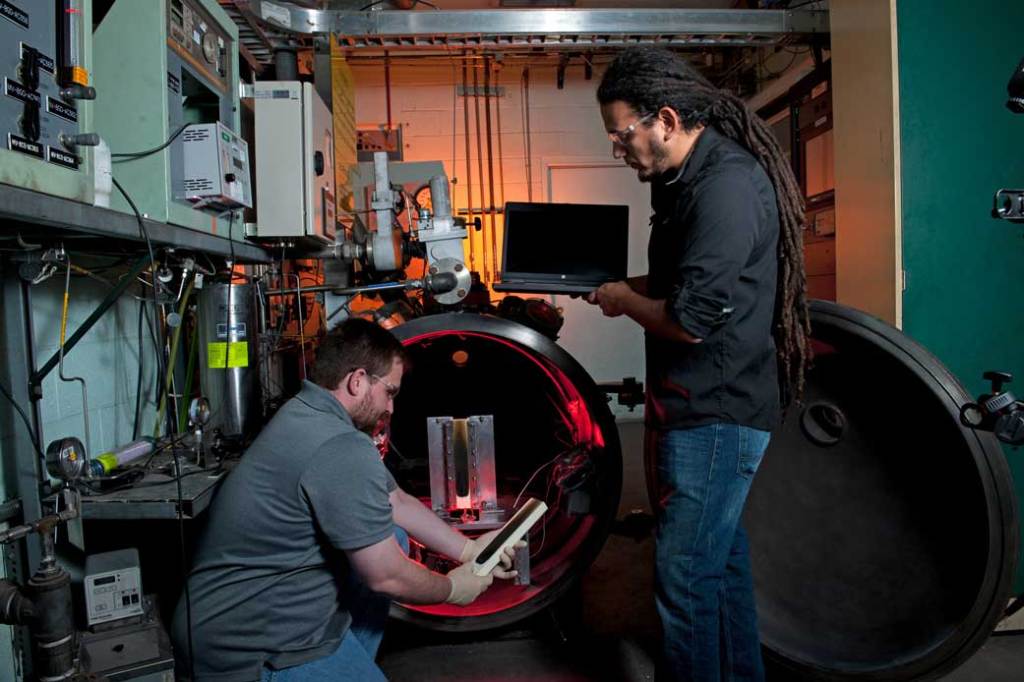

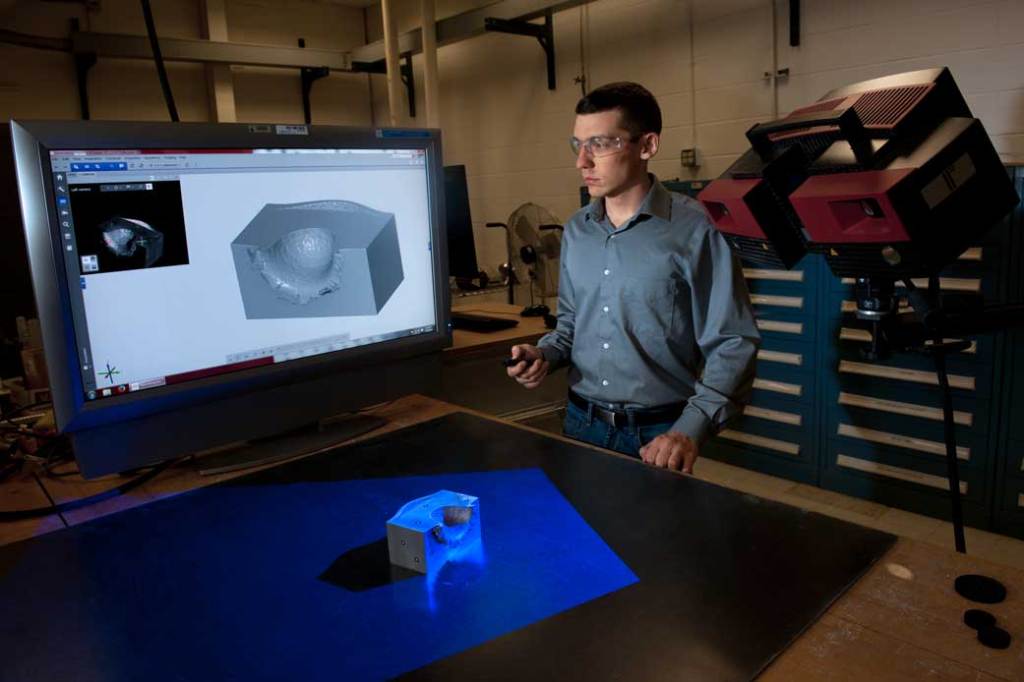

Nondestructive Evaluation

WSTF's nondestructive evaluation (NDE) professionals inspect, test and evaluate materials, components, and systems for discontinuities before they cause severe damage, operation inefficiencies, or in-service failures. Early detection of defects assures the high reliability, integrity, and safety of material used in aerospace.

3D Scanning and Digitization

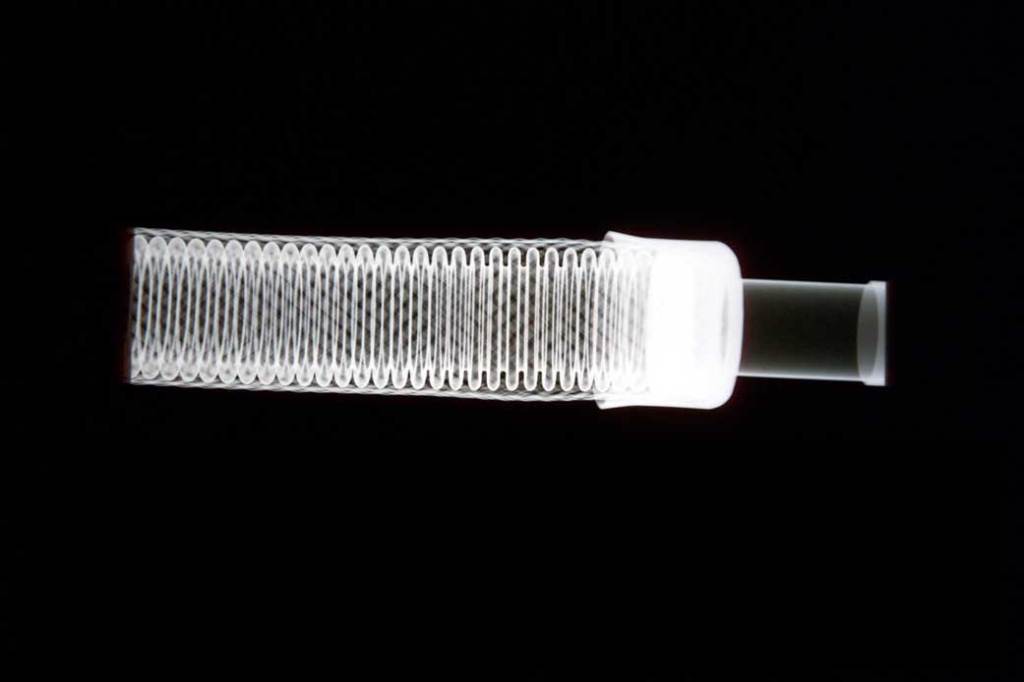

Ultrasonic Testing

Thermography

Radiographic Testing

Shearography Testing

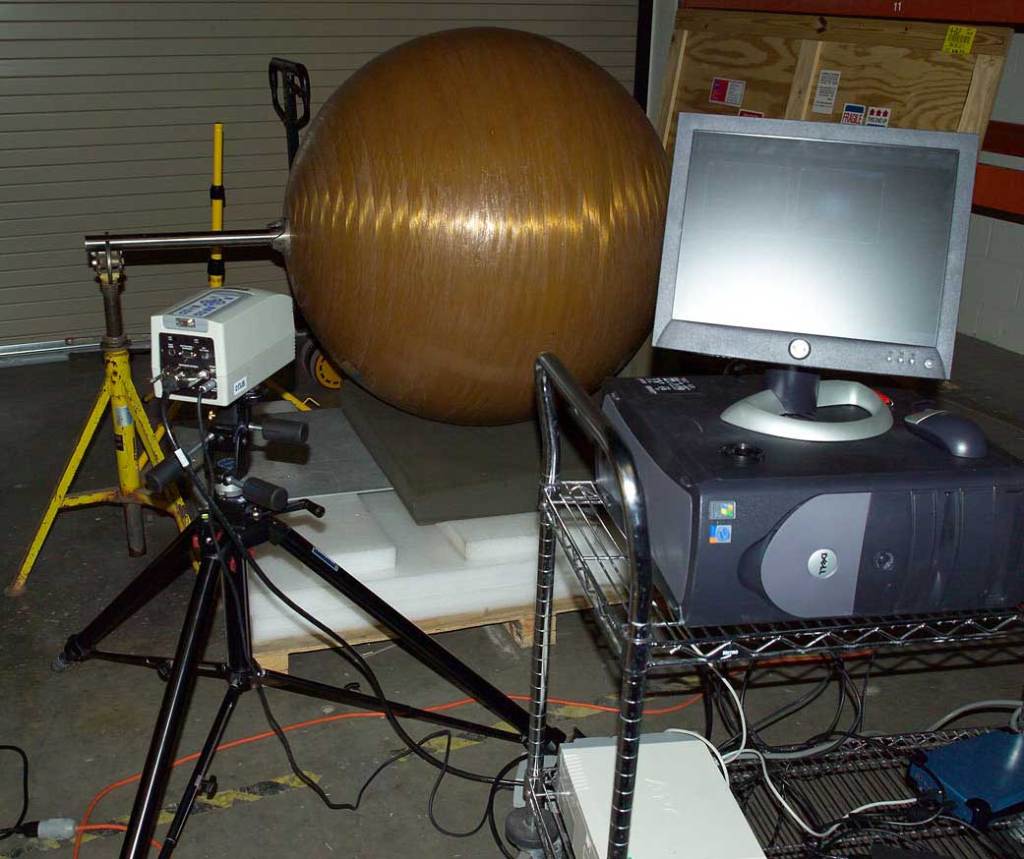

Acoustic Emissions (AE) Testing

Penetrant Testing

Magnetic Particle Testing

Electromagnetic Testing

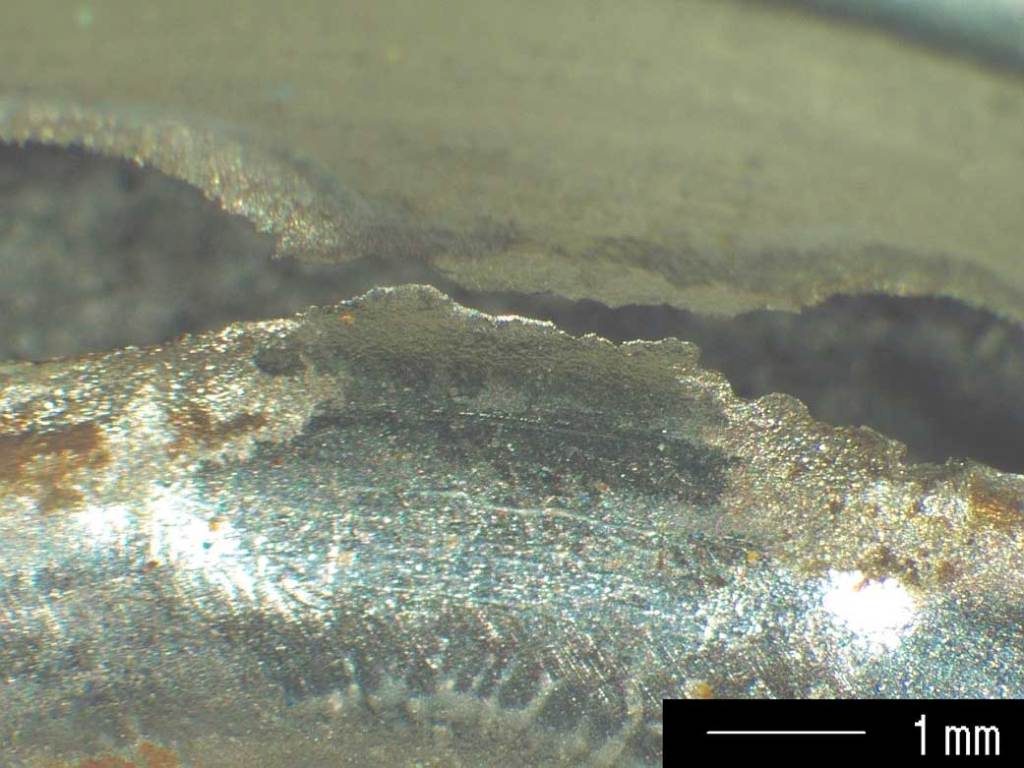

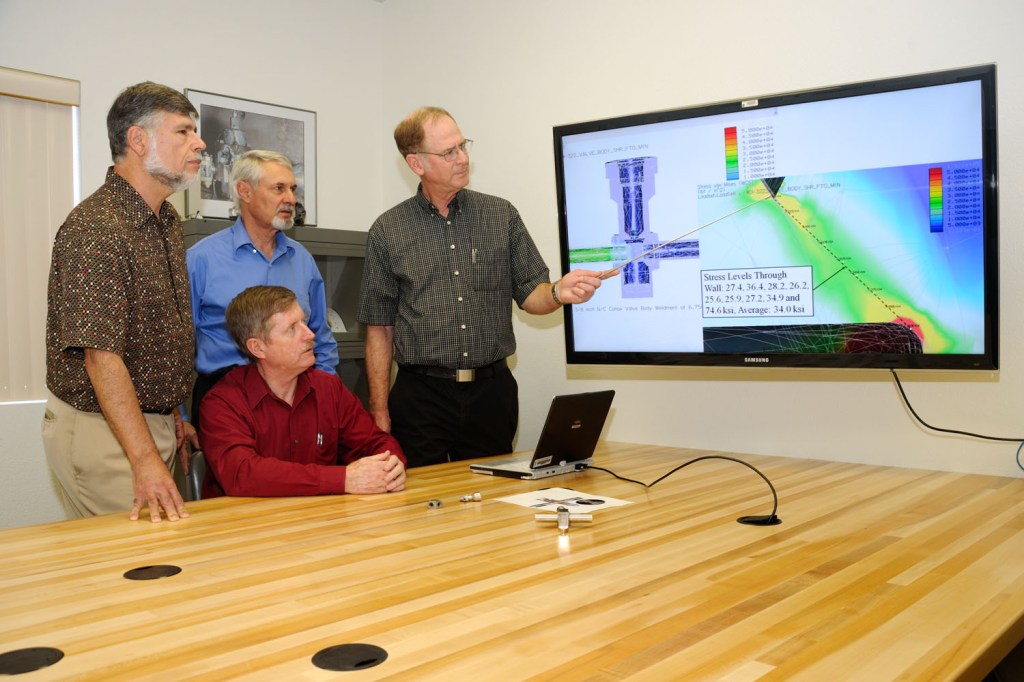

Failure Analysis

Failure analysis determines what, why and how things went wrong when a component, system, or structure fails and is a valuable tool in the development of new products and the improvement of existing ones. WSTF's multi-disciplined Failure Analysis team has the expertise and in-house capabilities to determine the root cause of failures on a wide range of materials including paints and coatings, adhesives and sealants, composites, rubbers, plastics, elastomers, and metals. The Failure Analysis team routinely applies expert knowledge of oxygen systems, composite pressure systems, propellants and aerospace fluids, and propulsion systems to root cause analysis and offer expert recommendations for improvements and corrective action.