The suitability of a material for its intended application is provided through mechanical testing. Measuring materials under various load and environmental conditions provides information about the mechanical properties and characteristics including ductility, fracture toughness, elongation, hardness, impact resistance, strength, and stress resistance.

Compressive Testing

Compressive testing characterizes the behavior of materials subjected to compressive loads helping to determine a material’s yield strength, failure mode, service life, and other critical performance characteristics.

Flexural Bend Testing

Flexural bend testing measures the behavior of materials such as strength and ductility when it is subjected to simple bending loads over a given radius.

Hardness and Microhardness Testing

A materials strength is measured by determining its resistance to penetration and indicates how easily a material can be machined, how well the material will wear, and if treatments and coating may be needed for the performance desired.

Impact Testing

Material impact strength is determined by fracturing a notched specimen and measuring the amount of energy is absorbed by the material during fracture.

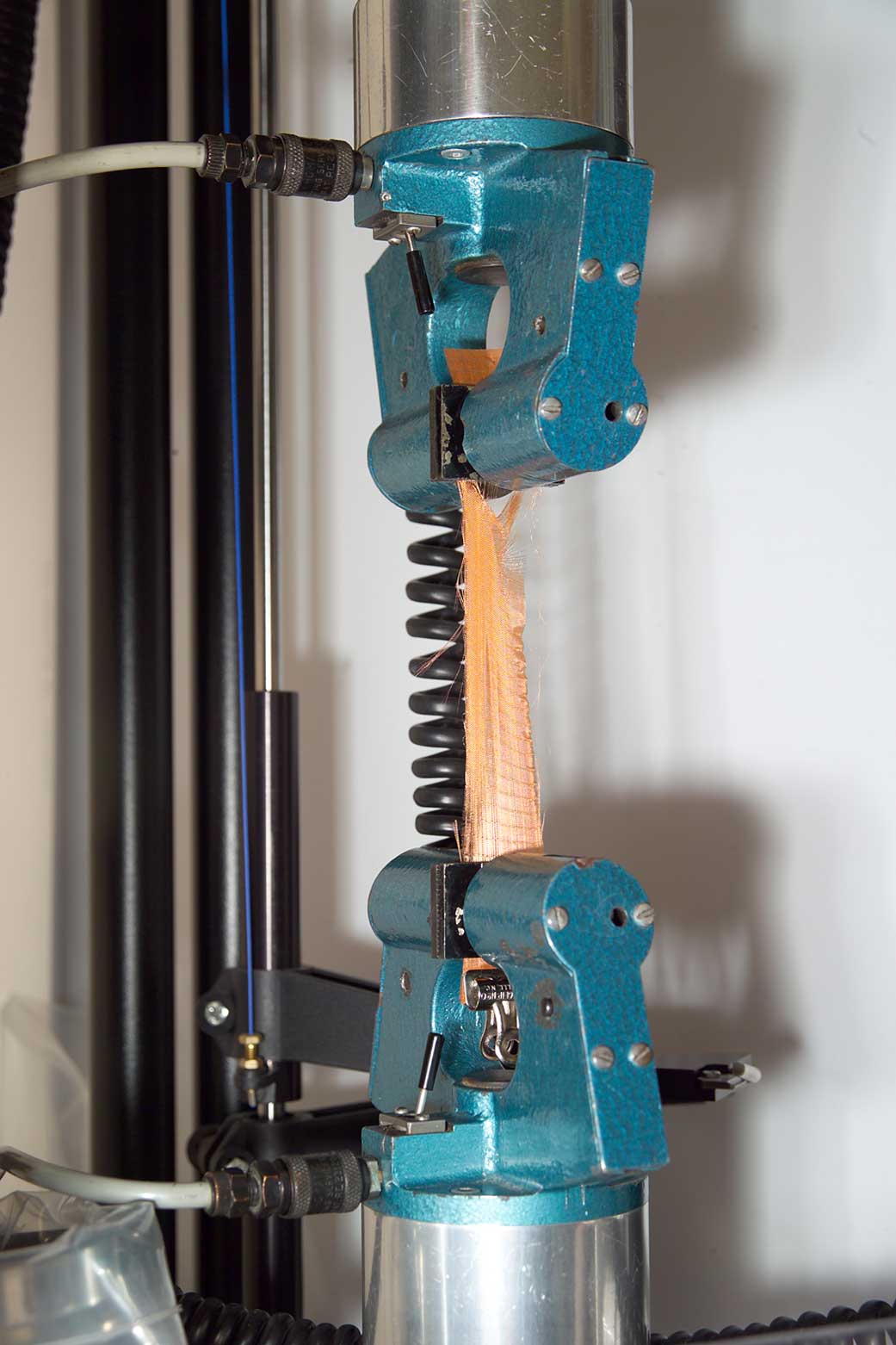

Tensile Testing

A varying load is applied to a test sample up to the point of failure or predetermined criteria, creating a stress/strain curve showing how the material reacts throughout the test. The data provides information about the tensile strength, strain, modulus, and ductility of the test material.