Ask International Space Station facility engineers and payload operations teams at NASA’s Marshall Space Flight Center in Huntsville, Alabama, what makes them proudest as they look back on two decades of developing and testing science hardware and providing real-time support for experiments on orbit. Many will instinctively glance upward, as if the source of that pride might be passing overhead at that moment, 250 miles up.

Just as often though, they look to one another.

Shawn Reagan, materials science research portfolio manager in Marshall’s International Space Station Projects Office, called that unified purpose and drive “tremendous.”

“Whatever our specific roles, we all share one goal: to get experiments developed, tested, manifested and flown to space, successfully conducted in orbit, and returned to Earth for analysis and practical application,” he said. “And it’s all in service of furthering our scientific knowledge, benefiting humanity, advancing our journey of exploration into the solar system, and aiding development of a thriving commercial space economy.”

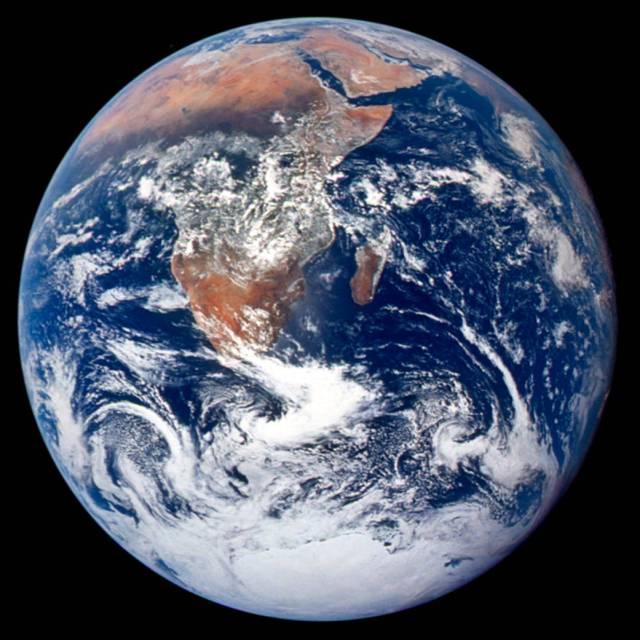

The space station, currently celebrating more than 20 years of continuous crew operations, is a marvel of teamwork, home to round-the-clock cutting edge science – some 200 discrete experiments underway in orbit at any given moment, overseen by the astronaut crew and by science teams on the ground.

Marshall oversees all payloads from its Payload Operations Center, monitoring use of the 15 unique science hardware facilities developed, built and tested here, all of which Marshall continues to manage for the agency. Crew and station operations are led by NASA’s Johnson Space Center in Houston.

EXPRESSly Designed for High-Volume Science

Central among the station’s science hardware facilities are the “EXpedite the PRocessing of Experiments to the Space Station” multipurpose payload shelving units, better known as EXPRESS Racks. Inspired by the space shuttle’s mid-deck lockers – used to house experiments during more than 130 shuttle flights from 1981-2011 – the EXPRESS Racks were developed and tested at Marshall by NASA and Boeing engineers.

The first two racks were delivered to the space station on STS-100 in 2001 and have been in continuous operation ever since. Today, there are 11 of them – including three Basic EXPRESS Racks, more streamlined, modern versions – the last delivered in 2020. Each refrigerator-sized rack houses up to eight configurable lockers and two payload drawers, all with direct access to power, cooling and heating, and command and data communications. Experiments of any duration can be conducted, removed independently in their protective storage drawers, and returned to Earth when complete.

Up to 80 experiments may be in process in the racks at any given time, controlled by station crew or remotely by NASA personnel in Marshall’s Payload Operations Integration Center. There, a cadre of nearly two dozen specialized team members are tasked with updating crew and ground command procedures for each rack. They monitor payload telemetry, heating, and cooling, ensure data is processing properly, and communicate in real time with the crew and researchers on the ground. They do this work around the clock, every day of the year.

Renee Garifi, a payload rack officer who has supported station science operations at Marshall since 2015 and also serves as facility operations lead for the Materials Science Research Rack, said it’s easy to get absorbed by the busy pace of the job.

“But then you step back and look at the team around you,” she said, “at all the good work this program is doing, the benefits of all that research on station – and it feels like this might be the most important work we could be doing for humanity right now.”

Shaun Glasgow, former project manager for the EXPRESS Racks at Marshall, now project manager for the Material Science Research Rack, agreed. “The sheer volume of science that’s been conducted using the racks is overwhelming,” he said. NASA estimates the racks have yielded more than 99 years of combined operational hours since the first were installed in 2001 – contributing to about 900,000 combined hours of research.

“As we prepare to return human explorers to the Moon and journey on to Mars, it’s even more exciting to consider all the scientific investigations still to come,” he added.

Laying Hands On New Research Breakthroughs

Also managed by Marshall are the station’s two self-contained workhorse facilities, the Microgravity Science Glovebox and the Life Sciences Glovebox, installed in 2002 and 2018, respectively.

Built by German developer Astrium for the European Space Agency (ESA) and flight-tested at Marshall, the Microgravity Science Glovebox remains a permanent, high-demand fixture on station. It’s a sealed facility roughly 3 feet wide and 2 feet high, with a 9-cubic-foot workspace where crew members use built-in glove ports to safely manipulate liquids, particulates, even open flame. Its integrated power, data acquisition, and communications systems permit researchers to pursue small and midsized investigations in the areas of fluid physics, combustion science, biotechnology, materials science, and more. During its years of service, it has enabled more than 60,000 hours of powered science research.

Demand on the glovebox was so great that the space station partners commissioned a second dedicated facility, the Life Sciences Glovebox, to ease demand. Roughly the size of a large fish tank, with 15 cubic feet of interior workspace and glove ports for up to three crew members at once, the newer glovebox primarily aids research into microgravity’s long-term impact on the human body.

“This versatile facility not only will help us better protect human explorers on long voyages into deep space, but it also could aid medical and scientific advances benefiting the whole world,” said Yancy Young, glovebox project manager at Marshall, prior to its launch to orbit.

The second glovebox was built by the Japan Aerospace Exploration Agency and the Dutch firm Bradford Engineering. Marshall contributed the secondary support structure, power system, and thermal control system. As with the racks, glovebox experiments are supported 24 hours a day by dedicated facility operations personnel in Marshall’s Payload Operations Integration Center.

Fiery Investigations and a Unique Window on the World

Building on standardized rack architecture and dramatically extending the station’s research capabilities are two unique laboratory facilities, the Materials Science Research Rack and the Window Observational Research Facility.

Developed jointly by NASA and ESA, the Materials Science Research Rack was launched in 2009 and installed in the Destiny module. It houses the European Materials Science Laboratory, one of two working furnaces on the station, capable of reaching temperatures up to 2,500 degrees Fahrenheit. Like its counterpart – the Japanese Electrostatic Levitation Furnace housed in the Kibo module – this facility enables materials science studies of metals, alloys, semiconductors, ceramics, and glasses, and research into new innovations in advanced metallurgical processes.

The facility relies on the Marshall-developed Sample Cartridge Assemblies, which look a bit like futuristic fireplace pokers, but actually serve as plug-in vessels to safely test, transfer, and store the experiment samples packed inside them. Researchers study how the samples melt in the facility’s furnaces and reform upon cooling, freed from the effects of Earth gravity.

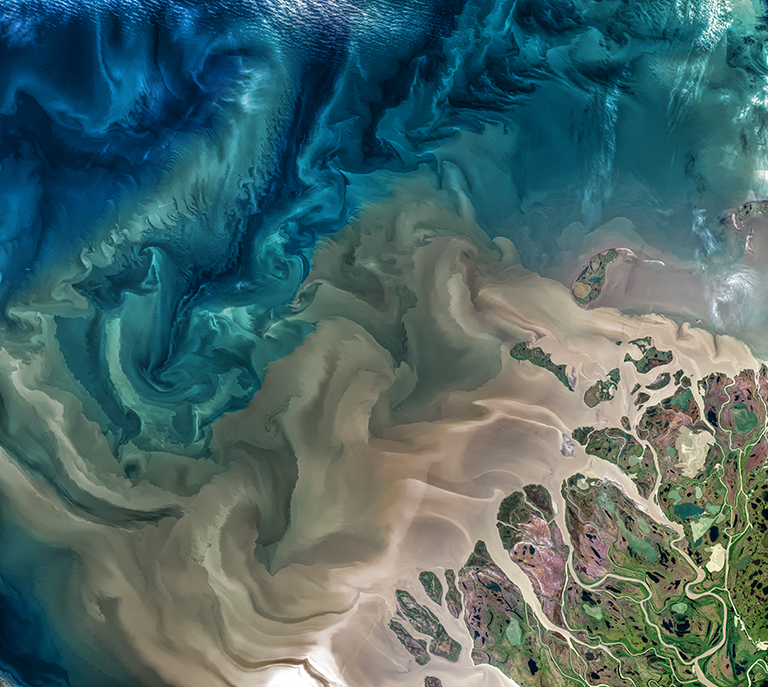

The Window Observational Research Facility, better known as WORF, isn’t just a lab facility but a literal window on the world. Designed and built by Boeing at Marshall with adapted EXPRESS Rack technology, the innovative facility offers Earth science and space science researchers the means to observe environmental changes on Earth, track hurricanes and other natural disasters, and document meteor showers and other near-Earth phenomena. Installed over the 20-inch-diameter, Earth-facing window in the U.S. Laboratory, the facility hosts a mix of crew-tended and automated science activities.

Into the Station’s Third Decade – and Looking Beyond

David Brady, associate program scientist in NASA’s ISS Program Research Office at Johnson, says there have been three distinct chapters in the life of the space station.

“Its first decade was devoted to assembly in orbit, and its second was all about research and technology development, continuing to grow and refine its utility as a landmark science platform,” Brady said. “Now we’re in the station’s third decade, the era of full scientific utilization, expanded commercial value, and global partnership.”

For payload facility project managers at Marshall, that means they’re busier than ever – but Lynn Farris, ISS Payload Facilities team lead, said they welcome the challenge. “During initial station construction, we were lucky to log eight hours of science each week,” she said. “Now the 15 station payload facilities managed by Marshall can clock in excess of 100 hours per week.”

Farris heads the team that helps scientists plan and verify new glovebox and rack experiments, conducting pre-flight development and verification tests using the Payload Rack Checkout Unit housed in Marshall’s Space Station Integrated Test Facility. Marshall also maintains a specialized checkout facility, complete with furnace, for developing and certifying Materials Science Research Rack payloads. Additional Payload Rack Checkout Units reside at Johnson and at NASA’s Kennedy Space Center in Florida and Glenn Research Center in Cleveland.

“These units are the most flight-like test facilities available on the ground,” Farris said. “Once our teams wring out an experiment there, we’re confident it will succeed on orbit.”

Marshall facilities and payload operations teams also work closely with the station crews on the other end of the process. “The crew’s feedback improves our processes, and helps us gauge how well the hardware is working and where it needs refinement,” Farris said.

Science teams and hardware developers at Marshall are already looking ahead to new challenges, drawing from their successes on the space station to develop next-generation experiment racks and lab facilities that could serve in NASA’s proposed Gateway lunar orbiting outpost and on future research bases on the Moon and, in time, Mars.

The International Space Station has been home to 242 individuals from 19 countries, working with more than 4,000 scientists in 108 countries to conduct some 3,000 total research investigations. To learn more about station research and technology on orbit, visit:

https://www.nasa.gov/iss-science

To read more about successful station science over the past 20 years, visit: