The International Space Station’s 3-D printer completed the first phase of a NASA technology demonstration by printing a tool with a design file transmitted from the ground to the printer. The tool was a ratchet wrench.

“For the printer’s final test in this phase of operations, NASA wanted to validate the process for printing on demand, which will be critical on longer journeys to Mars,” explained Niki Werkheiser, the space station 3-D printer program manager at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “In less than a week, the ratchet was designed, approved by safety and other NASA reviewers, and the file was sent to space where the printer made the wrench in four hours.”

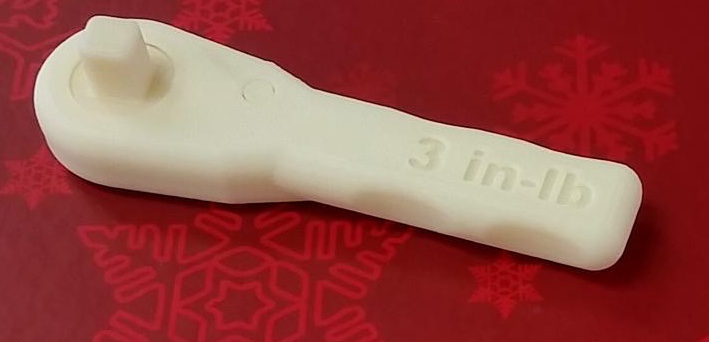

This ratchet wrench will be returned to the ground for analysis and testing, along with the other parts printed in space. The 4.48-inch-long by 1.29-inch-wide wrench was designed by Noah Paul-Gin, an engineer at Made In Space Inc., a northern California company that NASA contracted to design, build and operate the printer. The 3-D printer built the wrench by additive manufacturing, depositing 104 layers of plastic.

To make the tool, NASA had to approve something that would be on the station that had not been shipped to space, a review process that usually occurs before anything can be launched to the station. More than 1,600 experiments have been conducted on the station to date, so sending files back and forth to operate space experiments is routine. Controllers in NASA’s Payload Operations Integration Center at Marshall have worked with investigators and students in more than 80 countries to send millions of commands from locations around the world to station experiments. However, this is the first time a design file has been sent from the ground to make a tool.

“We wanted to work this just like we would for tools that the astronauts will 3-D print and use on the station,” explained Werkheiser. “This wrench will not be used in space, but what if it were a tool the crew needed? We are breaking new ground not only in the way we manufacture in space but also in the way we operate and approve space hardware that is built in space, rather than launched from Earth.”

It can take months or even years, depending on the launch resupply schedule, to get equipment to space, and for exploration missions, resupply from Earth may be impossible. This technology may change how NASA completes exploration missions and even the way science is conducted on the station.

“If you can transmit a file to the station as quickly as you can send an email, it opens up endless possibilities for all the types of things that you can make from CubeSat components to experiment hardware,” Werkheiser said. “We even may be able to make objects that previously couldn’t even be launched to space.”

NASA is exploring how the microgravity environment may benefit how objects are designed and built in space for parts that cannot be made on the ground. The printer made one object that is extremely difficult to make on the ground because of sag caused by gravity. In addition to the wrench, the printer made objects with 13 different designs and built a total of 20 objects, making some items more than once. Except for the ratchet, the other 19 objects were preprogrammed into the printer before it left Earth.

Objects were made on the ground with the same printer before it launched to the space station in September on the fourth SpaceX cargo resupply mission. The objects produced in space will be returned to Marshall for testing and comparison to the ground samples early next year.

“We can’t wait to get these objects home and put them through structural and mechanical testing,” explained Quincy Bean, the principal investigator for the experiment at Marshall. “We really won’t know how well this process worked in space until we inspect the parts and complete these tests.”

Data gleaned from these early tests will help NASA and Made In Space prepare for the second phase of printer operations scheduled for early next year.

“For our next phase of operations, we are working with the astronaut office to identify existing tools that we can make with the printer.” Werkheiser said. “We can’t wait until it is routine to see station astronauts use tools that they built in space.”

NASA makes open source files available that can be used for 3-D printing.