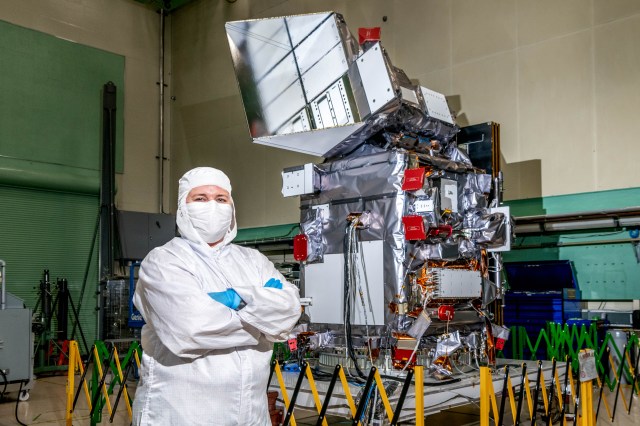

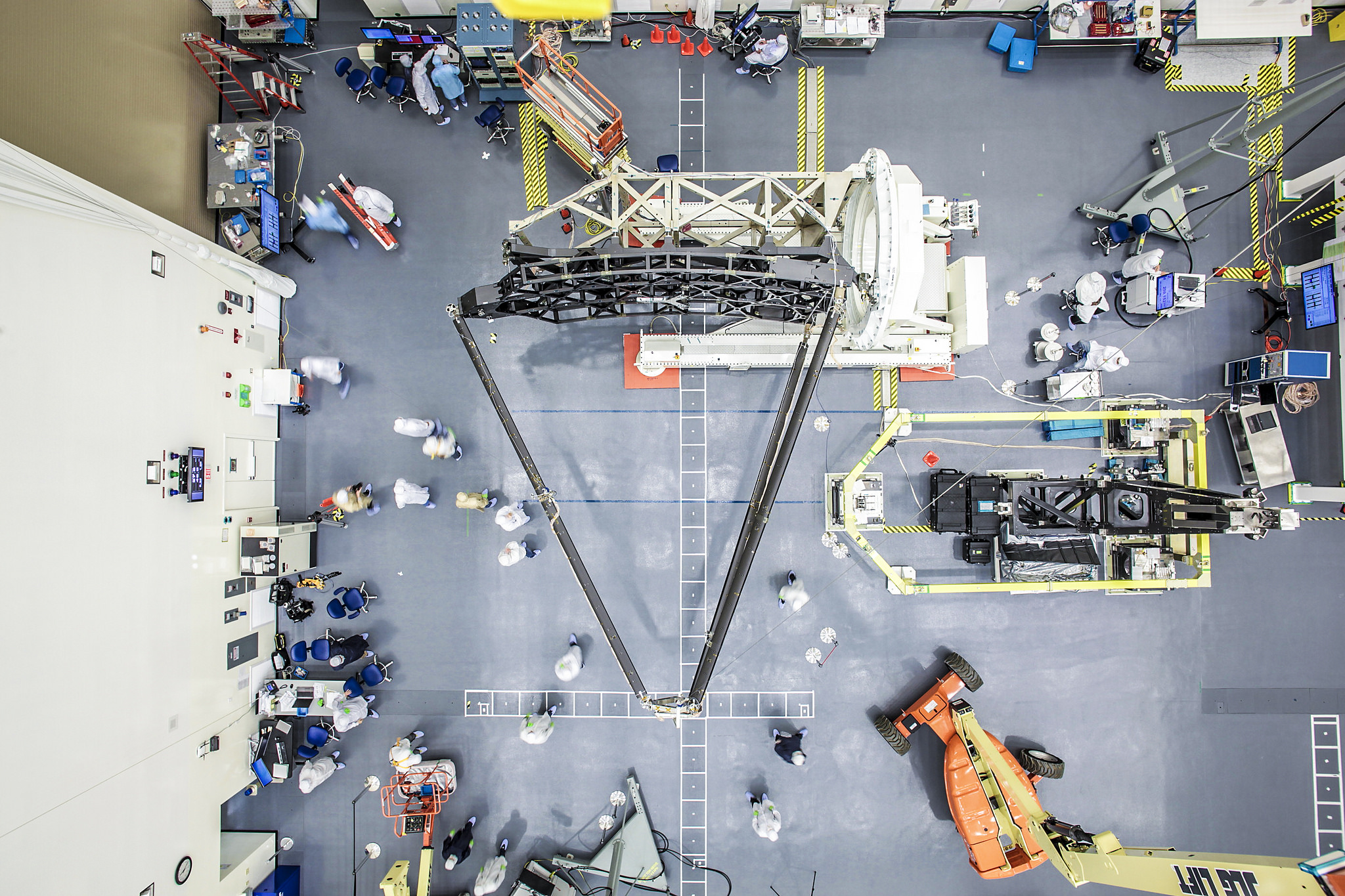

Credits: NASA/Mike McClare

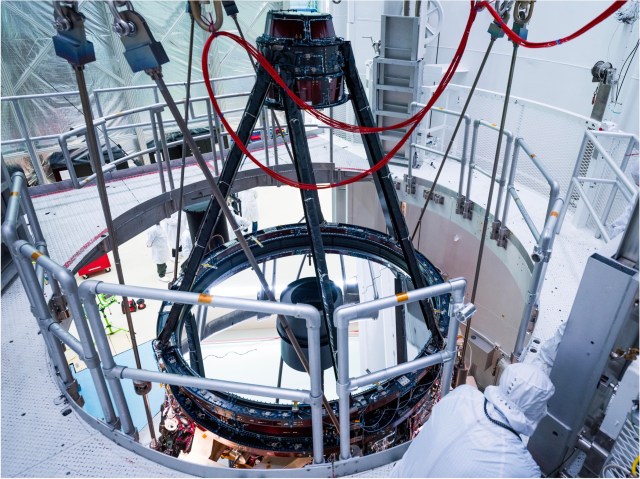

Setting up NASA’s James Webb Space Telescope’s secondary mirror in space will require special arms that resemble a tripod. NASA recently demonstrated that test in a NASA cleanroom and it was documented in a time-lapse video.

The secondary mirror support structure will unfurl in space to about 8 meters (26.2 feet) long once it is deployed. Recently, engineers in the giant cleanroom at NASA’s Goddard Space Flight Center in Greenbelt, Maryland tested the “tripod” in a successful deploy.

“This is the first time we have performed a deployment with a mirror on it and is an important next step in proving the system will work in space as planned,” said Lee Feinberg NASA’s Optical Telescope Element manager at the agency’s Goddard Space Flight Center in Greenbelt, Maryland.

Engineers did a test run using the Webb’s “Pathfinder” backplane, or test “backbone” structure, to ensure that one of the secondary mirrors would set up properly in its orbit a million miles from Earth.

“The deployment of the tripod that holds the secondary mirror has a tipping point, and this is controlled by the yellow gravity off-loading device,” said Ray Lundquist, the Webb telescope ISIM Lead Systems Engineer at NASA’s Goddard Space Flight Center in Greenbelt, Maryland.

The addition of the weights simulated the no-gravity environment Webb will encounter in orbit. Once the tripod was deployed, engineers locked it in place to ensure the tripod’s arms stay in a precise location.

The time-lapse video was taken using a handheld camera on Oct. 25 in NASA Goddard’s clean room, and runs 1 minute and 25 seconds.

It is a fairly complicated operation,” said Adam Carpenter, Mechanical Integration Engineer, of NASA Goddard. “There are various teams that collaborate to execute the operation precisely, including mechanical and electrical engineers and technicians. For example, with the deployment of the arm holding the secondary mirror, we have to ensure weights and measurements line up correctly.”

The tripod consists of three supports that fold out from the Webb’s backplane. “The Secondary Mirror Support Structure or tripod was assembled at Northrop Grumman’s Space Park facility in Redondo Beach, California,” said Josh Levi, Webb telescope Optical Telescope Element Deputy for Operations at Northrop Grumman Aerospace Systems, Redondo Beach, California.

“The tripod was constructed from composite tubes built by ATK in Magna, Utah, and four of the hinges were built by Northrop Grumman. Two of the four hinges are [actually] mechanisms,” Levi said. The hinges and mirror mount were aligned to better than 30 thousandths of an inch.

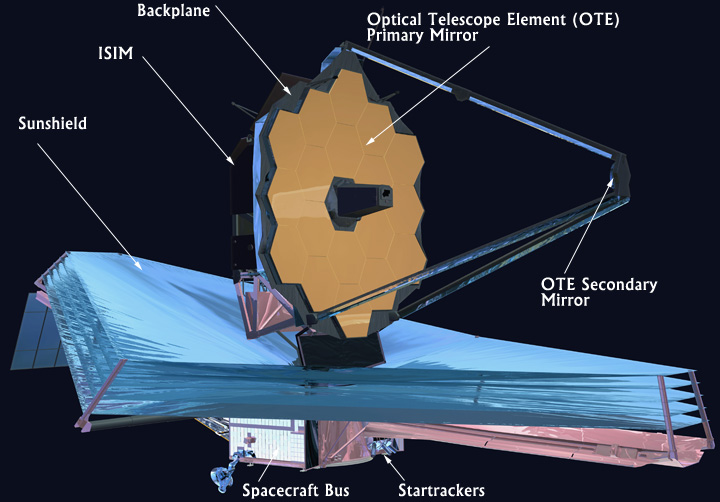

Webb’s backplane is a large structure which holds and supports 18 big hexagonal mirror segments that make up the primary mirror of the telescope. The backplane will support the primary mirror segments and carry the other telescope optics and the Integrated Science Instrument Module (ISIM). The ISIM is one of three major elements that comprise the Webb Observatory flight system. The others are the Optical Telescope Element and the Spacecraft Element (Spacecraft Bus or main spacecraft and Sunshield).

At the end of the tripod is the round secondary mirror that will face the primary mirror. The secondary mirror, like the segments that make up the primary mirror, are made from beryllium, which was selected for its stiffness, light weight, and stability at cryogenic temperatures. The secondary mirror is also convex, so the reflective surface bulges toward a light source. It looks much like the curved mirrors on the walls near parking garage exits that let motorists see around corners.

The quality of the secondary mirror surface is so good that the final convex surface at cold temperatures does not deviate from the design by more than a few millionths of a millimeter – or about one ten-thousandth the diameter of a human hair.

The most powerful space telescope ever built, the Webb telescope will provide images of the first galaxies ever formed and study planets around distant stars. It is a joint project of NASA, the European Space Agency and the Canadian Space Agency.

To download the video, visit: http://svs.gsfc.nasa.gov/cgi-bin/details.cgi?aid=10203

Rob Gutro

NASA’s Goddard Space Flight Center