Final Operations and Assembly at Kennedy

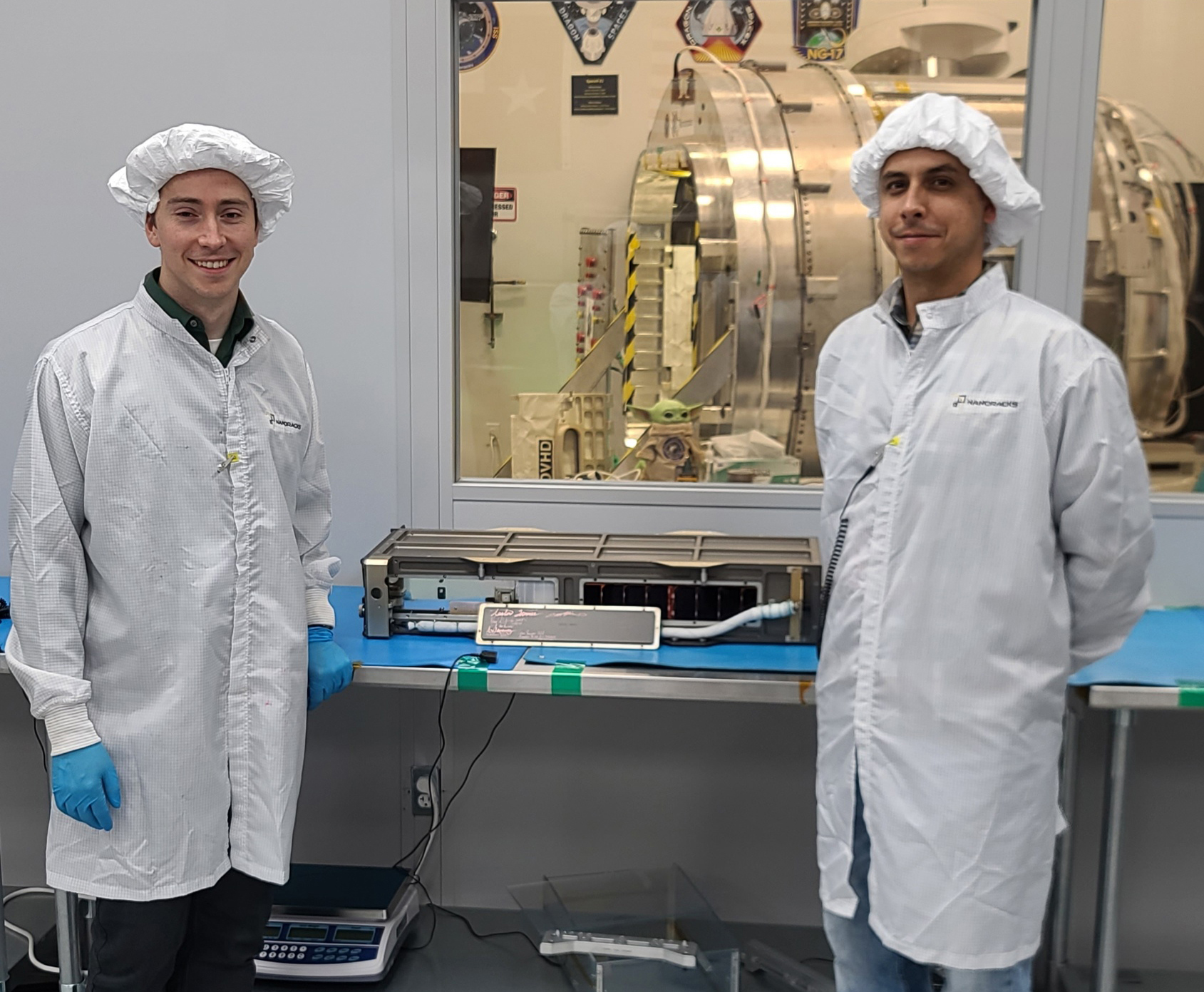

Operations and Checkout Building

The Neil Armstrong Operations & Checkout (O&C) Building has played a major role in NASA’s spaceflight history. It was the first building finished at NASA’s Kennedy Space Center and has housed the Astronaut Crew Quarters since the mid-1960s where the Gemini astronauts stayed prior to launch.

When the Orion spacecraft arrives to Kennedy following initial manufacturing at NASA’s Michoud Assembly Facility in New Orleans, it is placed in the O&C Building. The O&C contains a large room called a high bay that is operated by Lockheed Martin as a high-tech factory; it is where the spacecraft is assembled and readied for missions to deep space destinations. The high bay underwent an extensive, two-year renovation starting in 2007 to outfit the facility for assembly of Orion.

It includes unique tooling stations, test fixtures, chambers and clean rooms for the buildup and testing of the spacecraft and two 27.5-ton cranes used to move payloads.

Orion assembly in the O&C Building consists of joining the crew module, crew module adapter, and the service module which will carry the consumables astronauts will need for missions into deep space. Various testing on the crew and service modules also takes place in this facility, including a final round of testing and assembly in the Final Assembly and System Testing (FAST) cell. After final checkout in the O&C, the spacecraft is then transported to the Multi-Payload Processing Facility (MPPF) and handed over to Exploration Ground Systems for ground processing.

Multi-Payload Processing Facility

A unique facility at Kennedy, the Multi-Payload Processing Facility (MPPF) is used for commodity servicing and fueling the Orion spacecraft with its flight load of hazardous propellants, high pressure gases, coolant, and other fluids the spacecraft and astronauts will need to maneuver and carry out their missions in space. When Orion returns to Earth after its mission, it will be transported back to the MPPF, where specialized equipment will be used to remove unused hazardous propellants from its tanks during spacecraft postflight processing.

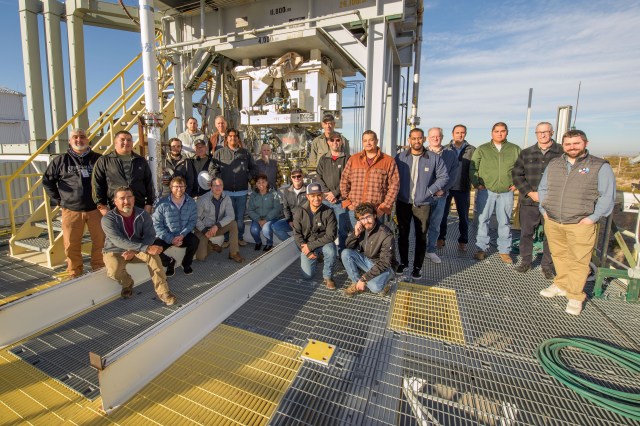

On Jan. 16, 2021, the Artemis I vehicle was transferred from the Operations & Checkout (O&C) Building to the MPPF, where it was moved onto a service stand that provides 360-degree access, allowing engineers and technicians from Exploration Ground Systems, its prime contractor Jacobs Technology, and other support organizations to fuel and service the spacecraft. Crane operators removed the transportation cover and used fuel lines and several fluid ground support equipment panels to load the various commodities into the crew and service modules.

The Space Launch System rocket’s interim cryogenic propulsion stage (ICPS) moved into the Multi-Payload Processing Facility Feb. 18, 2021, alongside one of its flight partners for the Artemis I mission, the Orion spacecraft.

Both pieces of hardware underwent fueling and commodity servicing in the facility ahead of launch. The ICPS will be positioned above the core stage and will provide the power needed to give Orion the big push it needs to break out of Earth orbit on a precise trajectory toward the Moon during Artemis I.

The fueling of hazardous commodities is performed remotely from a firing room in the Launch Control Center. Various electrical ground support equipment racks allow technicians to power up the spacecraft and perform service operations remotely. The spacecraft’s temperature and humidity is tightly controlled using mini-portable purge units, which provide a constant flow of conditioned air.

The 19,647-square-foot MPPF building, originally constructed in 1995, has undergone extensive upgrades and modernizations to support Orion, which began in The facility also will be used to install time-critical crew equipment and to process crew modules that have returned from space prior to being returned to the O&C for possible reuse. Ground support equipment also will be stored and maintained in the MPPF.

After Orion is fueled and final checks are performed in the MPPF, its transportation cover is re-installed and the spacecraft is moved to the Launch Abort System Facility (LASF) for integration with the launch abort system.

Launch Abort System Facility

After fueling and commodity servicing in the MPPF, the Orion spacecraft is moved to the Launch Abort System Facility (LASF). The 44-foot-tall launch abort system (LAS) is first prepared horizontally inside the LASF and is afterwards assembled vertically with the Orion spacecraft. The LASF, previously used to lift and rotate the canister that carried space shuttle payloads to the launch pad, is taller than many processing facilities at Kennedy to allow clearance for vertical assembly and has cranes and other equipment needed to integrate the system during launch processing. Installation of the ogive panels that protect the crew module and LAS and provide its aerodynamic shape also take place at the LASF. After the LAS is integrated with Orion, the entire stack is moved to High Bay 3 in the Vehicle Assembly Building. The Artemis I spacecraft moved into the LASF for integration on July 21, 2021.

Vehicle Assembly Building

The Vehicle Assembly Building (VAB) serves as the central hub of NASA’s premier multi-user spaceport, capable of hosting several different kinds of rockets and spacecraft at the same time. Whether the rockets and spacecraft are going into Earth orbit or being sent into deep space, the VAB has the infrastructure to prepare them for their missions.

The tallest portion of the VAB is called the high bay. There are four high bays, two on the east side, and two on the west side of the building. Each has a 456-foot-high door, enabling rockets to be stacked vertically and then rolled out to the launch pad.

The massive SLS rocket and its twin solid rocket boosters require a large high bay from which to process and prepare them for launch. Exploration Ground Systems recently completed many upgrades and modifications to High Bay 3 in the VAB where the SLS and Orion are stacked, processed and tested atop the new mobile launcher. Ten levels of new work platforms were installed in High Bay 3, Towers E and F, to accommodate the rocket. A total of 20 platform halves altogether surround the SLS and Orion spacecraft and provide access for testing and processing before they are transported to the launch pad.

Each of the giant steel platforms measures about 38 feet long and close to 62 feet wide. Each weigh between 300,000 and 325,000 pounds. The platforms are attached to rail beams which provide structural support and contain the drive mechanisms to retract and extend them. Each platform rides on four Hillman roller systems that are located two on each side – much like a kitchen drawer glides in and out. A mechanical articulated tray also moves in and out with each platform.

In the VAB, the Orion spacecraft is lifted and secured atop the SLS rocket on the mobile launcher. The completed SLS/Orion stack is then transported atop the mobile launcher on Crawler-Transporter 2 to Launch Pad 39B for launch.

The Artemis I Orion spacecraft was moved from the Launch Abort System Facility (LASF) to the VAB on Oct. 19, 2021. The Orion spacecraft and SLS rocket were hard mated on Oct. 21, 2021, marking completion of the Artemis I stack.