White Sands Test Facility

NASA’s White Sands Test Facility in New Mexico is a component of Johnson Space Center in Houston that tests and evaluates potentially hazardous materials, spaceflight components, and rocket propulsion systems for NASA centers, other government agencies, and commercial industry. Since the 1960s, White Sands has been an integral part of every United States human spaceflight mission, supporting programs associated with the safe exploration of space and leading the way in propulsion system testing. This includes testing of Orion’s European Service Module, the powerhouse of the spacecraft that provides in-space propulsion, power and other astronaut life support systems, including consumables like water, oxygen, and nitrogen.

European Service Module Propulsion Testing

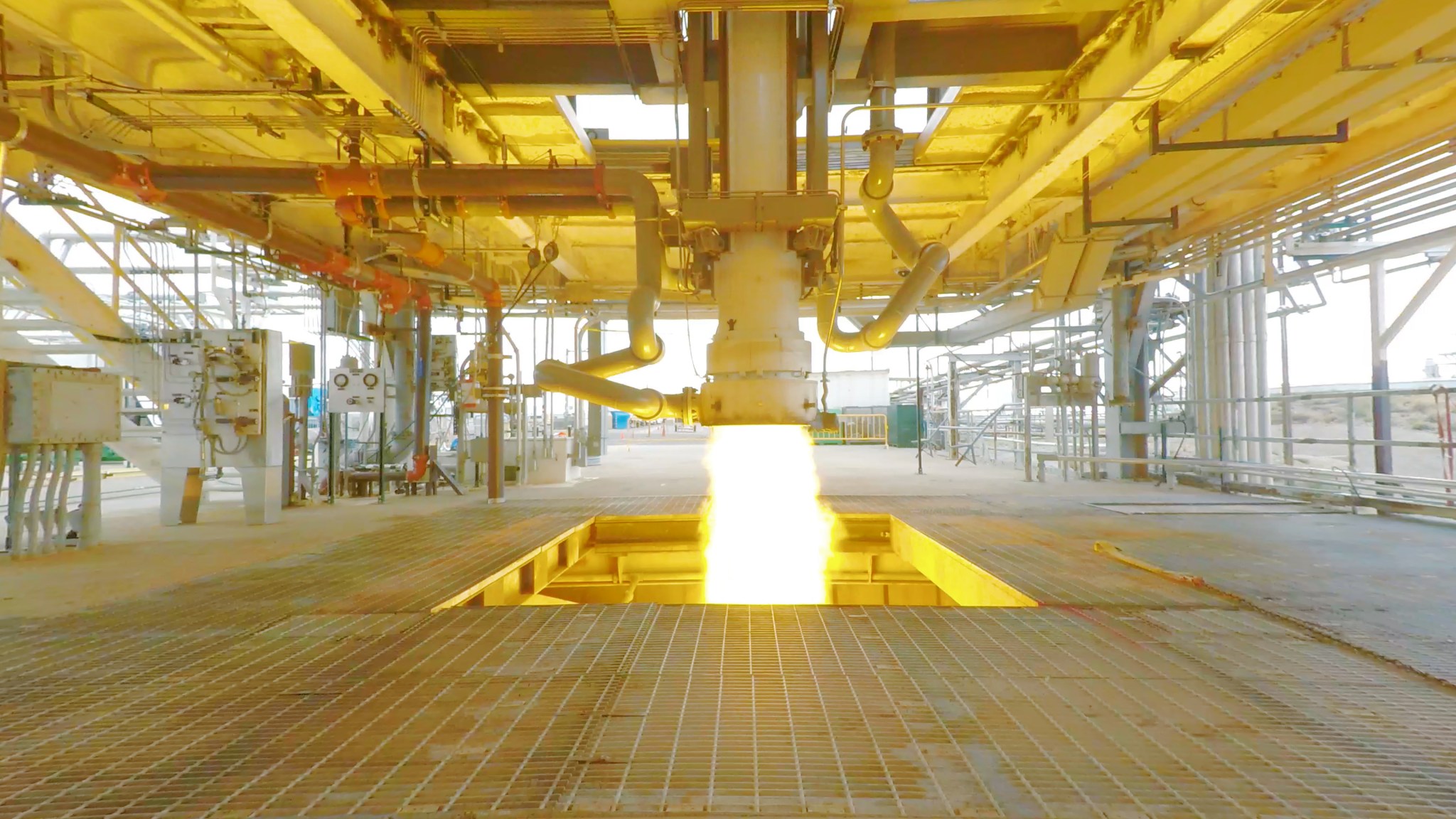

The propulsion qualification module (PQM) test article, a replica of the service module’s propulsion subsystem, was delivered by ESA and Airbus to White Sands in 2017. The PQM was designed to verify the performance of the service module engines, propellant feed systems, and various other propulsion operations during expected and unexpected conditions. Testing of the PQM is crucial for ensuring that all engines and thrusters fire safely and accurately to get the spacecraft where it needs to go.

The PQM model is equipped with a total of 21 engines: one U.S. Space Shuttle Orbital Maneuvering System (OMS) engine, eight auxiliary thrusters, and 12 smaller thrusters produced by Airbus in Germany. The Orion spacecraft that will fly on Artemis missions has 33 engines in total, double the amount of RCS thrusters included in the PQM.

The full model is roughly a 15-foot cube made of stainless steel and provides the full components for testing the thrusters, fuel lines, and firing of Orion’s engines. The propellant for the PQM is provided by four 2000-liter ground test tanks with 1-centimeter thick walls containing mixed oxides of nitrogen (MON) as oxidizer and monomethyl hydrazine (MMH) as fuel. Other elements of the PQM include two helium pressurization tanks to achieve optimal engine feedline pressures; pressure-control systems; a sensing and command system with drive electronics; propellant lines with isolation valves, filters, and additional ground test instrumentation. The facility was outfitted with a diffuser to enable pump down action to create a low pressure on the exit plane of the OMS engine as it operated, as testing was conducted in ambient pressure conditions.

In a test stand at White Sands, NASA and ESA used the PQM to complete 48 hot firing tests and 3 discrete pressurization tests conducted in two phases and concluding on Jan. 21, 2020. The data obtained during this test campaign was critical to the certification of the Orion/European Service Module propulsion system for the Artemis I and II missions and beyond. The focus on these firing tests was the interaction between the engines and the propulsion subsystem, as well as the performance of the pressurization control assembly. Five additional hot fire tests were conducted utilizing the auxiliary engines on PQM from Sept. 29 to Nov. 4, 2020. There were also isothermal and gradient tests conducted on the pressure control assembly valves in 2020 that involved chilling the valves and performing multiple cycles to see if anomalies could be re-created. The first gradient test was performed April 4 and repeated through April 21 of that year. A second gradient test was performed on May 5 and isothermal testing started May 12 and concluded June 3.

The first phase of propulsion testing had no active pressure regulation of the propellant tanks, with testing conducted in a “blow down” mode in which the tanks were pressurized prior to the start of each test. The second phase included active pressure regulation. The testing was divided into different campaigns and operated various combinations of the engines to simulate flight test scenarios, evaluate for engine cross talk or fluidic hammer in the propulsion system, evaluate engine performance, and test the pressurization cross feed assembly. Some campaigns evaluated system performance with saturated versus unsaturated propellant, or the amount of helium dissolved in the fuel and the oxidizer.

During testing, teams also successfully simulated the most taxing situation the spacecraft’s engines could encounter after launch. In one of the high-profile tests, engineers performed a 12-minute propulsion test simulating an abort-to-orbit scenario, in which the spacecraft’s service module must place Orion in a safe orbit because of a problem after the abort system has been jettisoned. The test, which was the longest ever continuous burn conducted on an OMS engine to date at White Sands, used the PQM to fire the Orbital Maneuvering System engine, eight auxiliary thrusters and six reaction control thrusters.

Over the course of this two-and-a-half-year test campaign over 15,000 kg of MON (mixed oxides of nitrogen – or propellant-grade nitrogen tetroxide) and almost 9,000 kg of MMH (monomethylhydrazine) hypergolic propellant were consumed.

PQM Quick Facts

| PQM height including frame | 4.6 m |

| Base dimensions | 4.9m x 4.872m |

| PQM mass (empty) | 12,000 kg |

| PQM mass (filled) | 22,000 kg |

PQM Testing

| Date | Test | Length | OMS-E | AUX | RCS |

| 4/2/19 | RCS Acceptance | 11:49 | N | N | Y |

| 4/4/19 | Waterhammer & Crosstalk Seq 1 | 12:32 | Y (52 sec) | Y | Y |

| 4/8/19 | Waterhammer & Crosstalk Seq 2 | 13:57 | N | Y | Y |

| 4/11/19 | Waterhammer & Crosstalk Seq 3 | 2:30 | N | Y | Y |

| 4/15/19 | GNC Flight Profiles (ATO Light) | 21:15 | Y (15 sec) | Y | Y |

| 4/29/19 | OMS-E Feed System Test Seq C, Run 1ab | 11:17 | Y (5 sec) | N | N |

| 4/29/19 | Waterhammer & Crosstalk Seq 1 | 12:32 | Y (52 sec) | Y | Y |

| 5/2/19 | OMS-E Feed System Test Seq C, Run 2 | 11:17 | Y (5 sec) | N | N |

| 5/2/19 | RCS & Aux | 5:10 | N | Y | Y |

| 5/6/19 | OMS-E Feed System Test Seq C, Run 4 | 11:17 | Y (5 sec) | N | N |

| 6/20/19 | Waterhammer & Crosstalk Seq 3 | 2:30 | N | Y | Y |

| 6/20/19 | OMS-E Delta Qual Seq B, Run 2 | 11:32 | Y (20 sec) | N | N |

| 7/15/20 | Waterhammer & Crosstalk Seq 2 | 13:57 | N | Y | Y |

| 7/17/19 | GNC Flight Profiles (ATO Light) | 21:16 | Y (15 sec) | Y | Y |

| 7/19/19 | OMS-E Delta Qual Seq B, Run 1 | 11:32 | Y (20 sec) | N | N |

| 7/19/19 | OMS-E Feed System Test Seq C, Run 3 | 11:17 | Y (5 sec) | N | N |

| 8/5/19 | Full ATO Operation | 23:21 | Y (11.5 min) | Y | Y |

| 9/9/19 | Long duration Aux (TEI) | 1:35:00 | N | Y | Y |

| 9/25/19 | Waterhammer & Crosstalk Seq 4 | 13:57 | N | Y | Y |

| 12/5/19 | Cross-Feed Test BOL, highest Aux regulation frequency) |

1:50 | N | Y (70 sec) | Y |

| 12/5/19, 12/10/19 |

Cross-Feed Test (BOL, highest OMS-E regulation frequency) (Runs 1&2 on 12/5, Run 3 on 12/10) |

1:40 | Y (70 sec) | N | Y |

| 12/10/19 | Cross-Feed Test (BOL, highest OMS-E regulation frequency) (Runs 1&2 on 12/5, Run 3 on 12/10) |

1:40 | Y (70 sec) | N | Y |

| 12/13/19 | Cross-Feed Test (EOL, lowest regulation frequency) | 9:20 | Y (530 sec) | N | Y |

| 1/14/20 | Aux Passenger Test 1 (includes 1.65 MR test for EM III+) |

8:48 | N | Y | N |

| 1/21/20 | Aux Passenger Test 2 | 5:05 | N | Y | N |