NASA is making progress and awarding prizes in its competition to build a 3-D printed habitat for deep space exploration.

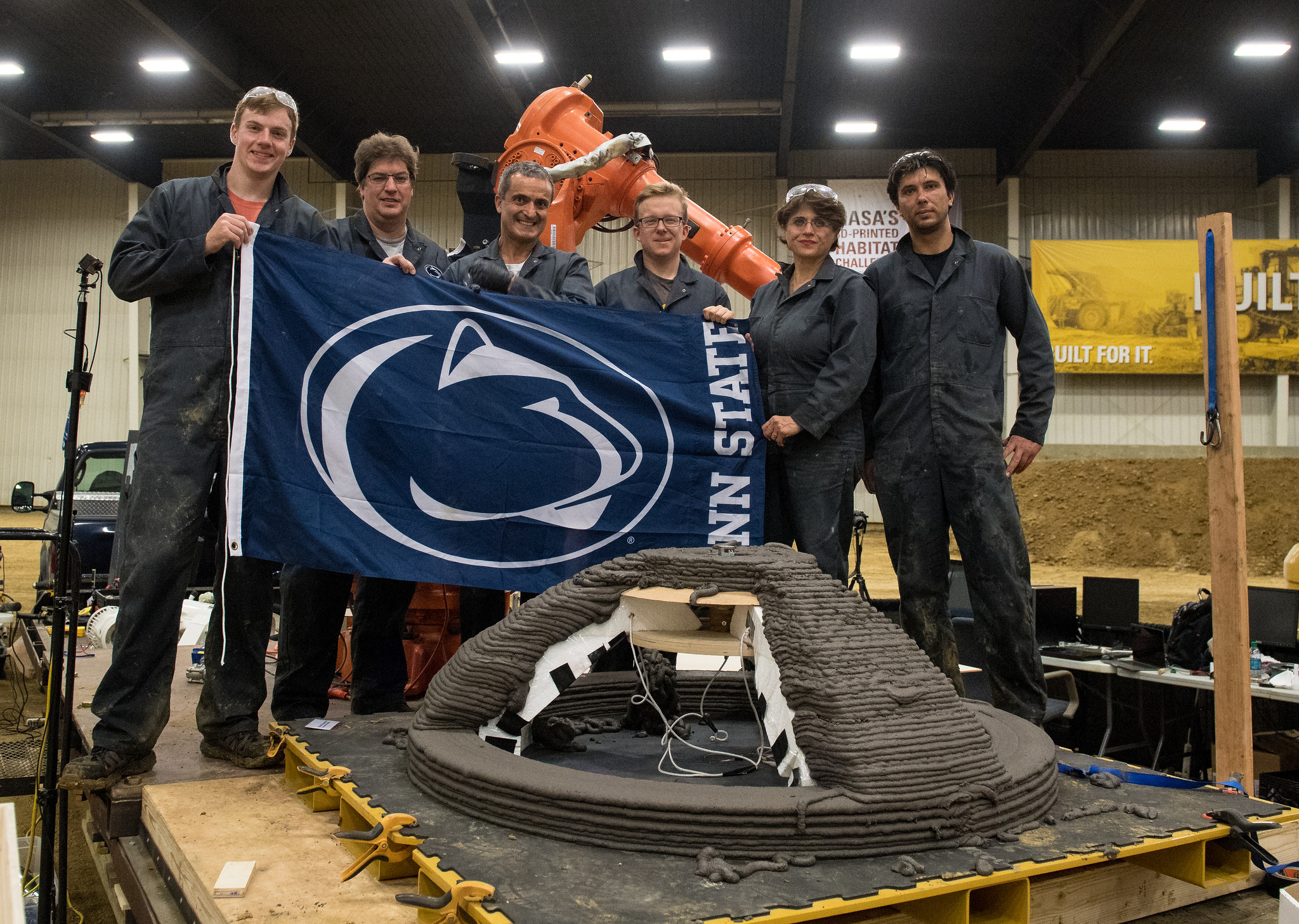

The agency has awarded first place and a prize of $250,000 to Team Foster + Partners | Branch Technology of Chattanooga, Tennessee, for successfully completing Phase 2: Level 3 of NASA’s 3D-Printed Habitat Challenge, a NASA’s Centennial Challenges prize competition. Pennsylvania State University of University Park received second place, and a reward of $150,000.

Challenge activities were held Aug. 23-26 at Caterpillar’s Edwards Demonstration and Learning Center in Edwards, Illinois. Teams were presented a check at the awards ceremony on Aug. 26 by Jim Reuter, deputy associate administrator for NASA’s Space Technology Mission Directorate.

The multi-phase, $2.5 million 3D-Printed Habitat Challenge is designed to advance construction technology needed to create sustainable housing solutions for Earth and beyond.

“The advancement and innovation in additive construction that we’ve seen from these teams is inspiring,” said Reuter. “Meeting the technology goals of this challenge proves that competition can push boundaries, and their work puts us that much closer to preparing the way for deep space exploration.”

Bradley University in Peoria, Illinois, is NASA’s 3D-Printed Habitat Challenge partner. Bradley University also partnered with sponsors Caterpillar, Bechtel and Brick & Mortar Ventures to run the competition.

“Being a part of this competition has been an extraordinary opportunity for Bradley University,” said Bradley University President, Gary Roberts. “Our students, faculty, staff and the Peoria community had a chance to see history in the making. We are a part of transforming technology and reshaping the way we think about construction. This was inspiring, and I am certain it changed the lives of many who experienced it.”

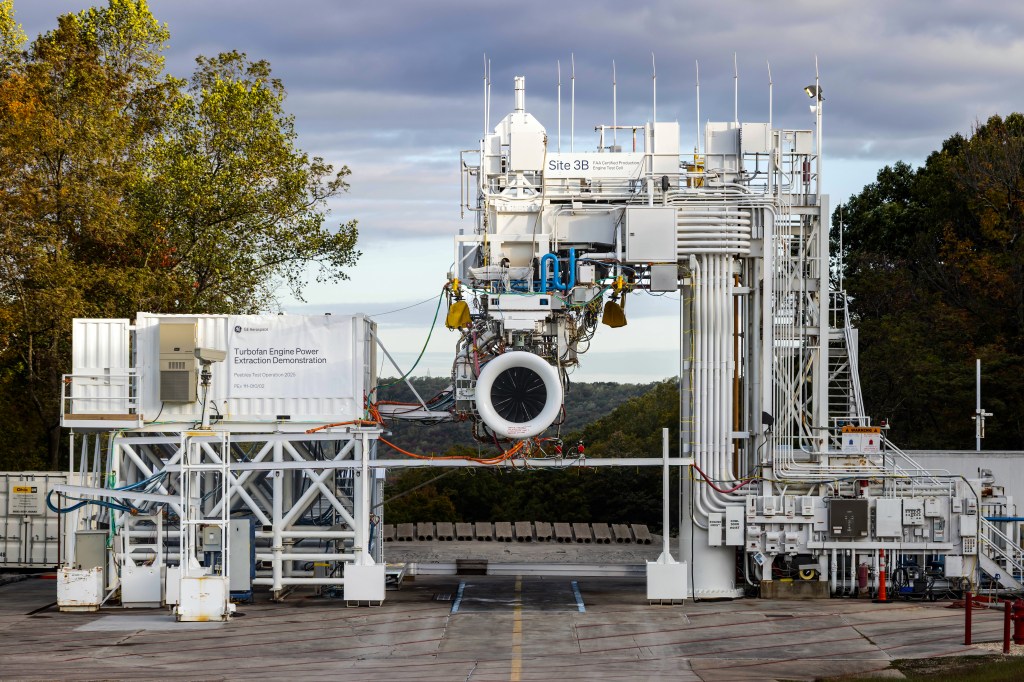

Teams were required to develop the fundamental 3-D printing technology necessary to produce a structurally sound habitat, including the printer itself and construction materials. Competitors then had to print beams, cylinders and domes that were analyzed and compressed to failure to determine scores and prize awards. The competition activities were open to the public, and many industry leaders and local school groups attended the event. A gallery of photos from the challenge events can be found on the NASA Headquarters’ Flickr site.

NASA’s Centennial Challenges Program is part of the agency’s Space Technology Mission Directorate, and is managed at NASA’s Marshall Space Flight Center in Huntsville, Alabama.

For more information about the Centennial Challenges Program, visit:

For more information about other challenges and prize opportunities with NASA, visit:

-end-

Gina Anderson

Headquarters, Washington

202-358-1160

gina.n.anderson@nasa.gov

Molly Porter

Marshall Space Flight Center, Huntsville, Ala.

256-544-0034

molly.a.porter@nasa.gov