Overview

Our aircraft engine inlet and nozzle researchers maintain and operate several test facilities at NASA’s Glenn Research Center in Cleveland where we perform the following tasks:

- Measure the performance of advanced inlets and nozzles designs

- Study flow control concepts for improved inlets and nozzles performance

- Provide inlet/fan interaction data

- Investigate nozzle aeroacoustic issues

- Understand fundamental flow physics issues relevant to inlets and nozzles flows

- Produce detailed test data for validation of computational fluid dynamics (CFD) codes

Our researchers also develop, maintain, support, and apply several computational fluid dynamics (CFD) codes, which are used for the following:

- Design advanced inlets and nozzles

- Predict inlets and nozzles performance

- Model flow control concepts

- Model inlet/fan interaction

- Understand aeroacoustic phenomena

- Study fundamental flow problems

- Develop and evaluate advanced prediction methods for turbulent flow physics, with a focus on propulsion system components

Advancing Flight Technology Through Research, Modeling, and Demonstration

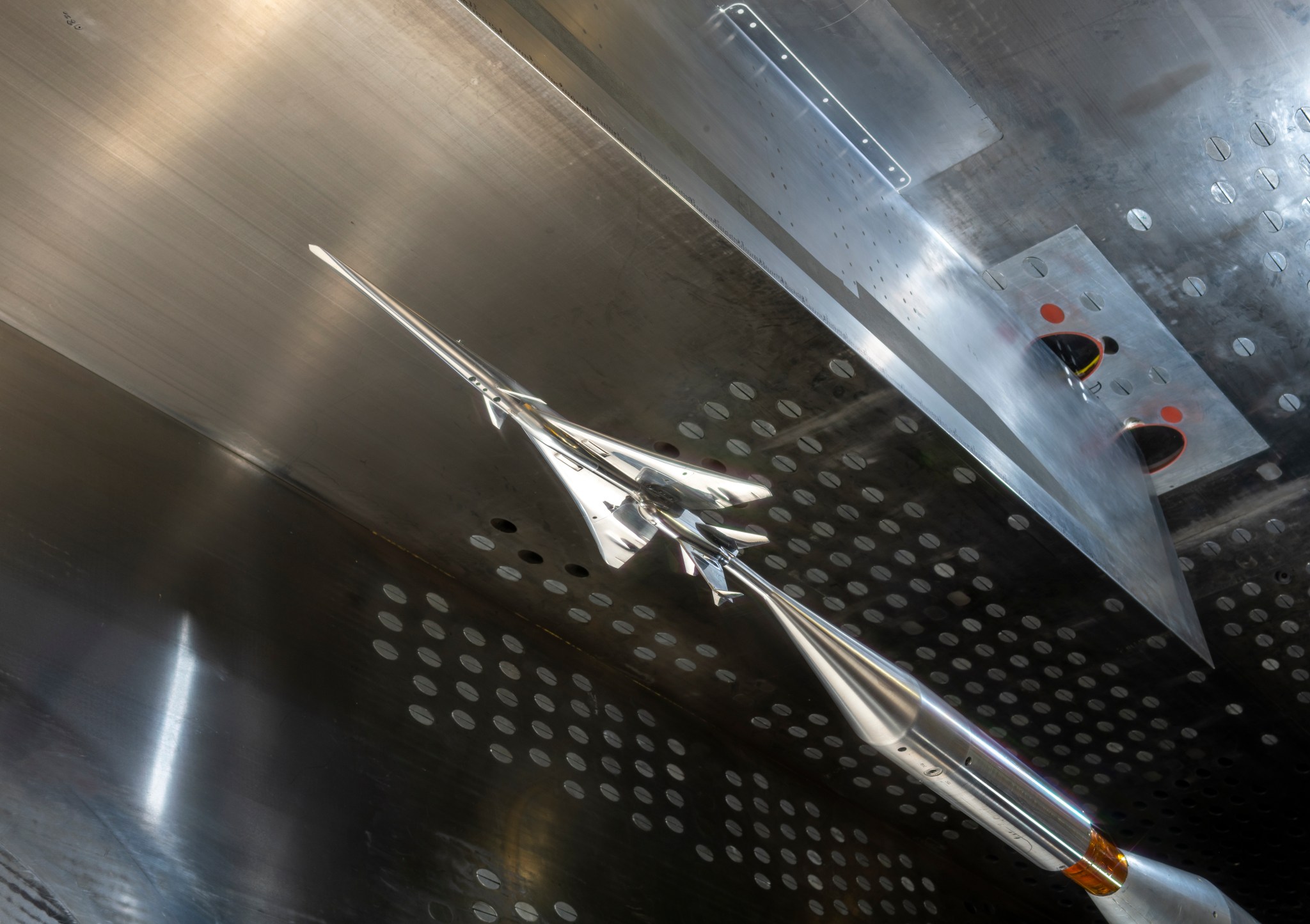

NASA Glenn conducts fundamental physics-based experiments and develops validated models to advance the understanding of inlet and nozzle aerospace propulsion performance. This includes rigorous component-level testing to characterize flow behavior and validate predictive tools under realistic operating conditions. Leveraging advanced design and analysis software—along with proven expertise in flight demonstrations such as the X-59—NASA Glenn enables high-fidelity simulation, system integration, and real-world validation of next-generation aerospace technologies.

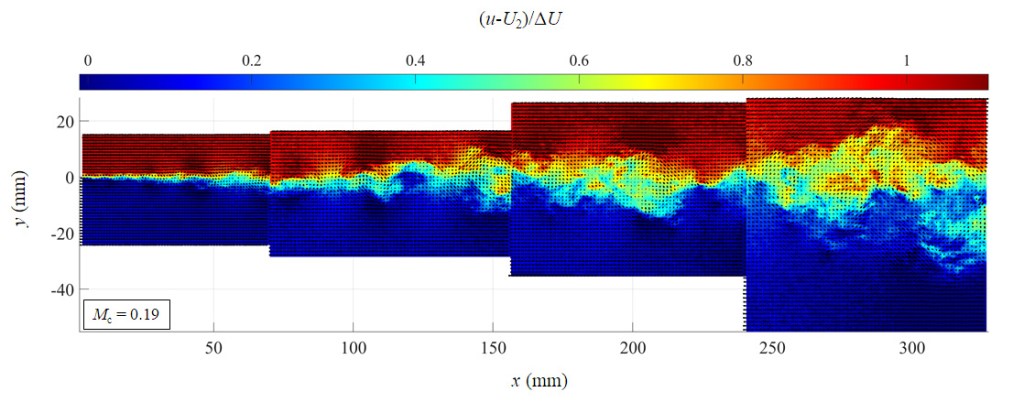

Fundamental Physics Experiments

Fundamental physics experiments increase our understanding of more complex problems and provide important data for improving and validating physical models.

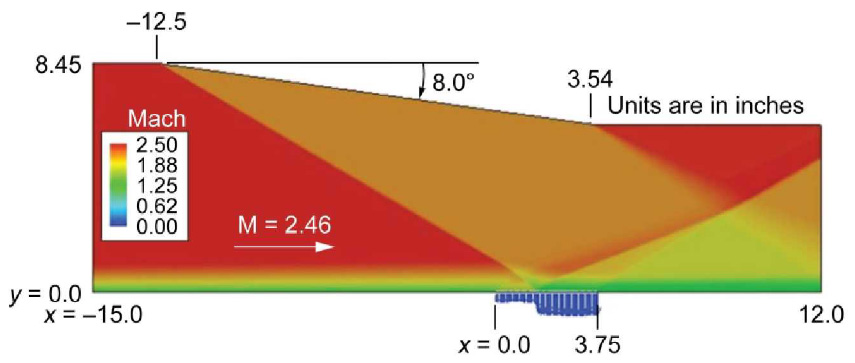

Physics Modeling and Validation

Improvements in physical modeling and the validation of these methods are critical to advancing numerical simulation capabilities.

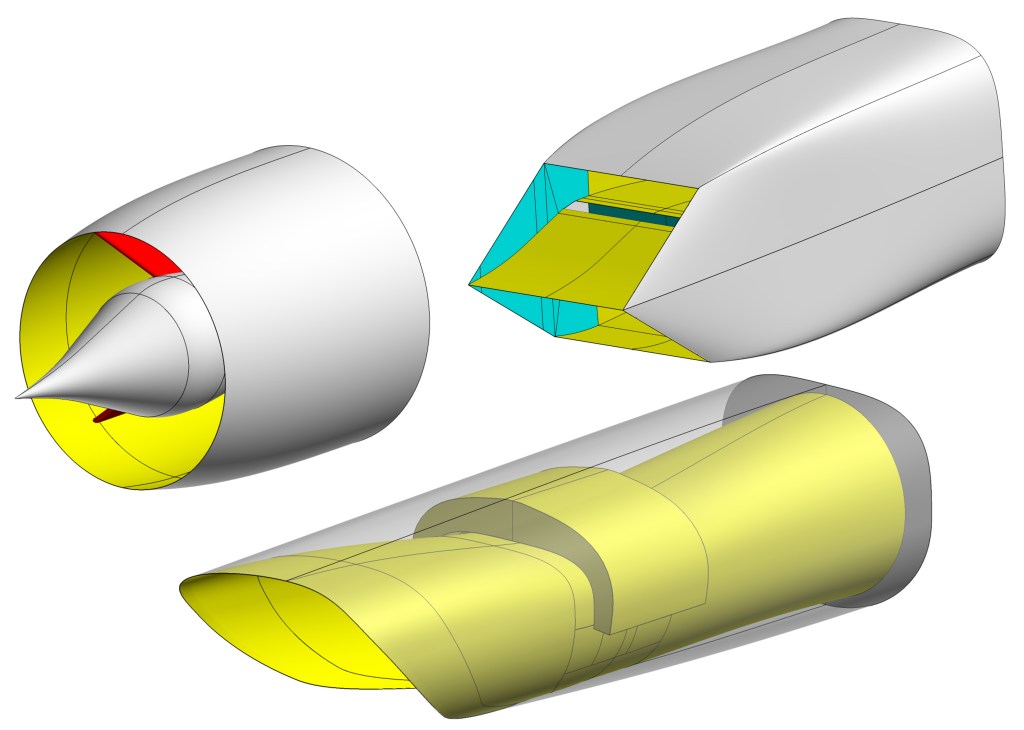

Design and Analysis Software

A range of advanced software tools is used to support the design, analysis, and testing of inlets and nozzles for aerospace propulsion systems.

Support of Flight Demonstration Projects

Computational fluid dynamics, wind tunnel tests, real-time displays, and system integration support X-59 supersonic flight.

Facilities

Our inlet and nozzle researchers maintain and operate several test facilities used to support the following activities:

- Measuring the performance of advanced inlet and nozzle designs

- Studying flow control concepts to improve inlet and nozzle performance

- Providing inlet/fan interaction data

- Investigating nozzle aeroacoustic phenomena

- Advancing understanding of fundamental flow physics relevant to inlet and nozzle flows

- Producing detailed test data for the validation of computational fluid dynamics (CFD) codes