Dynamic Thermal Energy Conversion

NASA advances Stirling power systems to deliver efficient, long-life energy for deep-space and planetary missions, expanding science and exploration impact.

Overview

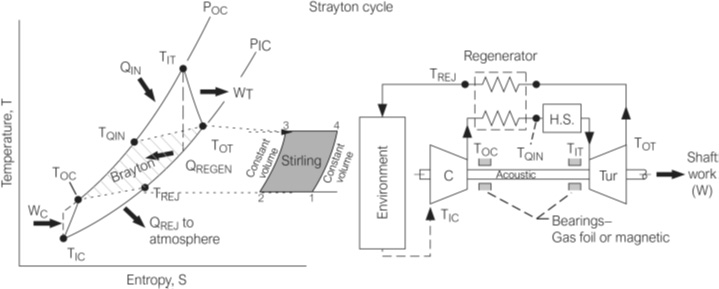

Dynamic thermal energy conversion uses moving components to generate electrical power from thermal energy. Unlike passive systems such as radioisotope thermoelectric generators (RTGs), dynamic systems incorporate mechanical motion, enabling significantly higher efficiencies — often approaching 30%, or up to six times greater than their passive counterparts. These systems typically use Stirling or Brayton engines, both of which convert thermal energy into reciprocating mechanical motion. An attached alternator then converts this mechanical energy into electrical power.

Dynamic conversion technologies can be applied in scenarios requiring either short-term or continuous power. Fuel sources may include the decay of radioisotopes for low-power systems or nuclear fission for higher-power applications. Some systems can also use waste heat from other onboard processes. Due to their high efficiency and durability, dynamic energy conversion systems are strong candidates for supporting long-duration space exploration and surface operations.

Stirling Engine Systems

Stirling Research Lab

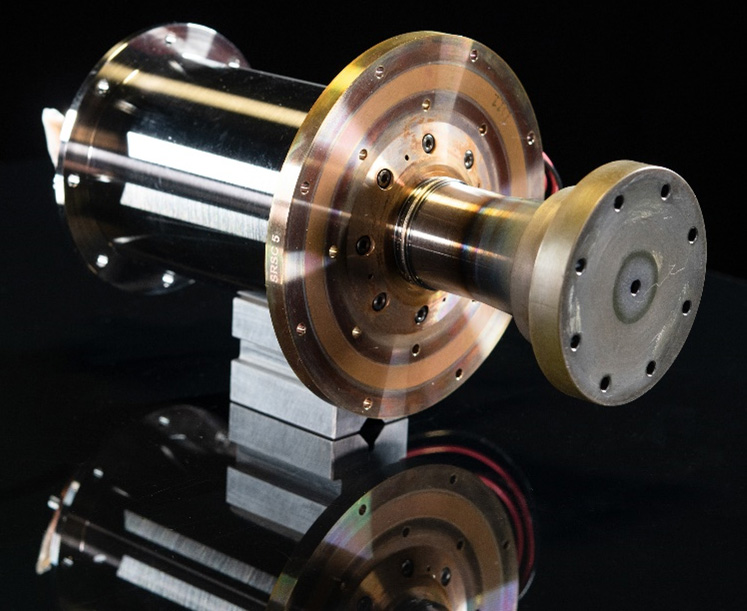

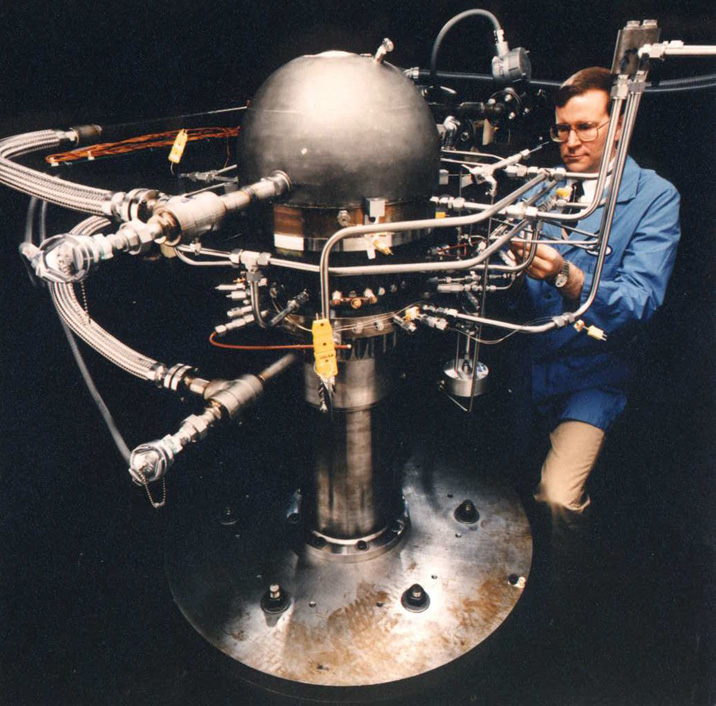

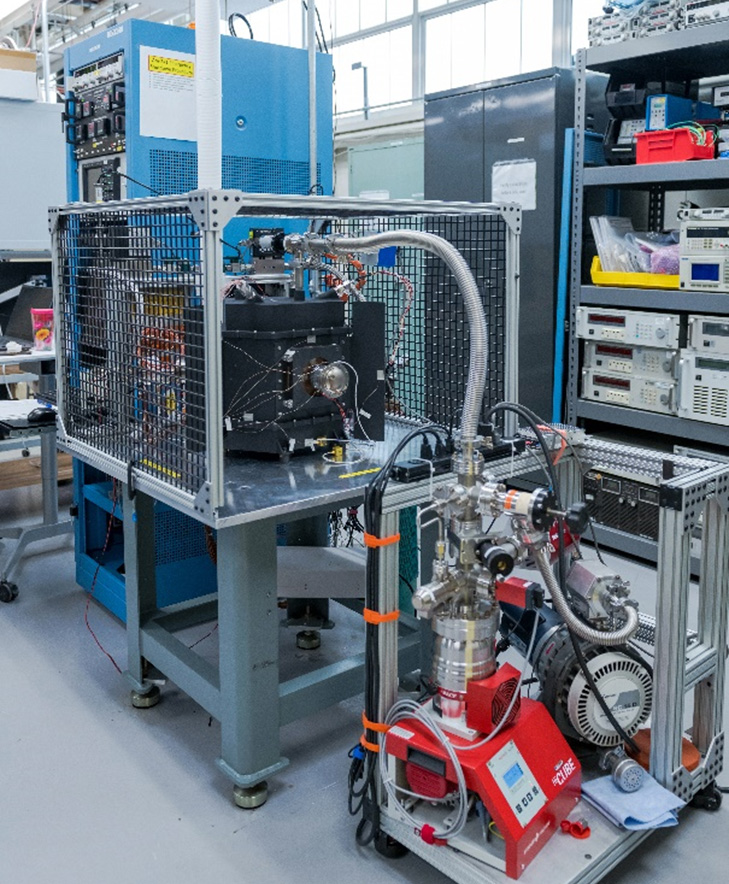

NASA’s Glenn Research Center in Cleveland is advancing free-piston Stirling dynamic power convertors to support future Radioisotope Power Systems (RPS) and Fission Power Systems (FPS). Working with industry partners, Glenn engineers have helped develop reliable, robust, and highly efficient Stirling prototypes. These convertors undergo rigorous testing to simulate the extreme environments expected during space missions, including random vibration to mimic launch conditions and centrifuge testing to replicate the forces experienced during descent and landing on planetary surfaces.

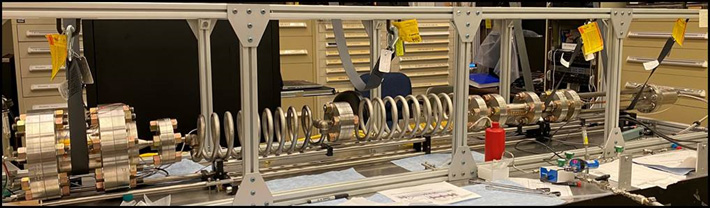

One notable prototype is the Technology Demonstration Convertor (TDC), developed by Stirling Technology Company (also known as Infinia). The TDC generates 55 watts of electricity at 25% conversion efficiency. Between 2000 and 2006, 16 TDC prototypes and two engineering units were built under a flight contract. These units use flexure bearings to maintain non-contacting clearances, enabling wear-free operation. Three TDCs have each operated maintenance-free for over 17 years. One of them, TDC #13, is the longest-running heat engine in the world.

The Advanced Stirling Convertor (ASC) was developed by Sunpower Incorporated to produce 80 watts of electricity with a conversion efficiency of 40%. Between 2007 and 2015, 17 ASC prototypes and 20 engineering units were built. These convertors use gas bearings to maintain non-contacting running clearances, allowing for wear-free operation. The longest-running unit, ASC-0 #3, has operated maintenance-free for more than 14 years. Some units were disassembled and inspected to identify design improvements that enhance thermal stability and increase resilience under test conditions exceeding operational limits.

The Sunpower Robust Stirling Convertor (SRSC) was developed by Sunpower Incorporated to produce 60 watts of electricity with 26% conversion efficiency. Based on the Advanced Stirling Convertor (ASC) design, the SRSC incorporates key improvements informed by lessons learned during ASC development. Enhancements include stiffer bearings, a more durable regenerator to reduce debris risk, and a passive collision-prevention system for temporary electrical load loss.

Five SRSC prototypes were produced between 2019 and 2025. The leading unit has operated for more than 2.5 years. This design has reached Technology Readiness Level (TRL) 5, having successfully completed qualification-level random vibration tests up to 7.7 grms (root-mean-square acceleration) and static acceleration testing up to 22.5 g.

Stirling Generators

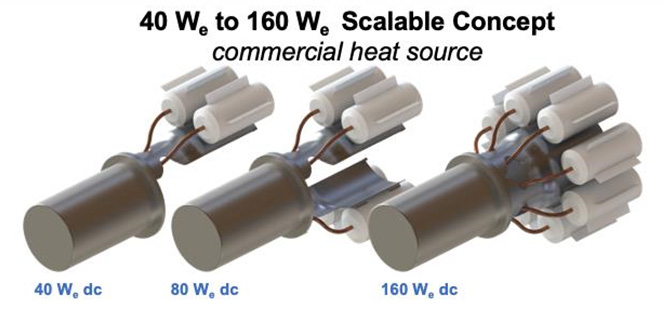

Researchers at NASA Glenn have advanced Stirling-based radioisotope power systems (RPS) for many years. Stirling RPS offer several advantages over legacy systems. With a conversion efficiency of approximately 20%, more than three times higher than previous NASA RPS (~6%), these systems require less radioisotope fuel and produce less waste heat.

Stirling RPS also exhibit zero mechanical degradation; power output declines only due to the natural radioactive decay of the fuel. For example, plutonium-238 (Pu-238) has a half-life of 88 years, while americium-241 (Am-241) has a half-life of 432 years. With convertors designed for multi-decade service life, Stirling RPS could support missions lasting significantly longer than any flown to date.

Another benefit is flexibility: a single Stirling RPS design can support a variety of mission types, including deep-space vacuum environments and planetary surface operations. Recent research has focused on a multi-hundred-watt configuration using redundant convertors. This design allows one or more convertor failures without reducing the total power delivered to the spacecraft.

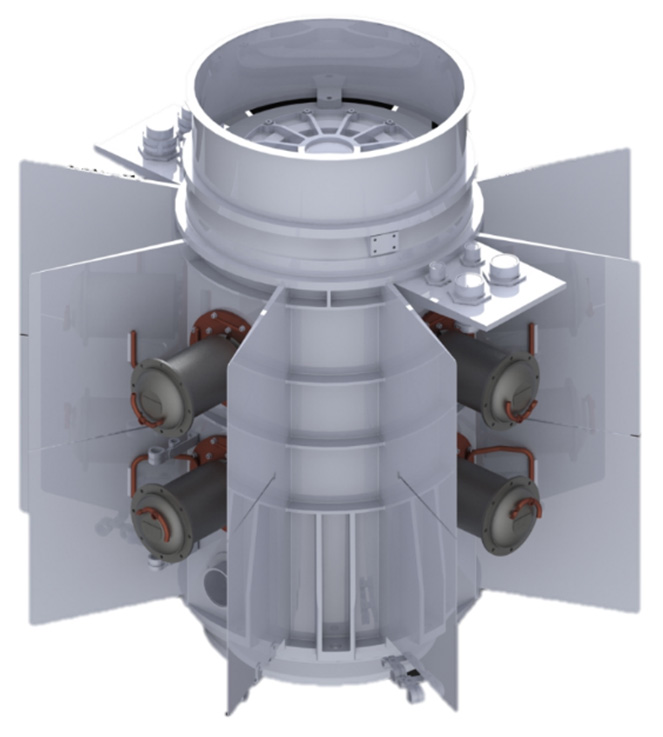

In 2022, NASA Glenn collaborated with the U.S. Department of Energy (DOE) and Aerojet Rocketdyne to complete a one-year effort resulting in a generator design comprising six General-Purpose Heat Source (GPHS) modules and eight Sunpower Robust Stirling Convertors (SRSCs). The system produces more than 350 watts of electrical power (We). The generator’s specific power could be increased by using multilayer insulation instead of solid insulation in vacuum-only environments.

NASA has also built and tested generator-like hardware to demonstrate system-level redundancy. One prototype, the Stirling generator concept shown below, integrates four convertors and a Pu-238 heat source and has achieved 17% efficiency in early lab testing. In another effort, NASA collaborated with the University of Leicester to develop and test a Stirling RPS concept powered by Am-241. The result, “Stirling generator designed for use with an americium-241 heat source,” shown further down, demonstrated 16% conversion efficiency.

SRSC-Based Generator Statistics

| Parameter | Multimission | Vacuum Only |

|---|---|---|

| Design Life | > 17 years | > 17 years |

| Number of GPHS Modules | 6 | 6 |

| Power Output (BOL) | 354 We | 356 We |

| Power Output (EODL) | 297 We | 298 We |

| Conversion Efficiency | 24% | 24% |

| BOL Specific Power | 3.2 We/kg | 4.0 We/kg |

| EOL Specific Power | 2.6 We/kg | 3.3 We/kg |

| Mass | 112 kg | 90 kg |

Reference Publications

- Wozniak, Ernestina, et al. “Assembly, Integration, and Initial Test Results of a Stirling Radioisotope Power System Generator Testbed.” Nuclear and Emerging Technologies for Space, 2024.

- Oriti, Salvatore M., and Scott D. Wilson. “Dynamic Power Convertor Development for Radioisotope Power Systems at NASA Glenn Research Center.” 2018 International Energy Conversion Engineering Conference, 2018.

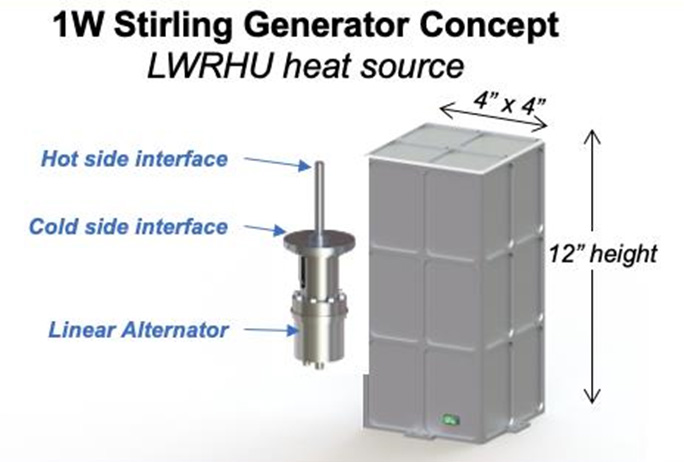

Small-Scale Stirling Engines

- Small nuclear power systems using Stirling technology could provide long-duration electric power for probes, landers, rovers, and communication repeaters on the Moon or Mars.

- These systems would convert heat from the decay of radioisotope fuel into usable electricity to support spacecraft mobility, science instruments, and communications.

- Each system would use a single convertor and balancer assembly to convert heat from an isotope source and eliminate residual dynamic disturbance.

- Small Stirling RPS could achieve 15% to 25% conversion efficiency, producing 20–50 watts of usable electrical power.

Reference Publications

- Wilson, Scott D., Nicholas Schifer, and Michael R. Casciani. “Small Stirling Technology Exploration Power for Future Space Science Missions.” International Conference for Aerospace Experts, Academics, Military Personnel, and Industry Leaders, 2019.

- Wilson, Scott D. “Development of Stirling Convertors for Radioisotope and Fission Power Systems.” Nuclear and Emerging Technologies for Space, 2023.

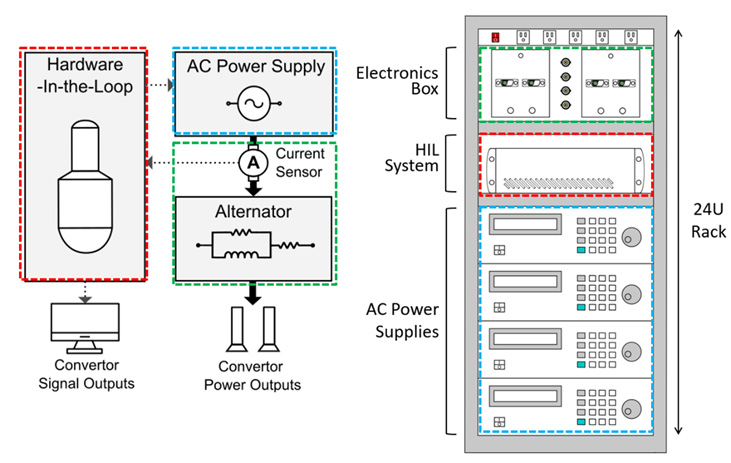

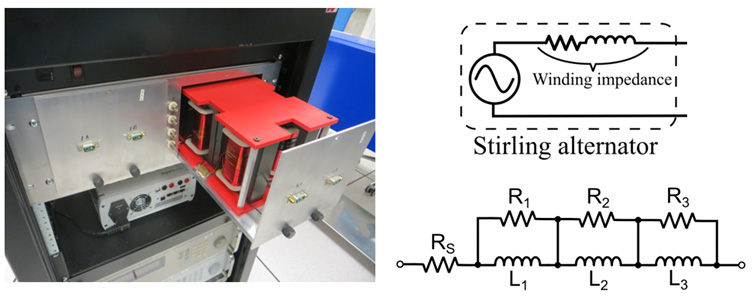

Stirling Simulators

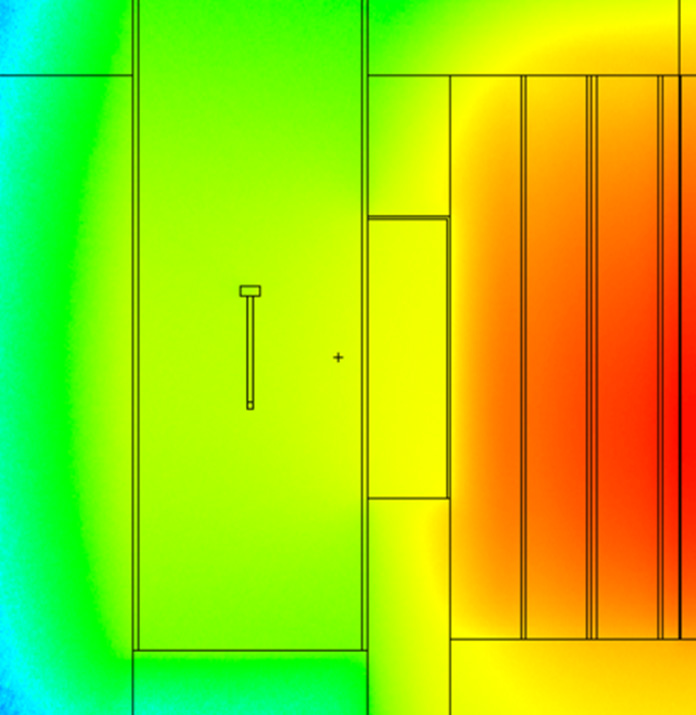

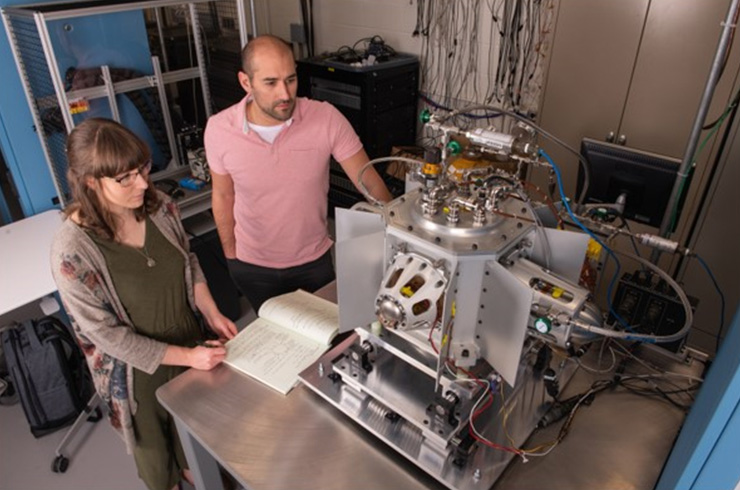

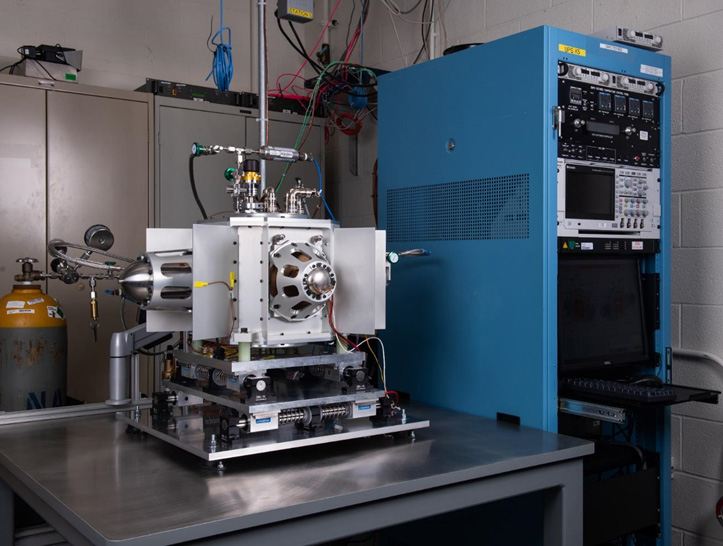

NASA Glenn is developing replicable Stirling simulator hardware to support the rapid development of Stirling engine controllers and power systems. These simulators streamline power system testing by eliminating the need for engine warm-up and cool-down cycles, and they are immune to damage during electronics debugging.

Stirling simulators accurately emulate the electrical and dynamic behavior of actual engines, including terminal characteristics, large-signal gas dynamics, and small-signal electrical parasitics. Successful integration with simulator hardware has consistently yielded performance results nearly identical to those achieved with operational heated engines.

Designs are available to help industry partners quickly adopt this simulation capability.

Reference Publications

- Yang, Max, Christopher Barth, Ronald Leibach, Michael Casciani, and Luis Rodriguez. “Multi‑Convertor Configurable Simulator for Dynamic Radioisotope Power Systems.” 44th International IEEE Aerospace Conference, 2023.

Controller Work

NASA Glenn develops in-house Stirling controllers for dynamic space power generation systems, including radioisotope power systems (RPS) and fission surface power (FSP). Multiple breadboard hardware units are built to support rapid design iteration, enabling timely development of robust flight-ready controllers.

NASA also collaborates with external partners to deliver Stirling controller technologies for a range of projects supporting both NASA and the U.S. Department of Defense.

Reference Publications

- Yang, Donguk Max, et al. “A Study on Effect of Tuning Capacitor in Dynamic Radioisotope Power Systems.” Nuclear and Emerging Technologies for Space (NETS 2023). 2023.

- Barth, Christopher B., Donguk Max Yang, and Max F. Chaiken. “Design of 1 kW Simplified Stirling Controller Using Capacitor‑Based Power Factor Correction.” Nuclear and Emerging Technologies for Space, 2021.

Fission Surface Power

Power Conversion

The power conversion subsystem is a central component in systems that use fission surface power (FSP) and nuclear electric propulsion (NEP), transforming a reactor’s thermal energy into usable electrical power for surface operations or spacecraft propulsion. Efficient and reliable energy conversion is essential for enabling long-duration missions.

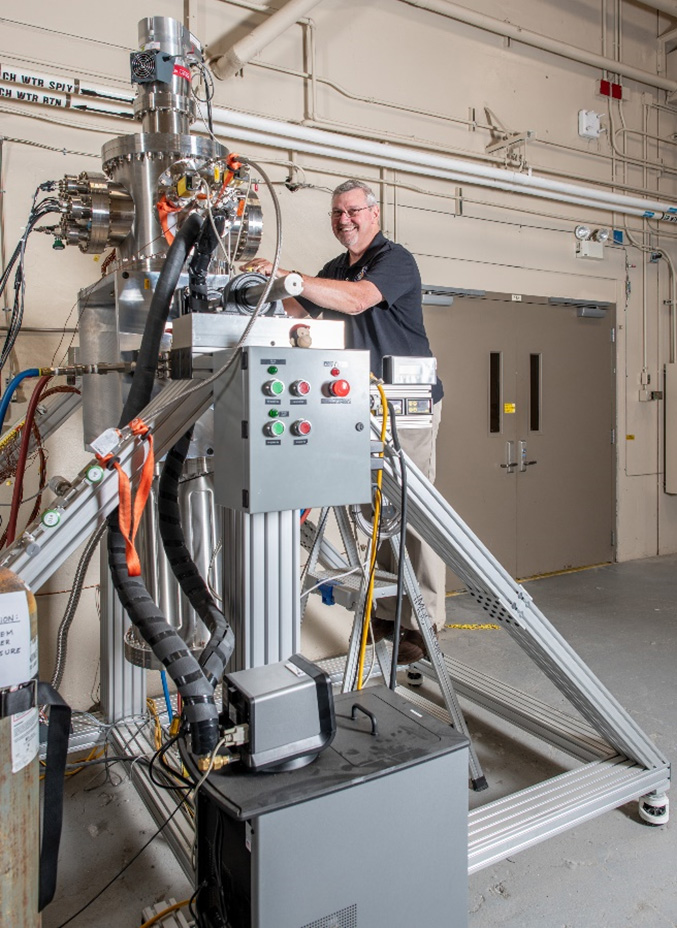

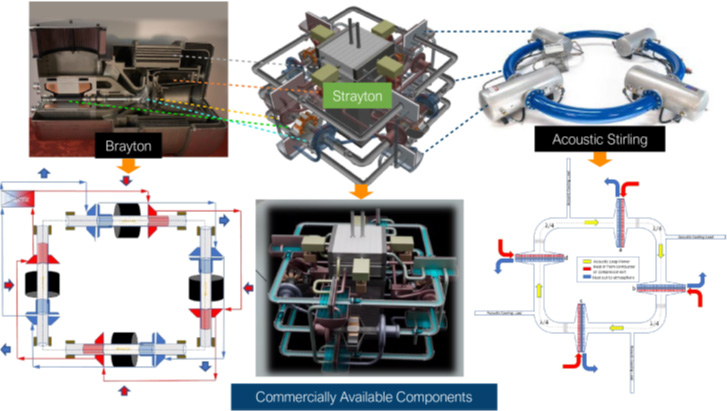

NASA Glenn is developing advanced high-efficiency power conversion technologies, such as free-piston Stirling and closed Brayton cycle convertors, to support these systems. Work focuses on improving thermal-to-electric conversion efficiency, enhancing long-term reliability, and reducing mass to enable sustainable missions to the Moon and Mars.

Thermal Transport

NASA Glenn researchers are advancing thermal management technologies for applications such as fission surface power (FSP), nuclear electric propulsion (NEP), and radioisotope power systems. Key technologies include high-temperature alkali metal heat pipes, which transfer heat between critical FSP or NEP subsystems, and advanced radiators that reject excess heat from power conversion systems.

These technologies are tested and evaluated in a range of conditions, including thermal-vacuum environments, microgravity, radiation exposure, and long-duration operations, to ensure performance and reliability for future space missions.

Reference Publications

- Thaikattil, Greeta J., et al. “Consolidation of A Sodium Heat Pipe and Stirling Engine for Fission Surface Power.” Thermal Fluids Analysis Workshop (TFAWS). 2023.

- Gibson, Marc A., et al. “Heat Transport and Power Conversion of the Kilopower Reactor Test.” Nuclear Technology, vol. 206, supplement 1, pp. 31–42, 2020

Radiation Effects

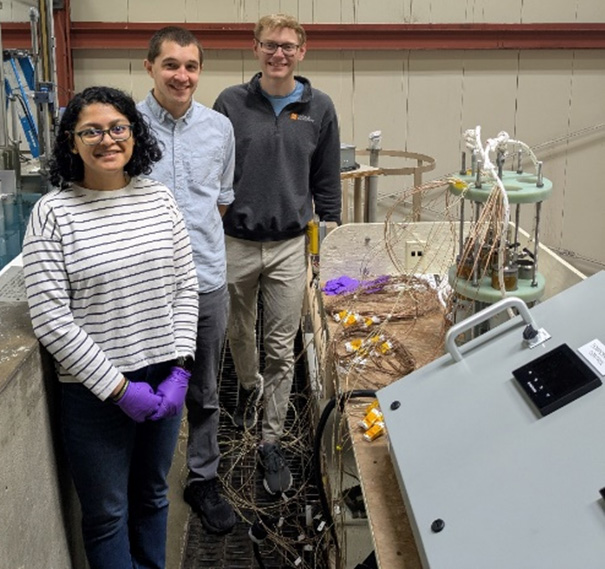

Radiation is ubiquitous in space. In addition to natural background radiation, some NASA missions will induce harsh radiation. NASA is advancing technology for a nuclear reactor that would provide surface power for human space exploration. This reactor will irradiate electronics, sensors, structural materials, heat-rejection mechanisms, power conversion systems, and most other technologies flown on the mission.

The effects of radiation on the various systems associated with this thermal energy source need to be understood to ensure a successful mission. To investigate radiation effects, NASA has conducted irradiation experiments, used radiation transport and neutron transmutation models, assessed potential testing facilities, and more. This work is conducted in close collaboration with the U.S. Department of Energy.

Reference Publications

- Steiner, Tyler R., Robert J. Bruckner, and Scott D. Wilson. “NASA’s Interest in Radiation Tolerance and Requirements of Candidate Technologies for Fission Surface Power and Further Relevance to Dynamic Radioisotope Power Systems.” Nuclear and Emerging Technologies for Space (NETS 2024). 2024.

- Steiner, Tyler R., Jarvis A. Caffrey, and Jonathan D. Barth. “Coalescence of Designed and Natural Space Radiological Environments.” Nuclear and Emerging Technologies for Space (NETS 2025), 2024.

- Hansen, Luke R., Tyler R. Steiner, Brandon A. Wilson, and Michael T. Barron. “Design Methodology of a Pressurized Irradiation Test Apparatus for Stirling Convertor Organics in a Fission Surface Power System.” Nuclear and Emerging Technologies for Space Conference (NETS), 2025.

Aircraft Thermal Management

Thermal Recovery Energy Efficient System (TREES)

The Thermal Recovery Energy Efficient System (TREES), developed at NASA Glenn, demonstrates how thermoacoustic waves can be used to manage heat. Aircraft, spacecraft, and power systems often generate high-grade waste heat, which can pose challenges for thermal control.

TREES harnesses this thermal energy and uses oscillating pressure waves to convert high-grade waste heat into low-grade waste heat. This process critically reduces the burden on heat rejection systems and improves overall energy efficiency.

Reference Publications

- Rodriguez, Luis A., Rodger W. Dyson, Mark P. Wernet, and Ronald J. Leibach. “Thermoacoustic Thermal Management for Electric Aircraft.” AIAA SciTech Forum, January 6–10, 2025.

Strayton

Reference Publications

- Zoldak, Philip S. “Potential of a Hydrogen-Fueled Opposed‑Piston Four‑Stroke (OP4S) Engine.” SAE Technical Paper Series, Paper 2023-01-1513, 2023.

Contact

| Area of Expertise | Name | |

|---|---|---|

| Stirling Engine Systems | Scott Wilson | scott.d.wilson@nasa.gov |

| Fission Surface Power | Salvatore Oriti | salvatore.m.oriti@nasa.gov |

| Aircraft Thermal Management | Luis Rodriguez | luis.a.rodriguez-1@nasa.gov |