Space Launch System/Universal Stage Adapter

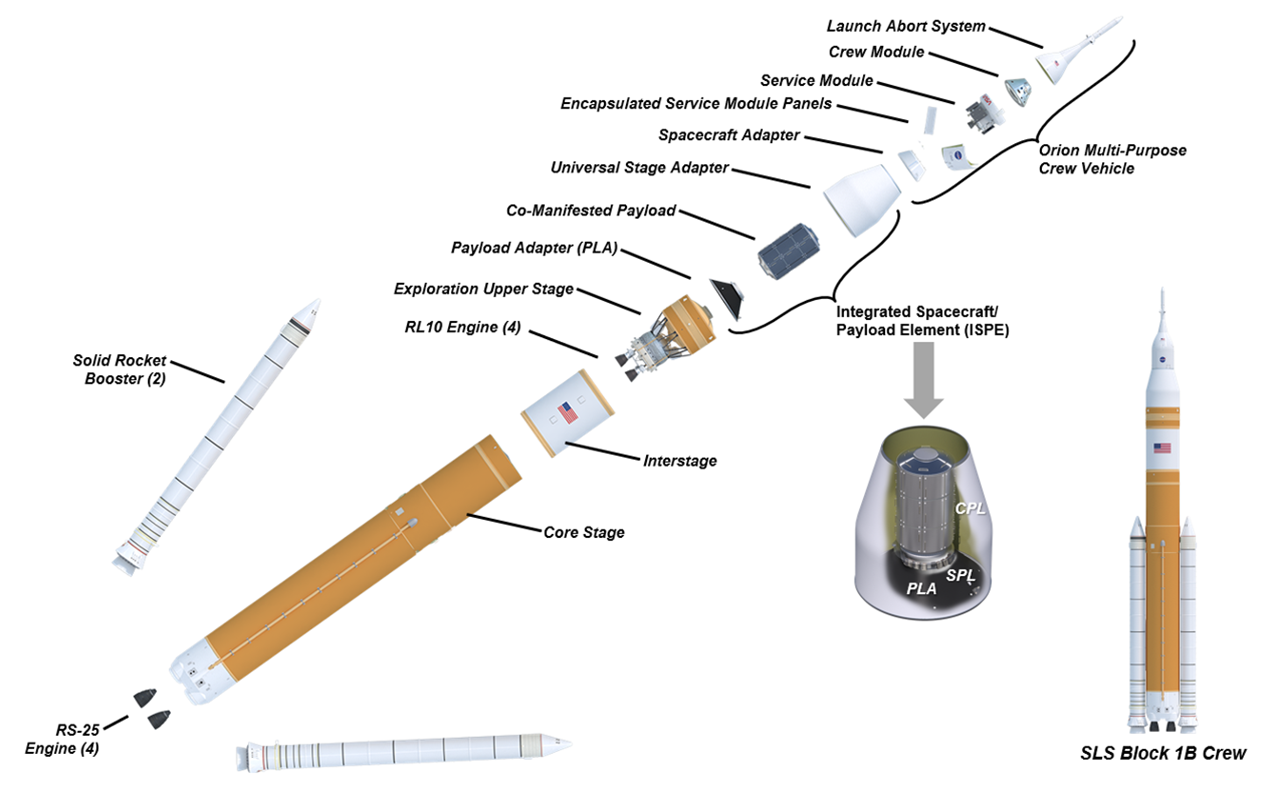

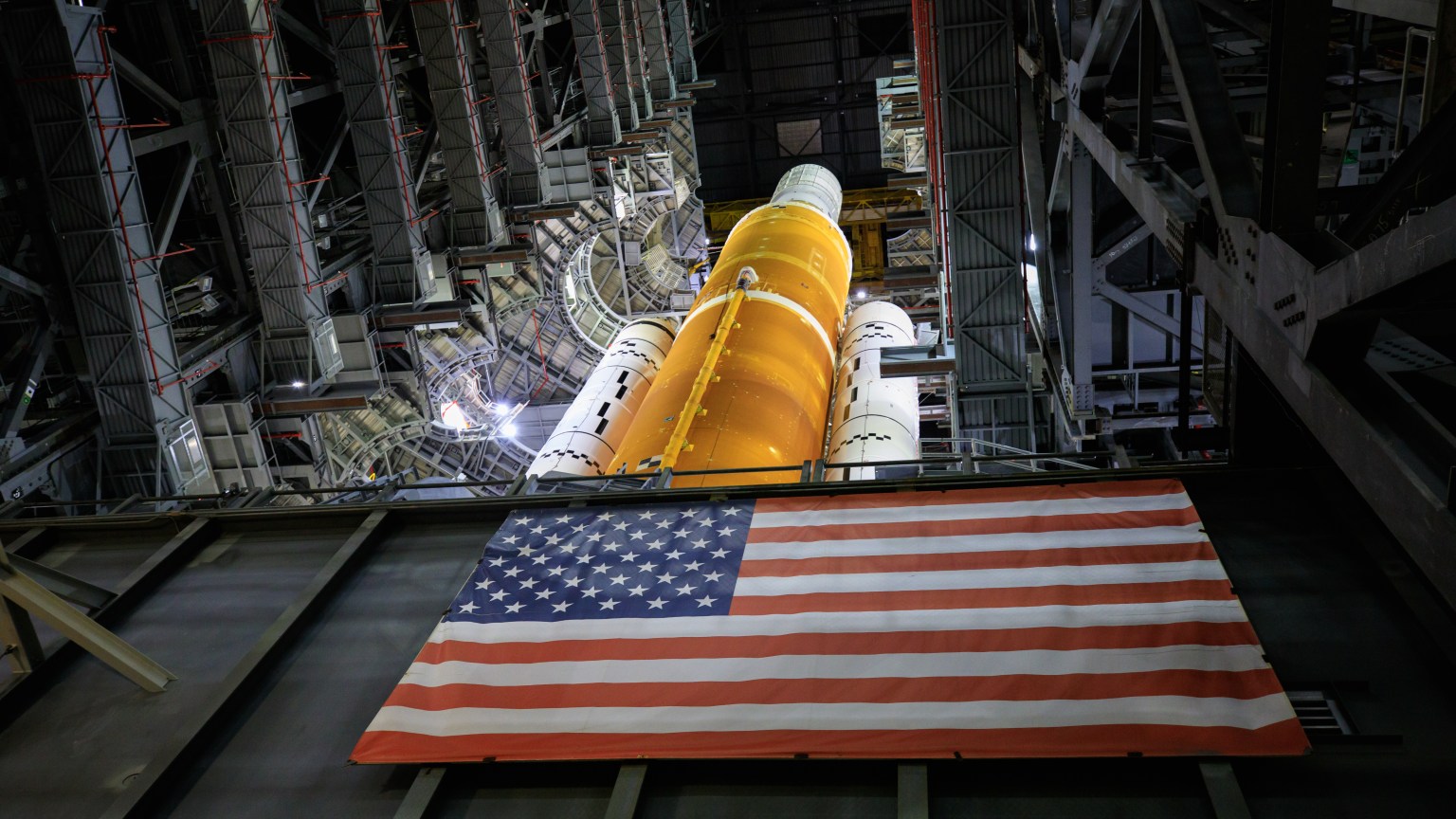

NASA’s SLS (Space Launch System) rocket is designed to be flexible and evolvable to meet the mission needs of the Artemis campaign. With the Block 1B upgrade, which adds an Exploration Upper Stage (EUS) to increase the payload capability, the rocket requires a new adapter to connect it to the Orion spacecraft.

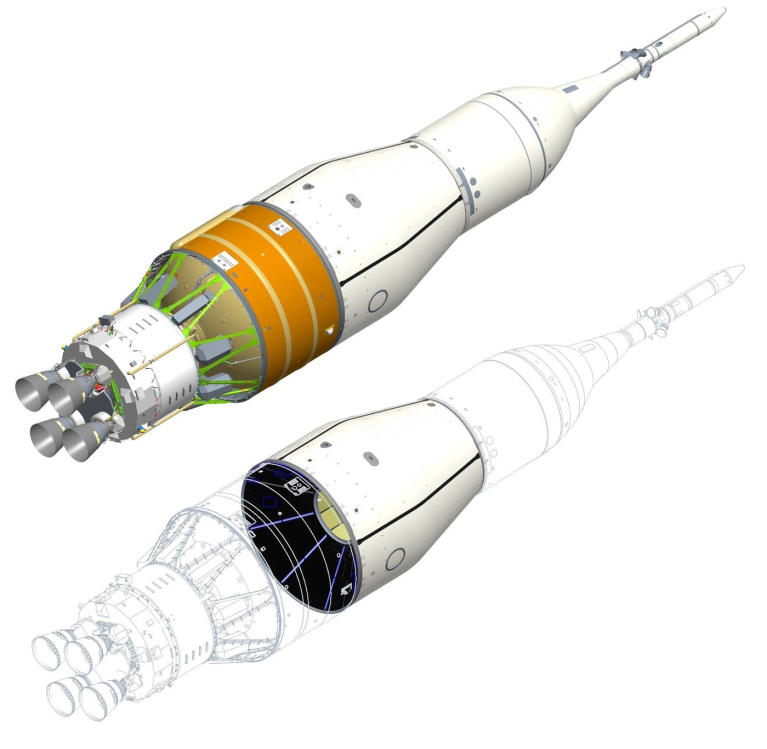

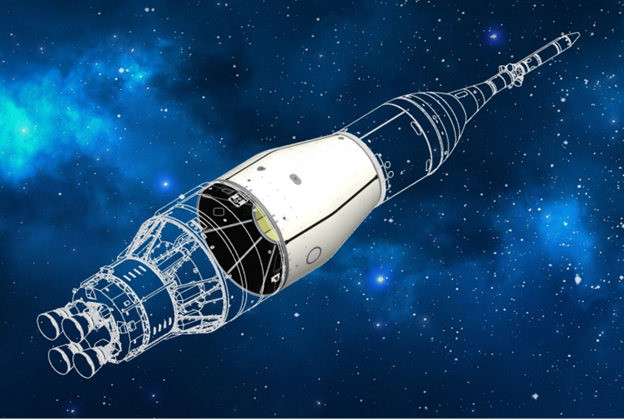

A Universal Stage Adapter (USA) was envisioned to not only provide the structural connection but also enable a co-manifested payload to be delivered to orbit. The adapter protects the payload from initial encapsulation and stacking onto the SLS rocket through integration, system checkout, processing, rollout to the pad, and finally through launch and ascent. Once on orbit, the adapter carefully separates from the Exploration Upper Stage to allow the Orion capsule to dock with the payload and journey on to the Moon.

NASA’s Glenn Research Center in Cleveland is leading the design and development of the Universal Stage Adapter on behalf of the SLS Program for the agency. The adapter will connect the Orion spacecraft to the SLS Exploration Upper Stage when it launches astronauts on the Block 1B Artemis IV mission.

The Universal Stage Adapter leverages the latest in advanced composite materials to be as light as possible. Every pound of structure is equivalent to a pound of payload because the adapter is carried through the Exploration Upper Stage trans-lunar injection burn that will send Orion to the Moon. The adapter will be the largest fully composite human-rated primary structure ever flown and will maximize the payload mass capability for future Artemis missions.

The Universal Stage Adapter will be made of four composite honeycomb-core panels, with access doors, a separation system, a Vehicle Damping System (VDS) connection to help stabilize the vehicle on the mobile launcher, and a purge umbilical with disconnect to maintain a clean air internal environment before launch. At liftoff, the adapter will weigh less than 9,650 pounds.

Expertise from across NASA was used to minimize the risk of the design and development of the new structures. This included the help of engineers not only at Glenn, but at NASA’s Langley Research Center in Hampton, Virginia, and NASA’s Marshall Space Flight Center in Huntsville, Alabama, to realize the design of the adapter.

The Universal Stage Adapter is cone shaped with a cylindrical lower barrel. It is 18.0 feet in diameter on the Orion end (forward end), 27.6 feet in diameter at the Exploration Upper Stage end (aft end), and stands 33.1 feet tall. It will provide environmental control to payloads during ground operations and launch and ascent, and it will provide electrical and communication paths between SLS’s Exploration Upper Stage and Orion.

The upgraded configuration of SLS, known as Block 1B, is the first use of the Universal Stage Adapter. It is managed by the SLS Spacecraft and Payload Integration and Evolution Office at NASA Marshall and will support Artemis IV and future missions.

With the Exploration Upper Stage, which will be powered by four RL10-C3 engines, SLS will be capable of lifting more than 105 metric tons (231,000 pounds) from Earth’s surface. Unlike the previous Block 1 adapter, the Universal Stage Adapter will be capable of carrying large co-manifested payloads, such as a habitat. To protect and deploy those payloads, the design incorporates systems to control temperature, mitigate the acoustic environment, and safely separate without recontact to enable release of the payload.

The Universal Stage Adapter is used for NASA’s SLS. The SLS is a powerful, advanced heavy-lift launch vehicle designed to be flexible and evolvable for deep-space destinations. The base contract effort, led by Dynetics (a subsidiary of Leidos), is to design, test, manufacture, and deliver one Universal Stage Adapter. The acquisition also includes qualification and flight quick disconnects, payload encapsulation tooling, lifting Ground Support Equipment (GSE), transportation hardware, and ground processing and transportation cover.

Universal Stage Adapter Image Gallery

Latest Space Launch System Content

Stay up-to-date with the latest Space Launch System content from NASA as we explore the universe and discover more about our home planet.

of exploration to destinations beyond Earth’s orbit with the successful launch of Artemis I in November 2022. In addition to…

NASA’s SLS (Space Launch System) is a super heavy-lift rocket that provides the foundation for human exploration beyond Earth orbit.…

On Nov. 16, 2022, NASA’s SLS (Space Launch System) rocket launched for the first time. Lifting off the launch pad…