NASA’s X-59 Quiet SuperSonic Technology, or QueSST, aircraft is on a mission to achieve supersonic speeds over land that create no more than a sonic “thump” to those below. This mission will provide data that could convince U.S. and international regulators to change the rules governing the speed of non-military aircraft over land. In order to achieve this, NASA engineers are designing all new shapes and systems to support this concept.

One such system is the eXternal Vision System (XVS). The aircraft’s elongated nose, combined with no forward-facing window, creates a visual blockage for the pilot. The XVS is a forward-facing camera and display system that shows the airspace in front of the X-59 pilot. The XVS uses image processing software and camera systems to create an augmented reality view of the pilot’s forward sight combined with graphical flight data.

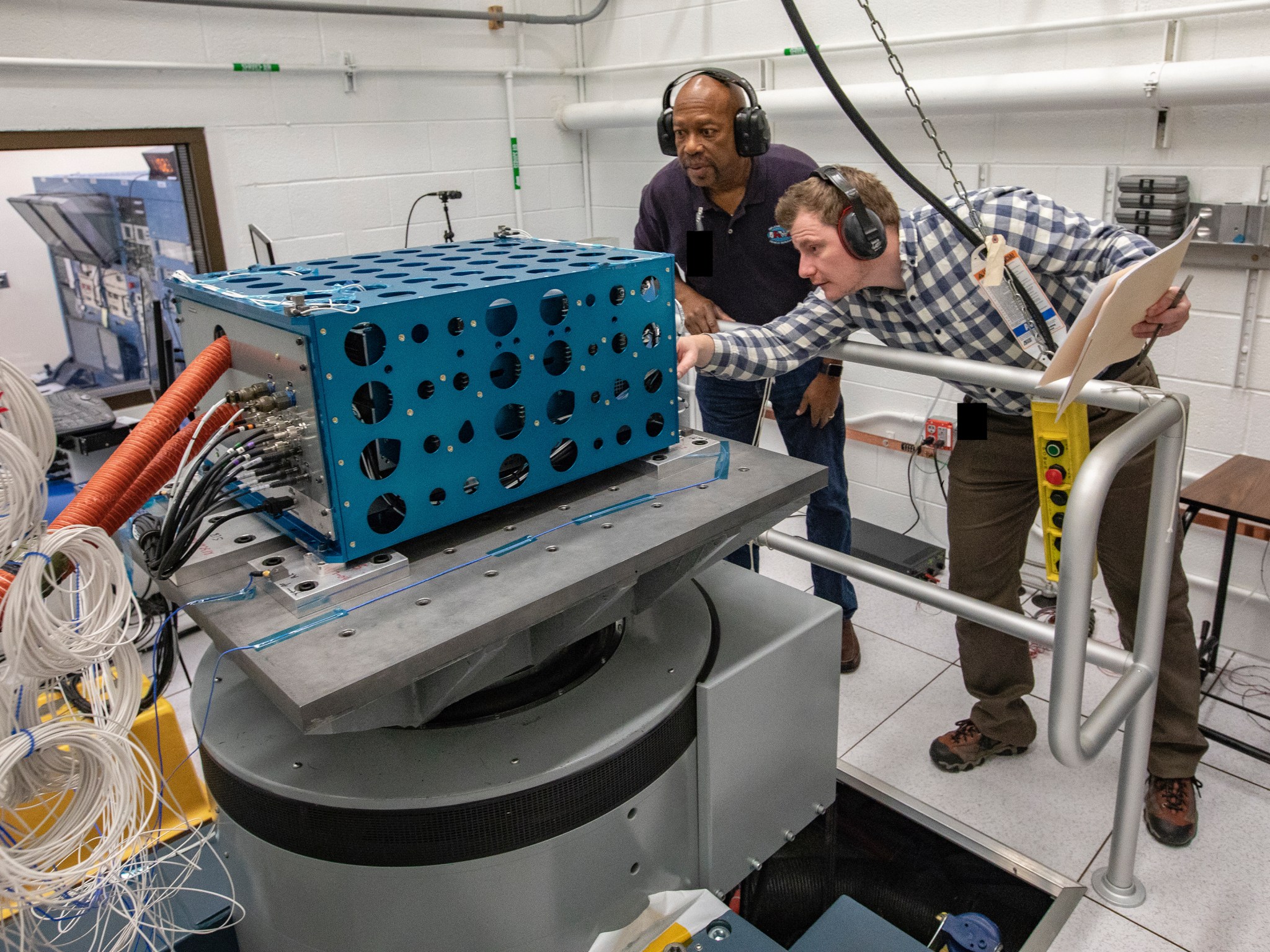

After successful in-flight tests of the XVS in August of 2019, researchers at NASA’s Langley Research Center in Hampton, Virginia, are now testing the structural integrity of the system through a series of vibration tests.

“All equipment installed on the X-59 has to meet the requirements of the vehicle environment,” said Randall Bailey, lead engineer for the XVS. “We are conducting vibration testing of the XVS pallet in accordance with these requirements.”

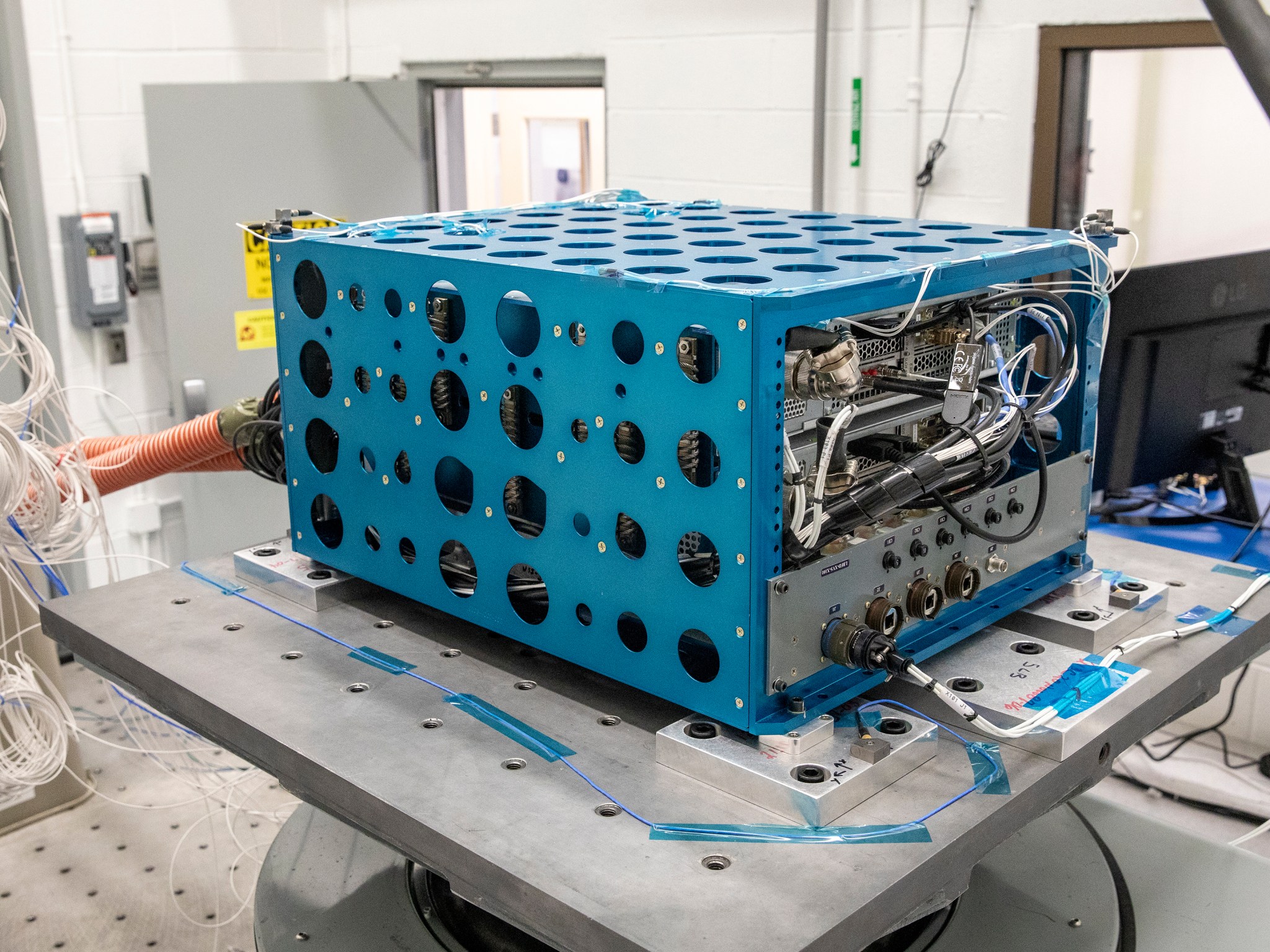

The XVS is comprised of three major components: XVS pallet, XVS camera, and the XVS monitor. These vibration tests of the XVS pallet hardware contains the processors, network equipment, video distribution, and power distribution components.

“We’re conducting proto-qualification, which in this case refers to the testing of equipment at vibration levels lower than qualification testing, but to the expected vibration levels of the flight environment to ensure the equipment will function nominally when installed on the X-59,” said Kemper Kibler, lead hardware engineer for the XVS. “This allows for the tested equipment to be flown as opposed to qualification testing which can test equipment to destruction.”

Lockheed Martin, who’s building the X-59, developed an Environmental Requirements and Test Document (ERTD) that defines the expected environment for the X-59.

“All equipment that will fly on the X-59 has to meet the requirements in the document from either manufacturer certification, test, or analysis,” said Kibler. “By conducting the test we are able to identify and correct design and workmanship issues before the equipment is installed on the aircraft.”

Safety is at the forefront of all NASA missions and this vibration test helps prevent a worst-case scenario.

“Without this kind of test, a component could fail in such a way that causes damage to the aircraft or injures the flight crew,” said Kibler. “We want to identify and correct those issues in a controlled lab environment.”

This test is just one piece in the overall qualification of XVS for flight on the X-59. The first test, a temperature and altitude test of the XVS camera, was completed in June of 2018 at NASA’s Armstrong Flight Research Center. Subsequently, the team has performed multiple tests at different NASA and vendor facilities including temperature, altitude, vibration, explosive decompression, and gaseous nitrogen environments.

“This test is another step in fully qualifying XVS for X-59 deployment,” said Bailey. “To reach this point has taken a significant amount of team work, from engineers to hardware designers to technicians to testers.”

Next the pallet will be traveling to New York at the end of the month to undergo temperature and altitude tests at a facility that could provide forced air at the expected flow rates and temperatures expected on the X-59.