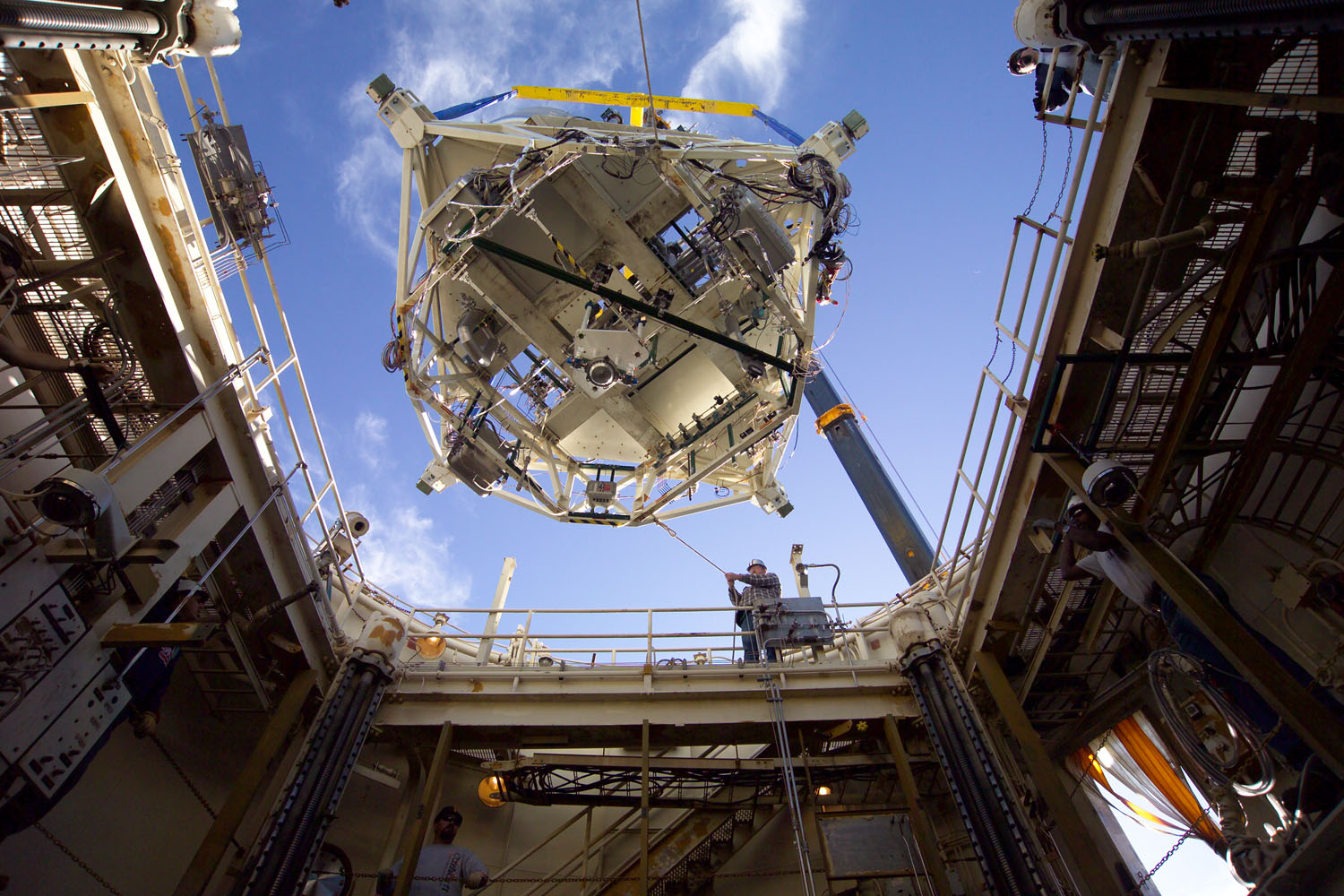

From the initial design to acceptance testing and flight qualification, our team can assist you at every step of your propulsion systems project. Our site offers cutting edge propulsion expertise as well as expertise in the propulsion related areas of propellant and aerospace fluids, oxygen systems, and composite pressure systems. We also have many in-house supporting services which offer quick turnaround and superior quality.

Development

Our engineers have a repository of information to draw from to assist you in the design of a new system or redesign/modification of an existing one.

- Materials Selection – Our materials personnel can test and/or recommend materials suitable for various applications and use with different configurations, propellants, and aerospace fluids.

- Component Services – Engine hardware, instrumentation, and parts can be custom fabricated in our machining and fabrication facility. Existing components can be repaired, refurbished, or modified.

- System Builds – Our team can assemble all of the components of a system to your exacting specifications.

Qualification

Rigorous testing of new and/or modified systems for compliance with space flight requirements, regulations, and conformity with standards is crucial. We verify that systems and components will function as expected in the harsh environment of space. If flight qualification cannot be met, we can offer solutions and assistance.

- Materials Flight Acceptance – Our Materials Flight Acceptance workforce offers flammability, offgas, reactivity, and vacuum stability testing.

- Flight Critical Hardware – Our Flight Critical Hardware personnel have hands-on experience in flight hardware processing including precision cleaning, disassembly, reassembly, repair, and flight acceptance testing.

- Supporting Capabilities – Various other supporting services are also available to resolve issues and/or suggest improvements including nondestructive evaluation, failure analysis, and materials testing.

Acceptance Testing

Regardless of the manufacturer, we can perform system testing to evaluate materials, components, and system configuration and performance to determine if test objectives have been met. If issues arise, we have excellent support staff to quickly determine the source and offer suggestions to help the system meet requirements.