Listen to an audio version of this story on the “NASA in Silicon Valley” podcast.

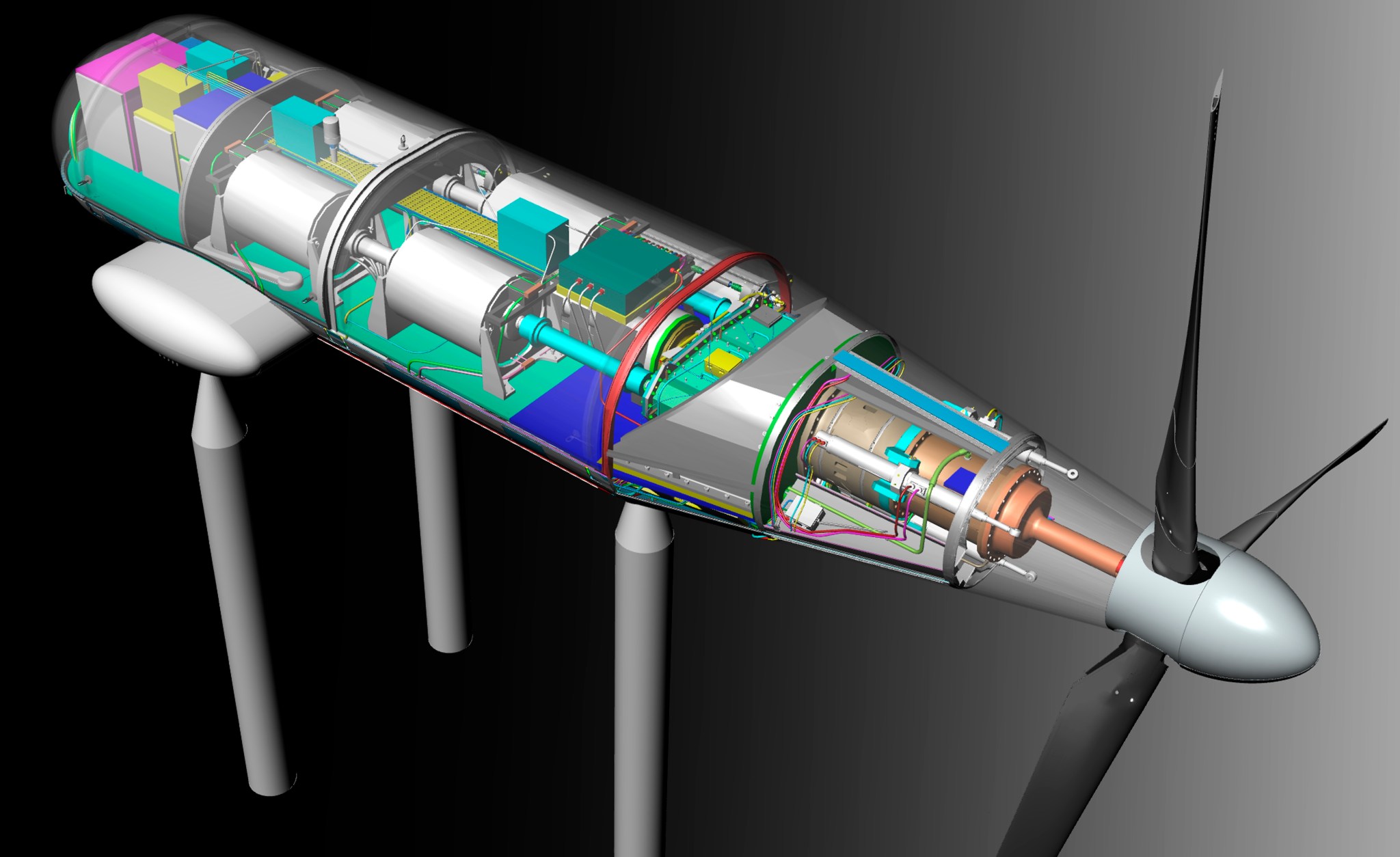

Someday, we may be able to commute to our jobs in aircraft that can take off and land like a helicopter, but fly like a plane. Developing these advanced tiltrotors is no simple task, so NASA is installing a new rig that will let experts test them at an unprecedented scale in wind tunnels, where pilots’ lives won’t be on the line.

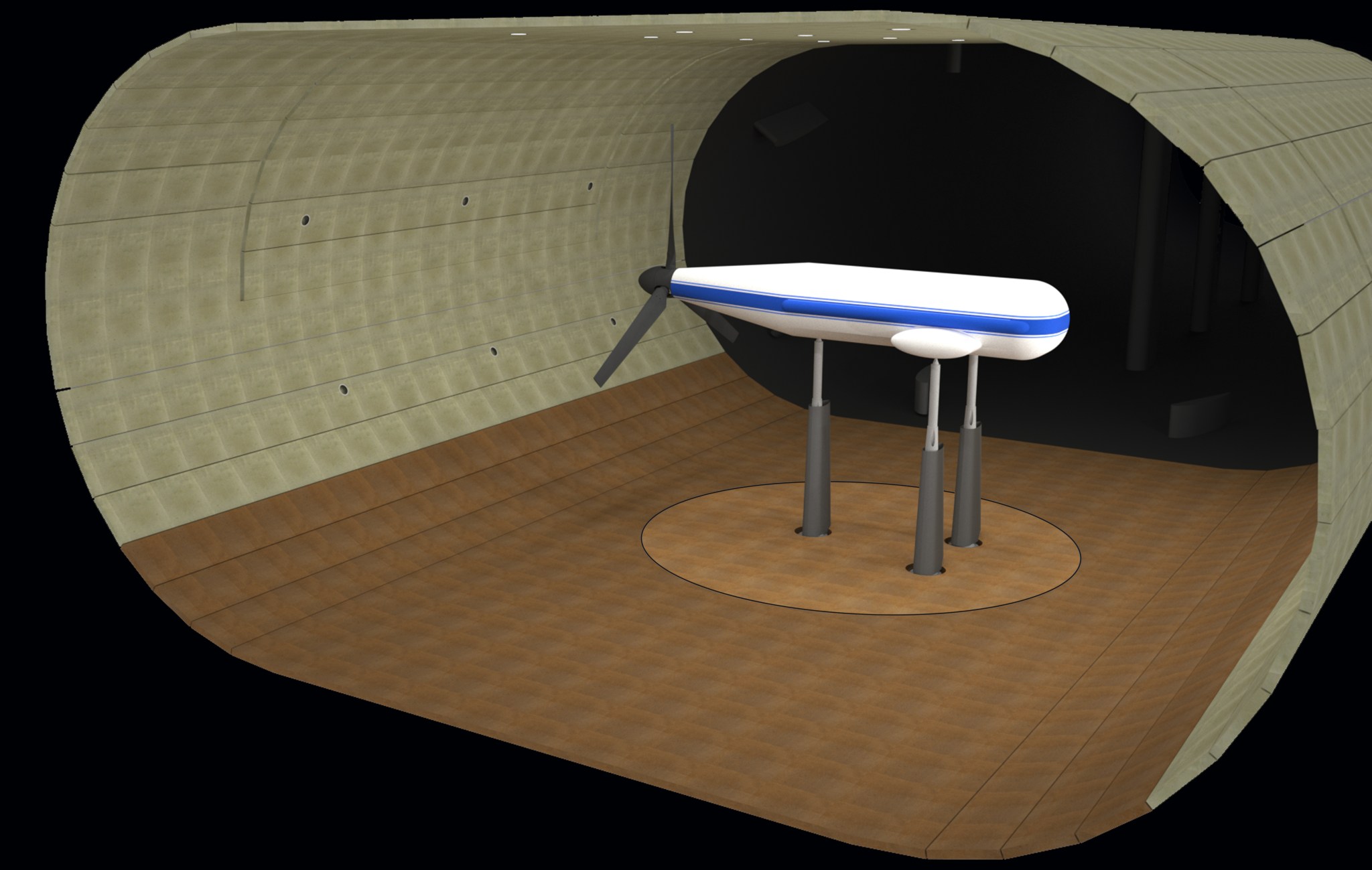

The new Tiltrotor Test Rig (TTR) will get its first functional trial next month at NASA’s Ames Research Center in Silicon Valley, California. The testing will take place in the biggest wind tunnel in the world – the National Full-Scale Aerodynamics Complex (NFAC).

“This first test is a functional checkout,” said Susan Gorton, lead for the Revolutionary Vertical Lift Technology project at NASA’s Langley Research Center in Hampton, Va.

Because TTR is so large, we’ve never been able to spin it with the rotor blades installed. This will be the first time that the system will be completely assembled and operated. If we find any anomalies, we’ll circle back to fix those. Our goal is to have our system completely checked out, so we can have confidence in it.

Susan gorton

Lead for the Revolutionary Vertical Lift Technology Project

The name tiltrotor reflects the ability of the rotors on the wings of these hybrid craft to shift from a helicopter-like orientation to an airplane-like orientation. The former lets the aircraft take off vertically, hover and land without a runway; the latter gives it greater forward speed.

Today, aviation is moving increasingly in the direction of tiltrotors. Although only one such craft currently is in production — the V-22 Osprey, used by the U.S. Marines — tiltrotors are expected to enter the commercial aviation market in 2018.

“With a tiltrotor, you get a lot more range and speed than a helicopter, but it’s still able to hover, which gives you good accessibility in remote locations,” Gorton said.

Anticipated civil uses for tiltrotor aircraft include offshore oil operations and executive transport. NASA is particularly interested in technologies for large configurations that could be used in commuter transport between cities.

Unprecedented in Size and Speed

Before those applications can be developed, large, high-performance tiltrotor systems need to undergo exhaustive testing. When the TTR gets up and running, it will be unique in its ability to handle rotors up to 26 feet in diameter, capable of reaching speeds of 300 knots (345 miles per hour).

“Other facilities out there test tiltrotor designs at much smaller scales, and then jump immediately to flight. They don’t have this advantage of being able to test at large scales,” Gorton said. “This is important, because we think the scale can have an impact on the test performance.”

NASA already was leading the way on advanced rotorcraft research in the 1970s, notably with the flight demonstrations of the XV-15 tiltrotor and other large-scale testing. In recent years, in a joint project with the Army and the Air Force, NASA has been working to replace the previous test hardware with a system of even greater capability.

Their efforts have culminated in the new TTR, which will pave the way for future tiltrotors by enabling NASA to test rotors producing more thrust and achieving higher speeds than any that exist today. The facility will provide a resource for the nation’s aviation research community to test specific rotor configurations, including those developed by private industry.

Fundamental aerodynamics research also is in TTR’s future. Projects conducted here provide a better understanding of what makes these rotors efficient, quantify the relative efficiencies of different configurations, and look for ways to improve upon the concept.

Further research and development could mean that, down the road, you’ll hop on your local tiltrotor aircraft to fly to work. The special rotors getting you there may well have taken their first spin at NASA Ames.

Aviation is vital to the U.S. economy; it generates more than $1.6 trillion in economic activity each year, supports a positive aerospace trade balance of $82.5 billion, provides nearly 11 million direct and indirect jobs, and transports more than 18 million tons of freight each year. Investments today in NASA’s cutting-edge aeronautics research are realized in benefits tomorrow from greener, safer, quieter and faster U.S. aviation.