They say you show your true colors when you’re under pressure.

Turns out the old saying works for models being tested in wind tunnels as well, specifically those coated with a unique Pressure-Sensitive Paint (PSP) that NASA engineers have used for more than 25 years.

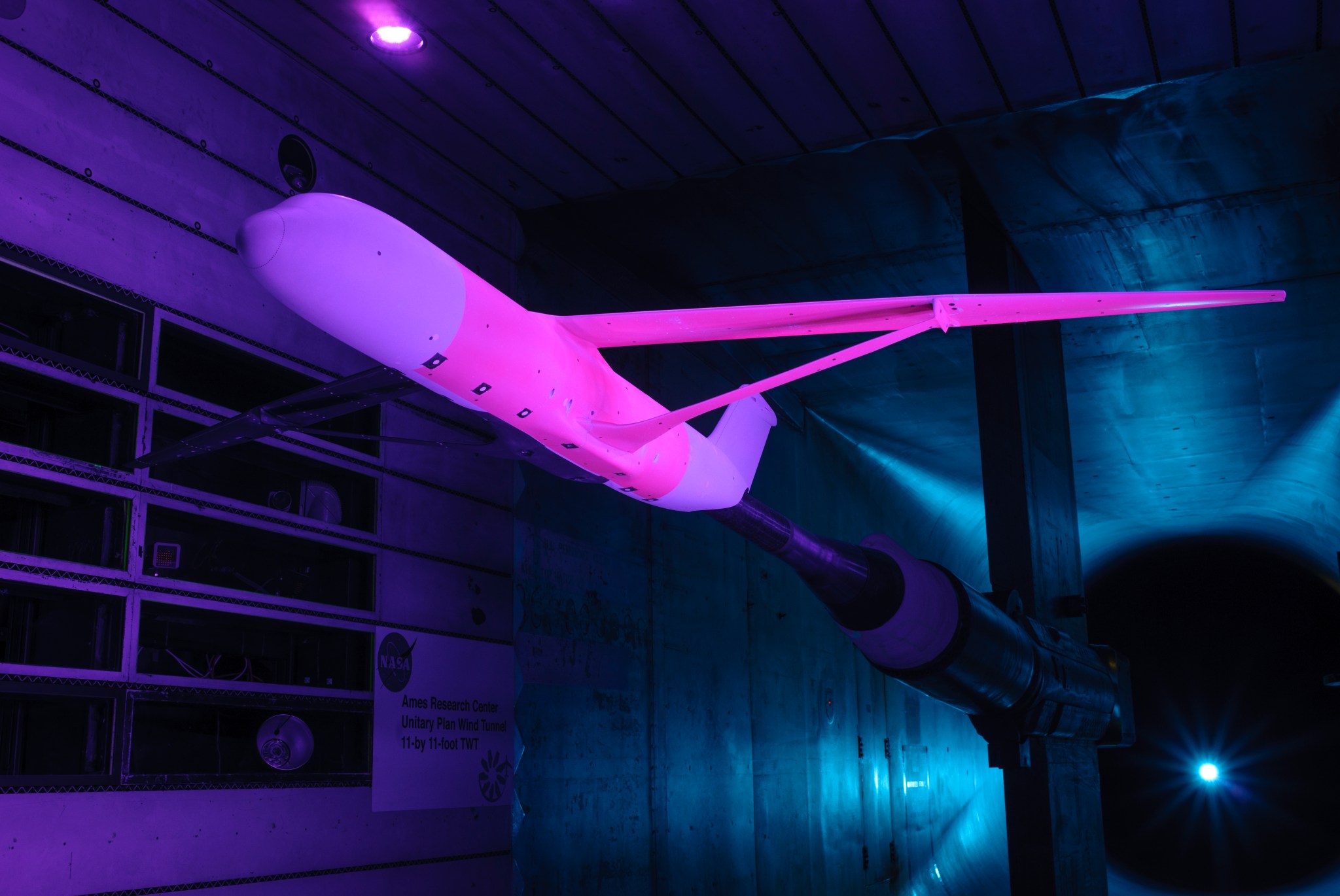

Today the bright pink paint is helping NASA’s aeronautical innovators test new aircraft designs that could cut fuel use in half, pollution by some 75 percent and noise to nearly one-eighth of what it is today.

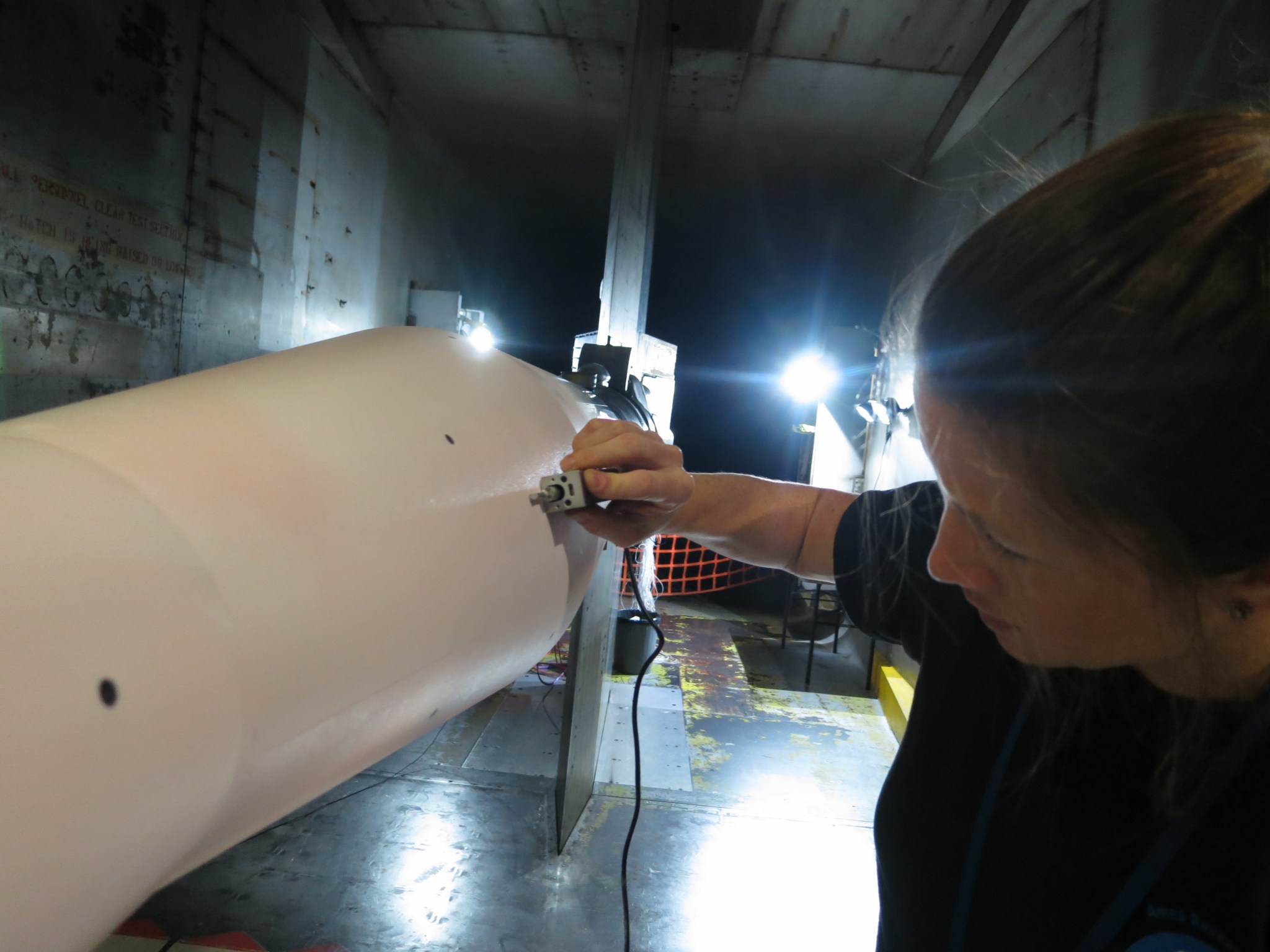

“PSP is great because as long as you can apply paint to the area you want to test, illuminate it with a lamp, and view it with a camera, you can gather data you might not otherwise be able to get,” said Nettie Roozeboom, an aerospace engineer with NASA’s Ames Research Center in California.

Engineers need to know how pressure is distributed across an airplane’s surfaces as it moves through the air so they can ensure, among many other critical variables, that they understand the loads the vehicle is experiencing at given wind tunnel conditions.

When testing scale models of aircraft designs in wind tunnels, pressure readings are traditionally taken using pressure taps, little plastic tubes that are strung through the model’s interior up to the surface through a small hole in key places.

“The challenge is you can only install so many of these taps, otherwise your whole model becomes one big pressure tap,” Roozeboom said. “And in some models, there just isn’t enough room inside the model to accommodate the taps.”

Case in point: Recent tests of a transonic truss-braced wing aircraft design, part of Boeing’s Subsonic Ultra Green Aircraft Research project, involved a model in which some of the parts were too tiny for documenting air pressure any other way than PSP.

“The wing struts in particular were very thin, and it was difficult to machine taps where the wing met the fuselage, so PSP really was the ideal solution,” Roozeboom said.

Power of Pink

Here’s how PSP works:

- A thin coat of the special paint, about one-and-a-half thousandths of an inch thick, is sprayed on to the model that will be tested in the wind tunnel and allowed to dry.

- The model is then installed in the wind tunnel, which also is equipped with a series of blue LED lights and a complement of specially equipped black and white cameras to record the test.

- With the wind tunnel active, air flows over the model resulting in varying surface pressures. The blue lights excite molecules known as luminophores within the paint causing them to fluoresce, or shine.

- At the same time, due to the nature of the paint’s chemistry, oxygen molecules quench the luminophores. High-pressure areas have more oxygen, so the pink shines dimmer. Lower pressure areas have less oxygen, so the pink shines brighter.

- These differences in how much the paint fluoresces or shines is recorded by the cameras, and the resulting black and white images are analyzed. The intensity of the different shades of gray are converted to a color scale indicating the varying pressure levels.

Researchers use PSP as one of many tools to better understand how a new aircraft design might perform. It also can be used to help make other tools, such as the computer modeling tool known as CFD, more accurate.

“When you start to marry all these technologies to arrive at the best answer, I think you can walk away knowing more,” Roozeboom said.

Colorful History

It was early in the 20th Century when the idea of correlating the luminescent properties of a coating to varying pressure levels was first developed. By 1935 a German scientist, Hans Kautsky, first deduced that the quenching of luminescence was caused by oxygen.

As the concept evolved through the years, it was during the 1960s that a potential use was explored in the field of medicine, with some success realized in using the idea as part of a tool for measuring oxygen content in blood.

Much of the work that led to biomedical applications of the concept was located at the University of Washington. It was there that during the 1980s a Boeing researcher turned to further develop an idea for using the concept in aviation, and then successfully demonstrated PSP in a wind tunnel.

NASA joined the story not long after, still during the 1980s, when an Ames researcher, Blair McLachlan, was doing some work on fluorescent dyes and was referred to the researchers at the University of Washington.

Realizing the tremendous potential value of PSP to NASA’s work in both aviation and space, McLachlan began the process of bringing that tool to the agency.

Interestingly, a key figure in those efforts turned out to be former astronaut Janet Kavandi, a three-time space shuttle veteran who is now director of NASA’s Glenn Research Center in Cleveland.

Kavandi was a PhD chemistry student at the University of Washington and, while waiting for a flight at the Seattle airport, happened to meet the researchers from her school who were working with NASA on PSP, which led to her joining the embryonic team.

By early 1989, Kavandi and others had developed a desirable PSP recipe, essentially creating the first generation of the pink paint used today. They drove down to Ames from Washington with the lighting, cameras and a painted wing segment to try out in a wind tunnel.

It worked.

Pink Plans

Today, NASA uses PSP as a research tool in the wind tunnels at Ames, Glenn Research Center in Ohio, and Langley Research Center in Virginia, and engineers continue to look for ways to make PSP even more effective for testing both aeronautical and space vehicles.

Roozeboom said the next big thing for PSP is to perfect a new version of the paint in which the luminophores molecules get excited faster and are less sensitive to temperature – work sponsored by NASA’s Aeronautics Research Mission Directorate.

Known as Unsteady PSP, the paint would reveal changes in pressure at the microsecond level, providing a more detailed look at what is happening on the surface of an aircraft or launch vehicle being subjected to high stress during a high-speed flight or launch.

But one thing that is not expected to change is the bright pink color of the specialty paint.

That means one thing for Roozeboom, who at Ames is currently the “go to” person for all things PSP, including procuring the Pepto Bismol-colored paint – not available in a hobby store – painting the models and leading the test analysis:

“Everything that’s pink ends up in my office.”