By Linda Herridge

NASA’s John F. Kennedy Space Center

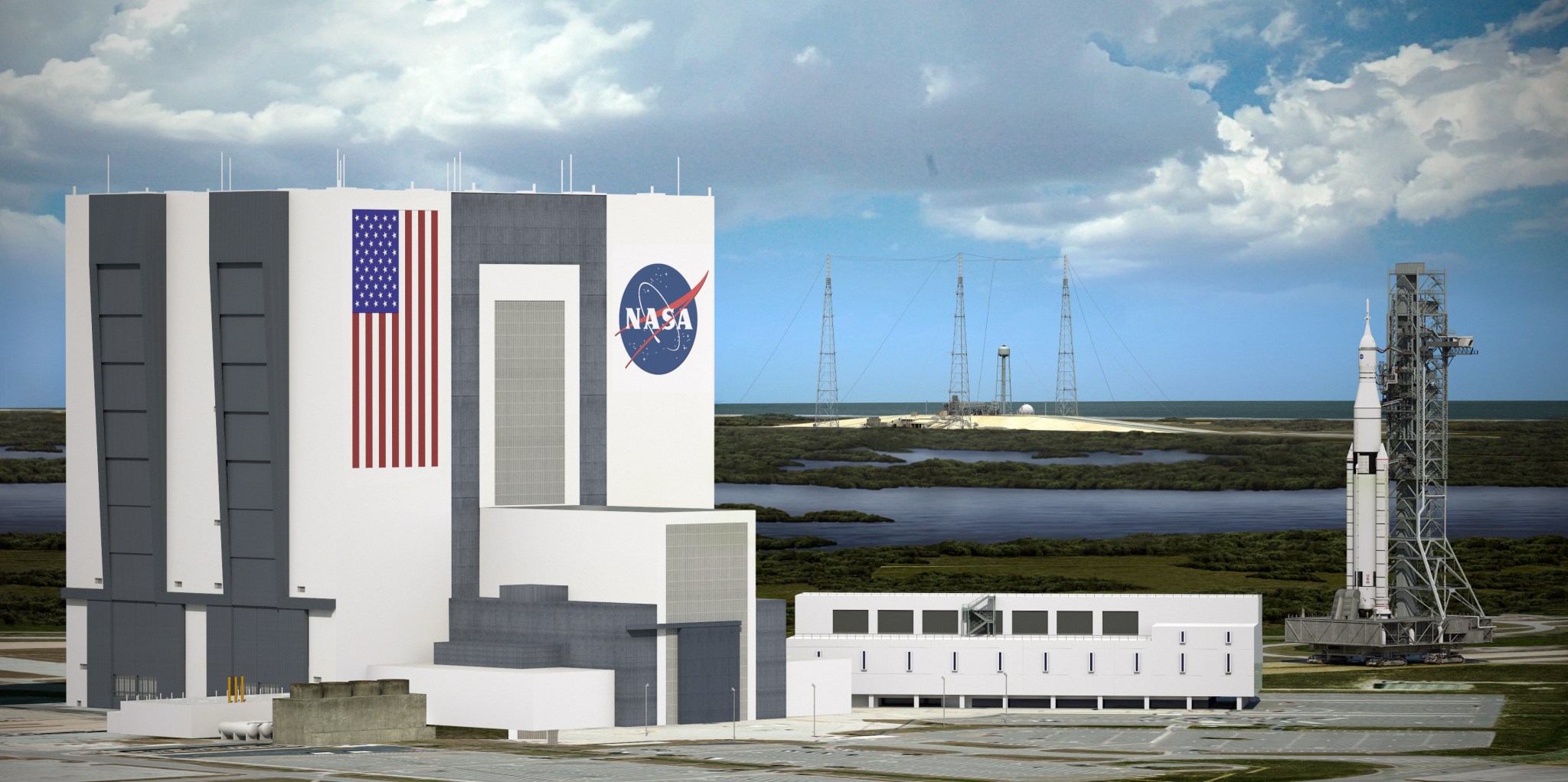

Not since NASA prepared Kennedy Space Center’s facilities for the Space Shuttle Program 35 years ago has there been such a large-scale effort to ready the center in anticipation of the launch of the Space Launch System (SLS) rocket and Orion spacecraft on Exploration Mission-1. The Ground Systems Development and Operations (GSDO) Program and support contractors at Kennedy are busier than ever as work continues to transform the center into a 21st century multi-user spaceport.

“Developing ground systems in parallel with flight systems, SLS and Orion, makes it especially challenging and demands a high level of integration,” said Mike Bolger, GSDO program manager. “Every day matters, and we have to continue to meet our commitments internally and externally to be ready for EM-1.”

GSDO will achieve a major milestone on the mobile launcher this month with the award of a new Ground Support Equipment Installation Contract. The work will include installing more than 800 pieces of mechanical, electrical and fluids equipment and about 300,000 feet of cable and several miles of tubing and piping to support mobile launcher operations. Most recently, modifications to the mobile launcher tower and platform were completed to accommodate the size and weight of the SLS rocket.

The first set of new work platforms, designated platform “K”, arrived in April and are being readied for installation in the Vehicle Assembly Building (VAB). A total of 10 levels of new platforms — 20 platform halves altogether — will surround the SLS rocket and Orion crew module and provide access for testing and processing in High Bay 3.

Also inside the VAB, upgrades to crawler-transporter 2 continue in order to prepare the giant vehicle for its exploration role. CT-2 will carry the SLS rocket and Orion spacecraft atop the mobile launcher along the 4.2-mile crawlerway trek to Launch Pad 39B. Upgrades to the vehicle include new steering arms; new jacking, equalizing and leveling hydraulic cylinders; and upgraded sprocket shaft assemblies.

A simulation test of the Resource Prospector payload RESOLVE for a mission to the moon was the first use of one of the new 21st century multi-user control rooms inside Firing Room 4 in the Launch Control Center (LCC). GSDO managed the construction of Firing Room 4 which can be partitioned into four separate control rooms to meet current and future NASA and commercial user requirements.

“We also just completed a major software release for Firing Room 1 that is critical to testing our KSC ground subsystems,” Bolger said. “We are now configuring it for testing that will continue over the next several months. We will build on this release to provide the capability that we need to process and launch the SLS and Orion.”

Modifications are nearing completion in the Multi-Payload Processing Facility (MPPF), where a new service platform, a deservicing platform and general purpose fuel tanks have been staged. A new elevator was added to the service platform. The facility will be used for offline processing and fueling of the Orion spacecraft and service module stack before launch.

The landscape at Launch Pad 39B has changed. A clean pad concept has replaced the configuration once used for space shuttle launches. The pad’s surface has been completely upgraded. New crawler track panels have been installed and concrete repairs have been completed. The flame trench walls have been resurfaced and work soon will begin on a new flame deflector that will support launch of the SLS rocket.

At the Launch Equipment Test Facility (LETF), both aft skirt electrical umbilicals (ASEU) have been tested. The two umbilicals will connect to the rocket at the bottom outer edge of the booster, referred to as the aft skirt, and will provide electrical power and data connections to the SLS rocket until it lifts off from its launch pad. Tests of the ASEU confirmed its design and function.

The ASEU is one of nine different types of umbilicals that will be put to the test before they are installed on the mobile launcher. Testing soon will begin on the Orion Service Module Umbilical.

What’s next for the GSDO workforce moving forward? Bolger said a key milestone, the program-level Critical Design Review, will occur in the fall. At that point, the program will transition from design to hardware fabrication, installation and testing.

In parallel, GSDO will develop the operations procedures and plans, train the test team, and develop the software that will be used to test and checkout flight and ground systems.

After the ground systems are tested and certified, Bolger said Kennedy will be ready to process flight hardware beginning in January 2018. Launching and recovering Orion on the first exploration flight test last December was the first step, and the GSDO team is ready for the next challenge.

“What we do is hard and there will be challenges, but communication and working together as a team is helping to overcome them,” Bolger said. “We’re making progress every day.”