NASA Dryden’s Gulfstream G-III aerodynamics research test bed aircraft, tail # 804, has returned to the air in a new phase of baseline flights in preparation for the Adaptive Compliant Trailing Edge, or ACTE, project.

The aircraft continues to be under modification to support ACTE, a joint effort between NASA and the U.S. Air Force Research Laboratory.

The primary objective of the Phase 0B flight series is to give the test pilots experience with G-III handling qualities with the flight spoilers disabled prior to actual ACTE flights. The flights will also gather data from onboard instrumentation that will be used to establish a baseline for engineers to compare with data acquired after the ACTE flap is installed. In addition, newly installed state of the art instrumentation such as a laser-based fiber optic shape sensing system, a “hot film” anemometer system and a wing deflection measurement system will be characterized.

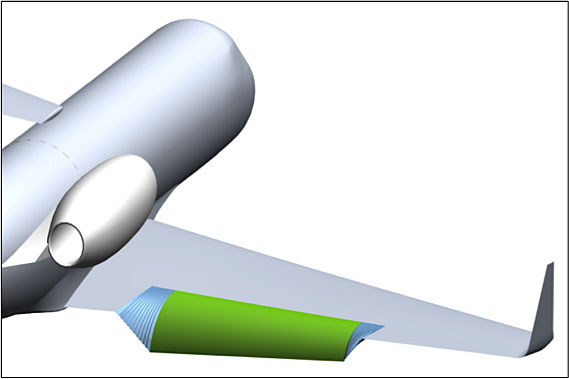

In the ACTE project, both of the G-III’s conventional 19-foot-long aluminum flaps will be replaced with advanced, shape-changing flaps designed by FlexSys, Inc., that form continuous bendable surfaces made of composite materials.

When conventional flaps are moved, gaps exist between the forward edge and sides of the flaps and the wing surface. The ACTE flap will be gapless, forming a seamless transition region with the wing while remaining attached at the forward and side. The improved flap should reduce drag friction and eliminate a major source of airframe noise generation.

If successful, this experiment will further technology to enable aircraft to be lighter weight, more fuel-efficient during cruise and significantly quieter during takeoff, approach and landing.

Work with the aircraft is funded through NASA’s Aeronautics Research Mission Directorate as part of the Environmentally Responsible Aviation, or ERA, project under the agency’s Integrated Systems Research Program.

Work with NASA Dryden’s G-III Aeronautical Research Test Bed is funded in part by NASA’s Aeronautics Research Mission Directorate as part of the Environmentally Responsible Aviation, or ERA, project under the agency’s Integrated Systems Research Program. Additional funding for aircraft acquisition and the ACTE project is provided by the Air Force Research Laboratory.