At A Glance

The Flight Systems Branch provides robotic systems management, analysis, and engineering support for robotic systems, robotic mechanical/ electrical interfaces and workstation simulation interfaces for robotic operations that occur in extreme environments.

The Flight Systems Branch also provides countermeasure system management and engineering support for reduced and microgravity exercise equipment and the supporting hardware/software that sustains a human’s health in environments in and beyond low earth orbit.

Our Expertise

The Flight Systems Branch provides System Management expertise for robotic and crew exercise (countermeasure) equipment on-board the International Space Station (ISS), providing engineering support, analysis, and sustainment of the flight hardware.

Our engineers interface with the ISS Program, International Partners, Commercial vehicles, and Human Health experts amongst NASA centers to integrate their needs and interactions with the flight hardware we develop and maintain.

Our Role in Flight Projects

As robotic system and subsystem managers, the Flight Systems Branch assists external payload customers with payload robotic interface design and verification; providing them with understanding and guidance to meeting the requirements placed on them.

Our countermeasure engineers work with human health personnel and crew to not only maintain but continually improve the exercise equipment on orbit and to provide lessons learned and insights into the design of future exercise equipment.

What We Need

• Accurate payload, hardware interface, and system models/simulations.

• Requirement documents, payload and interface testing/verification plans, and operational (trending) data with respect to our flight systems.

Challenges We Face

• Loads imparted on crew, vehicle, and hardware during system operations which is why testing and analysis is a critical function.

• Exercise equipment not being considered as a system in future exploration vehicle design.

When We Engage

The Flight Systems Branch engages whenever there is a flight system anomaly on-orbit, when a new payload/hardware that will interface with our system is receiving requirements, and whenever an evaluation of a future capability is needed.

Points of Contact

• Kerrie Rafalik, Branch Chief: kerrie.k.rafalik@nasa.gov

• Pat Bevill, Deputy Branch Chief: pat.bevill@nasa.gov

Highlights

Robotic Systems

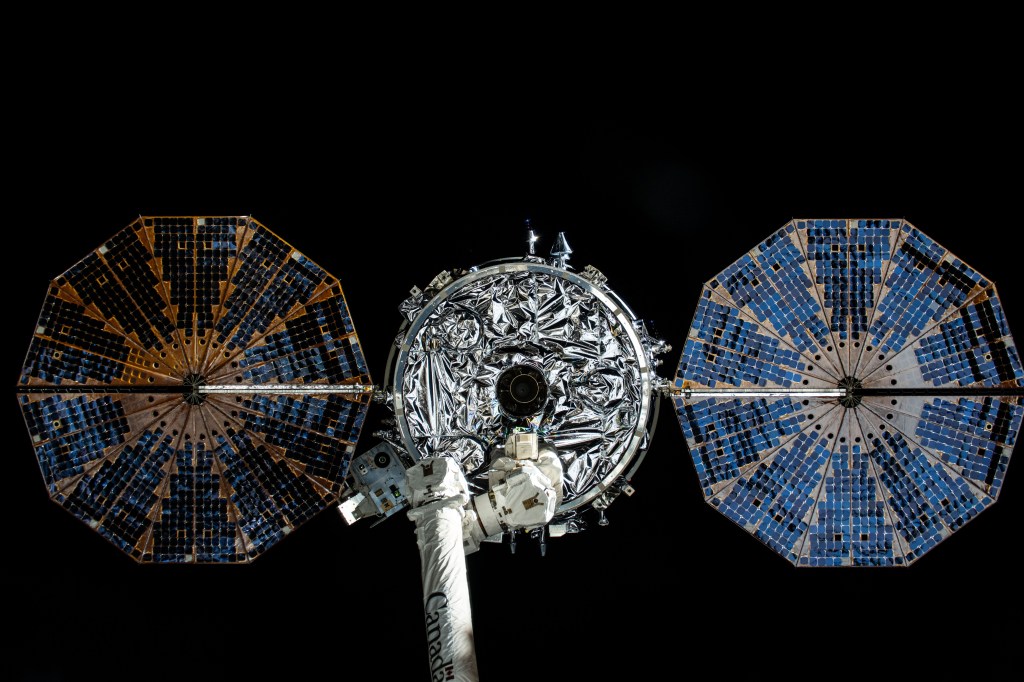

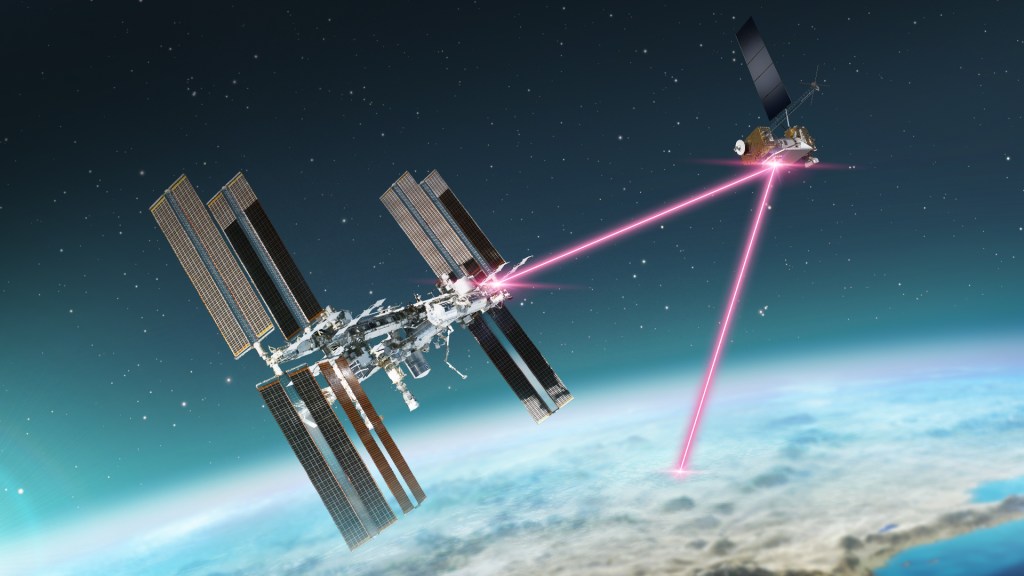

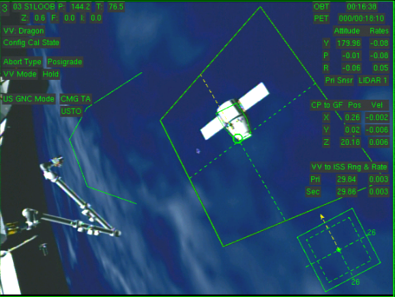

The Robotics Systems experts at NASA/JSC provide systems engineering, development, integration, and testing of robotic hardware and software technologies for robotic systems applications. We work with customers to refine robotic requirements, interfaces, and concept of operations. Our analysis capabilities include failed capture clearances and robotic hardware and payload load assessments during capture and berthing activities. Our simulated robotic workstation capability provides 3D scenes from the operator’s point of view overlaid with dynamic graphics showing vital information such as approach corridor and abort boundaries, allowing full interactive control of cameras, robotic arms, end effectors, and visiting vehicle/payload commands.

The Robotics Workstation (RWS) is the crew’s interface to Mobile Servicing System (MSS) operations. The MSS is the robotics system provided by the Canadian Space Agency and consists of the RWS, the Space Station Remote Manipulator System (SSRMS), the Mobile Base System (MBS), and Special Purpose Dexterous Manipulator (SPDM). The RWS enables the crew to issue commands and receive telemetry from the MSS components, including video camera routing and control of both external ISS cameras and cameras mounted on the robot arms. The crew uses the RWS to control the SSRMS during Extra-Vehicular Activities and for Free Flyer Visiting Vehicle captures and releases. Also, there are several graphical overlays that are used by the crew on the RWS monitors to aid them in monitoring the visiting vehicles’ approach and departure trajectories.

The Simulated Robotic Workstation Lab (SRWS) is an ER3 operated facility that has functionally equivalent software and Off-The-Shelf hardware that function similarly to the RWS on board the International Space Station.

The SRWS team supports MSS software modifications and performs integrated testing to ensure consistency with operational concepts, expected functionality, and compliance with ISS program requirements. The focus is on updates to the RWS flight software and interfaces to the Command and Control System (CCS), the main ISS computer, as well as integrated RWS testing. The team is instrumental in development and testing of Visiting Vehicle overlays for all robotically captured Visiting Vehicle missions.

In addition to their primary work, the SRWS team has developed application software for use by Flight Operations Robotics Flight Controllers to use for development and execution of their procedures, scripts, etc.

• MCT – MSS Application Computer (MAC) Controller Tool provides situational awareness of scripted MSS operations to the Robotics Flight Controller or Robotics Officer (ROBO) user for status monitoring. It provides the ability to select and configure scripts and send commands to the MAC. The MCT supports multiple simultaneous positions to allow monitoring users to verify inputs and commands of the active user.

• TIDE – Thicklayer Integrated Development Environment (TIDE). TIDE is a new tool that helps the ROBO Flight Controllers write ground scripts that will automate procedures.

• There are plans to work on several projects for the ROBO flight controllers that will be started soon.

Areas of Expertise

• Design and development of robotic interfaces.

• Robotic interface and system requirements definition and verification.

• Robotic capture and berthing analysis of free-flying vehicles.

• Development, simulation and verification of robotic workstation operator’s overlays.

• Robotic systems anomaly investigation, trouble shooting, and resolution.

Countermeasures System

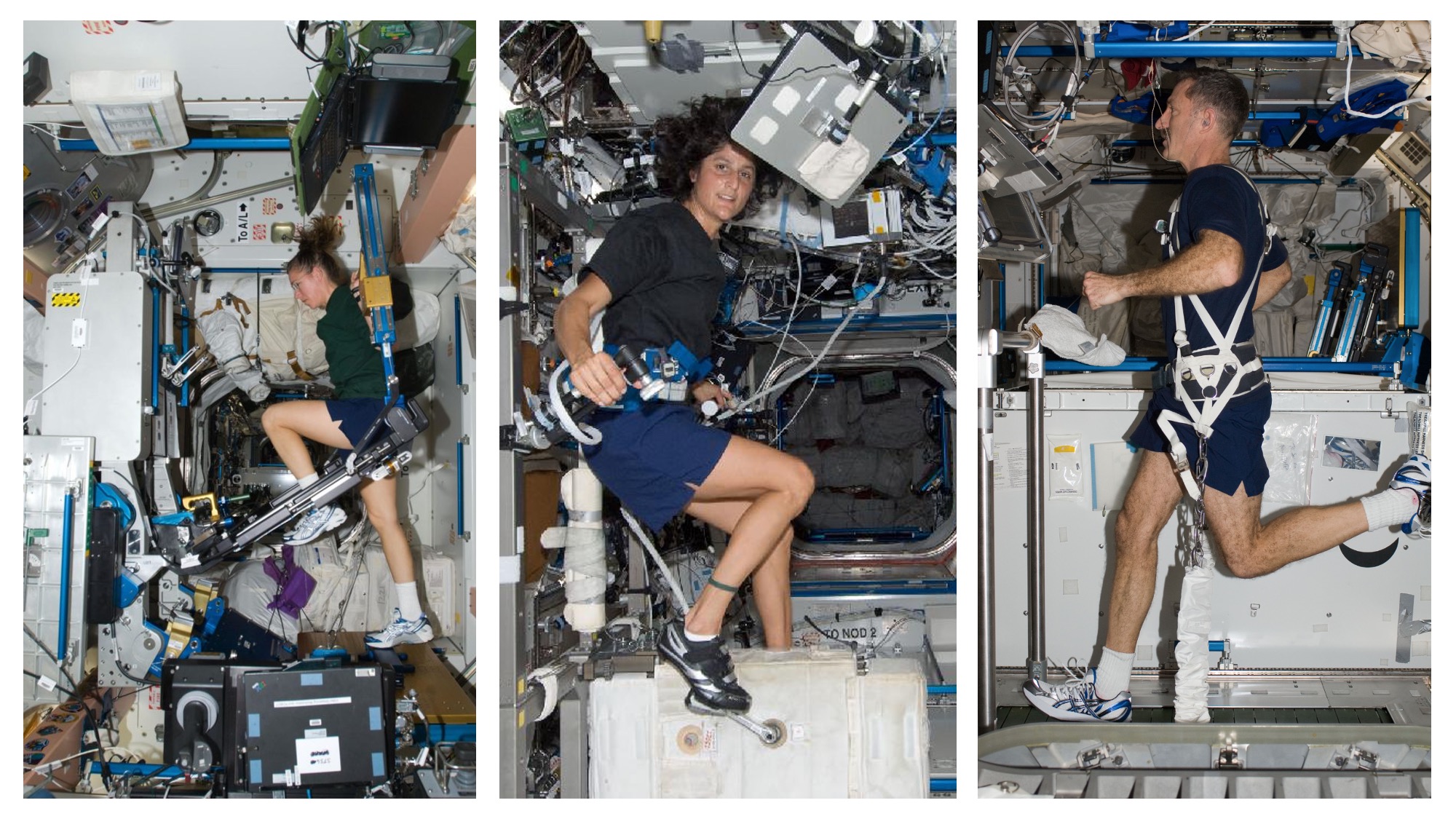

The Countermeasures System experts at NASA/JSC provide systems engineering for microgravity exercise devices and support equipment to ensure crew health and safety. Our system engineering support includes functional architecture definition, concept of operations, development and management of requirements and interfaces, design integration, verification and validation, and flight certification.

As the Subject Matter Experts for on-orbit exercise systems, we sustain the current suite of exercise equipment (recumbent bike, treadmill, resistive exercise device) by reducing maintenance, addressing obsolescence, providing spares and increasing reliability through creative engineering solutions.

Areas of Expertise

• Design and development of human health interfaces.

• Zero gravity countermeasure systems: aerobic and resistive exercise devices.

• Crew health system concept of operations, requirements definition and verification.

• Flight Systems anomaly investigation, trouble shooting, and resolution.

Humanworks Lab

Established: August 2016

Origins: The Humanworks Lab was founded in response to a recognized gap in exploration human performance support. While the International Space Station (ISS) boasts an array of tools, the ease of communication with the crew is a luxury that future exploration missions might not afford. These missions demand a higher degree of autonomy and AI intelligence, which the lab was set up to address.

Achievements:

• Internship Program: Over the past seven years, the lab has mentored over 100 unique interns, a testament to its commitment to nurturing the next generation of space scientists and engineers. Many of these interns have ascended to high-level roles within NASA and other organizations, including positions as project managers and CEOs.

• Awards & Recognition: The lab’s dedication to mentorship has been recognized with numerous NASA awards, including the prestigious Guiding Star, the highest honor for mentors.

• Innovations: The lab has pioneered several groundbreaking technologies, such as the wobbleboard and the breath sensor. These innovations have garnered support from neuroscience groups and secured multiple innovation grants from NASA. Collaborative efforts with entities like TRISH and DARPA have further solidified the lab’s reputation as a hub of innovation.

• Thought Leadership: Beyond tangible innovations, the lab has reshaped the discourse around human-centric tooling and problem-centric methodologies, establishing itself as a beacon of thought leadership in human potential spaces.

Future Vision: The lab envisions a future where its work seamlessly integrates with human-centric systems across diverse problem domains. From the challenges faced by astronauts in space to the daily hurdles encountered by workers on Earth, the lab’s goal is to elevate the baseline of human performance, unlocking unprecedented growth in every human-in-the-loop system.

Collaboration Model: The lab’s collaborative ethos is evident in its multifaceted engagement model. From Space Act Agreements (SAAs) and Cooperative Research and Development Agreements (CRADAs) to hosting tech demonstrations and leading development activities, the lab is a nexus of innovation. Its extensive network includes partnerships with the Space Force, the USAF office of the human weapon system, DEFENSEWERX, universities, researchers, and a plethora of human-focused companies.

Team Dynamics: The lab operates as a unified organism, adapting and evolving based on the challenges at hand. Boasting a diverse skill set that spans the spectrum of engineering, from software to hardware and from prototyping to flight unit development, the team embodies a human and problem-centric ethos. This adaptability ensures that the lab remains at the forefront of innovation, ready to tackle the challenges of tomorrow.

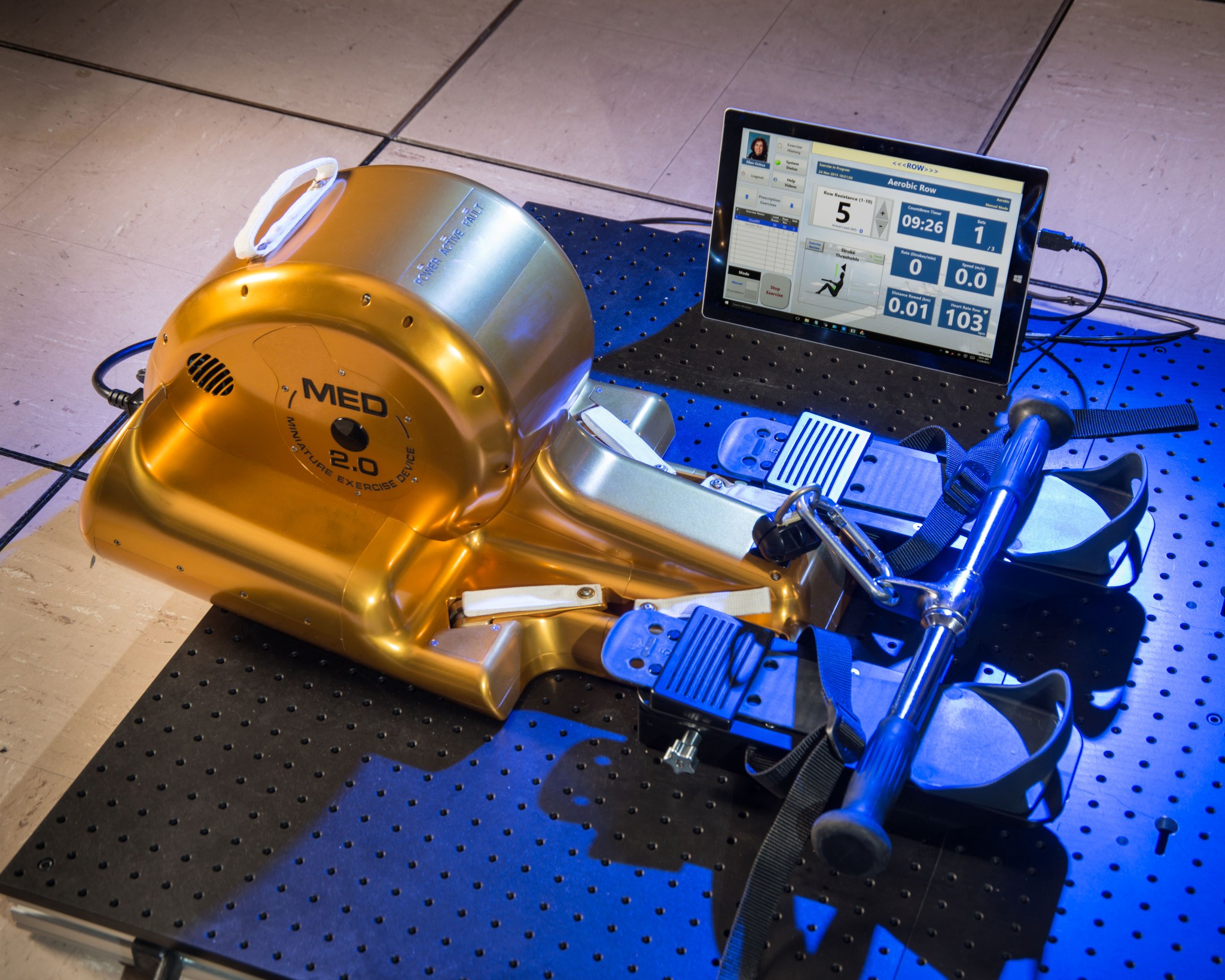

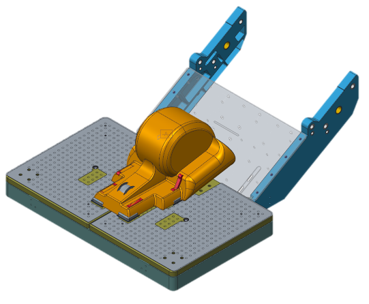

OnePortal

OnePortal is an agnostic crew interface software system intended to standardize the interface across current and future astronaut exercise devices. First used on the ISS by the miniature exercise device 2 (MED-2), OnePortal helps astronauts by improving usability, memorability and learnability, and provides a consistent crew experience across exercise systems by:

• Reducing training and time to execute protocols/session

• Addressing expansion of capabilities by leveraging commercial proven features/functionality

• Addressing user satisfaction and task efficiency with objective metrics and measures to assess and improve the quality of the user interface

• Minimizing astronaut training needs, utilize the latest GUI designs focused on intuitive ease of use approach

Exoskeletons

A spin-off of the Robonaut hand and limb technology, exoskeleton devices have many useful benefits for both space and terrestrial applications. In-space, exoskeletons can be used as a force resistive device to enable exercise in a weightless environment or enhancing an astronaut’s grip in a space suit glove. Here on earth, exoskeletons serve multiple purposes:

• Grasping assist

• Prevent fatigue and repetitive stress injuries

• Rehabilitation Strength augmentation

• Walking assist for the disabled

Exploration Exercise

The Exploration Exercise System Management experts at NASA/JSC enable human exploration mission success by developing and managing systems of exercise and monitoring capabilities that contribute to the effective sustainment of crews’ physical condition in all crewed environments beyond Low Earth Orbit.

We perform research and development and stay current on the latest technology advances to continuously evolve innovative exercise capabilities for long duration exploration-class vehicles and habitats that:

• Significantly reduce mass, volume, and power consumption compared to ISS,

• Improve reliability and modularity to minimize sparing logistics and crew time required for maintenance,

• Have intuitive operational interfaces, Integrate multiple exercise modalities and other exercise benefits (e.g. sensorimotor, monitoring), and

• Integrate other non-exercise functions where appropriate (e.g. augmentation, rehabilitation).