At A Glance

The Dynamic Systems Test Branch is responsible for engineering design and operation of high-fidelity robotic facilities supporting NASA’s missions along with the Simplified Aid for EVA Rescue (SAFER), and Robotic Micro Conical Tool (RMCT) flight hardware. Current work includes integration of dynamic systems with NASA mission architectures to create relevant test environments further enabling NASA’s advanced exploration capabilities.

Our Expertise

The Dynamic Systems Test Branch is responsible for engineering design and operation of high fidelity robotic test systems supporting NASA’s missions along with the Simplified Aid for EVA Rescue (SAFER) “jetpack”, and Robotic Micro Conical Tool (RMCT) dexterous robotic flight hardware. Current work includes integration of dynamic systems to create relevant test environments further enabling NASA’s advanced exploration capabilities.

The Dynamic Systems Test Branch provides the Active Response Gravity Offload System (ARGOS), designed and built to simulate reduced gravity environments, such as Lunar, Martian, or microgravity; the Dexterous Manipulator Testbed (DMT), a robotic platform configured to simulate the International Space Station (ISS) Special Purpose Dexterous Manipulator (SPDM); and the Six-degree-of-freedom Dynamic Test System (SDTS), a real-time motion based platform primarily used for the simulation of docking and berthing systems.

Our Role in Flight Projects

The Flight Projects Laboratory (FPL) supports major Ground Support Equipment and Flight Hardware projects for current and future space flight programs. SAFER units, SAFER Test Modules, and Extravehicular Robotic tools have been assembled and tested in the lab.

The Dynamic Systems Test Branch built six SAFER flight units, two SAFER Test module flight units, and three RMCT flight units. Participated in two Class 1-E flight projects including the ER Miniaturized Exercise Device 2 (MED2) and the ES Advanced Passive Thermal Experiment (APTx).

Testing and training for EVA & robotic hardware and docking or berthing systems interfaces. ARGOS provides a simulated environment for testing EVA tools and crew training.

What We Need

Hardware to build, assemble, or test.

Challenges We Face

Exploration missions are complex and challenging; we need dynamic systems with integrated simulation capabilities to support the development of flight tools, systems, and training.

When We Engage

The Dynamic Systems Test Branch can be engaged at any time.

Points of Contact

• David Read, Branch Chief: david.read-1@nasa.gov

• Deputy Branch Chief: Coming soon

Highlights

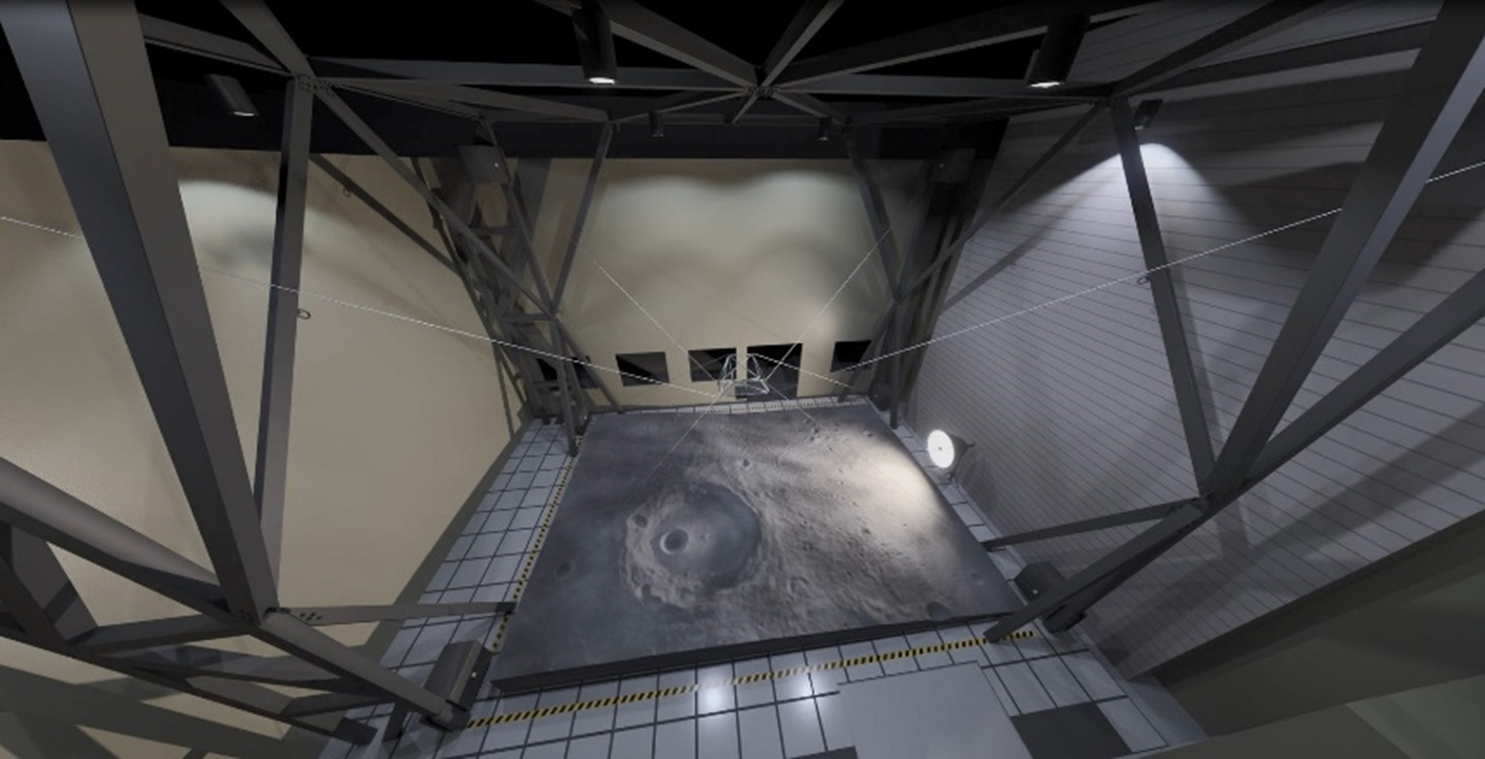

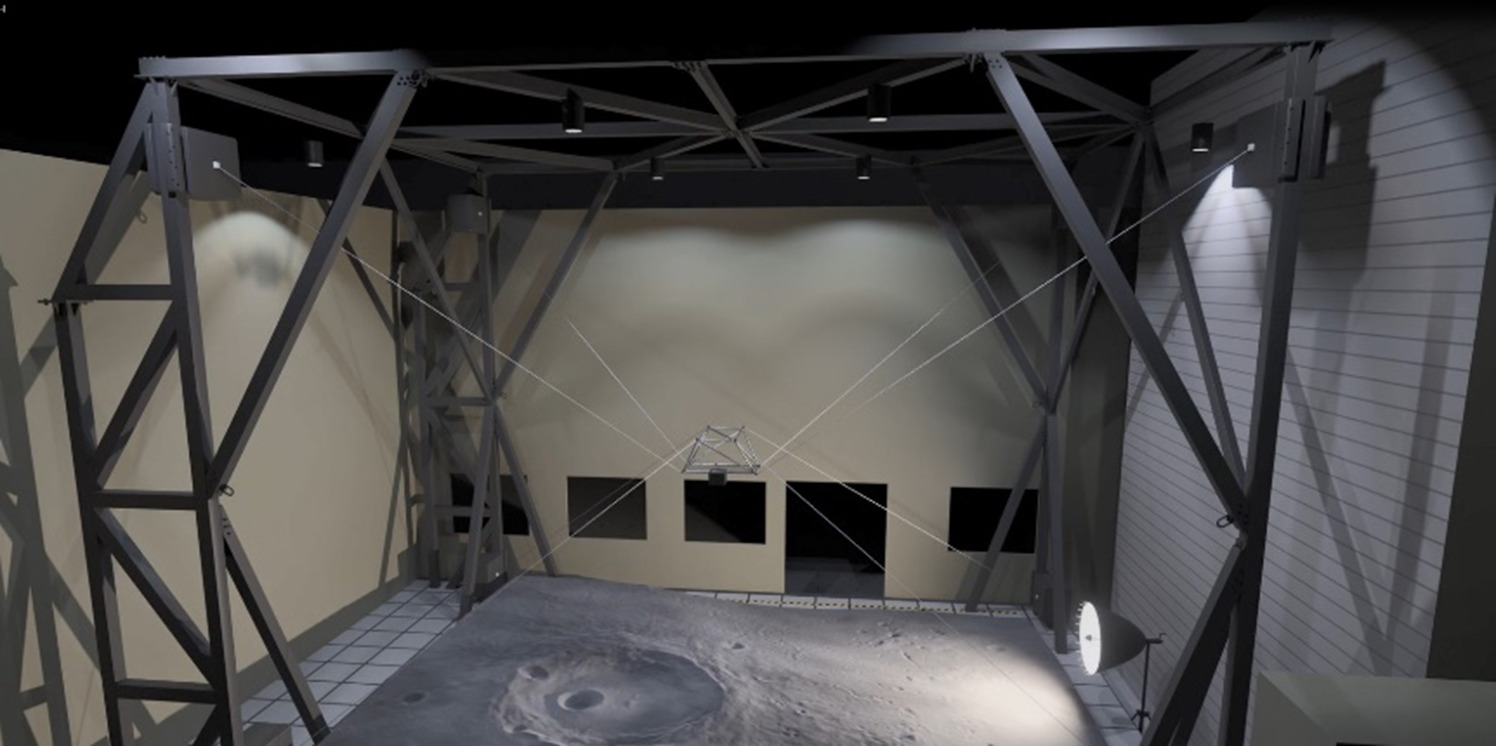

Active Response Gravity Offload System (ARGOS) and ARGOS 3 eXploration EVA Simulator (AX3S)

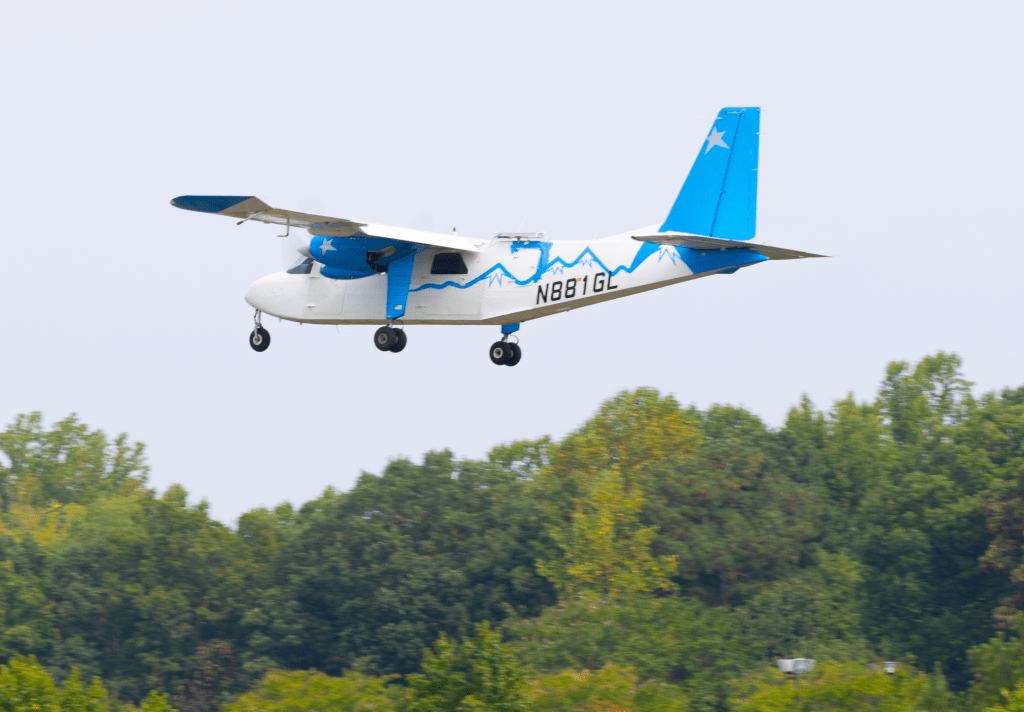

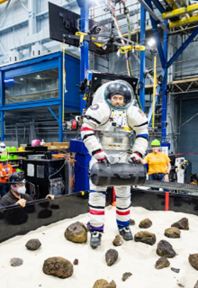

The Active Response Gravity Offload System (ARGOS) was designed and built to simulate reduced gravity environments, such as Lunar, Martian, or microgravity. The technology is capable of supporting surface operation studies, suit and vehicle requirements development, suit and vehicle design evaluation, and crew training with both suited and shirt-sleeved subjects. The ARGOS facility is rapidly reconfigurable and allows for a quick turnaround between different tests and a variety of surface or training analogs.

The future of ARGOS is bright with a larger structure planned to be constructed in the coming years. Within this new structure, there will be three bridges which will allow three subjects to be in the system simultaneously. This larger space will allow for more and different testing that will include lunar landers.

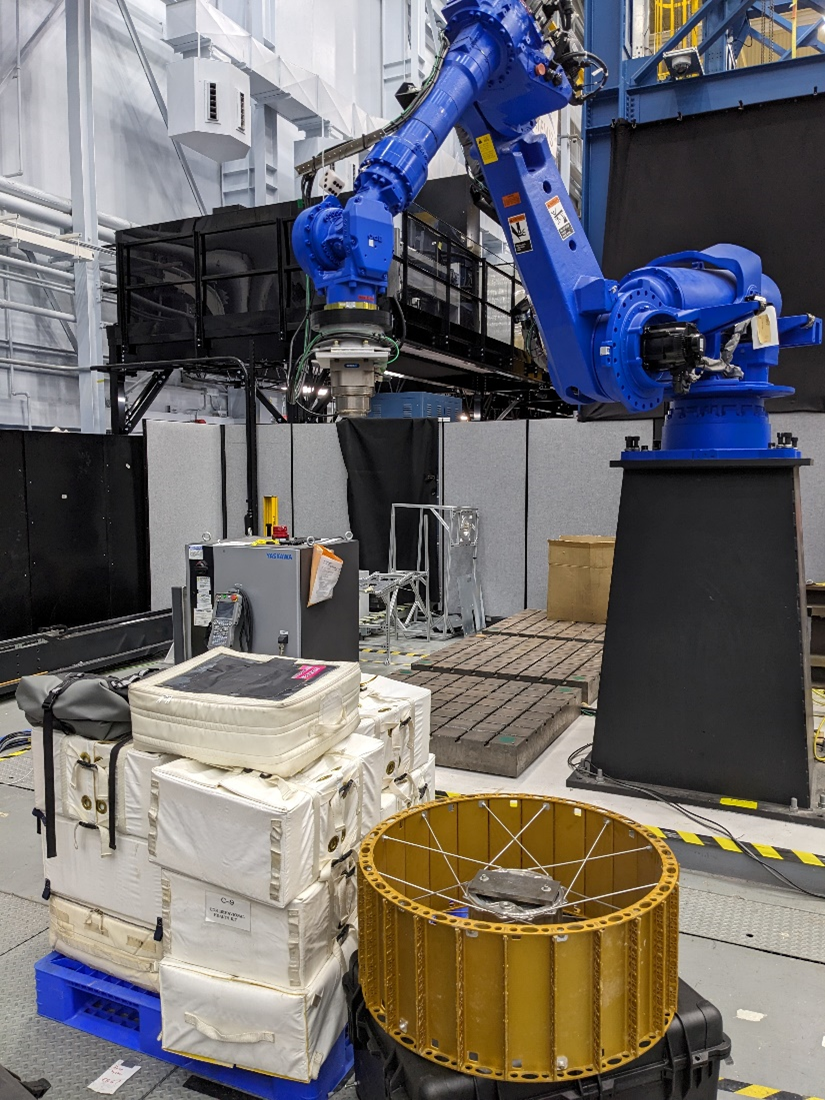

Dexterous Manipulator Testbed

The Dexterous Manipulator Testbed (DMT) is a robotic platform configured to simulate International Space Station (ISS) Special Purpose Dexterous Manipulator (SPDM) actions. This testbed allows engineers to perform robotic operations on Earth that emulate the SPDM end effector and arm motions before it is performed on the ISS.

Operations for the DMT include testing a payload’s robotic interfaces and establishing acceptable visual cues/clearance monitoring for robotic operations. Testing, verifying, and evaluating whether a payload performs as expected versus the design requirements for force application, accurate visual cues, and acceptable capture envelopes. The DMT can also be used for study of on-orbit anomalies related to the robotic system or to robot compatible hardware.

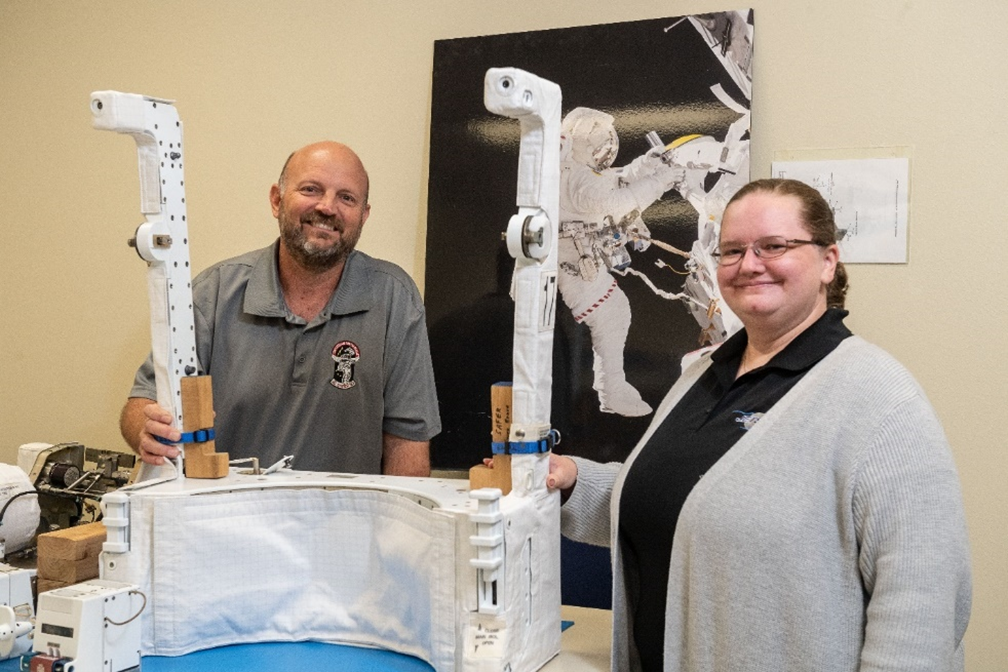

Robot Micro Conical Tool

The Special Purpose Dexterous Manipulator (SPDM) on the ISS carries two Robot Micro Conical Tools (RMCTs) to interface with external hardware which have Micro Conical Fittings (MCFs) for grasp interfaces. The RMCTs and tool holsters were developed for the ISS Program to enable the SPDM to grasp, remove, transport, and install On-orbit Replaceable Units (ORUs) and payloads equipped with an MCF. The RMCT has three functional modes: (1) grasp, soft-capture or release of the MCF; (2) extend or retract the RMCT’s 7/16 inch socket; and (3) apply torque through the RMCT’s socket to tighten or loosen standard robotically compatible bolt heads.

One spare flight RMCT and one spare holster are retained at JSC in controlled storage, available upon request of the ISS Program. The qualification unit remains a controlled item for future support, and the engineering unit is in use at the eDMT. ER5 is responsible for the sustaining engineering support of the RMCTs and holsters.

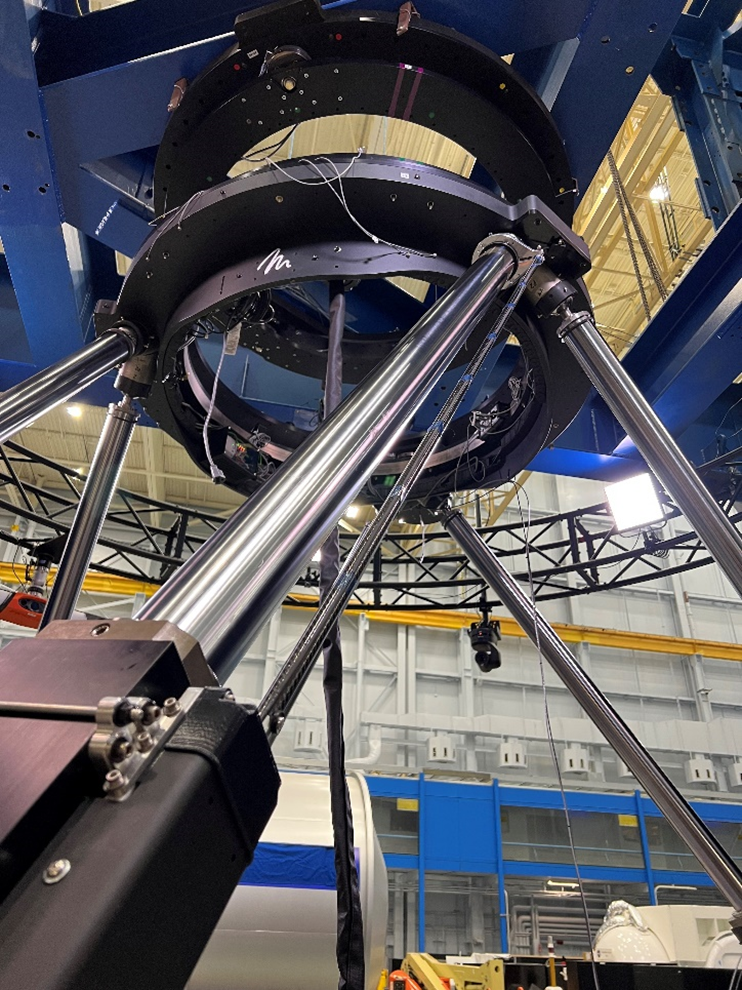

Six-degree-of-freedom Tendon Actuated Robot, and mini-STAR (STAR and mSTAR)

The Six degree of freedom Tendon Actuated Robot (STAR) is a large-form motion platform capable of moving laterally in the X, Y, and Z directions as well as being able to move rotationally about the X, Y, and Z axes. The working envelope of the machine is approximately 7m wide x 10m long x 7m tall. The performance capabilities of the STAR are a translational velocity of 2 m/s, an acceleration capability of 1 m/s2, a rotational capability of +/- 10 degrees, and able to fly trajectories with up-to 50kg of test articles at the end-effector.

The STAR system is modeled after a tendon actuated Stewart-Gough platform, a type of parallel robot utilizing multiple identical actuators to afford six degree-of-freedom motion. The STAR system utilizes eight identical robotic winches attaching to a central end-effector in a parallel configuration. Using a configuration of four winches on the top of the structure and four winches on the bottom of the structure, the end-effector can translate and rotate within the primary structure of the robot.

The STAR system uses tendons, or cables, made from synthetic materials rather than steel braids. Using synthetic cables reduces the inertia of the system while also being stiffer than the equivalent diameter steel cable. The synthetic cables do not appreciably stretch under load which improves controllability of the system as well as reduces the potential for cables to whip in the event of a cable failure.

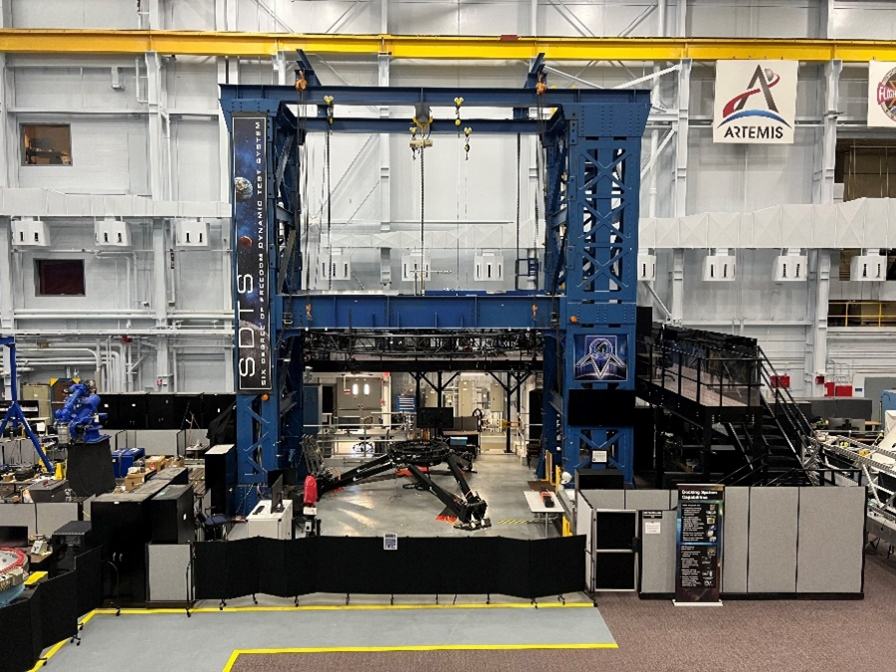

Six Degree of Freedom Dynamic Test System

The Six-Degree-of-Freedom Dynamic Test System (SDTS) is a real-time, six-degree-of-freedom, short-range simulator with a motion base designed to simulate the relative dynamics of two bodies in space mating together (i.e., docking or berthing). The SDTS has the capability to test full-scale docking and berthing systems. It features a repositionable, stationary upper platform with a maximum height of 9.5 meters. The motion base is an electric-powered Stewart platform, also referred to as the electric 6 Degree-of-freedom (e6DOF) robot, capable of supporting a 5000 kg payload with peak lateral motion range of 2 meters, vertical motion range of 2.7 meters, angular motion range of ±15 degrees, and maximum actuator rate of 30 centimeters per second.

Simulations are controlled by interconnected computers running real-time simulation software. The motion base also can be used for non-mating applications such as relative position sensor testing and evaluation (e.g., docking sensors, instruments). The SDTS provides precision test sensors including a laser tracker, infra-red motion detection system, load sensing assemblies, high-definition video, and a synchronized timing system for data acquisition. In addition, the facility provides a dynamic two-free-body docking simulation to control the table and is capable of accommodating customer provided motion simulations or profiles.

Flight Projects Laboratory

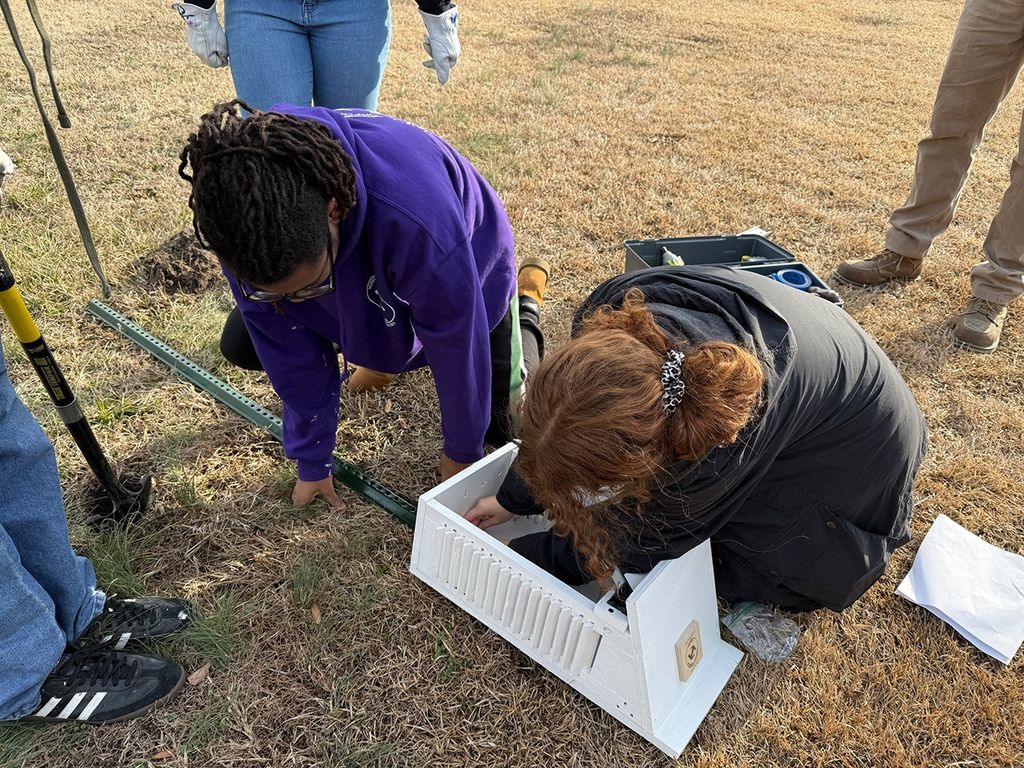

The Flight Projects Laboratory in ER5 supports major ground support equipment and flight hardware projects for current and future space flight programs.

SAFER units, SAFER Test Modules and Extravehicular Robotic tools have been assembled and tested in the lab.

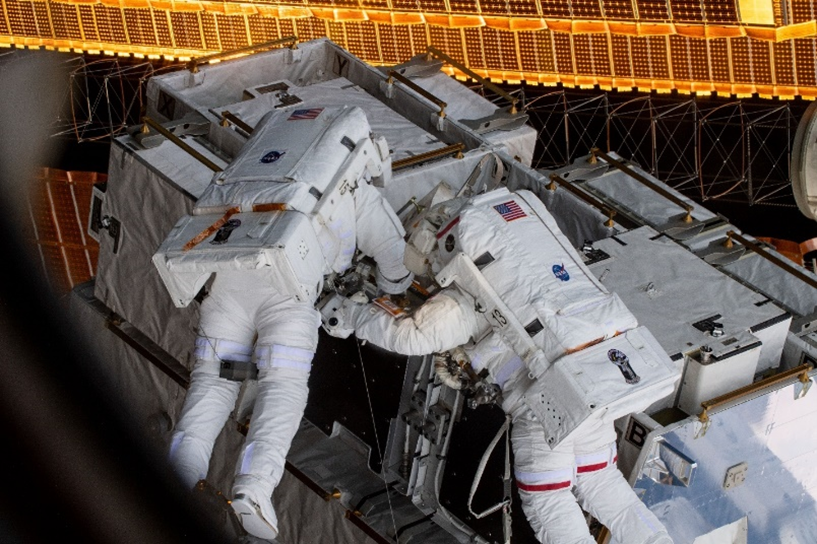

The Simplified Aid for EVA (Extra-Vehicular Activity) Rescue (SAFER)

The Simplified Aid for EVA (Extra-Vehicular Activity) Rescue (SAFER) is a small, self-contained, propulsive backpack system worn during spacewalks outside the International Space Station (ISS) to be used in case of emergency only. If an untethered astronaut were to lose physical contact with the vessel, SAFER would provide free-flying mobility to return to the vessel. SAFER is a smaller, simplified version of the Manned Maneuvering Unit (MMU), which was used for regular maneuvering in past spacewalks.

Explore more from ER

Spacecraft Software Engineering

The Spacecraft Software Engineering Branch provides world-class products, leadership, and technical expertise in software engineering, processes, and technology for human spaceflight programs. The branch maintains the JSC Engineering Directorate’s organizational CMMI rating for software and supports major programs/projects (e.g. ISS, CCP, MPCV) with in-house software development and prime contractor oversight.