Vibration & Shock

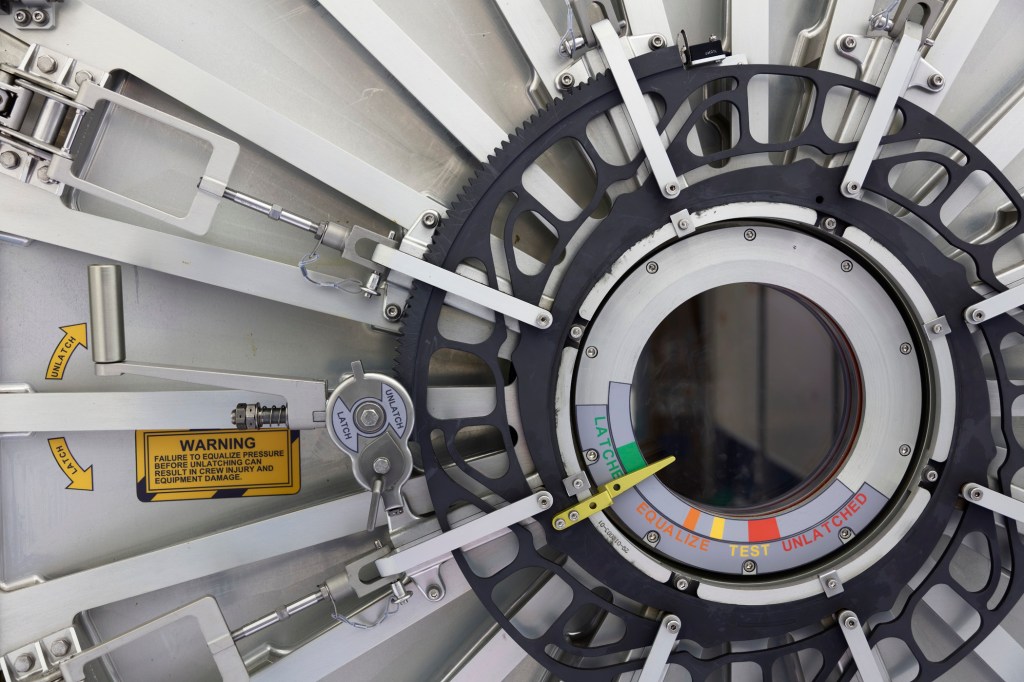

Vibration and shock testing are crucial for designing and testing spaceflight hardware to ensure its resilience against the intense and dynamic conditions of launch and space travel. The Johnson Space Center’s Structures Test Facility can provide structural vibration and shock testing of spaceflight hardware to ensure structural integrity and functionality of spacecraft components to guarantee mission success. Explore the capabilities below, as we invite you to join us in the exciting journey of space exploration at the forefront of discovery.

Structures Test Laboratory – Dynamic

The Structures Test Facility (STL) at NASA’s Johnson Space Center (JSC) houses a wide range of structural testing capabilities designed to evaluate aerospace components, subsystems, and full-scale structures under flight representative environments. These capabilities support the development, qualification, and certification of spacecraft systems for human spaceflight and other mission-critical applications. These structural test specialties enables the STL to validate critical spaceflight hardware from small-scale components to large integrated systems while ensuring safety, performance, and reliability for crewed and uncrewed missions. Key specialties include:

- Load Testing & Structural Verification – Static and fatigue load testing of components and large structures, including manned spacecraft hardware, to verify strength, stiffness, and design margins.

- Vibration Testing – Random vibration, and sine sweep load testing to simulate launch and ascent environments.

- Fracture Mechanics & Fatigue – Advanced crack growth monitoring, strain gauge instrumentation, and life-cycle fatigue testing of metals, composites, and other aerospace materials.

- Data Acquisition & Analysis – High-fidelity measurement systems with synchronized strain, load, displacement, and acceleration data for detailed structural response evaluation.

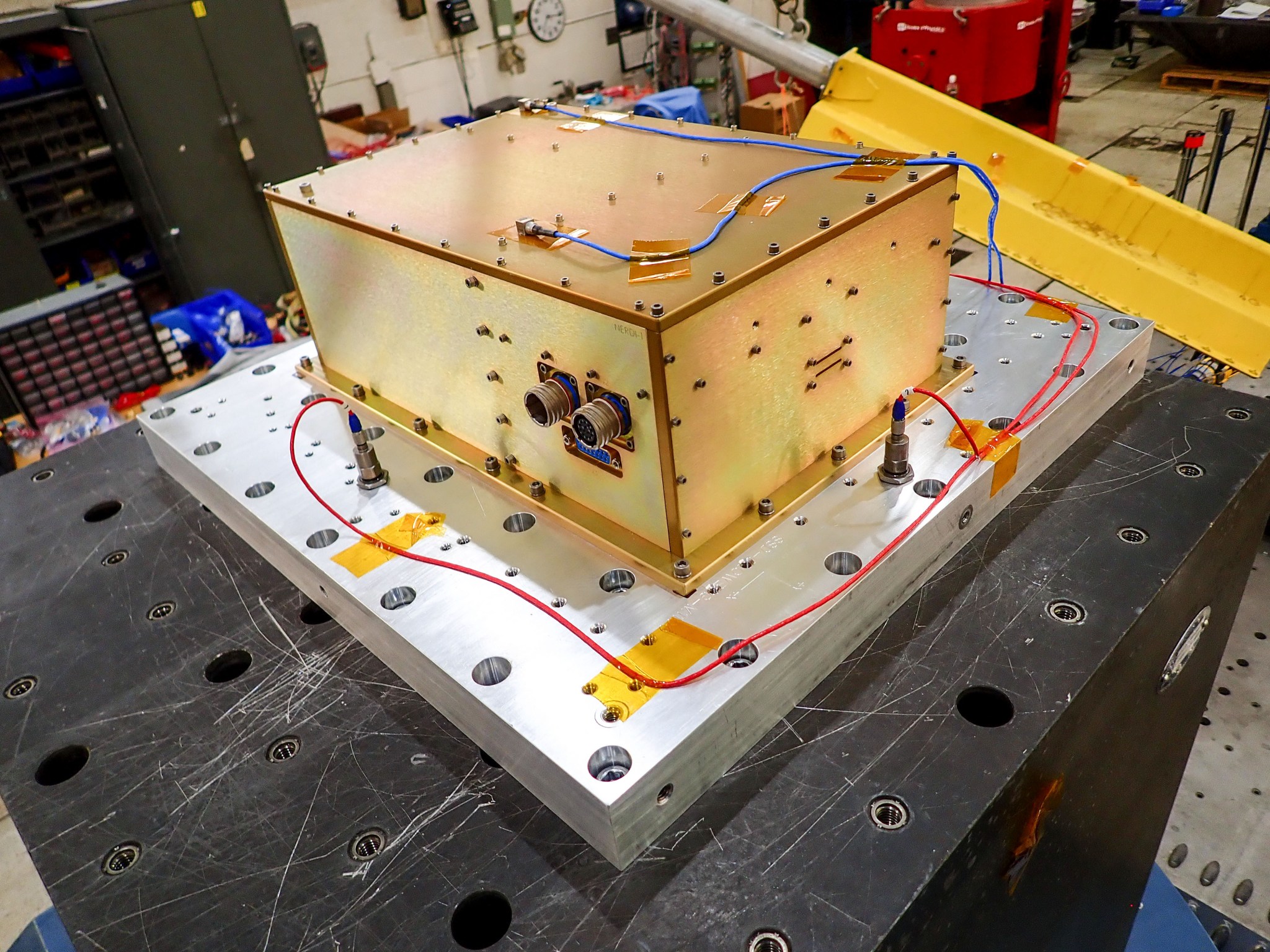

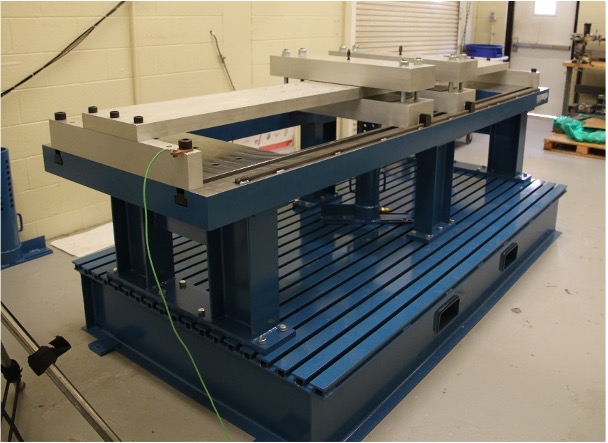

Hazardous Vibration & Shock Testing

The Pyrotechnics Test Facility includes the capability to subject hardware to vibration and pyroshock environments encountered during launches and landings.

- The Vibration Shaker System is capable of subjecting components and systems to random and sinusoidal vibration levels up to 26,000 g-lb, over a frequency range of 20 to 2000 Hz. The vibration table is located in a blast-resistant test cell capable of handling hazardous test articles.

- The test facility also houses two Pyroshock Test Stands, the pneumatically-operated Tunable Beam and the explosively-operated Resonant Plate Stand. Both test stands are regularly utilized for subjecting components to shock environments up to 10,000 g, over a frequency range of 100 to 10,000 Hz.

Particle Impact Noise Detection (PIND)

The Receiving, Inspection and Test Facility (RITF) team maintains Particle Impact Noise Detection capabilities, known as PIND or PIN-D. PIND or PIN-D, is performed to detect loose particles inside a device cavity which could ultimately prevent a failure during a mission.

PIND is a nondestructive test to identify any devices that may have particles such as solder balls that could become dislodged during vibrational loads and cause an internal short.

- Load up to 1 lb.

- Frequency Range: 40Hz to 130Hz

- Vibration Range: 10g to 20g

Related Software

Connect With Us

Whether you are a public agency, private company, or academic institution, we look forward to hearing from you. Fill out the Statement of Interest form to submit your inquiry.