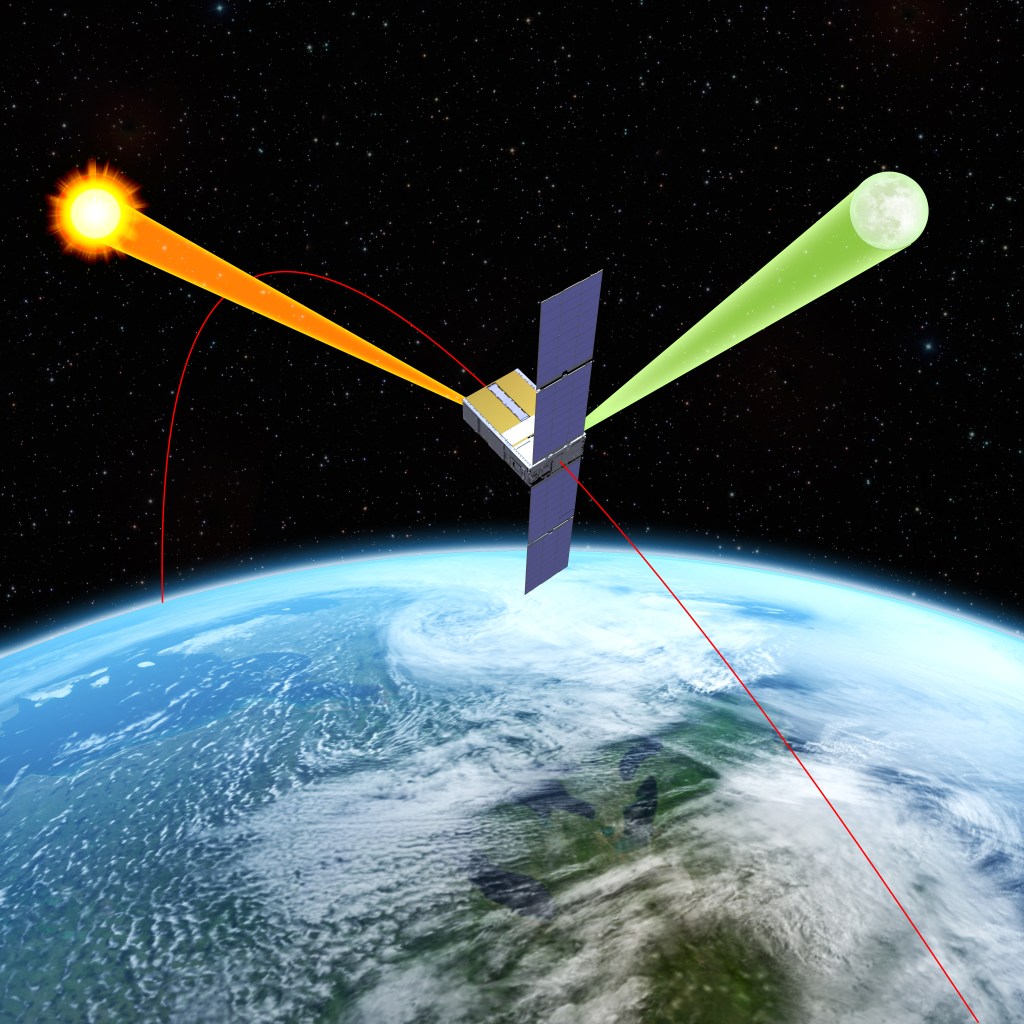

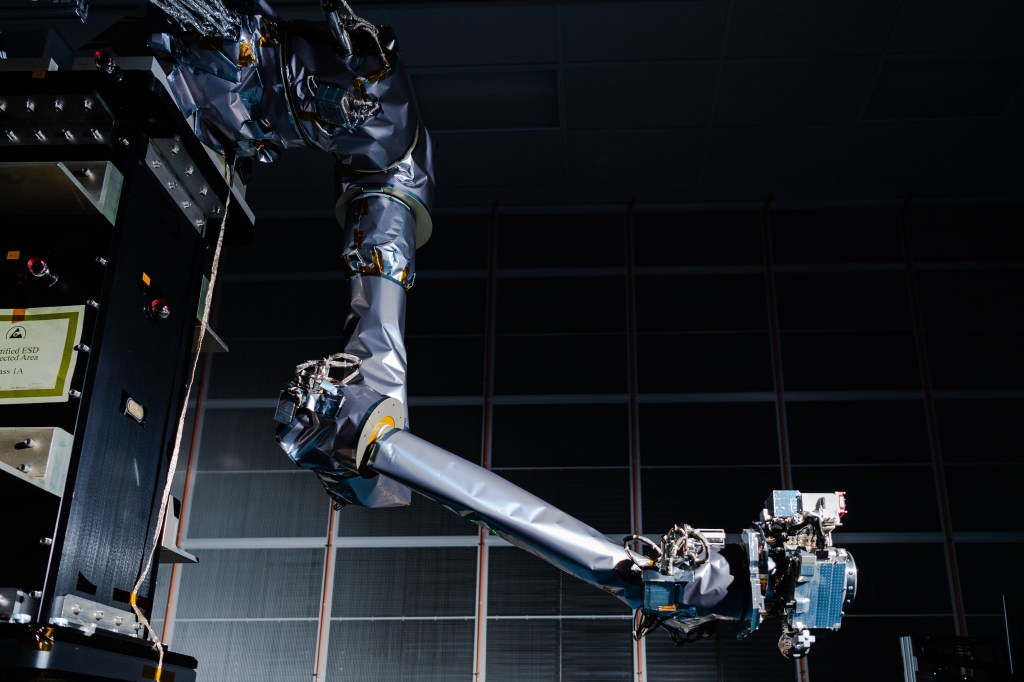

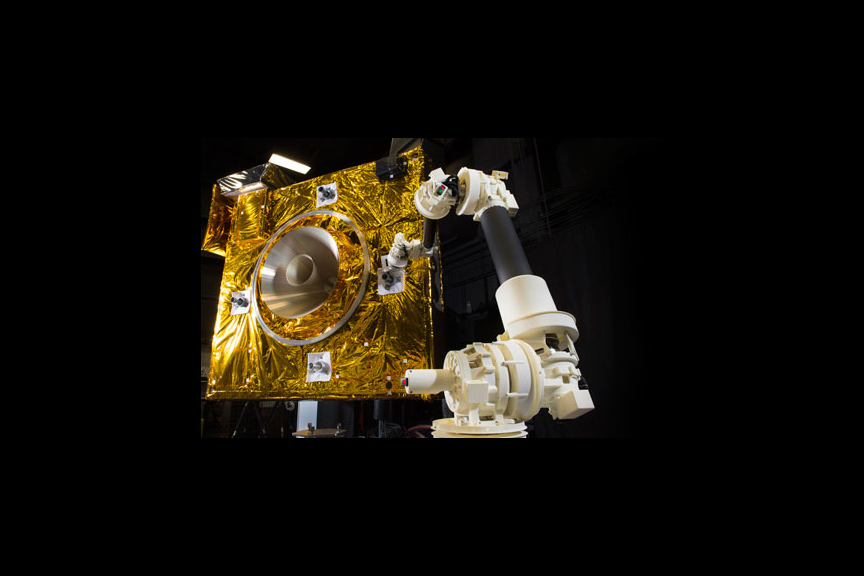

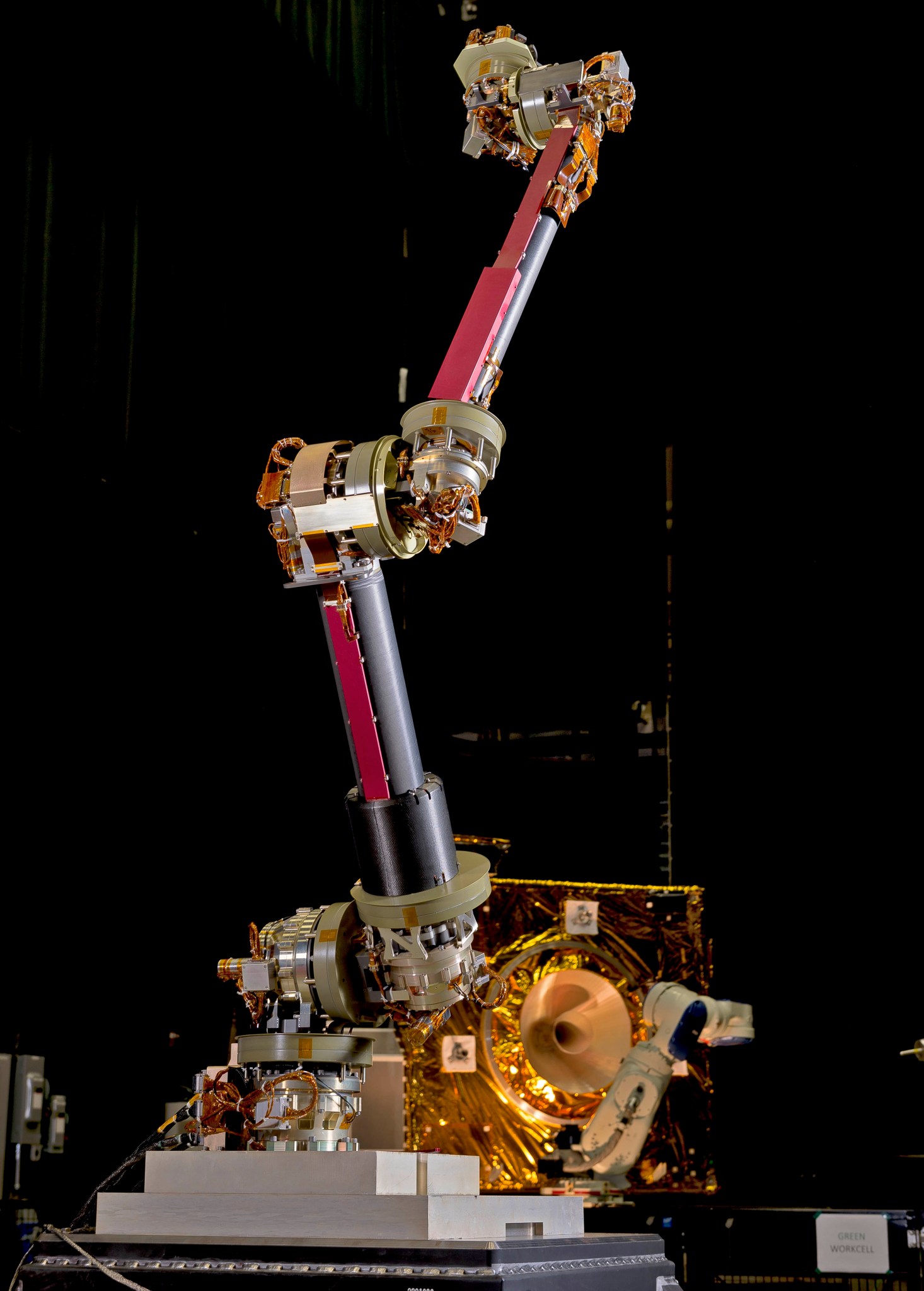

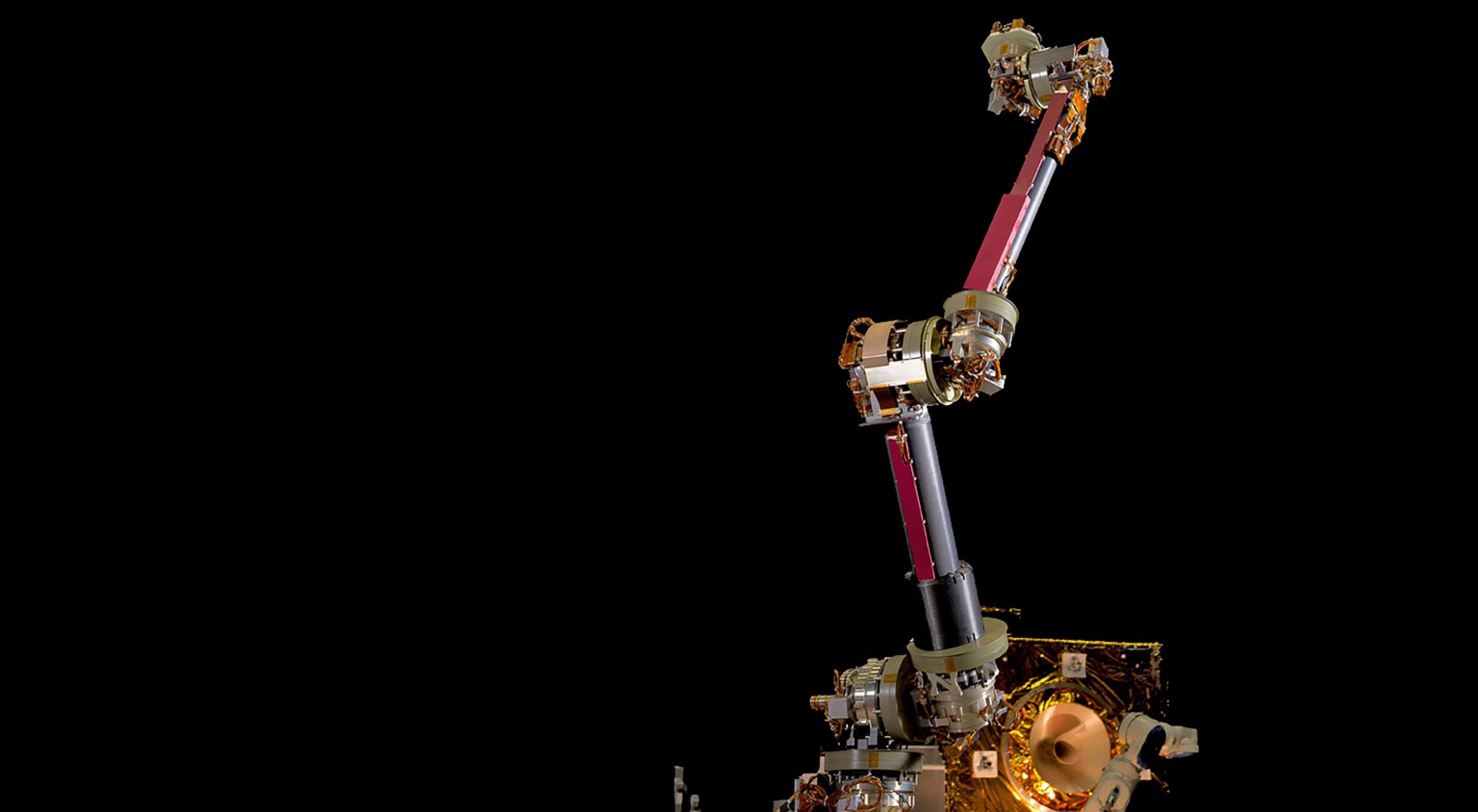

Robotic Servicing Arm

A seven-degree-of-freedom robot arm is used on missions as diverse as on-orbit satellite servicing, asteroid capture, and the assembly and servicing of large telescopes in space.

The foundation of the Robotic Servicing Arm has extensive heritage from arms used in past Mars rover missions. The system design heavily leverages the flight-qualified robotic arm developed for Defense Advanced Research Projects Agency (DARPA)’s Spacecraft for the Universal Modification of Orbits and Front-end Robotics Enabling Near-term Demonstration (FREND) programs in the mid-2000s. It builds off of previous NASA and DARPA investments in motion control, robotic software frameworks, flex harnesses, force-torque sensor, joint design, and flight operations experience.

Range of Motion

Opening a door, grabbing a pencil, pouring a glass of water; these are all are examples of simple, everyday tasks that use your arm. Like your arm, the NASA servicing robot has “seven degrees of freedom”— a three-axis shoulder, a pitch actuator at the elbow, and a three-axis spherical wrist. Other features include a six-axis force/torque sensor at the end of the arm, and a flex harness that routes data, power, and video.

With such a high level of maneuverability, this arm is ideally suited for missions requiring autonomous capture and dexterous operations; from grabbing a satellite for on-orbit servicing, to extracting a boulder from a spinning asteroid, to assembling and servicing a large telescope in orbit, or setting up worksites on Mars for astronauts.

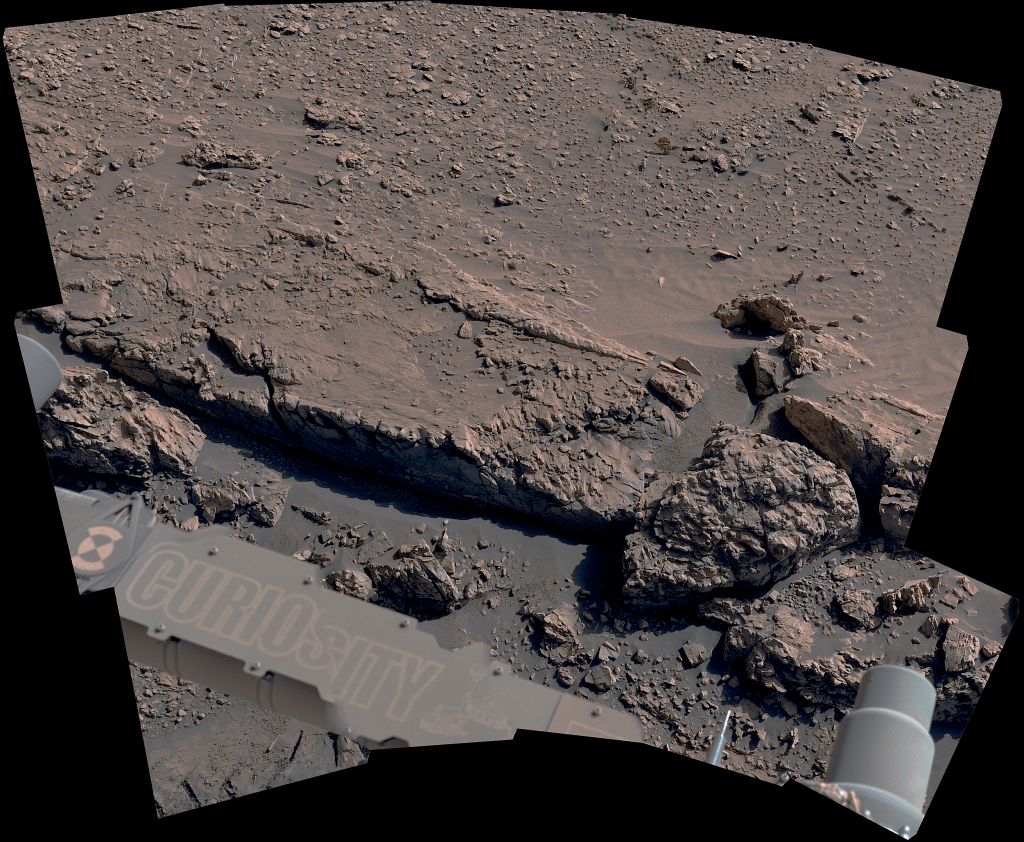

An Early Version Arrives at Goddard

In the process of building space hardware, an engineering design unit (EDU) is manufactured before final flight hardware. An EDU is made of less expensive materials that are simpler to manufacture and subjected to less stringent qualifications, allowing them to be manufactured in about half the time needed for flight hardware. An EDU helps “work out the kinks.” It also helps ensure that final flight hardware will not need to be modified after it is assembled.

In June 2015, Goddard welcomed an EDU of the robot arm to the facility – a working, ground-based version that helps the Robo team hone, refine, and evaluate their design before they build the “real” arm destined for spaceflight.

This is the arm that NASA is currently being used for the OSAM-1 servicing mission.