For space missions that venture beyond low Earth orbit, new challenges include how to provide basic needs for crew members without resupply missions from the ground. NASA is developing life support systems that can regenerate or recycle consumables such as food, air, and water and is testing them on the International Space Station.

Ideally, life support systems need to recover close to 98% of the water that crews bring along at the start of a long journey. The space station’s Environmental Control and Life Support System (ECLSS) recently demonstrated that it can achieve that significant goal.

ECLSS is a combination of hardware that includes a Water Recovery System. This system collects wastewater and sends it to the Water Processor Assembly (WPA), which produces drinkable water. One specialized component uses advanced dehumidifiers to capture moisture released into the cabin air from crew breath and sweat.

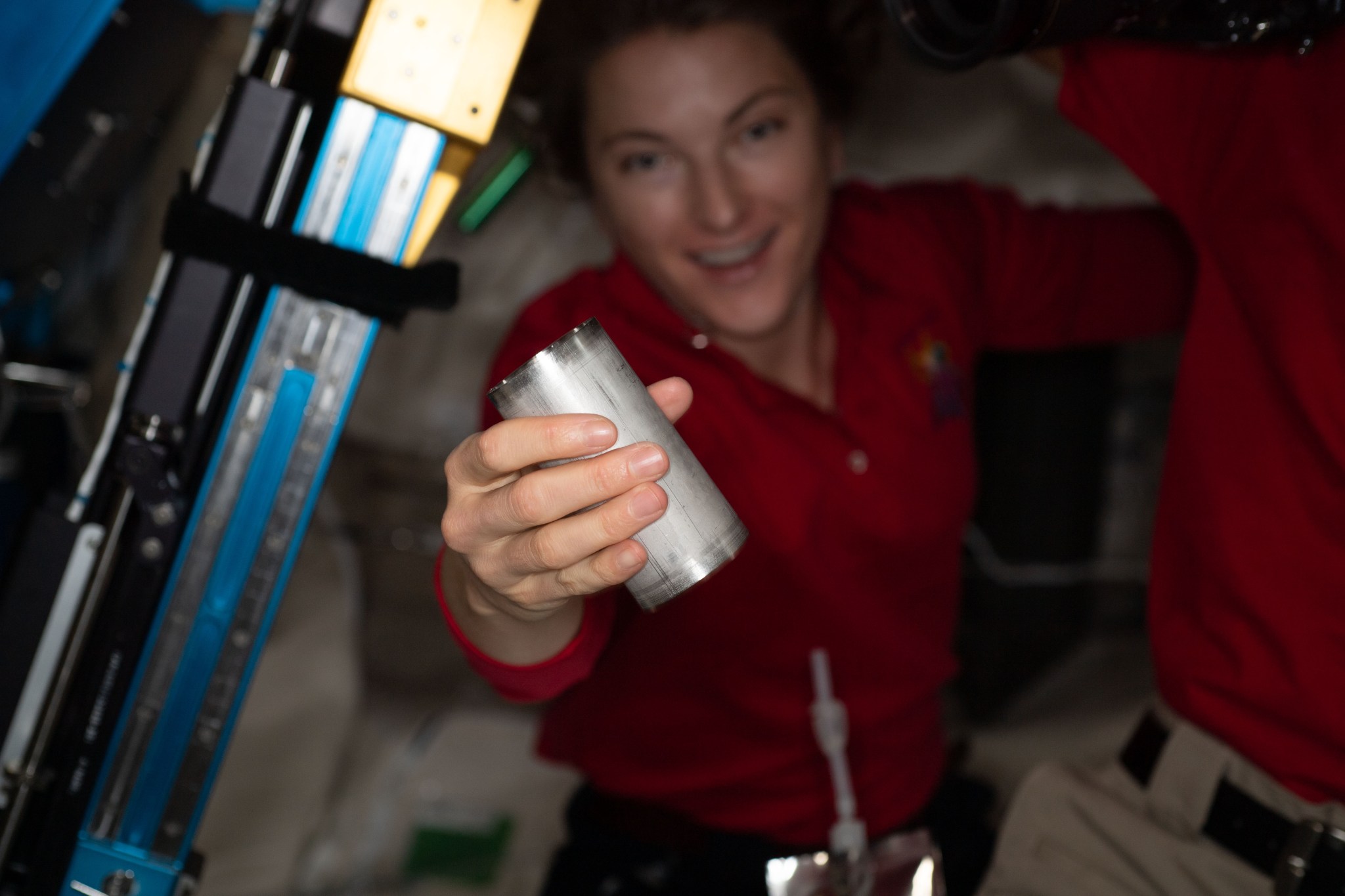

Another subsystem, the Urine Processor Assembly (UPA), recovers water from urine using vacuum distillation. A previous technology demonstration on the space station tested improvements to the UPA’s Distillation Assembly. Distillation produces water and a urine brine that still contains some reclaimable water. A Brine Processor Assembly (BPA) developed to extract this remaining wastewater has been on the space station as a demonstration of its operation in microgravity. Recent assessments found that the BPA helped the system achieve the 98% water recovery goal.

“This is a very important step forward in the evolution of life support systems,” says Christopher Brown, part of the team at Johnson Space Center that manages the space station’s life support system. “Let’s say you collect 100 pounds of water on the station. You lose two pounds of that and the other 98% just keeps going around and around. Keeping that running is a pretty awesome achievement.”

“Before the BPA, our total water recovery was between 93 and 94% overall,” says Jill Williamson, ECLSS water subsystems manager. “We have now demonstrated that we can reach total water recovery of 98%, thanks to the brine processor.”

The BPA takes the brine produced by the UPA and runs it through a special membrane technology, then blows warm, dry air over the brine to evaporate the water. That process creates humid air, which, just like crew breath and perspiration, is collected by the station’s water collection systems.

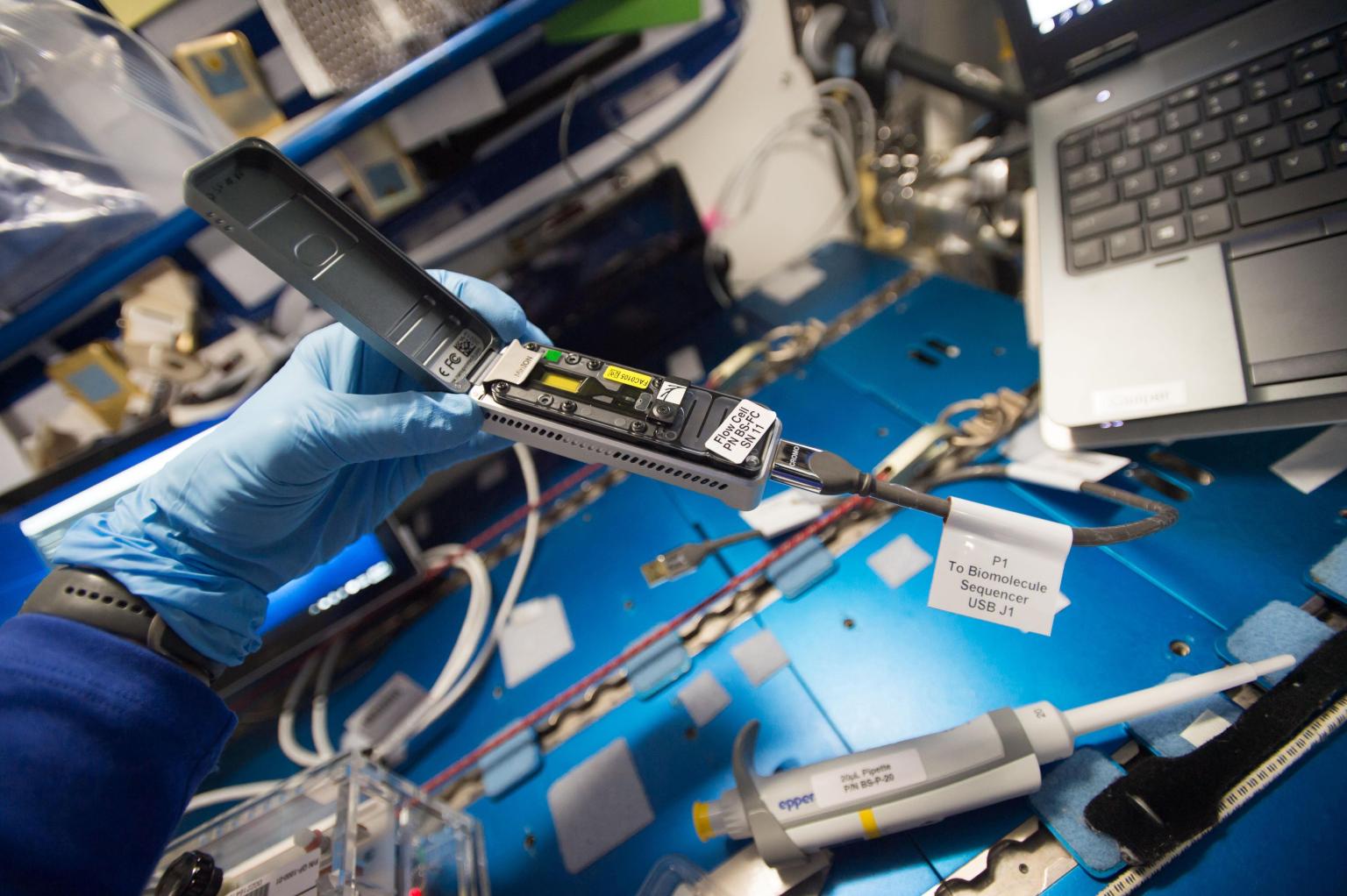

All the collected water is treated by the WPA. It first uses a series of specialized filters, then a catalytic reactor that breaks down any trace contaminants that remain. Sensors check the water purity and unacceptable water is reprocessed. The system also adds iodine to the acceptable water to prevent microbial growth and stores it, ready for the crew to use. Each crew member needs about a gallon of water per day for consumption, food preparation, and hygiene such as brushing teeth.

The team acknowledges that the idea of drinking recycled urine might make some people squeamish. But they stress that the end result is far superior to what municipal water systems produce on the ground.

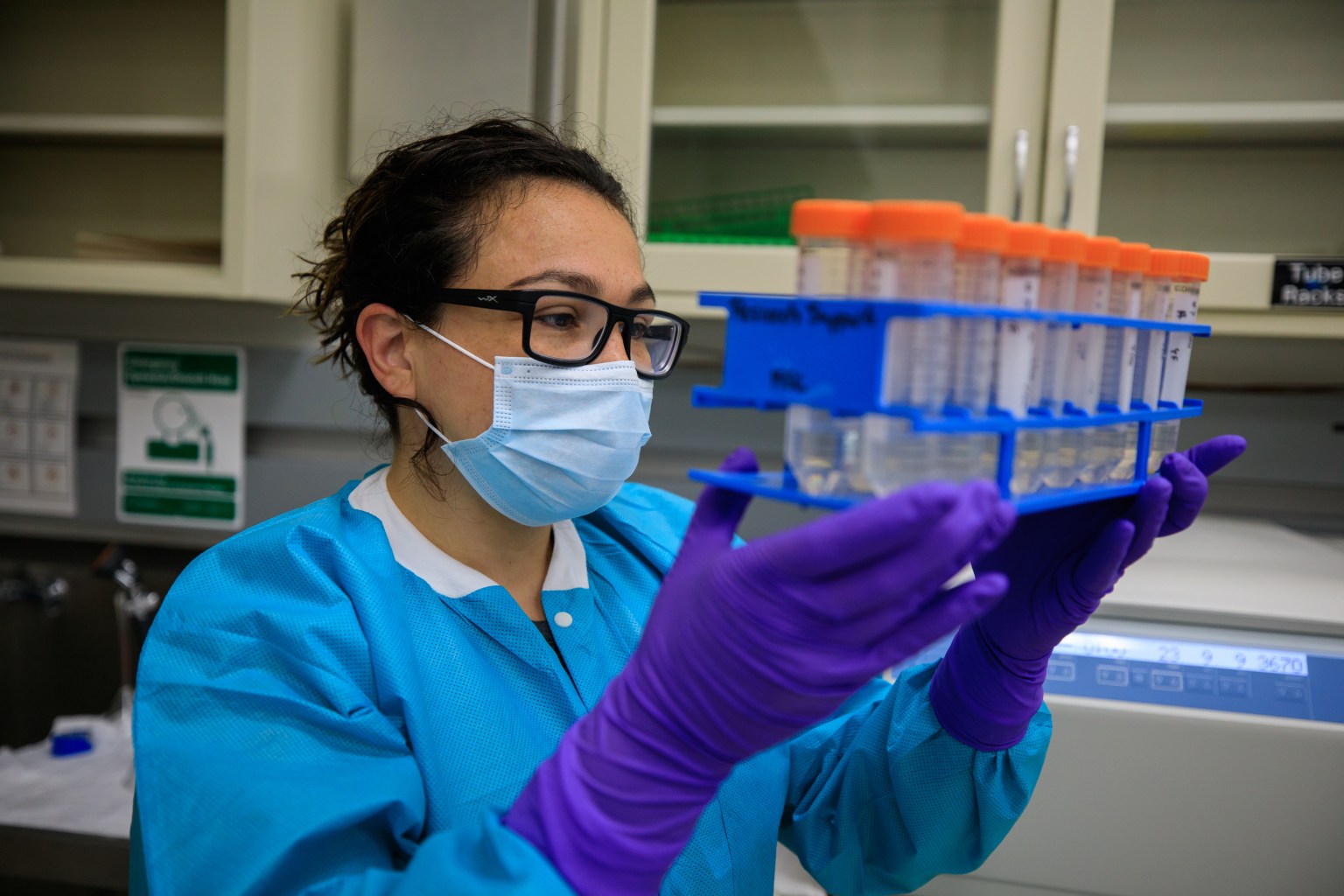

“The processing is fundamentally similar to some terrestrial water distribution systems, just done in microgravity,” Williamson says. “The crew is not drinking urine; they are drinking water that has been reclaimed, filtered, and cleaned such that it is cleaner than what we drink here on Earth. We have a lot of processes in place and a lot of ground testing to provide confidence that we are producing clean, potable water.”

The systems in ECLSS have been carefully tested, not only to ensure that they perform as intended, but also to demonstrate that each is reliable and can operate long-term without a lot of maintenance or spare parts.

“The regenerative ECLSS systems become ever more important as we go beyond low Earth orbit,” Williamson says. “The inability of resupply during exploration means we need to be able to reclaim all the resources the crew needs on these missions. The less water and oxygen we have to ship up, the more science that can be added to the launch vehicle. Reliable, robust regenerative systems mean the crew doesn’t have to worry about it and can focus on the true intent of their mission.”

More information:

Environmental Control and Life Support System (ECLSS) Fact Sheet

Video: Space Station Live: Environmental Control and LIfe Support System

Melissa Gaskill

International Space Station Program Research Office

Johnson Space Center