NASA Glenn Labs and Test Facilities

NASA’s Glenn Research Center at Lewis Field in Cleveland and the Neil Armstrong Test Facility in Sandusky, Ohio, house ground test facilities where scientists and engineers develop and verify cutting-edge aerospace technologies. These world-class test facilities support private industry, government, and academia.

Using our Facilities about NASA Glenn Labs and Test Facilities

We Test Like We Fly

NASA Glenn’s world-renowned test facilities bring agency, military, and private industry customers to Ohio.

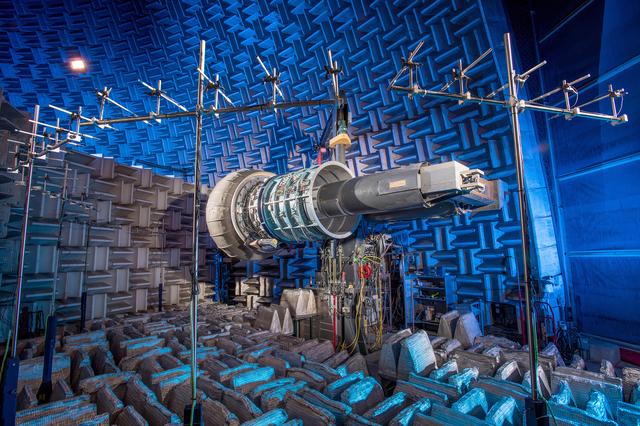

Acoustics Facilities

Aero-Acoustic Propulsion Laboratory

The Aero-Acoustic Propulsion Laboratory is a world-class facility for conducting aero-propulsion noise reduction research.

Reverberant Acoustic Test Facility

The Space Environments Complex houses the most powerful space environment simulation facilities, including the Reverberant Acoustic Test Facility.

Combustion Facilities

Advanced Subsonic Combustion Rig

The Advanced Subsonic Combustion Rig is a unique high-pressure and high temperature combustor facility. It is significant because of its one-of-a kind ability to simulate combustor tests up to 60 atmospheres.

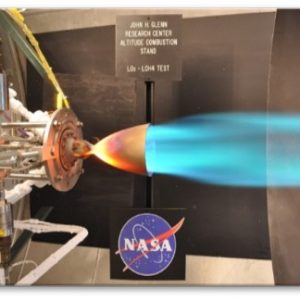

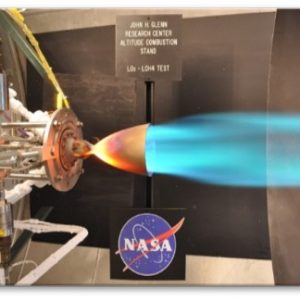

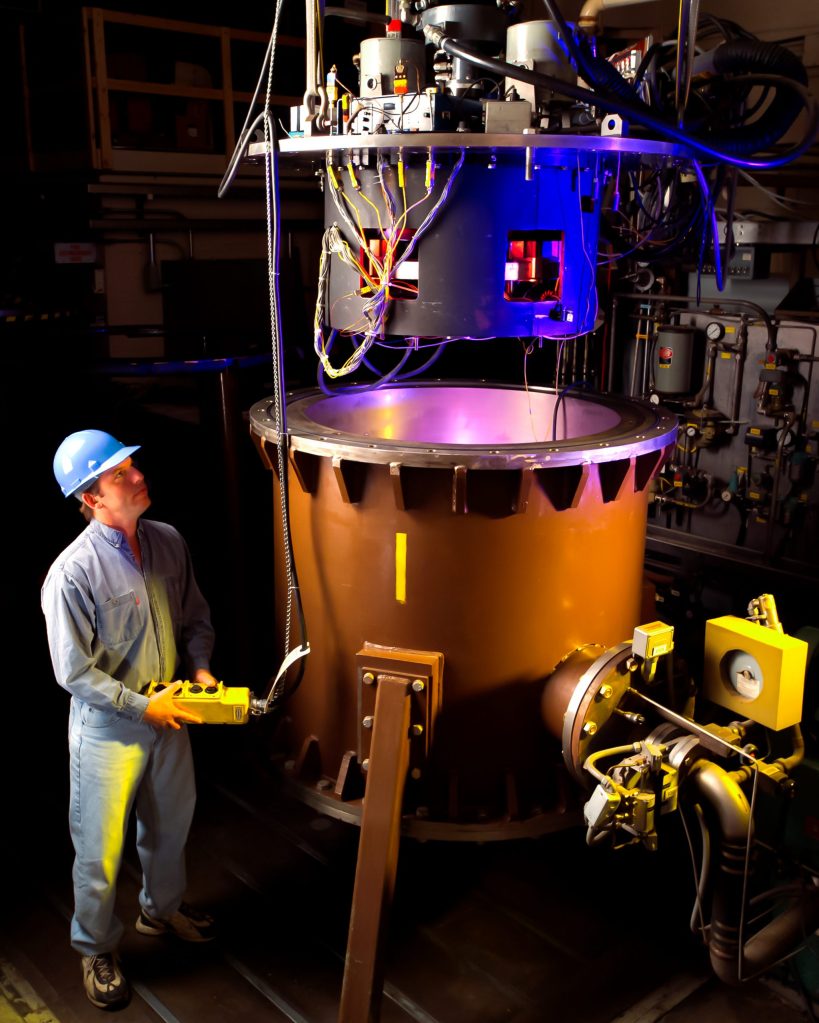

Chemical Propulsion Research Complex

The Chemical Propulsion Research Complex develops advanced chemical propulsion concepts and evaluates safer propellants for launch vehicles, spacecraft thrusters and advanced ignition systems for next generation launch vehicles.

Components Facilities

1×1 Supersonic Wind Tunnel

The 1- by 1-Foot Supersonic Wind Tunnel specializes in fundamental research in supersonic and hypersonic fluid mechanics, supersonic-vehicle-focused research, and detailed benchmark quality experiments for computational fluid dynamics code validation.

Engine Research Building

The Engine Research Building supports research in all aspects of engine development, providing superior testing of turbomachinery, aerodynamics flow, physics, aero-propulsion heat transfer, mechanical components, and combustor facilities.

Conceptual Design Facilities

Compass Lab

The Compass Lab conducts rapid conceptual spacecraft designs for NASA, industry, and the scientific community.

Cryogenic Facilities

Combined Effects Chamber

The Combined Effects Chamber is part of NASA's Cryogenic Test Complex which allows large-scale liquid hydrogen experiments to be conducted safely.

Creek Road Cryogenics Complex

The Creek Road Cryogenics Complex consists of four test cells: the Small Multi-Purpose Research Facility, Cryogenics Components Lab 7, Cryomotor Test Bed, and 20K to 90K Calorimeter Test Bed.

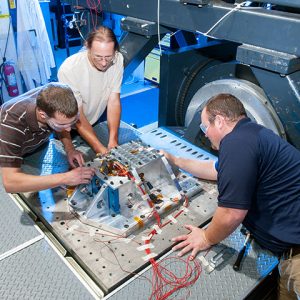

Electronics Facilities

Electromagnetic Interference Laboratory

The Electromagnetic Interference Laboratory offers analysis of hardware requirements and specification comparisons, electronic component testing, testing of hardware for shielding effectiveness, and final qualification testing of experiments.

Microsystems Fabrication Laboratory

The Microsystems Fabrication Laboratory supports design, fabrication, packaging, and testing of durable, extreme- environment silicon carbide sensors and electronics

Materials-Structures Facilities

Structural Dynamics Laboratory

The Structural Dynamics Laboratory performs structural dynamic testing to verify the survivability of a component or assembly when exposed to vibration stress screening, or a controlled simulation of the actual flight or service vibration environment.

Lunar Environment Structural Test Rig

The Lunar Environment Structural Test Rig simulates the intense cold of the lunar night, ranging from 40 Kelvin (K) to 125 K while maintaining a vacuum environment.

Microgravity Facilities

2.2 Second Drop Tower

The 2.2 Second Drop Tower has been used for nearly 50 years to study the effects of microgravity on physical phenomena such as combustion and fluid dynamics and to develop technology for future space missions.

ElectroMotive Drop Tower Initiative

The Electro-Motive Drop Tower is a proposed upgrade to the existing Zero Gravity Research Facility – NASA Glenn’s 5.2-second drop tower.

Zero Gravity Research Facility

The Zero Gravity Research Facility is the largest facility of its kind in the world. It provides researchers with a near weightless environment for a duration of 5.18 seconds.

Planetary Exploration Test Facilities

Planetary Exploration Test Facilities

NASA Glenn’s mTRAX Planetary Exploration team operates test rigs to evaluate planetary roving vehicle systems and components in simulated planetary and lunar conditions.

Power Systems Facilities

Power Systems Facility

The Power Systems Facility provides development, testing, and validation capabilities of electrical power systems and associated support systems for a variety of aerospace applications in the International Space Station.

Fuel Cell Testing Laboratory

The Fuel Cell Testing Laboratory consists of multiple testing stations. This cell has been designed to accommodate a wide variety of sizes and types of fuel cells, including hydrogen/air and hydrogen/oxygen fuel cells ranging from 1 kW up to 125 kW.

Propulsion and Vacuum Chamber Facilities

Chemical Propulsion Research Complex

The Chemical Propulsion Research Complex develops advanced chemical propulsion concepts and evaluates safer propellants for launch vehicles, thrusters, and advanced ignition systems.

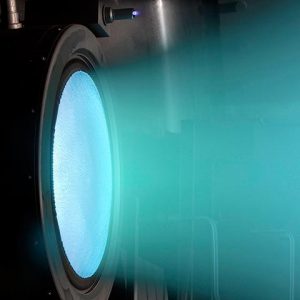

Electric Propulsion and Power Laboratory

The Electric Propulsion and Power Laboratory supports research and development of spacecraft power and electric propulsion systems.

Electric Propulsion Research Building

The Electric Propulsion Research Building houses eight vacuum chambers and five bell jars to conduct fundamental research in space power and electric propulsion.

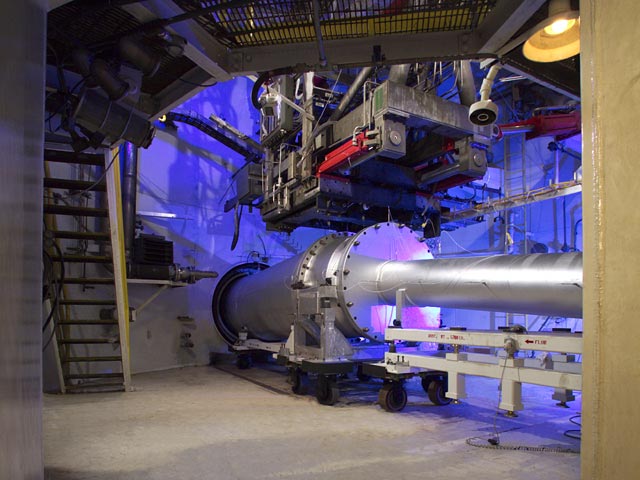

Propulsion Systems Laboratory

The Propulsion Systems Laboratory is NASA’s only ground-based test facility that provides true flight simulation for experimental research on air-breathing propulsion systems.

Visualization Facilities

Graphics and Visualization Lab

The Graphics and Visualization Lab applies advanced visualization technology and expertise to create innovative solutions for NASA and the scientific community.

Wind Tunnels

10×10 Supersonic Wind Tunnel

The 10- by 10-Foot Supersonic Wind Tunnel is the largest and fastest wind tunnel facility at NASA’s Glenn Research Center and is specifically designed to test supersonic propulsion components from inlets and nozzles to full-scale jet and rocket engines.

1×1 Supersonic Wind Tunnel

The 1- by 1-Foot Supersonic Wind Tunnel specializes in conducting research in supersonic and hypersonic fluid mechanics, supersonic-vehicle-focused research and detailed benchmark quality experiments for computational fluid dynamics code validation.

8×6 Supersonic Wind Tunnel

The 8- by 6-Foot Supersonic Wind Tunnel operates either in an aerodynamic closed-loop cycle, testing aerodynamic performance models, or in a propulsion open-loop cycle that tests live fuel burning engines and models.

9×15 Low-Speed Wind Tunnel

The 9- by 15-Foot Low-Speed Wind Tunnel is the most utilized low-speed propulsion acoustic facility in the world. It is the only national facility that can simulate takeoff, approach, and landing in a continuous subsonic environment.

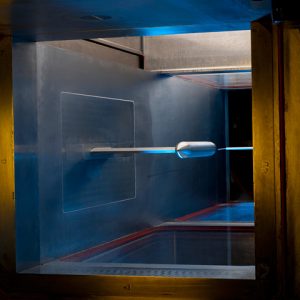

Icing Research Tunnel

The Icing Research Tunnel supports the development of tools and methods for simulating the growth of ice on aircraft surfaces and the development and certification of ice protection systems.

Neil Armstrong Test Facilities

NASA’s Neil Armstrong Test Facility is a remote campus of Glenn Research Center. Situated on 6,700 acres in Sandusky, Ohio, it is home to some of the world’s largest and most capable space simulation test facilities

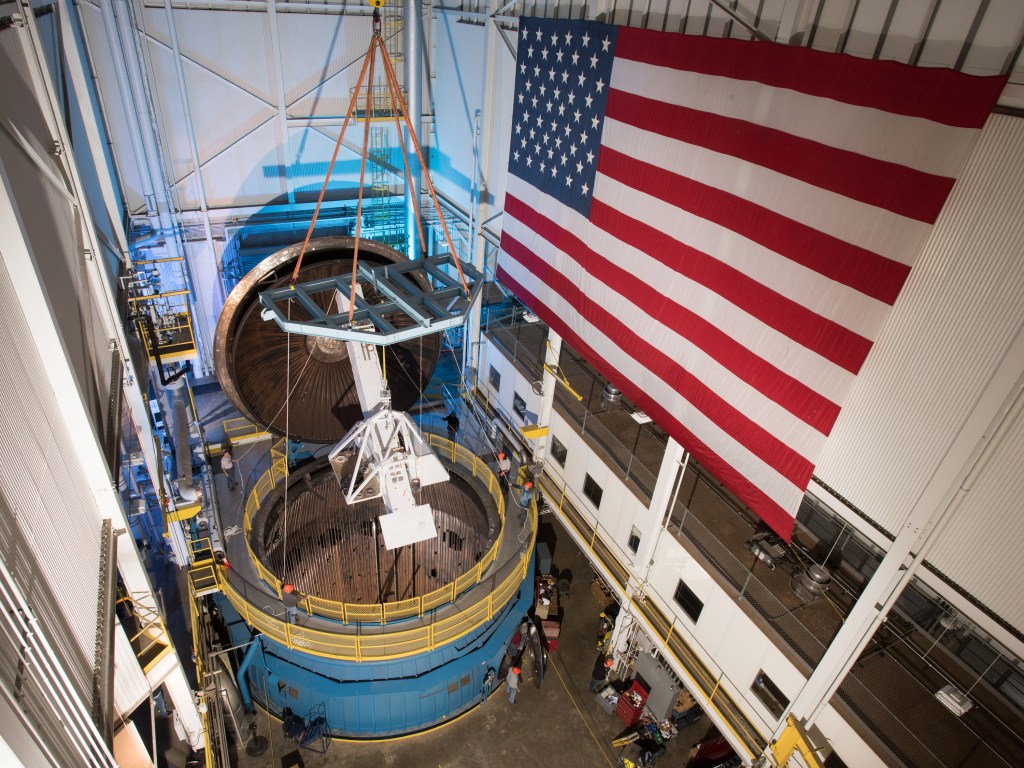

Space Environments Complex

The Space Environments Complex houses some of the world’s largest and most powerful space environment simulation facilities, including the largest vacuum chamber, most powerful spacecraft acoustic test chamber, and most high-powered spacecraft shaker.

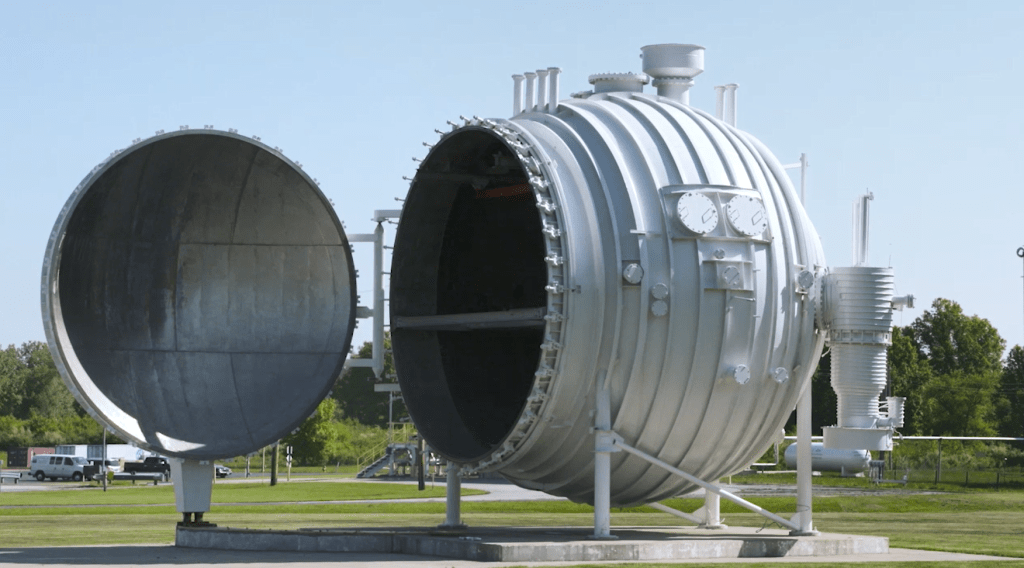

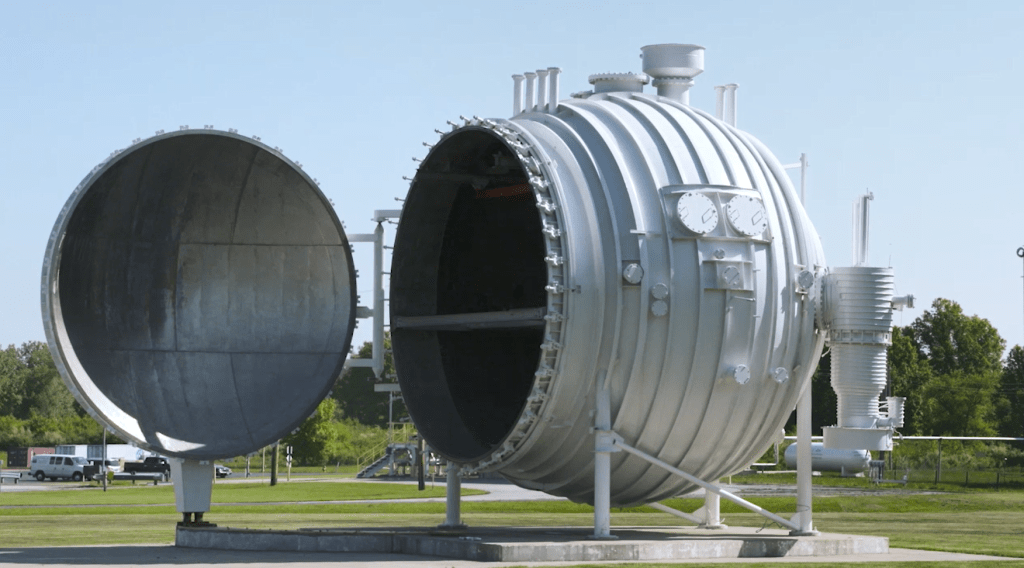

In-Space Propulsion Facility

NASA’s In-Space Propulsion Facility is the world’s only facility capable of testing full-scale upper-stage launch vehicles and rocket engines under simulated high-altitude conditions.

Combined Effects Chamber

The Combined Effects Chamber is part of NASA's Cryogenic Test Complex which allows large-scale liquid hydrogen experiments to be conducted safely.

Hypersonic Tunnel Facility

The hypersonic tunnel facility is a hypersonic (Mach 5, 6, and 7) blowdown, nonvitiated freejet facility that tests large-scale hypersonic air-breathing propulsion systems.

NASA Electric Aircraft Testbed

The NASA Electric Aircraft Testbed is an aeronautics test facility that provides end-to-end testing of megawatt -scale electrified aircraft powertrains to demonstrate next-generation hybrid and turboelectric commercial aircraft capabilities.

Electrified Aircraft Propulsion Labs and Testbeds

NASA Glenn is home to world-class laboratories and testbeds with unique capabilities for advancing research and development of electrified aircraft propulsion (EAP) technologies to enable more efficient air transportation.

NASA Electric Aircraft Testbed

Megawatt-scale electrified aircraft powertrain testing under simulated flight altitude conditions to enable next-generation hybrid and turboelectric commercial aircraft.

High-Power Advanced Cable Technology

The High-Power Advanced Cable Technology rig is designed to evaluate the thermal performance of advanced wiring technology for future electrified aircraft systems.

Scaled Power Electrified Drivetrain

A low-power, direct current, single-string testbed that helps familiarize engineers with electrified aircraft powertrains, verify operations, and characterize motor and inverter components.

Advanced Reconfigurable Electrified Aircraft Lab

A high-power, direct current testbed designed to investigate electric powertrain architectures and support development of new power standards and verification guidelines for vertical lift vehicles and electrified air transportation.

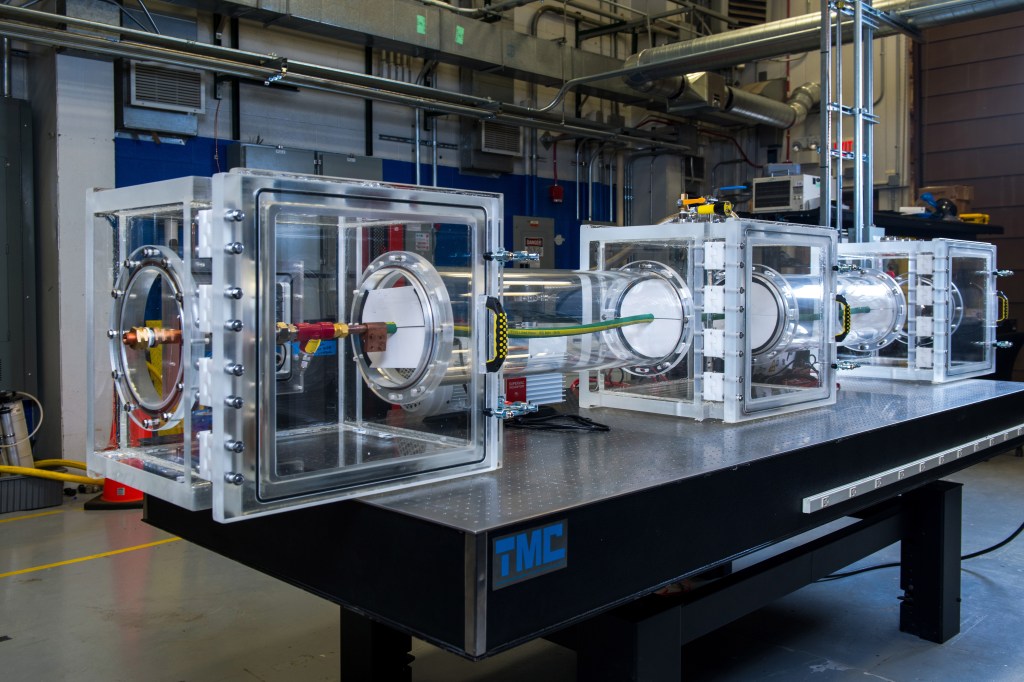

Integrated Cryogenically-Cooled Experiment Box

Cryogenic testing that enables quick, low-cost methods for conducting low-temperature tests on aircraft components.

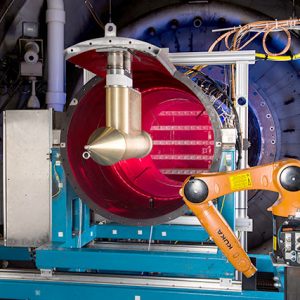

Dynamic Spin Rig

Vibration and structural mode properties testing of rotating aircraft engine systems and components.

Hybrid Propulsion Emulation Rig

The Hybrid Propulsion Emulation Rig provides a low-cost, low-risk solution for testing aircraft propulsion control technologies using a unique hardware-in-the-loop (HIL) environment.

/Hubble%20Space%20Telescope%20(A).png)