Researchers are one step closer to autonomously 3D printing metals in space.

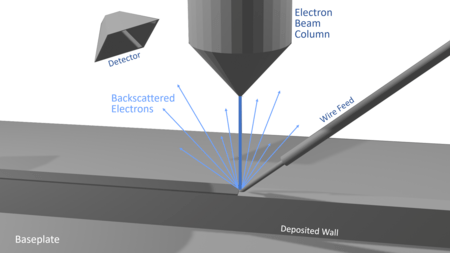

Electron Beam Freeform Fabrication, or EBF3, uses an electron beam gun, dual wire feed, and computer controls to manufacture metallic structures. In development for more than two decades, the process still relies on a human to observe and adjust the system.

Now, working through a Small Business Innovation Research (SBIR) contract, researchers at NASA’s Langley Research Center in Hampton, Virginia, and at COSM Advanced Manufacturing Systems in Ipswich, Massachusetts, are developing sensors that could allow the system to run on its own.

“Right now, a person watches to see if there’s drip about to fall or the beam is too hot or too cold. We watch all that and we can adjust all manually,” explained Karen Taminger, Langley materials research engineer. “Having a human in the loop has held back all of additive manufacturing. Having these sensors that can observe what’s happening in the system and use algorithms to control and correct any issues is the holy grail.”

When EBF3 was first developed it was used for improving construction on Earth. Removing humans from the equation and implementing a higher degree of control and repeatability allows the process to be certified for building human spaceflight structures, like rocket segments. EBF3 systems could also be used for large-scale metal structures like next generation airplanes.

“We need that fine tuning to keep it consistent so we can build the same part every time. That guarantee is critical for certification,” Taminger said. “Precise control over the electron beam is paramount. We’ve had ideas but COSM is helping us put them into practice.”

COSM began working with Langley on EBF3 starting with a Phase I NASA SBIR contact in 2014. In 2016 a portable EBF3 system was loaned to the company as part of the Phase II contract to begin designing a new electron beam gun with the sensors allowing autonomy built in. A follow-on Phase II Sequential contract totaling more than $4.9 million was awarded to the company in 2020, bringing the total NASA investment to more than $6 million. The latest contract is for COSM to build and test a prototype of its new electron beam gun design with the new closed-loop system integrated into the controls.

“The electron beam gun is where the energy comes into the manufacturing process. It has to be controlled very precisely. If you can control where the energy is going you can control where the material is going,” Taminger explained. “We’re used to manipulating matter with matter, but here we’re turning that thinking around and moving matter with energy. It’s a different way of looking at things.”

With NASA researchers sharing information gathered over the past 20 years and COSM developing and integrating the sensors and algorithms into the system, the team is manufacturing a more reliable product.

The EBF3 system offers a potential Swiss Army knife tool for space. The electron beam can be used at very low power to illuminate things and can be used as a microscope for high resolution imaging. At a slightly higher power it can be used as a heater or deicer. Increasing power, a little more, it can be used for welding and when the metal wire is added structures can be built by additive manufacturing. At a very high power it can even be used as a cutting tool. This type of multi-purpose tool could be useful for extended human missions to the Moon, and eventually Mars.

NASA invests in disruptive capabilities in emerging markets, increasing the country’s competitive advantage, and generating opportunities for job creation across the country. The SBIR program is part of the Space Technology Mission Directorate (STMD) and is managed by NASA’s Ames Research Center in California’s Silicon Valley.

For more information about NASA’s investments in space technology, visit: