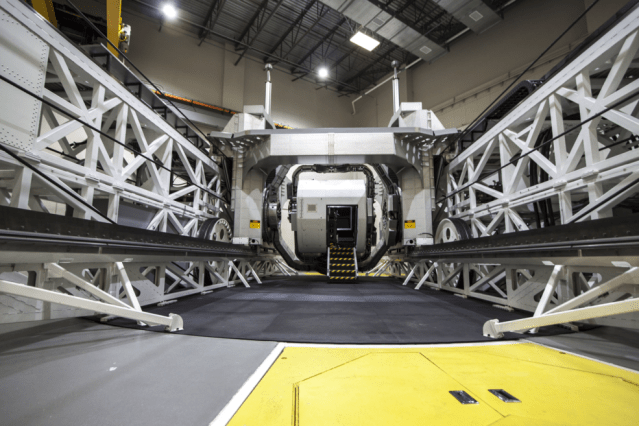

The International Space Station’s EXPRESS Rack 1 – EXPRESS Rack is a multipurpose rack system that houses and supports research aboard the space station — has now exceeded 100,000 hours of operation as of Oct. 4.

Since 2001 the rack has housed numerous experiments leading to ground-breaking science discoveries, Earth benefits and technology innovations that will aid in future space travel.

EXPRESS stands for EXpedite the PRocessing of Experiments to the Space Station and can support science experiments in any discipline by providing structural interfaces, power, data, cooling, water and other items needed to operate science experiments in space.

“It’s rewarding to see one of our EXPRESS Racks reach this milestone and continue to serve as an integral part of space station science research,” said Annette Sledd, International Space Station Office manager at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “The versatility of the EXPRESS Racks to provide standard interfaces and utilities has been key to their success and expanded use in support of ISS research, technology demonstrations and housing of payload support equipment.”

Key science payloads flown in EXPRESS Rack 1 range from Protein Crystal Growth, Advanced AstrocultureTM (ADVASC), Acceleration Monitoring systems (SAMS & MAMS), Lab refrigerators/incubators, to the Rodent Research hardware currently installed.

The ADVASC plant growth chamber research demonstrated that plants can complete their seed-to-seed life cycle in microgravity over two generations, and also determined the effects of microgravity on genetic and chemical differences in soybean seeds produced on the ISS as compared to seeds harvested on Earth. Soybeans are a widely used food crop on Earth and a potential food crop for future long duration space missions, so understanding their growth is critical for production for those on Earth and in space. The unique air scrubber that was designed to keep the plants healthy within the ADVASC hardware has also contributed to National Security, cancer-fighting pharmaceuticals and educational tools for students.

Protein crystals grown in microgravity can help scientists gain detailed knowledge of the atomic, three-dimensional structure of many important protein molecules used in pharmaceutical research for cancer treatments, stroke prevention and other diseases. On Earth, the protein crystallization process is hindered by forces of sedimentation and convection since the molecules in the crystal solution are not of uniform size and weight. The knowledge gained from growth without these restrictions could be instrumental in the design and testing of new drugs.

Marshall manages the EXPRESS racks for the ISS Program. The racks are successfully operating beyond their original 10-year design life, and Huntsville and Boeing engineers continue to provide replacement parts and assist investigators in building experiments to work in the station racks.

The EXPRESS Rack system was developed by the Marshall Center and built by the Boeing Co. in Huntsville.

Kimberly Newton

Marshall Space Flight Center, Huntsville, Alabama

256-544-0034

Kimberly.d.newton@nasa.gov