On Wednesday, the SpaceX Dragon that launched April 2 arrived at the International Space Station to deliver more than 5,800 pounds of research investigations, cargo and supplies, including NASA’s Materials International Space Station Experiment (MISSE). This is the ninth MISSE mission in the program’s long history of testing material samples in space.

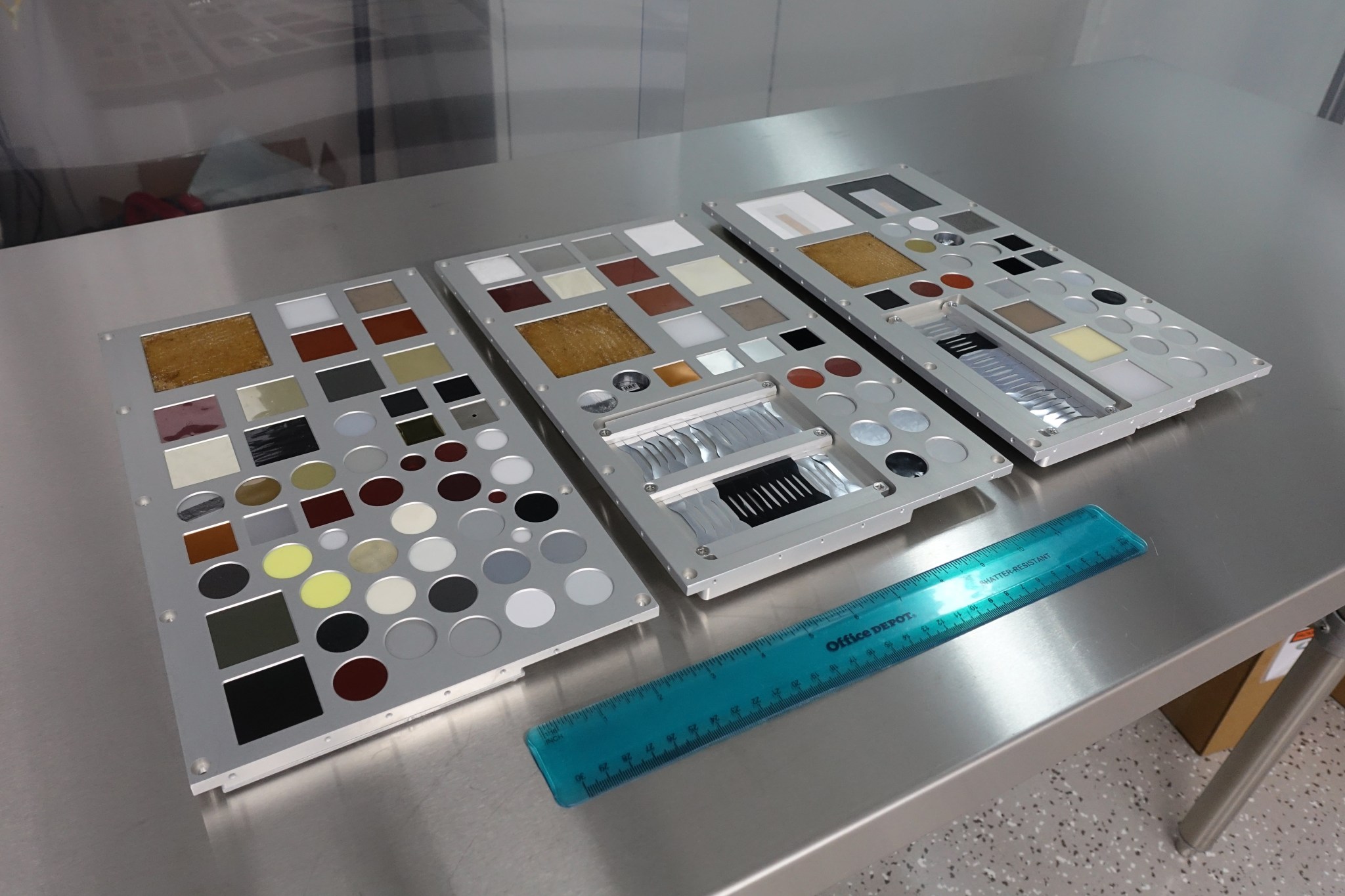

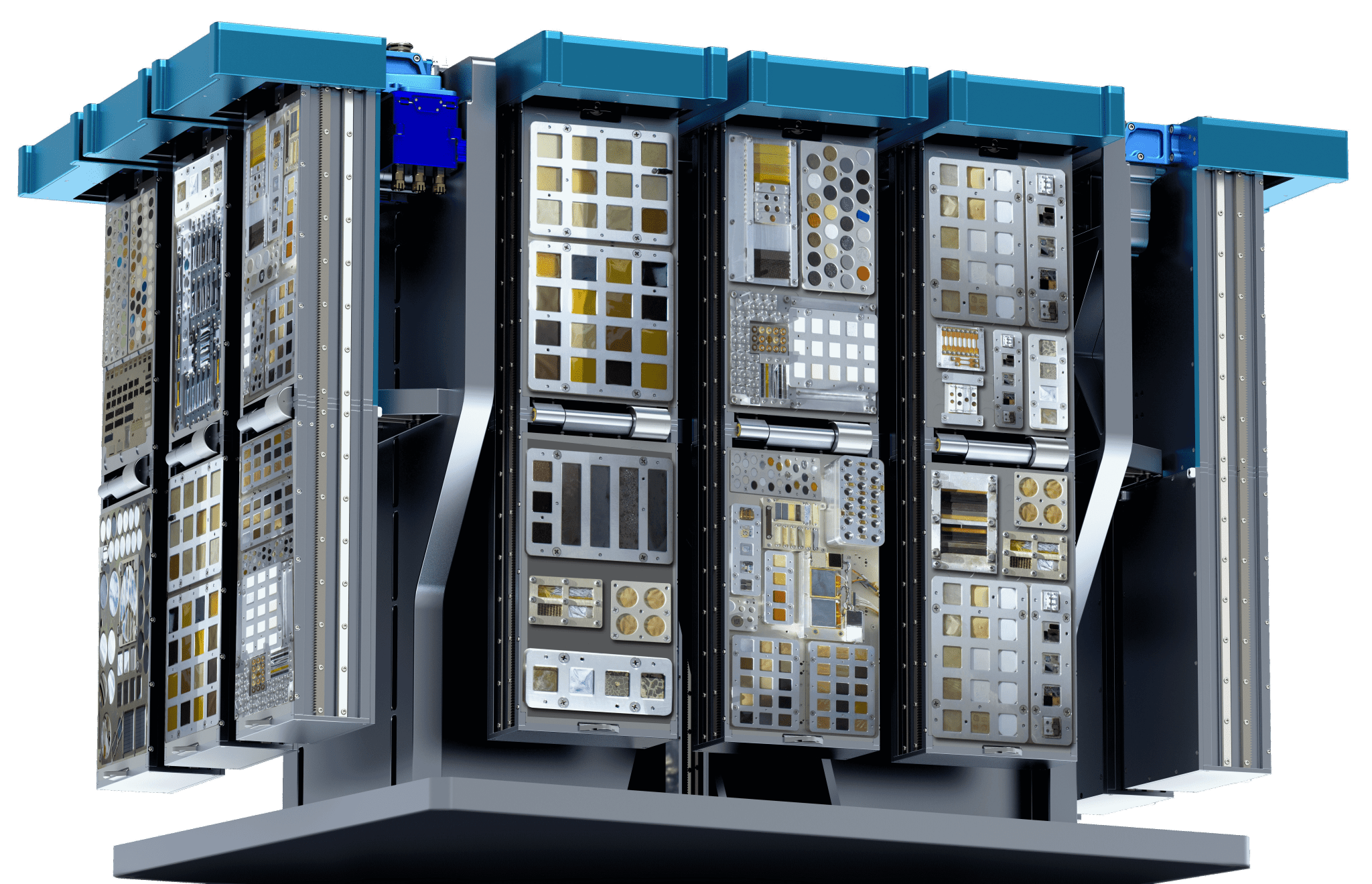

Also on board was the new MISSE flight facility hardware developed by Alpha Space Test and Research Alliance of Houston. The flight facility holds several new polymers and other material samples from both NASA researchers and commercial organizations.

“The long series of MISSE flights leading up to MISSE-9 has been an unparalleled success for on-orbit material science,” said Alpha Space President and CEO Mark Gittleman. “MISSE-9 continues that tradition and also represents a huge step forward in space science in several important ways.”

Gittleman explained that the flight facility will remain permanently installed on the exterior of the orbiting laboratory.

“The mass and cost to launch science experiments and investigations will be reduced to only the incremental mass and cost of launching experiment trays and carriers, rather than an entire facility,” Gittleman said.

He also noted that experiments requiring very long exposure can remain in place on the flight facility not just for weeks or months, but for years if required.

In addition, Gittleman said, Alpha Space and NASA have entered into a commercialization agreement for the flight facility that reserves a portion of its capacity for NASA samples while leaving the remaining space open for use as a commercial facility.

“This makes space available to all scientists through contracts with Alpha Space,” said Gittleman. “Alpha Space provides turn-key, fixed price integration services that make getting science to the station as simple and inexpensive as possible, and we think that opens up the benefits of space science to a whole new audience.”

The material samples currently on the flight facility will remain on the station for one year of testing as part of MISSE-9. This long-duration exposure to the harsh space environment will enable researchers to evaluate the potential performance of their materials in future long-term space applications.

NASA’s material samples included on MISSE-9 have a variety of research objectives, including:

Testing the Durability of New Polymers

Along with her research partner Larry Thomsen, Sheila Thibeault of NASA’s Langley Research Center in Virginia has patented several new spacecraft materials, including polymer films and fiber laminates for radiation shielding—an important role in protecting both astronauts and expensive equipment from potentially dangerous exposure. MISSE-9 will allow them to test these materials for strength and durability in the space environment.

Thibeault noted that testing for a long duration and then having the experiments returned from space is a specific advantage of the MISSE program.

“Missions like MISSE are important because they bring our samples back to us,” said Thibeault. “We can get as much data as possible, which gives us more assurance of how these materials will respond in future NASA missions.”

Improving Model Predictions for Material Performance

Kim de Groh and Bruce Banks of NASA’s Glenn Research Center in Ohio have used flight data from their previous MISSE experiments to develop a model to predict the erosion of new polymers in space. They also developed a model to predict the problems scattered atomic oxygen can cause for spacecraft.

“We’re flying again on MISSE-9 to continue our studies in determining the low-Earth orbit atomic oxygen erosion yield of a wide variety of polymers, composites, and coatings,” said de Groh. “We will fly some materials in each mission orientation (ram, wake, zenith, and nadir) to see how the varying atomic oxygen and solar exposures affect erosion. In addition, we will characterize changes in optical, thermal, and mechanical properties of these materials after being exposed to the space environment for a year.”

When the samples come back at the mission’s conclusion, de Groh’s and Banks’s MISSE-9 flight data should help improve predictions of material and component lifetimes in space, along with improved model predictions.

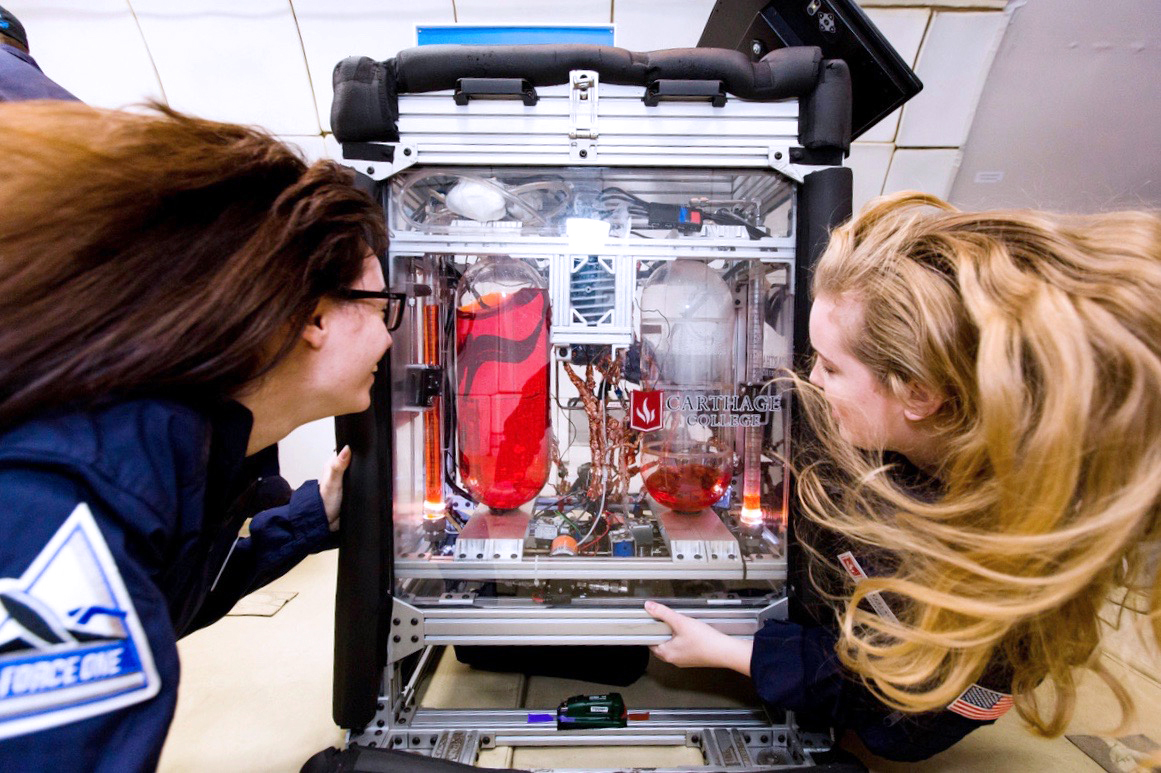

Evaluating Space-Based, 3-D Printed Materials

NASA’s Marshall Space Flight Center in Alabama is also represented on MISSE-9, with researchers studying several different additively manufactured (3-D printed) materials in an effort to further the advancement of space-based manufacturing.

“We are flying metallic and non-metallic samples, to cover what might be made on the ground or 3-D printed on the space station,” said Miria Finckenor, principal investigator.

“During a long-duration mission, an astronaut may need to print a replacement part, and we want to make sure that part will hold up in space,” said Finckenor.

In addition to the 3-D printed samples, Finckenor’s team sent sensors on MISSE-9 to measure how much ultraviolet radiation the flight facility is receiving.

Supporting STEM Educational Outreach

In addition to supporting NASA’s own research, MISSE-9 continues the agency’s tradition of educational outreach focused on science, technology, engineering, and mathematics (STEM) with an experiment from the University of Delaware. Norman Wagner and Maria Katzarova, along with their students, are working to improve astronaut spacesuits with shear-thickening fluid (STF)-intercalated textiles—helping increase their resistance to damage associated with orbital impacts.

“The threat of a micrometeoroid or orbital debris impacting an astronaut is small, but a more likely threat is damage to the spacesuits caused by sharp edges on the station itself—often the result of orbital impacts to the handrails and other structures,” noted Katzarova. “The STF-treated materials we’re testing on MISSE-9 could be integrated into the spacesuits to protect the astronauts, and this mission will help us learn how they hold up to long-term storage in space.”

For More Information

The MISSE flight facility was co-funded by the International Space Station Program Office and Alpha Space Test and Research Alliance, LLC. Under its cooperative agreement, Alpha Space manages the flight missions. MISSE supports both NASA and commercial flight experiments and investigations, and NASA’s Space Technology Mission Directorate (STMD) selects the NASA investigations through NASA’s Flight Opportunities program.

Managed at NASA’s Armstrong Flight Research Center in Edwards, California, Flight Opportunities selects promising technologies from industry, academia and government, and provides opportunities for testing and technology demonstration. STMD is responsible for developing the crosscutting, pioneering new technologies and capabilities needed by the agency to achieve its current and future missions.

For more information on NASA’s Flight Opportunities program, future MISSE missions, calls, and opportunities, visit: