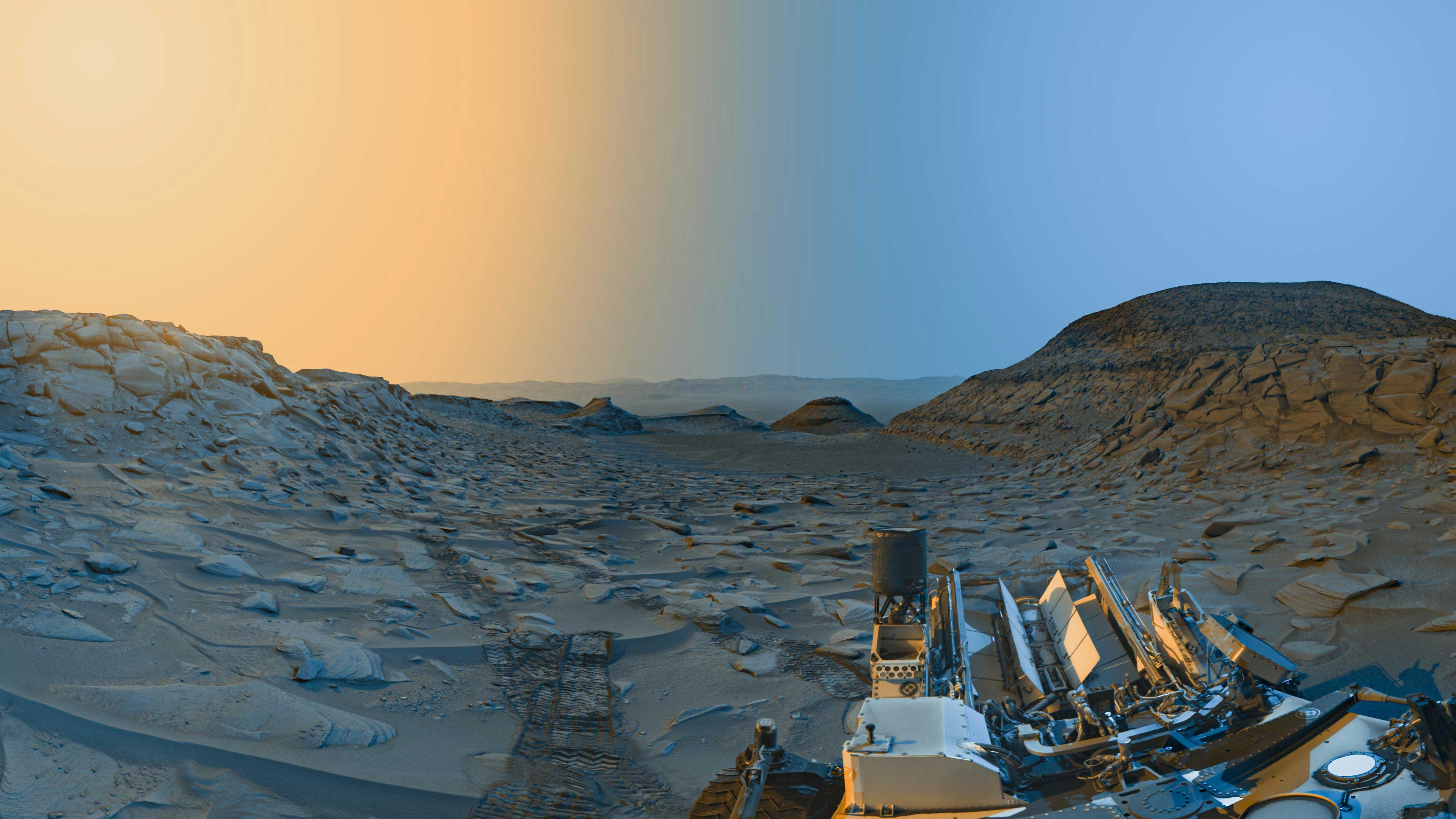

NASA Tech Contributes to Soft Moon Landing

For the first time in more than 50 years, new NASA science instruments and technology demonstrations are operating on the Moon following the first successful delivery of the agency’s CLPS (Commercial Lunar Payload Services) initiative.

Intuitive Machines’ Nova-C lander, called Odysseus, completed a seven-day journey to lunar orbit and executed procedures to softly land near Malapert A in the South Pole region of the Moon at 5:24 p.m. on Feb. 22. The mission marks the first commercial uncrewed landing on the Moon.

NASA and Intuitive Machines co-hosted an afternoon news conference Feb. 28 from the agency’s Johnson Space Center. NASA+, NASA Television, and the agency’s website will provide updates.

Carrying six NASA science research and technology demonstrations, among other customer payloads, all NASA science instruments completed transit checkouts en route to the Moon. A NASA precision landing technology demonstration also provided critical last-minute assistance to ensure a soft landing. As part of NASA’s Artemis campaign, the lunar delivery is in the region where NASA will send astronauts to search for water and other lunar resources later this decade.

“For the first time in more than half a century, America returned to the Moon. Congratulations to Intuitive Machines for placing the lunar lander Odysseus carrying NASA scientific instruments to a place no person or machine has gone before, the lunar South Pole,” said NASA Administrator Bill Nelson. “This feat from Intuitive Machines, SpaceX, and NASA demonstrates the promise of American leadership in space and the power of commercial partnerships under NASA’s CLPS initiative. Further, this success opens the door for new voyages under Artemis to send astronauts to the Moon, then onward to Mars.”

During the journey to the Moon, NASA instruments measured the quantity of cryogenic engine fuel as it has been used, and while descending toward the lunar surface, teams collected data on plume-surface interactions and tested precision landing technologies.

New lunar science, technology

NASA’s Navigation Doppler Lidar for Precise Velocity and Range Sensing (NDL) guidance system for descent and landing ultimately played a key role in aiding the successful landing. A few hours ahead of landing, Intuitive Machines encountered a sensor issue with their navigation system and leaned on NASA’s guidance system for an assist to precisely land. NASA’s instrument operates on the same principles of radar and uses pulses from a laser emitted through three optical telescopes. It measures speed, direction, and altitude with high precision during descent and touchdown.

NASA instruments focused on investigating lunar surface interactions and radio astronomy. The Odysseus lander also carries a retroreflector array that will contribute to a network of location markers on the Moon for communication and navigation for future autonomous navigation technologies.

Additional NASA hardware aboard the lander includes:

- Lunar Node 1 Navigation Demonstrator: A small, CubeSat-sized experiment that will demonstrate autonomous navigation that could be used by future landers, surface infrastructure, and astronauts, digitally confirming their positions on the Moon relative to other spacecraft, ground stations, or rovers on the move. LN-1 was developed, built, and tested at NASA’s Marshall Space Flight Center.

- Laser Retroreflector Array: A collection of eight retroreflectors that enable precision laser ranging, which is a measurement of the distance between the orbiting or landing spacecraft to the reflector on the lander. The array is a passive optical instrument and will function as a permanent location marker on the Moon for decades to come.

- Radio Frequency Mass Gauge: A technology demonstration that measures the amount of propellant in spacecraft tanks in a low-gravity space environment. Using sensor technology, the gauge will measure the amount of cryogenic propellant in Nova-C’s fuel and oxidizer tanks, providing data that could help predict fuel usage on future missions.

- Radio-wave Observations at the Lunar Surface of the Photoelectron Sheath: The instrument will observe the Moon’s surface environment in radio frequencies, to determine how natural and human-generated activity near the surface interacts with and could interfere with science conducted there.

- Stereo Cameras for Lunar Plume-Surface Studies: A suite of four tiny cameras to capture imagery showing how the Moon’s surface changes from interactions with the spacecraft’s engine plume during and after descent.

NASA is committed to supporting its U.S. commercial vendors as they navigate the challenges of sending science and technology to the surface of the Moon.

“In daring to confront one of humanity’s greatest challenges, Intuitive Machines created an entire lunar program that has ventured farther than any American mission to land on the Moon in over 50 years,” said Steve Altemus, CEO of Intuitive Machines. “This humbling moment reminds us that pursuing the extraordinary requires both boldness and resilience.”

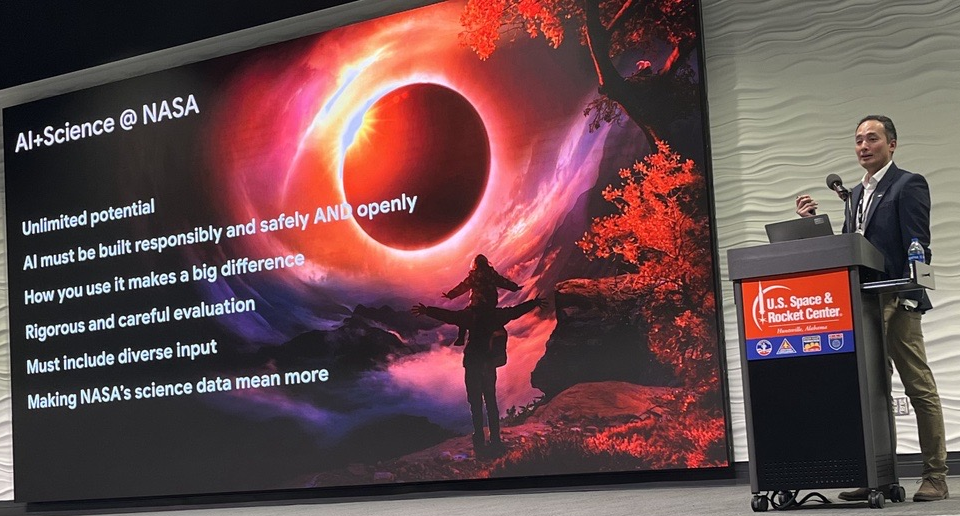

Take 5 with Manil Maskey

By Wayne Smith

As a NASA senior research scientist, Manil Maskey supports the development of artificial intelligence technologies. What isn’t artificial is his drive to make a difference.

From a young age, Maskey has been fascinated with applied mathematics and solving problems. This led him to pursue fields where these skills could be applied, such as working at NASA. But while getting his undergraduate degree in math from Fairmont State University in West Virginia, Maskey was rejected for a NASA internship.

“That lesson has been invaluable throughout my career,” said Maskey, the senior research scientist and project manager for the IMPACT (Interagency Implementation and Advanced Concepts Team) project in the Earth Science branch at NASA’s Marshall Space Flight Center. “That moment was a powerful motivator.”

After working in industry and academia, he sought a new challenge with NASA. Maskey said the agency’s commitment to pushing the frontiers of science and technology resonated with his own aspirations.

“I was fortunate to have a supportive mentor at NASA who had been encouraging me since my time as an academic researcher,” he said. “My mentor showed me the value of our expertise and work that aligned with NASA’s mission. I saw it as an excellent opportunity for me to utilize my mathematical and problem-solving skills to support those missions.”

In addition to his role at Marshall, Maskey is also on a detail to NASA Headquarters, where he is the data science and innovation lead in the Chief Science Data Office within the agency’s Science Mission Directorate.

“An element of my position is to encourage and support the development of collaborative AI projects,” Maskey said. “This involves bridging various divisions and teams across the Science Mission Directorate to fully leverage AI’s potential.”

He said his work is a combination of personal growth, impact, and the joy of sharing knowledge.

“What really motivates me is the desire for knowledge and the continuously evolving landscape of data science,” Maskey said. “Collaborating with other scientists, sharing knowledge, and working together on projects amplify my passion for continuous learning. I’m motivated by the potential to harness new tools and technologies to push the boundaries of what we can achieve in scientific research. This includes leveraging artificial intelligence, machine learning, and other cutting-edge technologies to solve problems more efficiently and effectively.”

Question: What are some of your primary responsibilities?

Maskey: At Marshall, I lead the development and deployment of cutting-edge data systems that facilitate interactive visualization, processing, and scalable analysis, enhancing our ability to understand and interpret science data for actionable insights. My work involves leading research and development efforts in data science tailored to the unique demands of the scientific community. This encompasses staying at the forefront of data science innovations and employing novel methodologies to address science challenges.

At NASA Headquarters, in addition to fostering collaborative AI projects, I am tasked with developing a comprehensive data science strategy for the SMD, aiming to integrate data science into our science missions. My other role is education and training of the SMD community in data science practices and methodologies, ensuring our teams are equipped with the knowledge and tools necessary for advancing our mission.

Question: What excites you most about your work within the Science Mission Directorate?

Maskey: The work we are doing at NASA, particularly within my team, excites me on multiple fronts. At the core of the opportunity is NASA’s Open Science Initiative. Our team is developing open science solutions that are inclusive, widely adopted, and enhancing the user experience to achieve scientific goals.

One of the most important aspects of my role is the ability to work across domains and science divisions. This cross-disciplinary approach is crucial for the future of science, where the integration of knowledge from different fields can lead to groundbreaking discoveries and advancements. It allows us to leverage the diverse expertise and perspectives within NASA, fostering innovation that no single team could achieve alone.

Maximizing the investments NASA has made in science missions is also a key part of my work. This means not only ensuring the success of these missions but also extending their impact through the application of data science, well beyond the life of the missions.

Finally, the prospect of helping to upscale the science community with the latest tools and technologies is incredibly motivating. It’s about empowering scientists with the capabilities they need to push the boundaries of what’s possible.

Question: What has been the proudest moment of your career and why?

Maskey: Choosing a single moment is difficult. Broadly speaking, these achievements fall into two primary categories: the success of my team and our impactful contributions at the convergence of data science innovations and scientific knowledge extraction.

Above all, the growth and success of individuals within our team represents some of the proudest moments in my career. Seeing many team members, some who began as students in my project, evolve into successful professionals within NASA and in the industry brings me the greatest satisfaction. Their growth is not merely a reflection of their hard work but also highlights the supportive and development-focused culture we’ve fostered. Each success story is a reminder of the powerful role mentorship and leadership play in shaping futures.

My role in pioneering data science initiatives, particularly in AI and machine learning within the Earth Science branch at Marshall, represents a significant career highlight. The inception and growth of these activities into a core component of our expertise and project portfolio mark a significant shift from our traditional role. The recognition of our work, both within NASA and by external communities, is a testament to the collective effort, innovation, and forward thinking. It symbolizes a shift in how we approach scientific inquiry, underscoring the critical role of data science in advancing our understanding of the Earth and beyond.

Question: What advice do you have for employees early in their NASA career or those in new leadership roles?

Maskey: Embarking on a career at NASA or stepping into a leadership role within this organization opens many potentials and opportunities for growth. My path to NASA was not straightforward. Early rejection from an internship taught me the invaluable lesson that setbacks are not roadblocks but steppingstones. Each challenge you face is an opportunity to learn, grow, and prove yourself. Embrace these challenges with a growth mindset. The desire for continuous improvement is crucial. Remain curious, and seek to learn from every experience. This passion for learning will not only fuel your personal growth but also enhance your contributions to your team and the broader NASA mission.

Collaboration is at the heart of NASA’s many achievements. Whether you’re just starting or stepping into a leadership role, actively seek to build inclusive, interdisciplinary teams where diverse perspectives are valued. Encourage open dialogue, share knowledge, and create an environment where everyone feels empowered to contribute their best.

Finally, remember the why behind your work. The projects and missions you contribute to at NASA have the potential to make significant impacts on our understanding of our planet, the universe, and beyond. Let this purpose drive you and guide your leadership.

Question: What do you enjoy doing with your time while away from work?

Maskey: Outside of work, I enjoy spending time with my family. I have a teenage son, who shares my passion for math and sports. Unlike me, he’s a talented soccer player and involved in competitive play. Supporting him in his soccer activities means we travel frequently, which turns into exciting adventures for our entire family, allowing us to discover new places. I also enjoy volunteering whenever possible. Whether it’s related to education, sports, or any other area where I can contribute, volunteering offers a sense of purpose outside of work.

Smith, a Media Fusion employee and the Marshall Star editor, supports the Marshall Office of Communications.

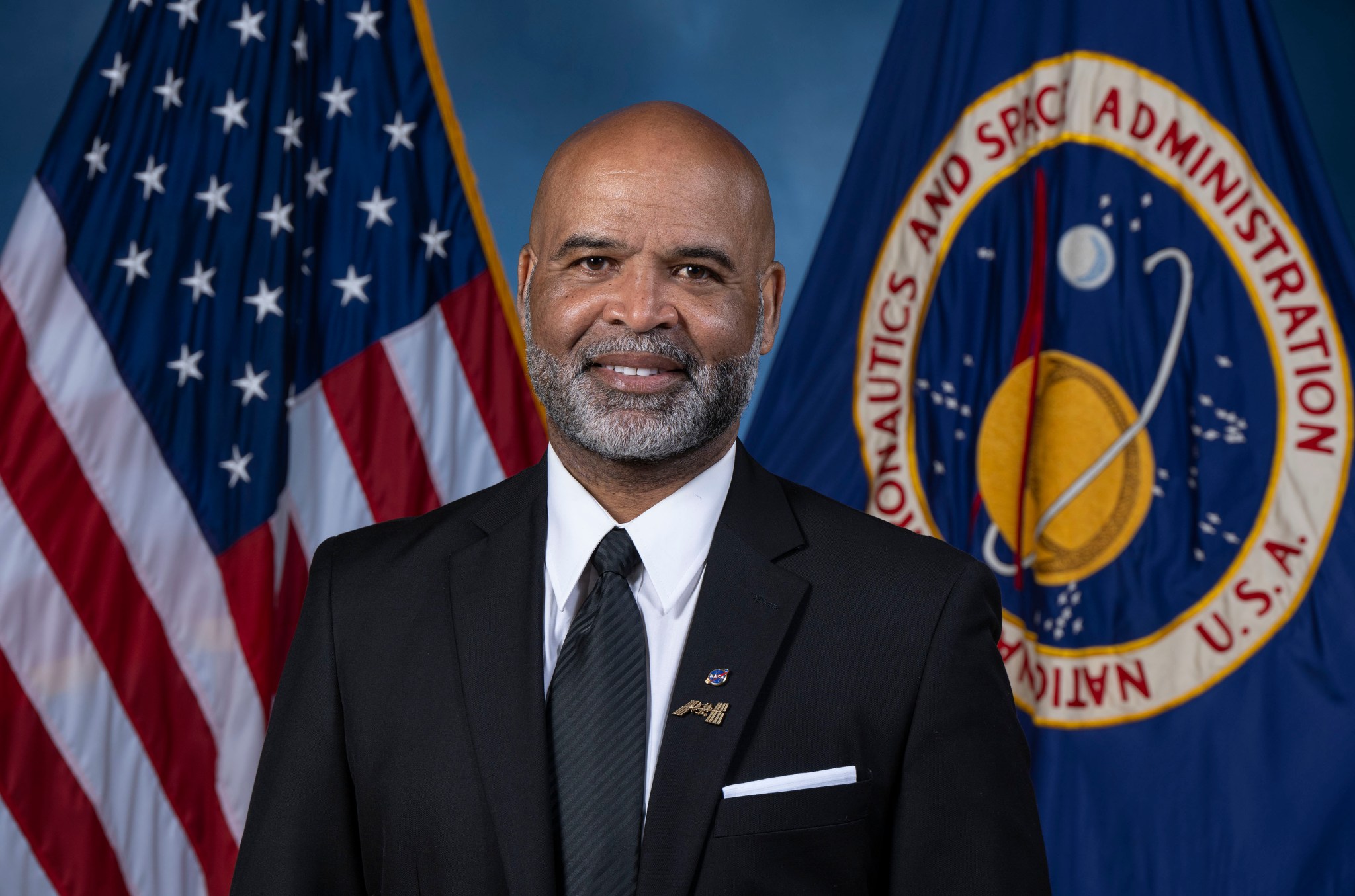

Black History Month Profile: Joseph Gaines on Endurance

By Celine Smith

Joseph Gaines joined the U.S. Army Reserve while he was a student at the University of Memphis in Tennessee. But there was one hitch – as a reservist he was stationed in Mobile, Alabama, more than 350 miles away from the school.

So, each Sunday after Gaines finished his drills at 4 p.m., he made the six-plus hour commute from Mobile to Memphis to attend his 8 a.m. class the following Monday.

“It was rough,” Gaines said, briefly laughing at the memory. “Of course, that was a lot of sacrifice.”

Gaines joined the Army Reserve to financially support his education. Gaines’ dedication to his education reflects the effort and work ethic still present with him after 34 years with NASA’s Marshall Space Flight Center. It’s also a reflection of the values his mother instilled in him.

“She’s my biggest influence,” Gaines said. “She was a single parent taking care of two boys, while attending night school and working a full-time job.”

Along with his mother, Gaines said his high school math teacher, Melton McMullan, had an immense influence on him. McMullan constantly told Gaines he had what it took to become an engineer after noticing his strength in the subject.

While Gaines majored in electrical engineering at the University of Memphis, he could not have imagined a career with NASA. “I was so enamored with NASA, but I didn’t even think I had the opportunity to work there,” Gaines said.

His stance changed in one day.

“I was a junior sitting in my power systems class,” Gaines said. “A senior walked in wearing a suit, so I asked him where he came from. He told me an interview and I asked with who. He said NASA and then told me where the interviewer was.”

Gaines left during the middle of class and headed for his dorm room. He changed clothes, grabbed his resume, found the interviewer, and got an interview. Two weeks later, he was juggling a NASA co-op role while also in the Army Reserve, all while completing his degree.

Thirty-four years later, Gaines is the manager of Marshall’s Safety and Quality Assurance Department. He ensures the continuous improvement of safety by overseeing industrial safety and pressure systems, along with quality assurance for the center and its contracted industrial activities.

“I really enjoy making sure that Marshall has quality flight hardware and a safe work environment while doing so,” Gaines said.

His journey at Marshall began with Frank Nola, an esteemed engineer who taught him everything about circuits while he was in control systems during his co-op. “It was fascinating,” Gaines said. “I developed a lot of skills and confidence working with senior level engineers in my early career.”

After graduating in 1989, Gaines began as a technical engineer at Marshall. He developed control software for the Dynamic Solar Simulator, the RATT (Remote Automated Target Transporter), and a graphical user interface for an Advanced Video Guidance Sensor. He also designed control electronics for the RATT and Dynamic Solar Simulator.

“Early in my career, I worked in the Flight Robotics Lab,” Gaines said. “I absolutely loved that job! So much so, I saw myself retiring doing that type of work. Later on, I decided to develop my career in other skillsets. I found leadership roles just as rewarding and challenging as well.”

In 2008, Gaines became the deputy avionics and software lead for the Ares V heavy lift rocket. In 2011, he served as the avionics and software lead engineer for the SLS (Space Launch System) in support of the Spacecraft and Payload Integration Office. Gaines was the department lead engineer for the ECLSS (Environmental Control Life Support System) in 2012. He later became the senior integration lead for SLS secondary payloads safety in 2015.

Gaines served as the Quality Assurance (QA) branch chief in 2017. He was in communication with QA civil and contract engineers, ensuring all spaceflight hardware met quality requirements. In 2018, before becoming manager of the Safety and Quality Assurance department, he was the technical assistant there. He managed Marshall’s workmanship standards and electrostatic programs while being a representative for NASA’s Safety Culture Working Group.

Gaines lives in Harvest, Alabama, and has three adult children. His brother, Darryl Gaines, is the acting deputy for the Commercial Low Earth Orbit Development Program at NASA’s Johnson Space Flight Center.

Joseph Gaines was selected as the 121st U.S. Army Reserve Soldier of the Year in 1992.

“I think having a good work ethic, developing more than one skill, along with being a good communicator and detail oriented is needed to be successful,” he said. “Also learning from others as you branch out is very helpful.”

Second in a two-part series in the Marshall Star highlighting team members during Black History Month.

Smith, a Media Fusion employee, supports the Marshall Office of Communications.

Combatting Organizational Silence Focus of Mission Success Forum; Tag Taglilatelo Receives Golden Eagle Award

By Wayne Smith

Bob Conway, deputy director of the NASA Safety Center, discussed organizational silence and how it relates to safety and mission success during a Shared Experiences Forum at the agency’s Marshall Space Flight Center on Feb. 22.

The theme of the forum was “The Impact of Breaking the Silence.” Conway discussed factors that can contribute to organizational silence, like failing to call attention to problems that can potentially result in mission failures. The hybrid event was part of the Mission Success is in Our Hands safety initiative and held in Activities Building 4316.

Conway described organizational silence as a collective phenomenon of saying or doing little in response to perceived problems. He said organizations may verbalize openness but send conflicting signals to employees to keep quiet. Conway pointed to the space shuttle Challenger accident as an example of organizational silence.

“Are we allowing our folks to talk,” Conway said. “Are we hearing what they have to say, and are we putting it all in context?”

Conway said an organization’s culture has an impact on safety. He referenced the NASA Safety Reporting System as an internal method for anonymously reporting safety concerns.

“An organizational excellence DNA is learning lessons from the past, applying it forward, and most importantly, speaking up when we have that,” Conway said. “The constant pursuit of excellence is what we always need to be doing. When you achieve excellence, safety and a lot of other things become effortless byproducts of it.”

Mission Success is in Our Hands is a safety initiative collaboration between Marshall and Jacobs Engineering. The goal is to help team members make meaningful connections between their jobs and the safety and success of NASA missions.

As part of the forum, Mission Success is in Our Hands presented its 39th Golden Eagle Award to Tag Taglilatelo of Jacobs Space Exploration Group. The award recognizes individuals who have contributed to flight safety and mission assurance above and beyond their normal work requirements.

Bill Hill, director of Safety and Mission Assurance at Marshall, said Taglilatelo noticed an incorrect valve configuration that could have caused a hydrazine leak during an SLS (Space Launch System) booster test. As a result of his observation, the configuration was modified, leading to a safe test.

Management or peers can nominate any team member for the Golden Eagle Award. Honorees are typically recognized at quarterly Shared Experiences forums.

Smith, a Media Fusion employee and the Marshall Star editor, supports the Marshall Office of Communications.

Listen to the Universe: New NASA Sonifications and Documentary

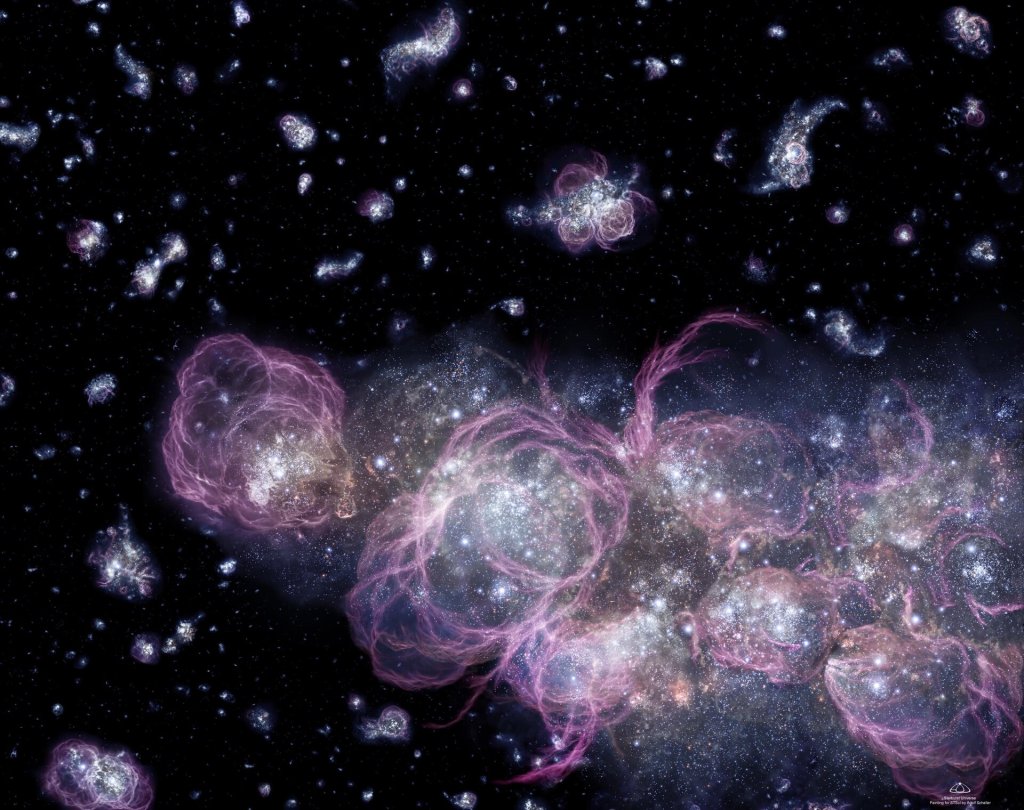

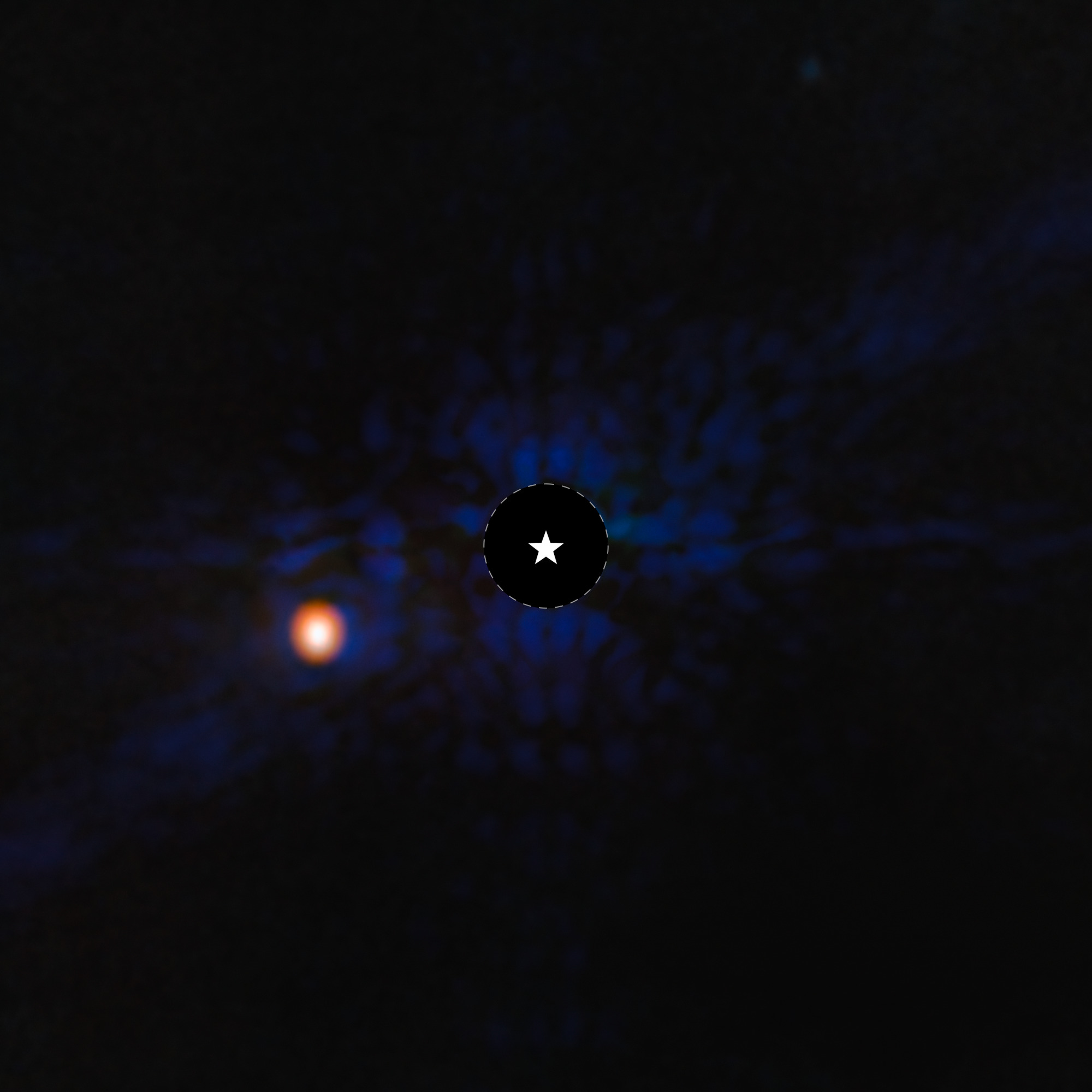

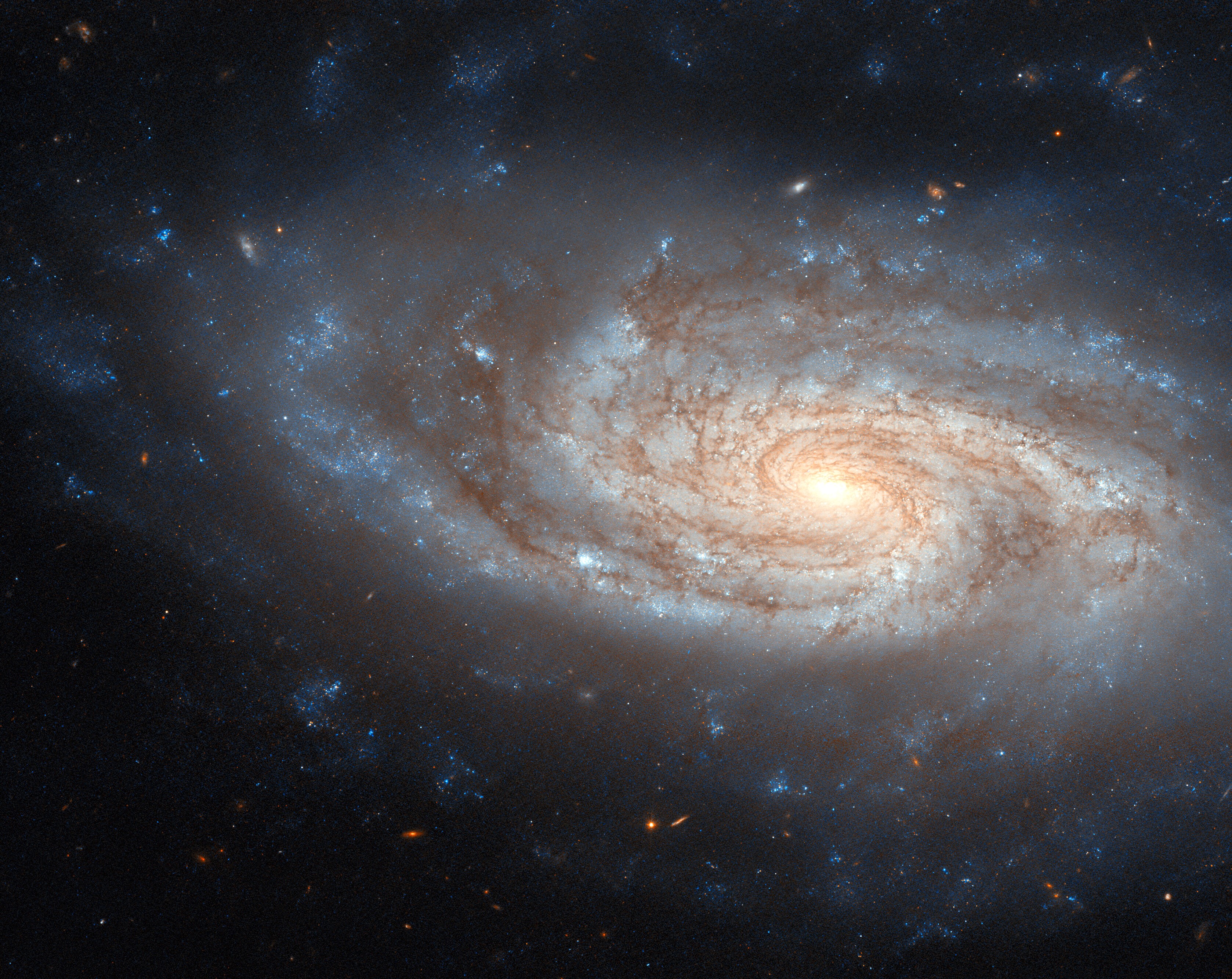

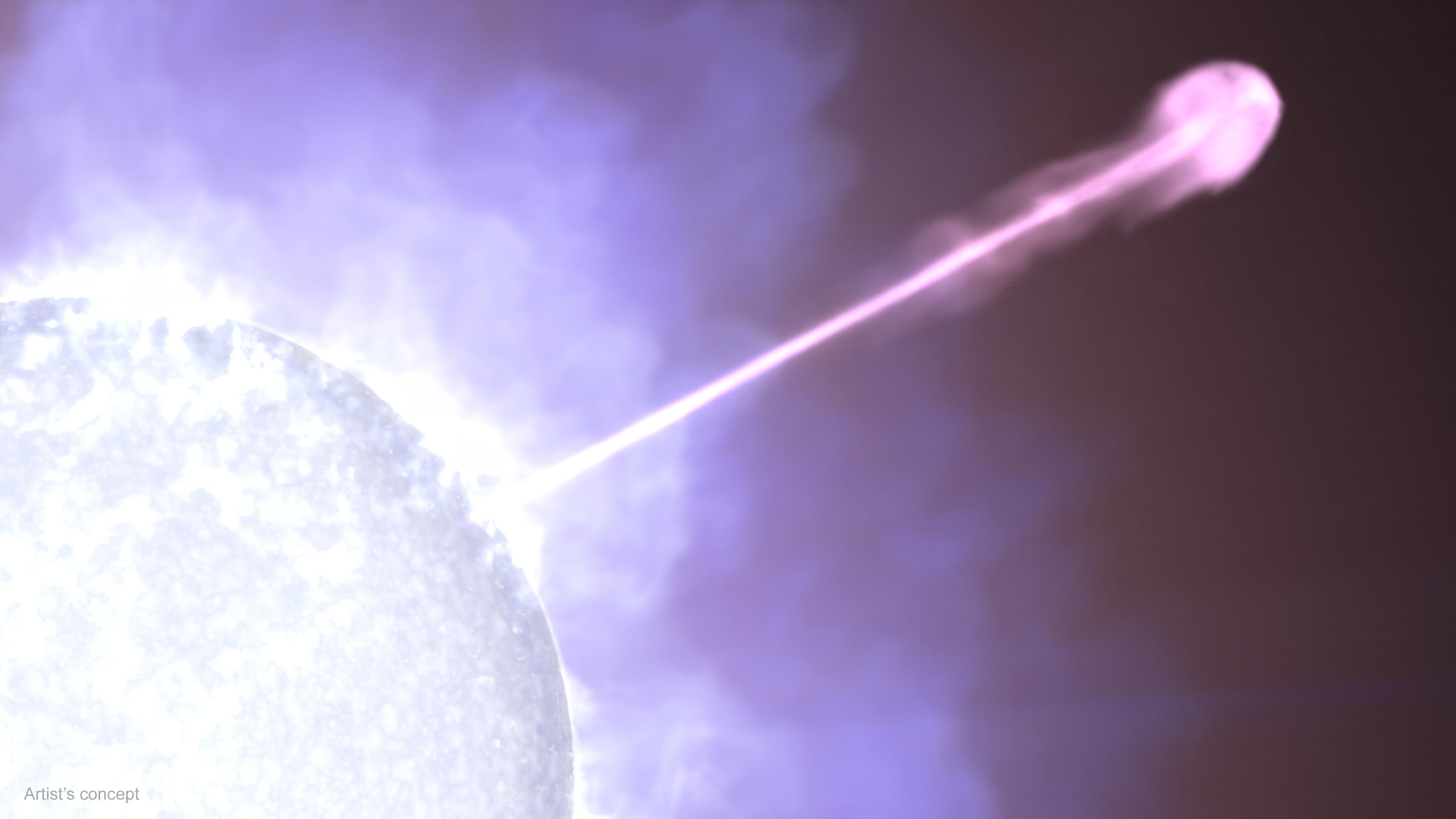

Three new sonifications of images from NASA’s Chandra X-ray Observatory and other telescopes have been released in conjunction with a new documentary about the project that makes its debut on the NASA+ streaming platform.

Sonification is the process of translating data into sounds. In the case of Chandra and other telescopes, scientific data are collected from space as digital signals that are commonly turned into visual imagery. The sonification project takes these data through another step of mapping the information into sound.

The new sonifications feature different objects observed by NASA telescopes.

The first is MSH 11-52, a supernova remnant blowing a spectacular cloud of energized particles resembling the shape of a human hand, seen in data from Chandra, NASA’s Imaging X-ray Polarimetry Explorer, or IXPE, and ground-based optical data.

M74 is a spiral galaxy like our Milky Way and this sonification combines data taken with NASA’s James Webb and Hubble Space Telescopes as well as X-rays from Chandra.

The third object in this new sonification trio is nicknamed the Jellyfish Nebula, also known as IC 443. These data include X-rays from Chandra and the now-retired German ROSAT mission as well as radio data from NSF’s Very Large Array and optical data from the Digitized Sky Survey.

The new documentary, “Listen to the Universe,” now available on NASA+ explores how these sonifications are created and profiles the team that makes them possible.

Started in 2020, the NASA sonification project built off of other Chandra projects aimed at reaching blind and visually-impaired audiences. It has since shown to be meaningful to that community but also impacts much wider audiences, finding listeners through traditional and social media around the world.

“We are so excited to partner with NASA+, along with her collaborators at SYSTEMS Sounds, to help tell the story about NASA’s sonification project,” said Kimberly Arcand, Chandra’s Visualization and Emerging Technology Scientist, who leads the sonification efforts. “It’s wonderful to see how this project has grown and reached so many people.”

NASA+ is the agency’s new streaming platform, delivering video and other content about NASA to the public whenever and wherever they want to access it. The on-demand streaming service is available to download on most major platforms via the NASA App on iOS and Android mobile and tablet devices, as well as streaming media players Roku and Apple TV.

“Sonifications add a new dimension to stunning space imagery, and make those images accessible to the blind and low-vision community for the first time,” said Liz Landau, who leads multimedia efforts for NASA’s Astrophysics Division at NASA Headquarters and oversaw production of the “Listen to the Universe” documentary. “I was honored to help tell the story of how Dr. Arcand and the System Sounds team make these unique sonic experiences and the broad impact those sonifications have had.”

More information about the NASA sonification project through Chandra, which is made in partnership with NASA’s Universe of Learning, can be found here.

NASA’s Marshall Space Flight Center manages the Chandra program. The Smithsonian Astrophysical Observatory’s Chandra X-ray Center controls science operations from Cambridge, Massachusetts, and flight operations from Burlington, Massachusetts.

NASA’s Universe of Learning materials are based upon work supported by NASA under cooperative agreement award number NNX16AC65A to the Space Telescope Science Institute, working in partnership with Caltech/IPAC, Center for Astrophysics | Harvard & Smithsonian, and the Jet Propulsion Laboratory.

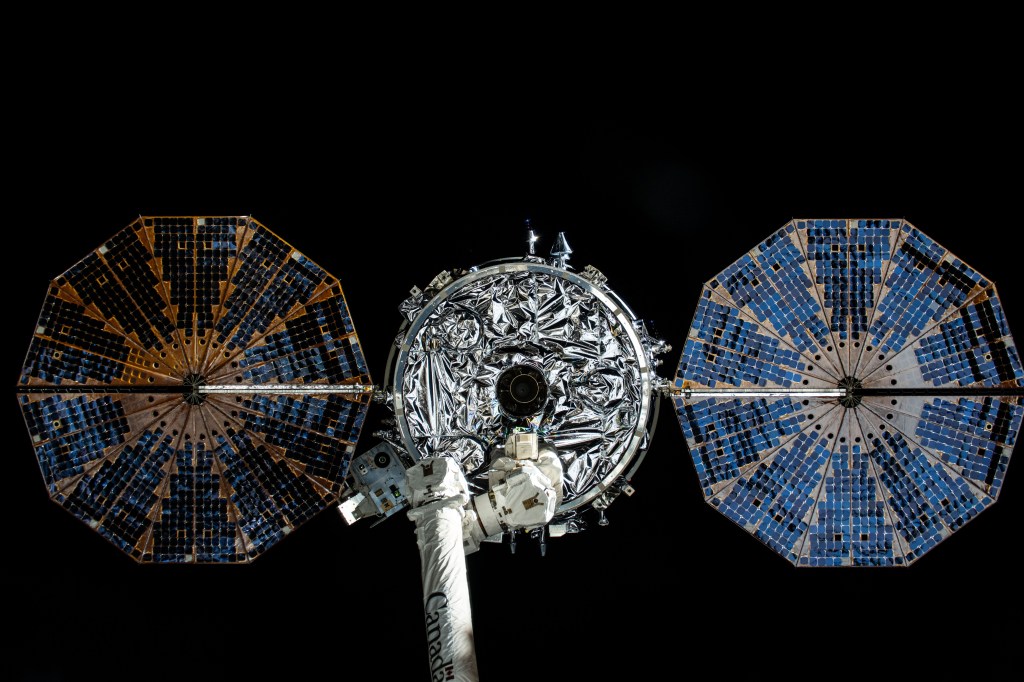

NASA Sets Coverage for Agency’s SpaceX Crew-8 Launch, Docking

NASA will provide coverage of the upcoming prelaunch and launch activities for the agency’s SpaceX Crew-8 mission with astronauts to the International Space Station.

The launch is targeted for 11:04 p.m. CST, Feb. 29, from Launch Complex 39A at NASA’s Kennedy Space Center. The targeted docking time is about 6 a.m. on March 2.

Crew arrival will be available on Kennedy’s streaming channels including YouTube and X. Coverage of launch, the postlaunch news conference, and docking will be available on NASA+, NASA Television, the NASA app, YouTube, and the agency’s website. NASA also will host an audio-only post-Flight Readiness Review news teleconference. Learn how to stream NASA TV through a variety of platforms including social media.

The Crew-8 launch will carry NASA astronauts Matthew Dominick, Michael Barratt, and Jeanette Epps, as well as Roscosmos cosmonaut Alexander Grebenkin.

As part of the agency’s Commercial Crew Program, the mission marks the eighth crew rotation mission and the ninth human spaceflight mission for NASA to the space station supported by a SpaceX Dragon spacecraft since 2020. Endeavour is the name of this Dragon spacecraft.

A flag for Crew-8 was raised Feb. 28 at the HOSC (Huntsville Operation Support Center) at NASA’s Marshall Space Flight Center. The HOSC is a multi-mission facility that provides engineering and mission operations support for NASA’s Commercial Crew Program, Space Launch System rocket, Artemis lunar science missions, and science conducted on the space station. A Marshall team that is part of the agency’s Commercial Crew Program will be supporting Crew-8 launch operations from inside the HOSC.

The Payload Operations Integration Center within HOSC operates, plans, and coordinates the science experiments onboard the space station 365 days a year, 24 hours a day.

Former Student Launch Competitor Turns Experience into NASA Engineering Career

By Jessica Barnett

Sometimes, all it takes is a few years and the right people to completely change a person’s career trajectory. One such example is Meredith Patterson, an aerospace engineer at NASA’s Marshall Space Flight Center, who went from knowing little to nothing about rockets to being part of the team that is working to put humans back on the Moon.

She credits her success in large part to NASA’s Student Launch, which not only helped her uncover her passion for aerospace engineering but gave her the knowledge and experience she needed to get where she is today.

The annual Student Launch competition invites student teams from across the U.S. to spend nine months designing, building, and testing a high-powered rocket carrying a scientific or engineering payload. The hands-on, research-based engineering activity culminates each year in a final launch in Huntsville. This year’s challenge conclusion is set for April 10-14, with the final launch date set for April 13 at Bragg Farms in Toney, Alabama.

While Student Launch is open to students as young as sixth grade, Patterson was in her junior year of high school when she learned about the competition during a tour of North Carolina State University.

“When I walked into the rocketry lab there, I knew then, however many years it was going to take, I wanted to be the person who was able to run that and help put together everything for us to be successful in Student Launch,” Patterson said.

She attended North Carolina State for five years, participating in each year’s Student Launch competition and leading the team to a fourth-place win during her final year. She received her Level I and Level II certifications from Tripoli Rocketry Association through Student Launch, and she was able to connect with mentors from Tripoli and the National Rocketry Association that helped her get the hands-on experience and technical know-how she believes are key to success in the aerospace industry.

“My leadership skills grew, my system engineering skills grew, and my technical writing skills grew,” Patterson said. “Having mentors through the competition allowed me to ask questions and learn on the technical side of things, too. I think I use more information from Student Launch day to day than from almost any of my classes in college.”

She said attending an engineering camp at 16 years old first unlocked her interest in spaceflight and rocketry, but it was through Student Launch that she got to really dive in and deepen her passion.

“It’s crazy to think that less than 10 years ago, I had never even built a rocket, and now I can build Level II-sized rockets on my own and I’m actively working on the biggest solid rocket boosters in the world,” Patterson said. “Just in the past year, I’ve gone from the L-class motor that we used for Student Launch to casting 11-inch motors to now actively watching the casting of the SLS (Space Launch System) boosters.”

Student Launch is part of NASA’s Artemis Student Challenges. Seventy teams representing 24 states and Puerto Rico were selected to compete in the 2024 Student Launch Challenge.

Marshall hosts the Student Launch challenge with management support provided by NASA’s Office of STEM Engagement – Southeast Region. Funding is provided, in part, by NASA’s Space Operations Mission Directorate and NASA’s Next Gen STEM project.

Barnett, a Media Fusion employee, supports the Marshall Office of Communications.

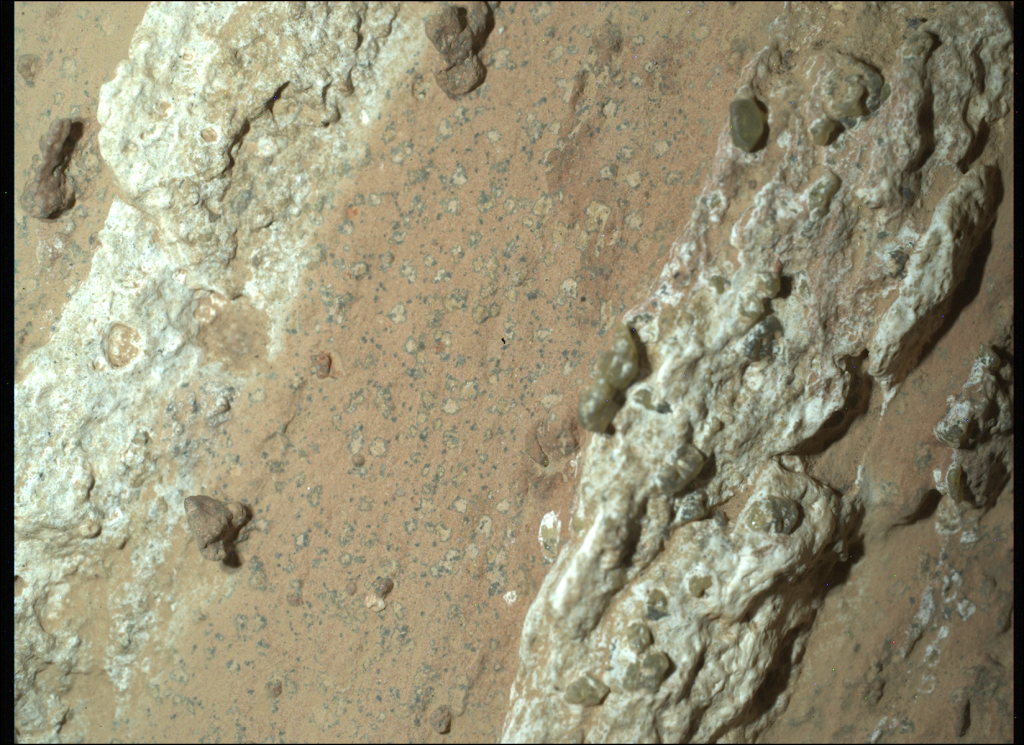

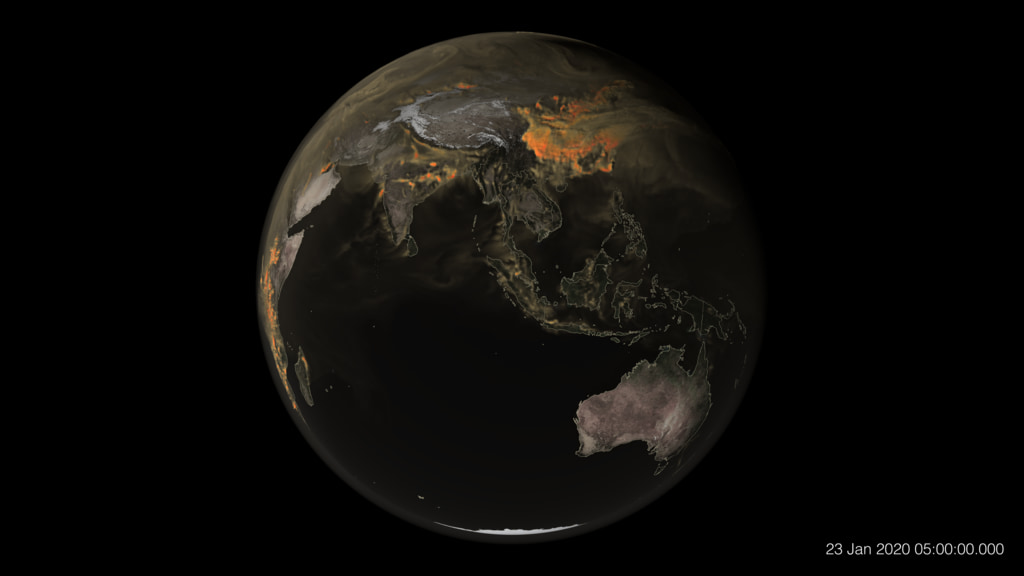

NASA’s Planetary Protection Team Conducts Vital Research for Deep Space Missions

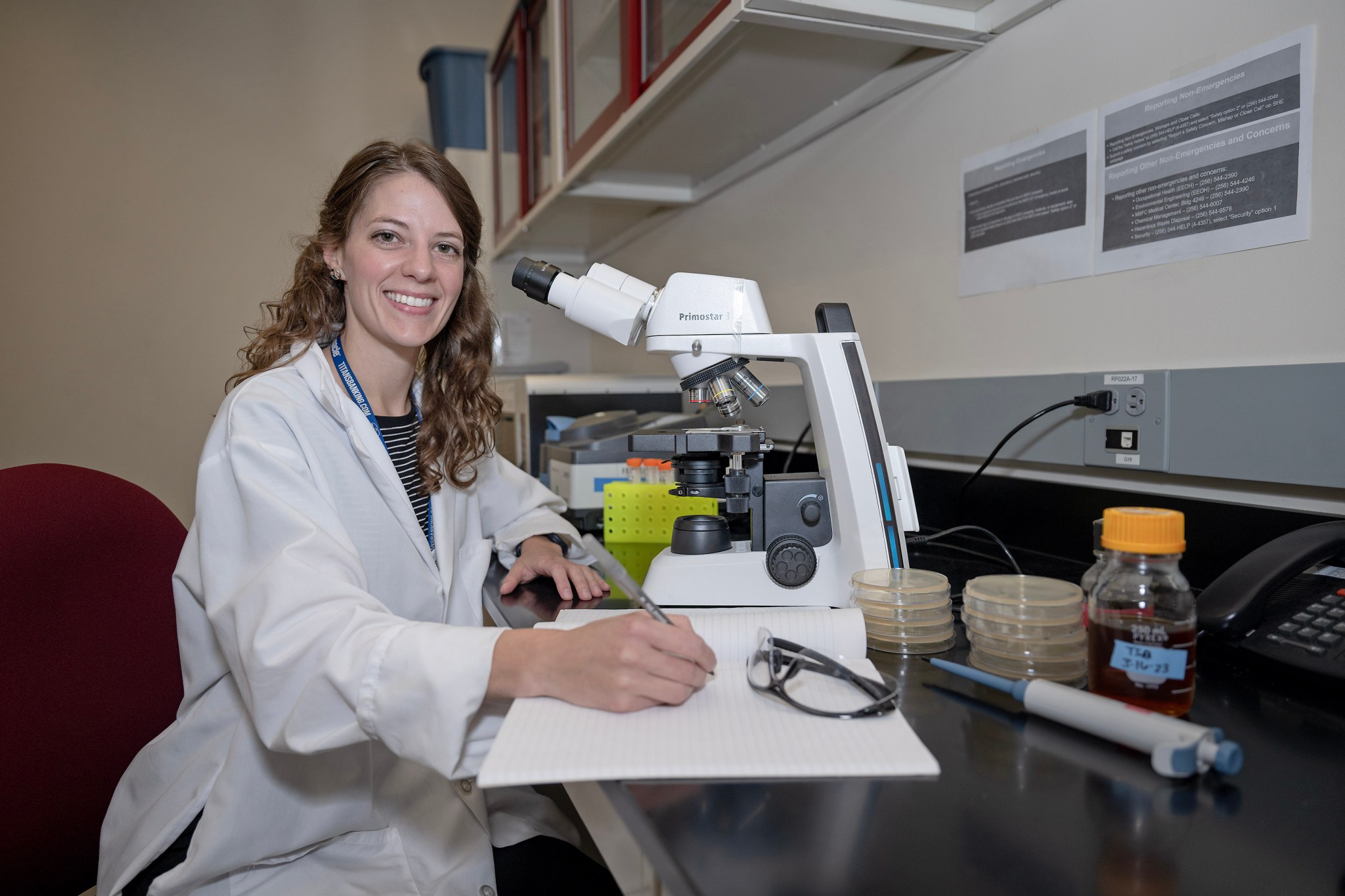

By Celine Smith

As NASA continues its exploration of the solar system, including future crewed missions to Mars, experts in the agency’s Office of Planetary Protection are developing advanced tactics to prevent NASA expeditions from introducing biological contaminants to other worlds.

At NASA’s Marshall Space Flight Center, the Planetary Protection team is contributing to this work – pursuing new detection, cleaning, and decontamination methods that will protect alien biospheres, safeguard future planetary science missions, and prevent potentially hazardous microbes from being returned to Earth. The Planetary Protection team is a part of the Space Environmental Effects team in Marshall’s Materials and Processes Laboratory.

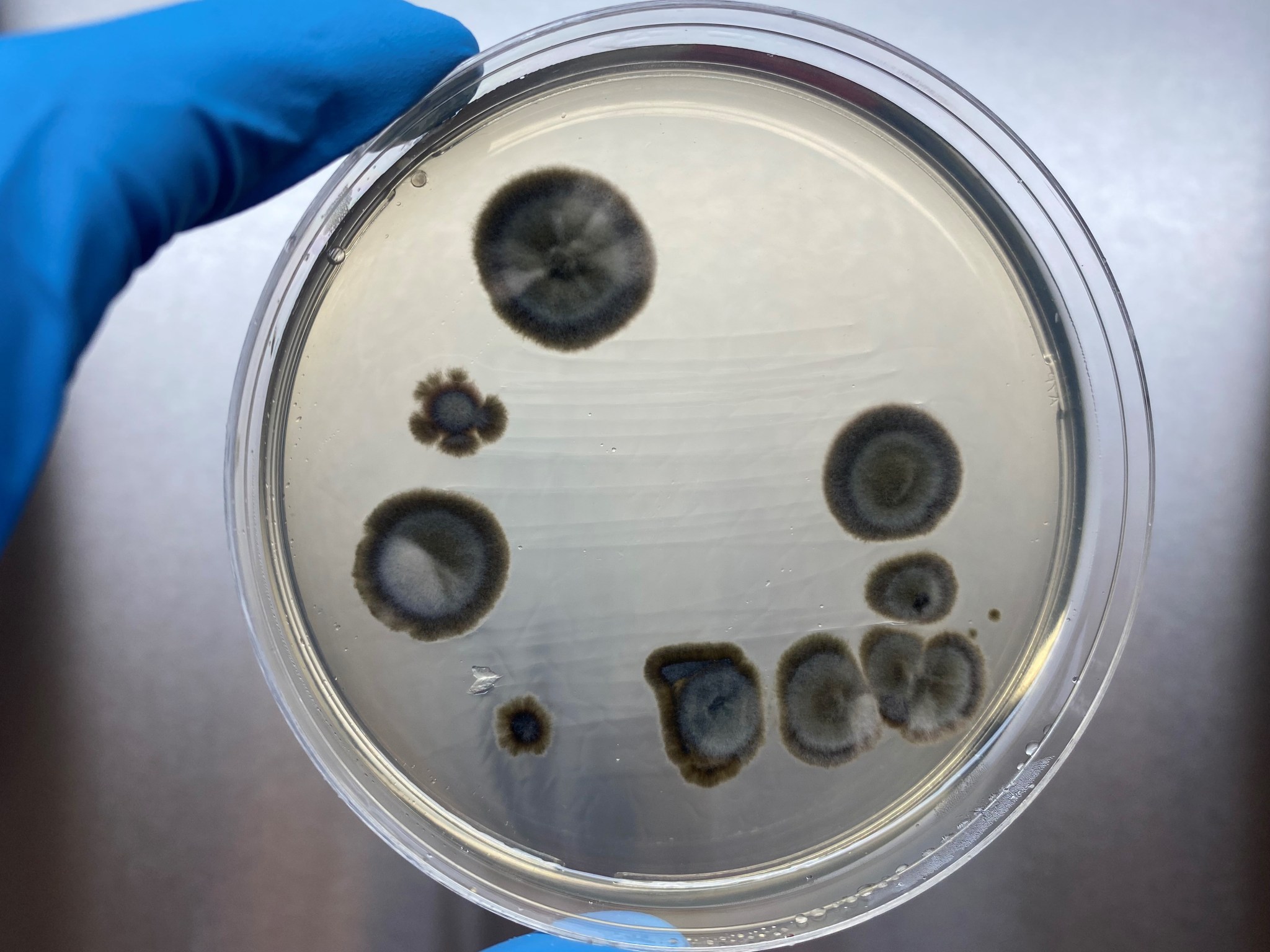

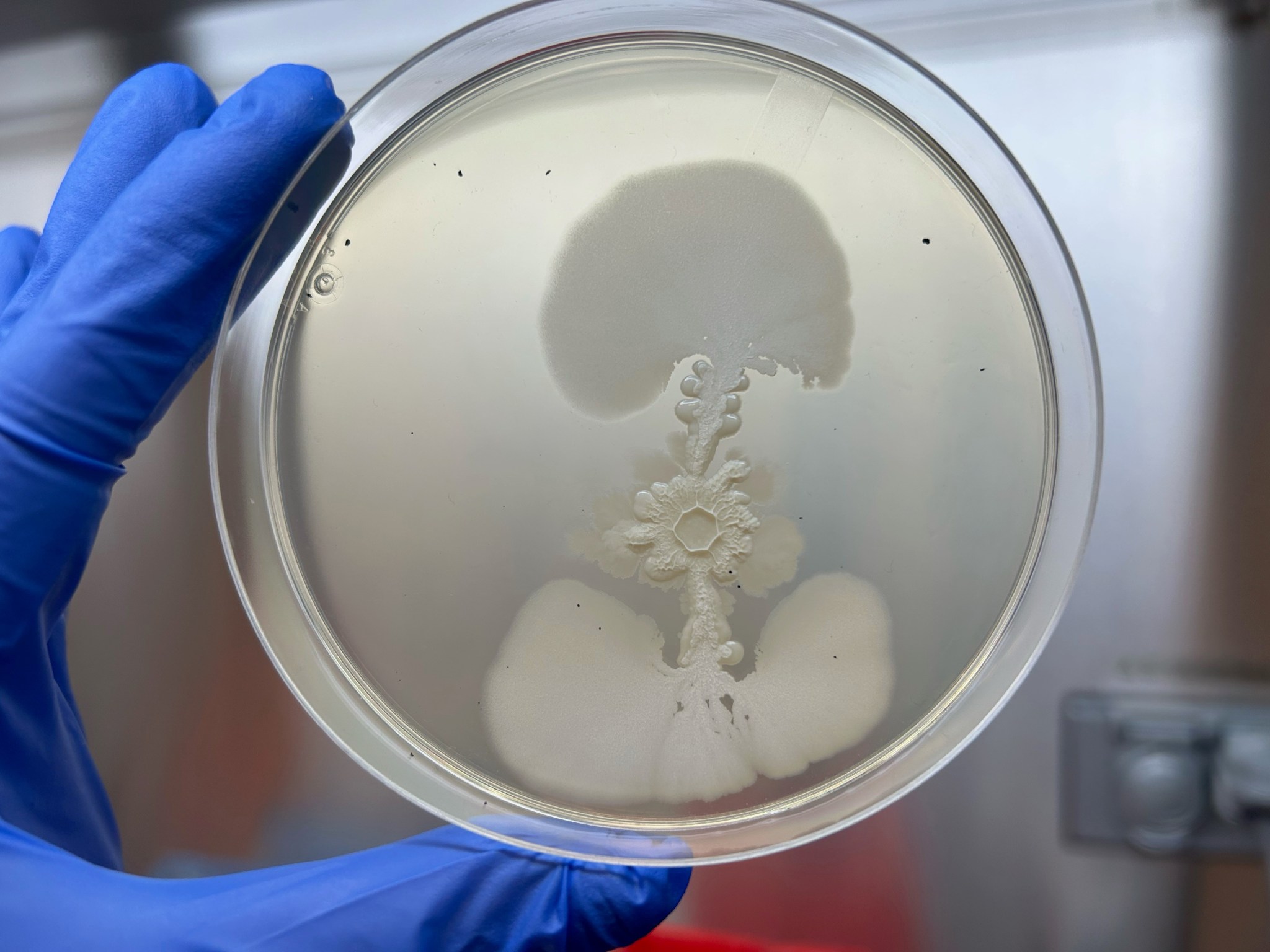

Planetary Protection microbiologist Chelsi Cassilly said much of Planetary Protection focuses on “bioburden,” which is typically considered the number of bacterial endospores (commonly referred to as “spores”) found on and in materials. Such materials can range from paints and coatings on robotic landers to solid propellants in solid rocket motors. NASA currently requires robotic missions to Mars meet strict bioburden limits and is assessing how to apply similar policies to future, crewed missions to the Red Planet.

“It’s impossible to eliminate microbes completely,” Cassily said. “But it’s our job to minimize bioburden, keeping the probability of contamination sufficiently low to protect the extraterrestrial environments we explore.”

Currently, Marshall’s Planetary Protection research supports NASA’s Mars Ascent Vehicle, a key component of the planned Mars Sample Return campaign, and risk-reduction efforts for the Human Landing System program.

Critically, Planetary Protection prevents the introduction of microbes from Earth onto planetary bodies where they might proliferate and interfere with scientific study of past or current life there. If Earth’s microbes were to contaminate samples collected on Mars or Europa, the scientific findings would be an inaccurate depiction of these environments, potentially precluding the ability to determine if life ever existed there. Preserving the scientific integrity of these missions is of the utmost importance to Cassilly and her team.

Contamination mitigation tactics used in the past also may not work with modern hardware and materials. For the Viking missions to Mars, NASA employed a total spacecraft HMR (heat microbial reduction) process, a prolonged exposure to high temperatures to kill off or minimize microbes. As spacecrafts advance, NASA is more discerning, using HMR for components and/or subassemblies instead of the entire spacecraft.

According to Cassilly, HMR may not always be an ideal solution because, extended time at high temperatures required to kill microbes can degrade the integrity of certain materials, potentially impacting mission success. While this is not a problem for all materials, there is still a need to expand NASA’s repertoire of acceptable microbial reduction techniques to include ones that may be more efficient and sustainable.

To contribute to NASA’s Planetary Protection efforts, Cassilly undertook a project – funded by a Jacobs Innovation Grant – to build a microbial library that could better inform and guide mitigation research. That meant visiting cleanrooms at Marshall to collect prevalent microbes, extracting DNA, amplifying specific genes, and submitting them for commercial sequencing. They identified 95% of the microbes within their library which is continually growing as more microbes are collected and identified.

The Planetary Protection team is interested in taking this work a step further by exposing their microbial library to space-like stressors – including ultraviolet light, ionizing radiation, temperature extremes, desiccation, and vacuum – to determine survivability.

“The research we’re doing probes at the possibility of using space itself to our advantage,” Cassilly said.

Cassilly and Marshall materials engineers also supported a study at Auburn University in Auburn, Alabama, to determine whether certain manufacturing processes effectively reduce bioburden. Funded by a NASA Research Opportunity in Space and Earth Sciences grant, the project assessed the antimicrobial activity of various additives and components used in solid rocket motor production. The team is currently revising a manuscript which should appear publicly in the coming months.

Cassilly also supported research by Marshall’s Solid Propulsion and Pyrotechnic Devices Branch to assess estimates of microbial contamination associated with a variety of commonly used nonmetallic spacecraft materials. The results showed that nearly all the materials analyzed carry a lower microbial load than previously estimated – possibly decreasing the risk associated with sending these materials to sensitive locations.

Such findings benefit researchers across NASA who are also pursuing novel bioburden reduction tactics, Cassilly said, improving agencywide standards for identifying, measuring, and studying advanced planetary protection techniques.

“Collaboration unifies our efforts and makes it so much more possible to uncover new solutions than if we were all working individually,” she said.

NASA’s Office of Planetary Protection is part of the agency’s Office of Safety and Mission Assurance at NASA Headquarters. The Office of Planetary Protection oversees bioburden reduction research and development of advanced strategies for contamination mitigation at Marshall; NASA’s Jet Propulsion Laboratory; NASA’s Goddard Space Flight Center; and NASA’s Johnson Space Center.

Smith, a Media Fusion employee, supports the Marshall Office of Communications.

I Am Artemis: Josh Whitehead

Launching a rocket to the Moon takes perseverance and diligence. Josh Whitehead – a world-class engineer, race-winning long-distance runner, and father – knows that it also takes a good attitude.

“Positive energies are vital, particularly when working through challenges,” Whitehead said. “Challenges are opportunities to learn and grow. There’s always more than one way; always more than one solution.”

Whitehead’s job as the associate manager for the Stages Office of NASA’s SLS (Space Launch System) rocket supports design, development, certification, and operation of the 212-foot-tall SLS core stage. The massive core stage with two propellant tanks that collectively hold more than 733,000 gallons of super-cold propellant is one of the largest cryogenic propulsion rocket stages.

Whitehead joined the SLS Program, based at NASA’s Marshall Space Flight Center, early on during the COVID-19 pandemic. Complicating matters further, in June 2020, Whitehead was injured in a hit-and-run cycling accident so devastating that it separated his right shoulder and broke his back in three places.

Amid his necessary rehabilitation and surgeries, Whitehead learned to type left-handed and one-handed. Through it all, he was working to further the agency’s Artemis campaign and preparing for the first launch of the SLS rocket for Artemis I.

Now back to running and having participated in a local charity race every year since 2007, the avid runner and engineer will tell you that, like a recovery, the road to launch is not a sprint. It’s a cadenced effort as teams across the country worked toward a common goal. During his rehabilitation and path to run again, Whitehead and his team finished assembling the first SLS core stage and the successful eight-part Green Run test campaign of the entire stage at NASA’s Stennis Space Center prior to the Nov. 16, 2022, Artemis I launch.

Whitehead and his team are now manufacturing and processing core stages for multiple Artemis missions, including Artemis II in 2025, the first crewed flight under Artemis that will test the life-supporting systems in the Orion spacecraft ahead of future lunar missions.

Whitehead holds multiple advanced degrees in engineering from Auburn University and the University of Alabama in Huntsville. He got his start in the aerospace industry conducting subscale motor manufacturing tests for NASA’s Space Shuttle Program. From systems engineering supporting NASA’s Constellation Program and verifying and validating the solid rocket booster element in the SLS Program’s early days, to qualification activities and safety and mission assurance for the Artemis I flight, Whitehead has a passion for cross-discipline work.

“Being able to work systems engineering activities and multiple elements is all complementary,” he said. “But the common thread is it’s about the people, the process, and the product.”

SLS is part of NASA’s backbone for deep space exploration, along with the Orion spacecraft, advanced spacesuits and rovers, the Gateway in orbit around the Moon, and commercial human landing systems. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.

NASA Conducts 7th in Series of RS-25 Engine Tests at Stennis

NASA conducted an RS-25 hot fire Feb. 23, moving one step closer to production of new engines that will help power the agency’s SLS (Space Launch System) rocket on future Artemis missions to the Moon and beyond.

The latest test at NASA’s Stennis Space Center began the second half of a 12-test RS-25 certification series on the Fred Haise Test Stand, following installation of a second production nozzle on the engine. The remaining hot fires are part of the second, and final, test series collecting data to certify an updated engine production process, using innovative manufacturing techniques, for lead engines contractor Aerojet Rocketdyne, an L3Harris Technologies company.

As NASA aims to establish a long-term presence on the Moon for scientific discovery and exploration, and prepare for future missions to Mars, new engines will incorporate dozens of improvements to make production more efficient and affordable while maintaining high performance and reliability.

Four RS-25 engines, along with a pair of solid rocket boosters, will launch NASA’s powerful SLS rocket, producing more than 8.8 million pounds of thrust at liftoff for Artemis missions.

During the seventh test of the 12-test series, operators planned to fire the certification engine for 550 seconds and up to a 113% power level.

NASA’s Marshall Space Flight Center manages the SLS Program.