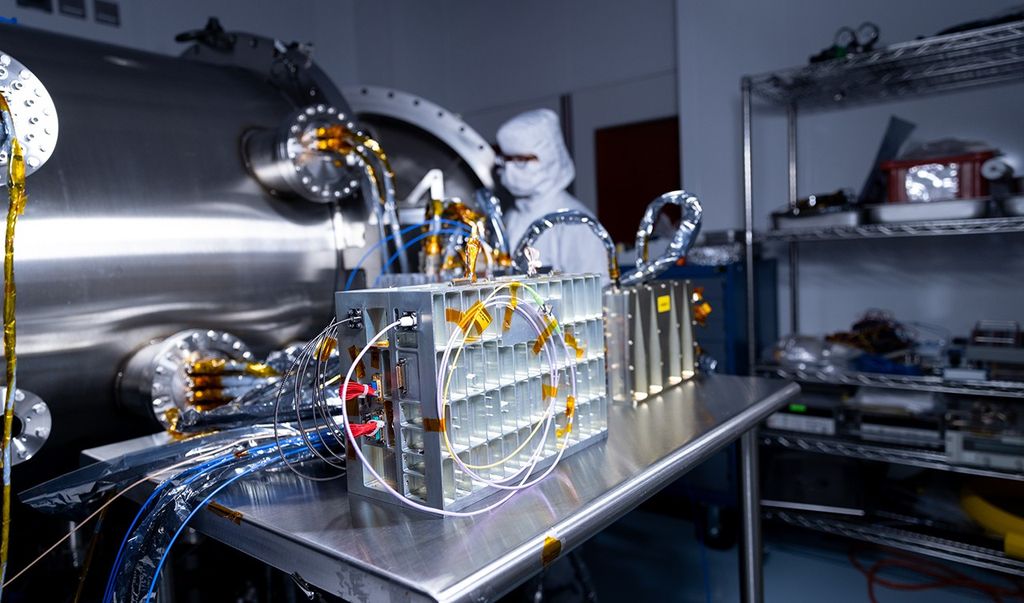

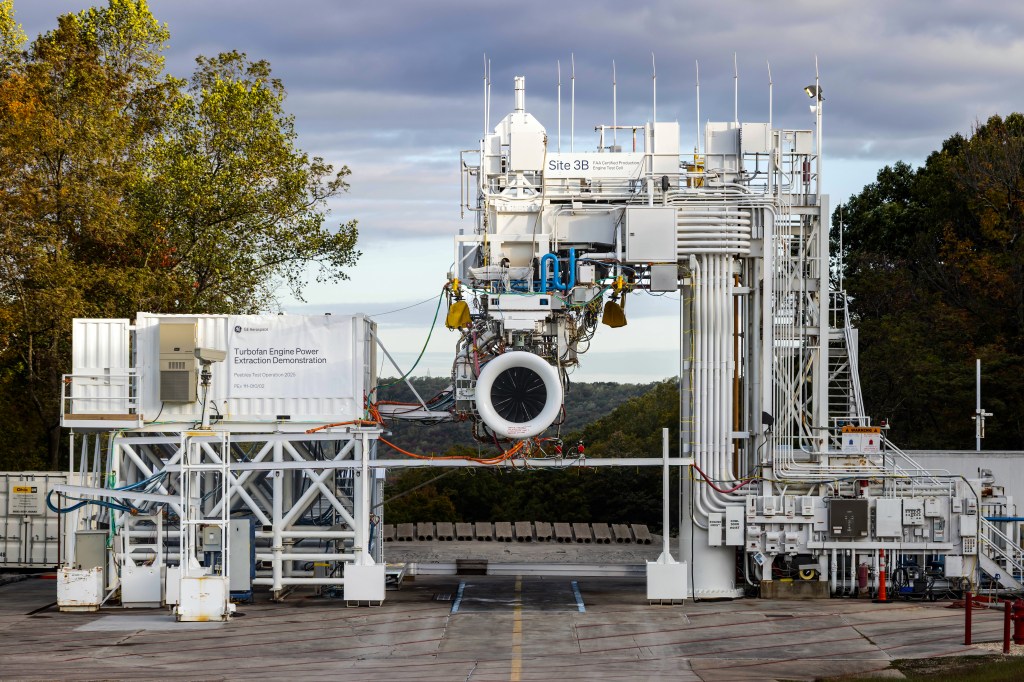

Aerodynamic Heating Facility

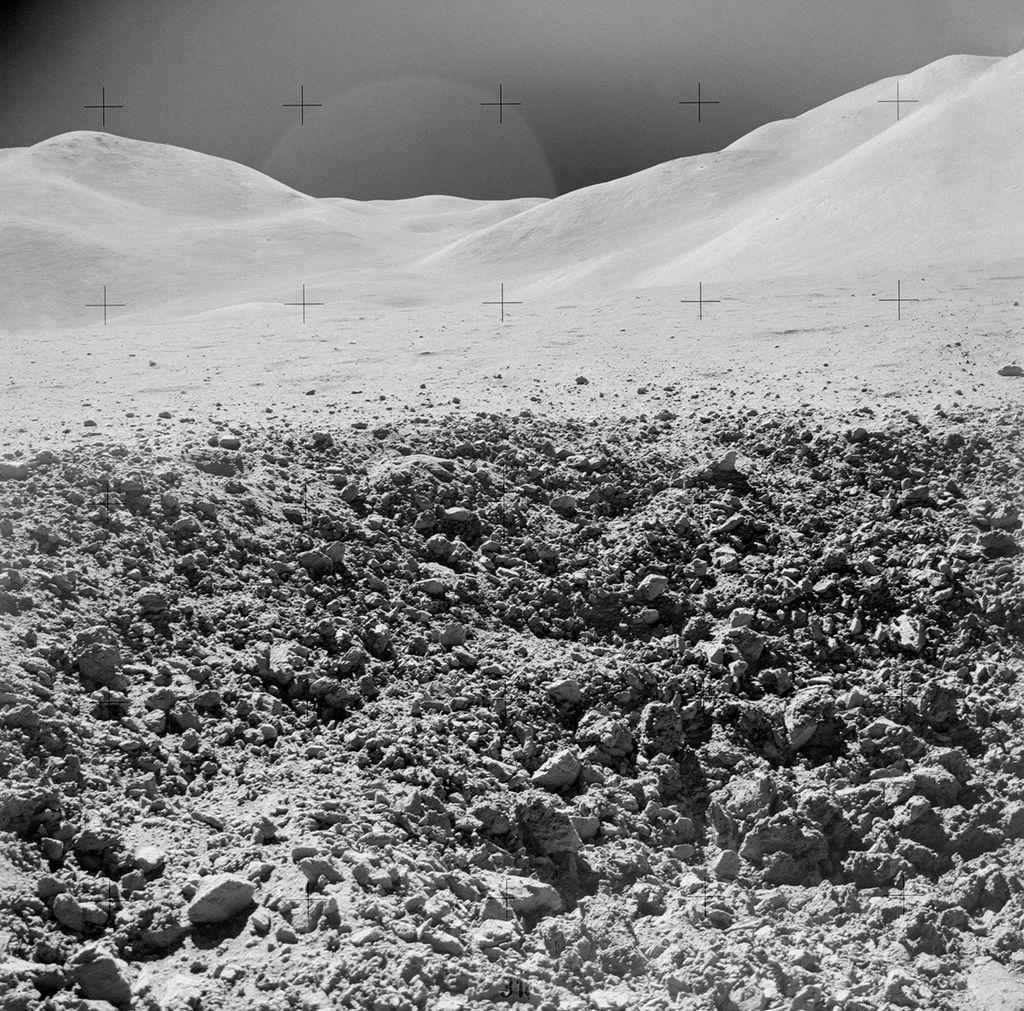

The Aerodynamic Heating Facility (AHF) is part of the Arc-Jet Complex at NASA’s Ames Research Center at Moffett Field, California, where generations of NASA space vehicles and thermal protection systems, including the space shuttle, have been designed and tested.

The AHF can operate with either a 10 or 20-MW constricted arc heater or a Huels arc heater. The constricted heater operates at pressures from 1 to 9 atm and enthalpy levels from 1 to 33 MJ/kg (500 to 14000 Btu/lb), while the Huels heater operates at pressure from 1 to 40 atm and enthalpies from 3.5 to 9.5 MJ/kg (1500 to 4500 Btu/lb). Either heater can be coupled with a family of conical nozzles with exit diameters ranging from 12.7 to 101 cm (5 to 40 inch). A large add-air mixing plenum allows for very low enthalpies for ascent-heating simulations. A fully programmable model insertion system independently controls five test samples during a single run.

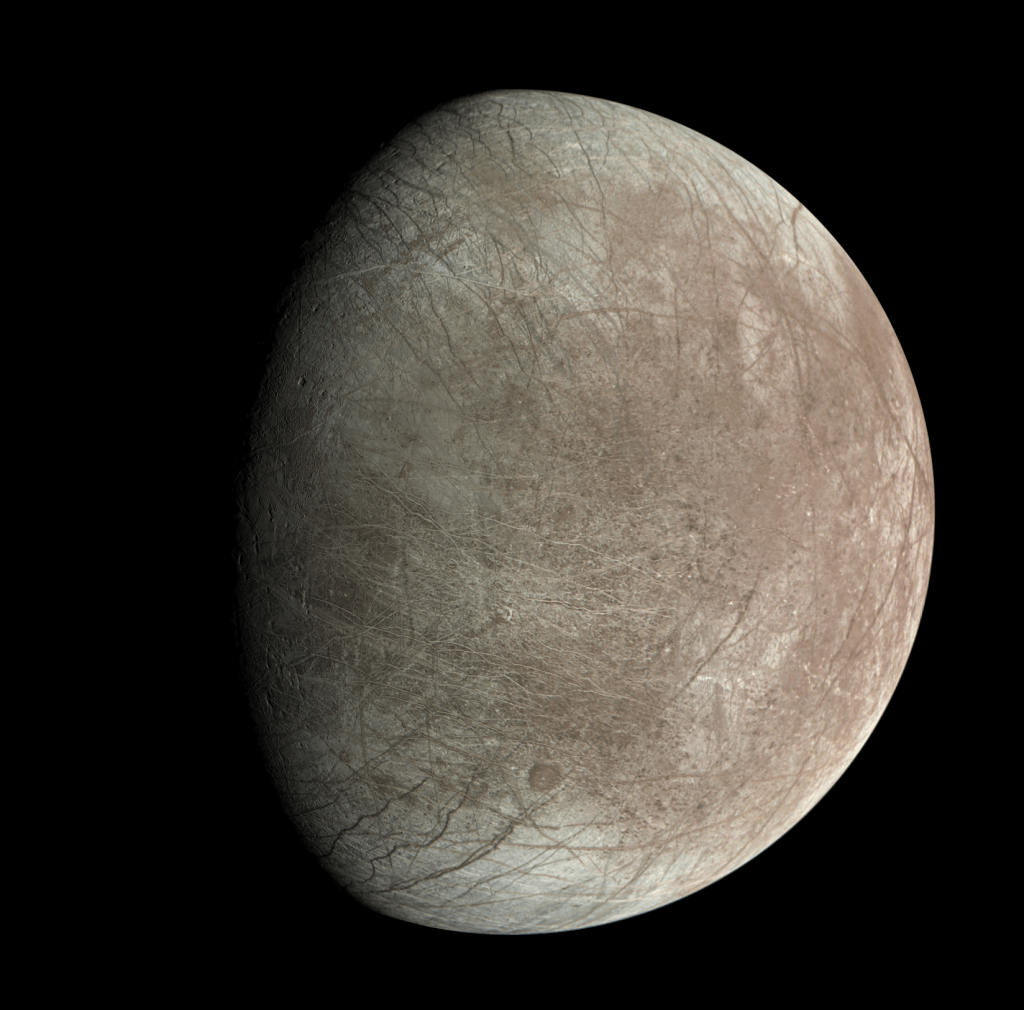

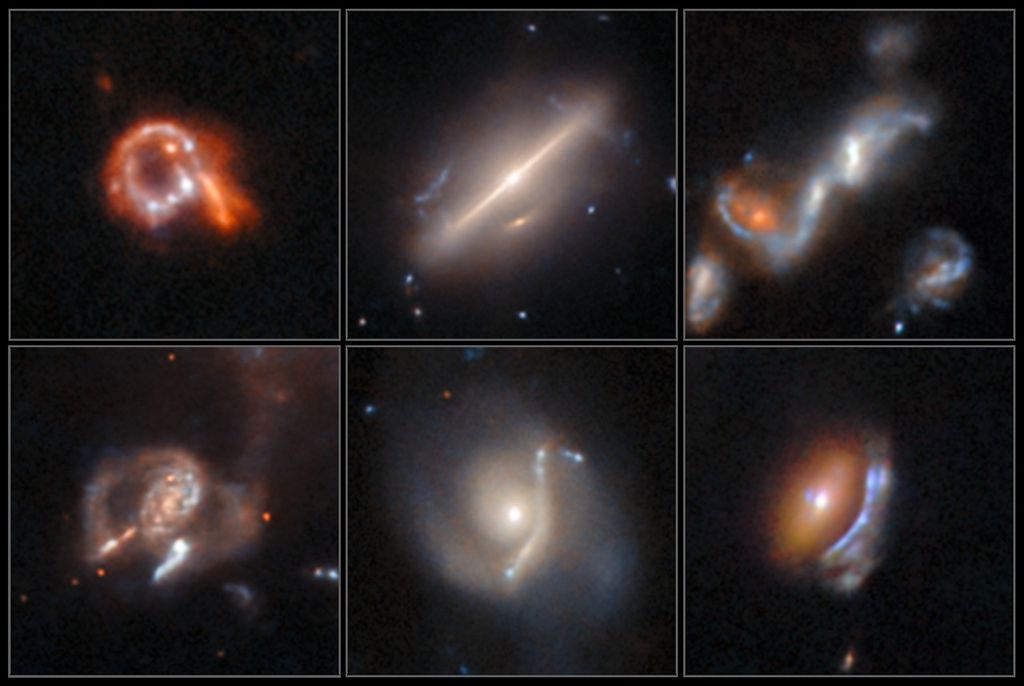

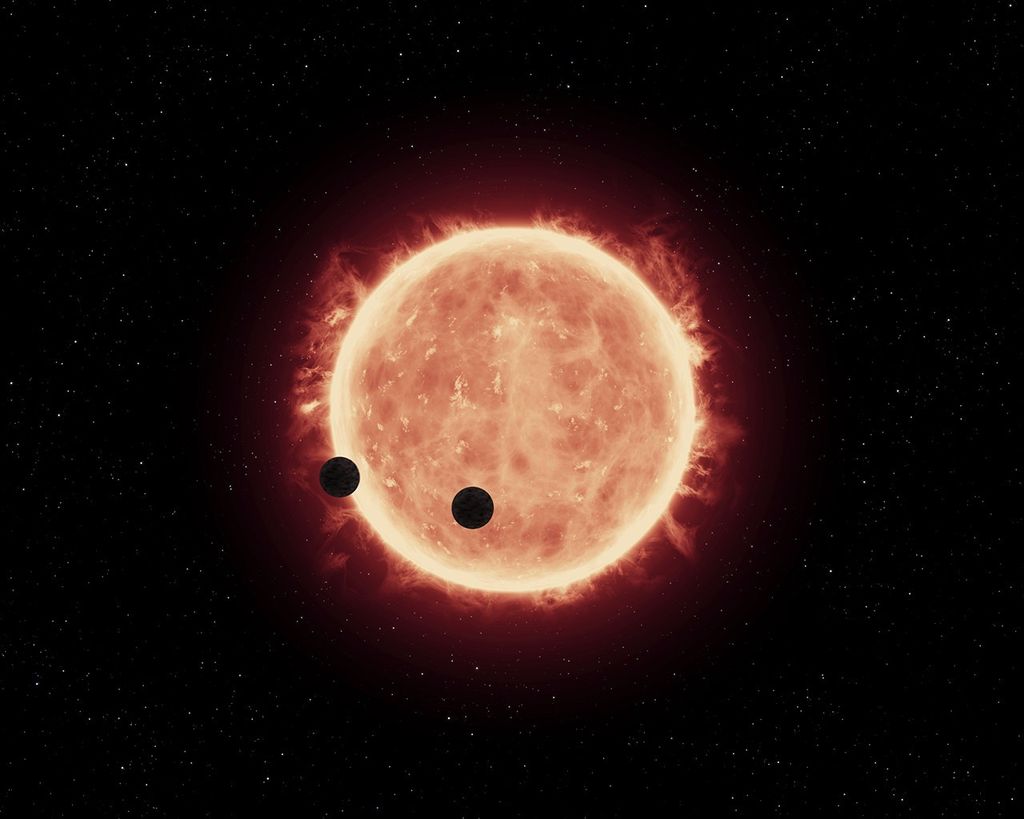

The AHF continues to provide data on thermal protection materials for NASA’s space probes and human spaceflight efforts whose goal it is safely enter a planetary atmosphere with a spacecraft necessary to take explorers to Earth orbit, the Moon, Mars and beyond.

- Air, Nitrogen and Oxygen gases

- 20-MW Ames-designed constrictor arc heater, a 20 MW Huels arc heater, or a 10 MW constrictor arc heater

- Conical nozzles from 178 mm (7 in) minimum to 914 mm (36 in) maximum at a 8-degree half angle for the 20 MW and from 127 mm (5 in) to 1016 mm (40 in) at 15 degree for the 10 MW

- Throat sizes are 1-in and 1.5 in for the 20 MW, 1-in for the Huels, and 2.25 in for the 10-MW arc heater

- Samples sizes up to 356 mm (14”) diameter or 660 by 660 mm (26” by 26”) wedge

- Surface or stagnation pressures from 0.005 to 0.3 (dependent on the arc heater and nozzle)

- Heat fluxes from less than 1 on a wedge, to over 3000 kW/m2 on a 102 mm diameter hemisphere

- 5-arm fully programmable model insertion system

- Nearly-vertical model insertion as well as transverse motion

- Streamwise adjustment of model position

- Fully water-cooled design

- Hydraulic motion controllers give reliable feedback control, programmable motion and digital communication

- Programmable/variable insertion time, dwell time on centerline, retraction time, and carriage traverse time.