Today, NASA took a big step toward changing the way we plan for long-duration space voyages when astronaut Barry “Butch” Wilmore successfully installed and prepared the first 3-D printer for upcoming manufacturing operations on the International Space Station.

“This printer is a critical first step for in-space manufacturing,” said Jason Crusan, director of NASA’s Advanced Exploration Systems Division at NASA Headquarters in Washington. “Additive manufacturing with 3-D printers will allow space crews to be less reliant on supply missions from Earth and lead to sustainable, self-reliant exploration missions where resupply is difficult and costly. The space station provides the optimal place to perfect this technology in microgravity.”

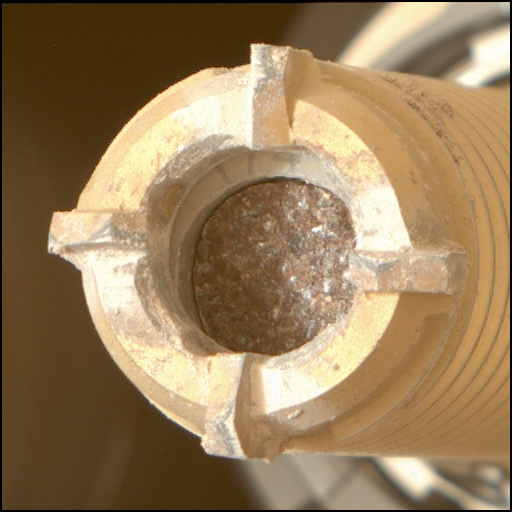

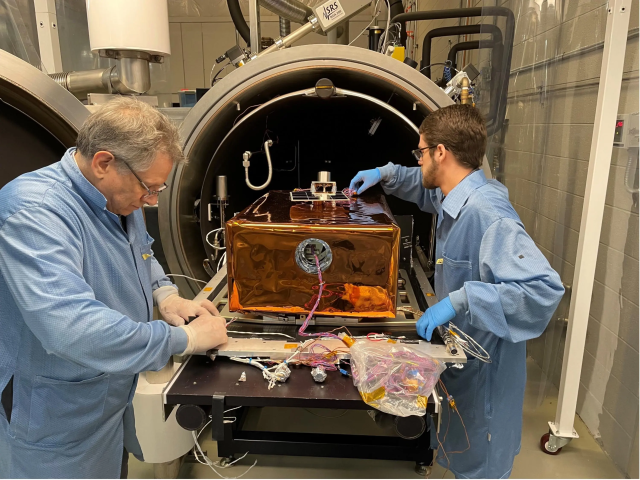

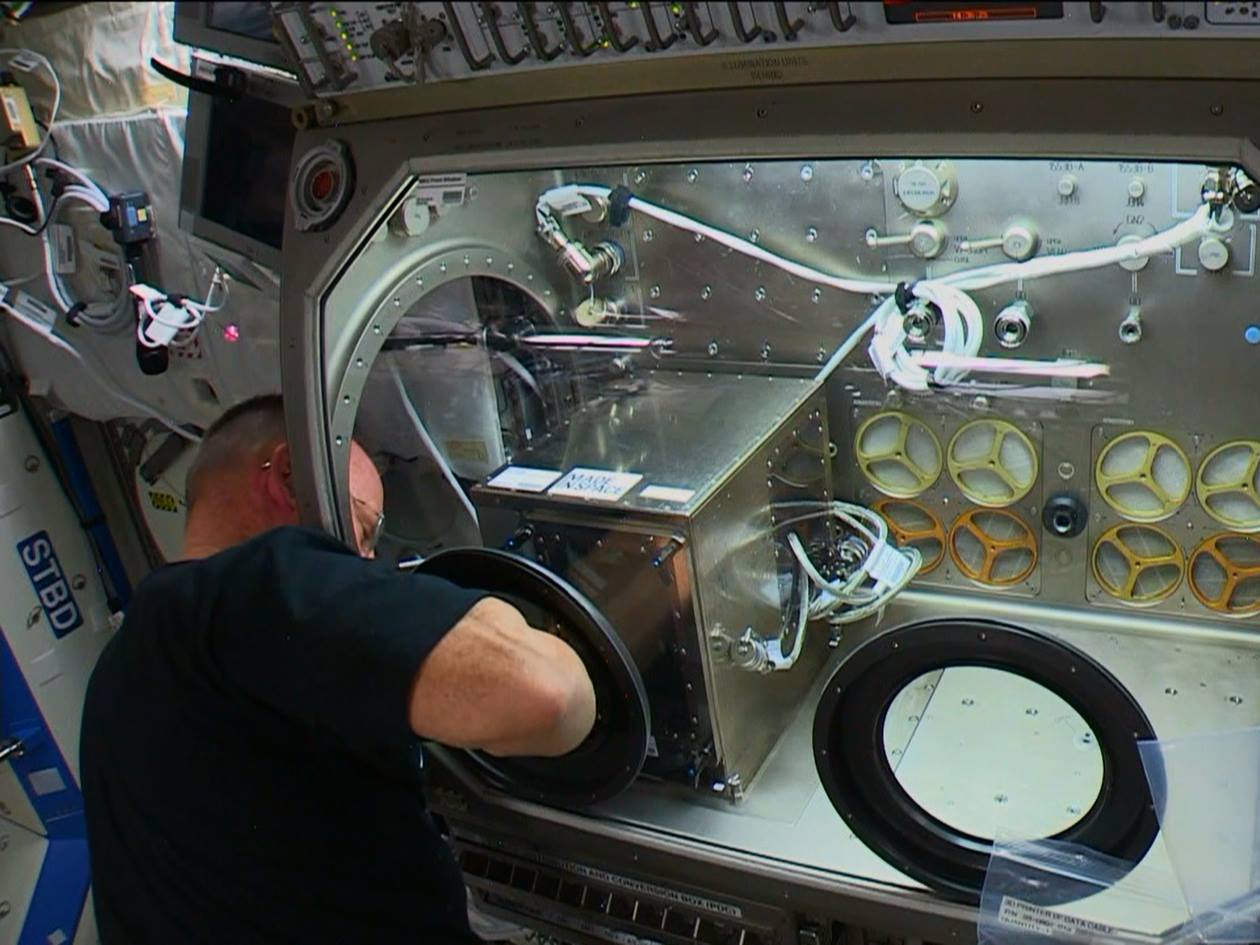

Wilmore installed the printer in the station’s Microgravity Science Glovebox and started the printer, which extruded plastic to form the first of a series of calibration coupons, a small plastic sample about the size of a postage stamp. After calibration of the printer is complete and verified, the printer will make the first NASA-designed 3-D printed object in space. The goal of the 3-D Printing in Zero-G Technology Demonstration on the space station is to show that additive manufacturing can make a variety of parts and tools in space. The 3-D printer heats a relatively low-temperature plastic filament to build parts layer on top of layer in designs supplied to the machine.

Before the printer left Earth in September 2014 on SpaceX’s fourth commercial cargo resupply mission, engineers loaded the first files to be printed. These initial parts — primarily test coupons — will be returned to Earth for detailed analysis and comparison to identical ground control samples made earlier this year prior to launch with the same printer while it was at NASA’s Marshall Space Flight Center in Huntsville, Alabama.

“The goal of the first phase of printing is to verify that the 3-D printing process works the same in microgravity as it does on the ground,” said Niki Werkheiser, NASA’s 3-D printer project manager at Marshall. “Once we confirm that the process works, we will move to the second phase of printing which focuses more on the design and utilization of the parts we print, which will ultimately lead to establishing an on-demand machine shop in space.”

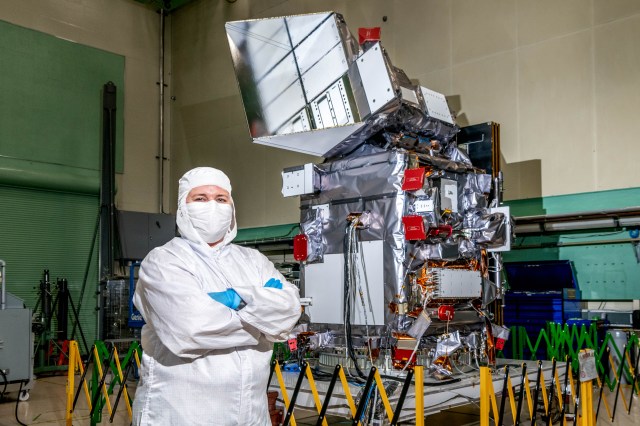

NASA contracted Made In Space, Inc. at NASA’s Ames Research Center in Moffett Field, California, to design and build the printer. Going forward, Made In Space engineers will use NASA-provided software and work with controllers at NASA’s Payload Operations Integration Center (POIC) in Huntsville to send commands directly to the printer from the ground. As the first objects are printed, NASA and Made In Space engineers will monitor printing via downlinked images and videos. The majority of the printing process is controlled from the ground to limit crew time required for operations.

“We’re approaching the most exciting moment of this experiment after years of intensive work, which dates back to Made In Space’s first microgravity testing with NASA’s Flight Opportunities Program in 2011,” said Aaron Kemmer, CEO of Made In Space, Inc. “Our team is on standby to send the command to print the first object in space. We are taking everything we are learning on the space station and using it to design an even more elaborate 3-D printer, which will be available for anyone to use.”

That printer is scheduled to be launched to the station next year and will be available to meet manufacturing needs of both NASA and commercial users.

NASA invited students to propose what they would print in space as part of a Future Engineers competition. Students can create and submit a digital 3-D model of a tool they think astronauts need in space. The winning student will watch from the POIC alongside the operations control team as their design is printed in space. The deadline for entry is Dec. 15.

Learn more about additive manufacturing at NASA’s 3-D printing website or follow updates on Twitter at @NASA3DPrinter.

By Bill Hubscher International Space Station Program Science Office