Contents

- Surface Infrastructure

- 15-foot Dirty Thermal Vacuum Chamber

- 3-foot Dirty Thermal Vacuum Chamber

- Integrated Mobile Evaluation Testbed for Robotics Operations (iMETRO)

- Electric Dexterous Manipulator Testbed (eDMT)

- Surface Mating

- Lunar Surface Element/Module/Cargo/Payload Offloading

- Related Patents

- Connect With Us

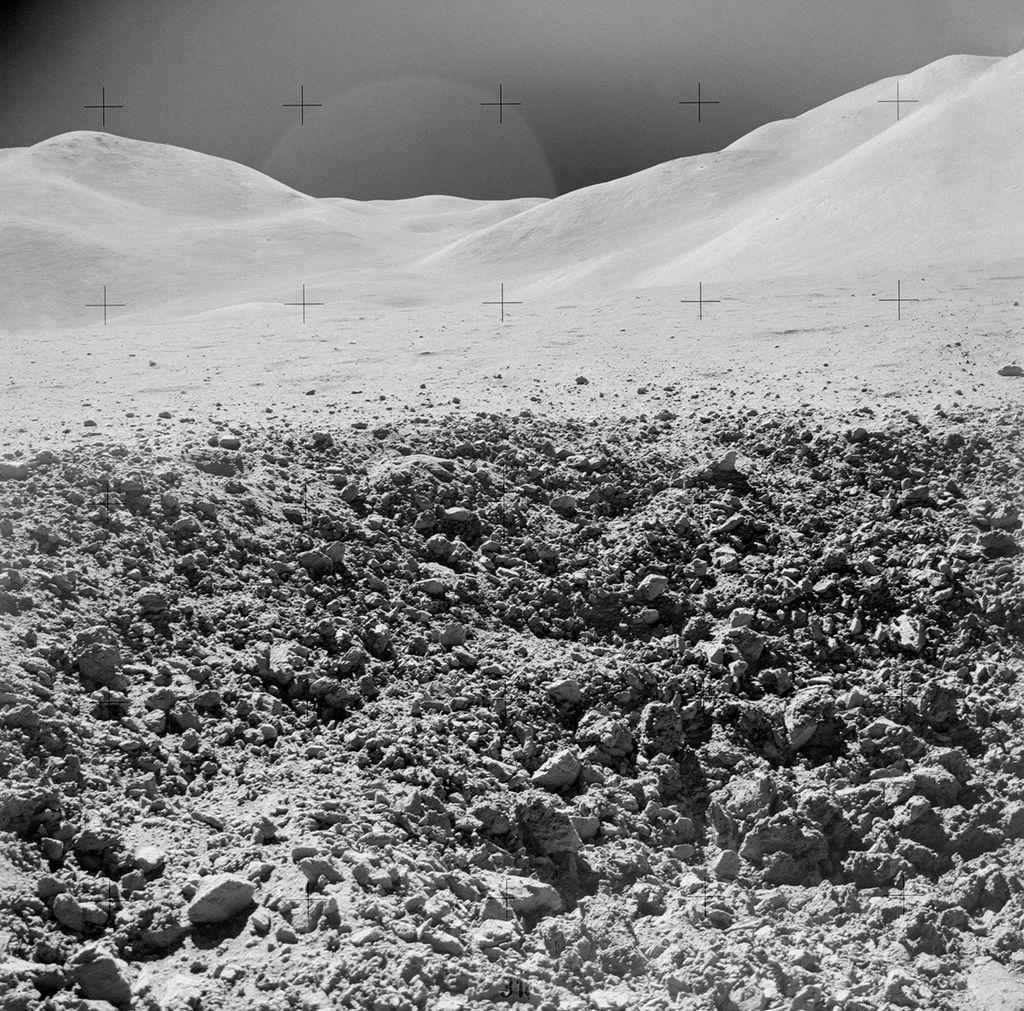

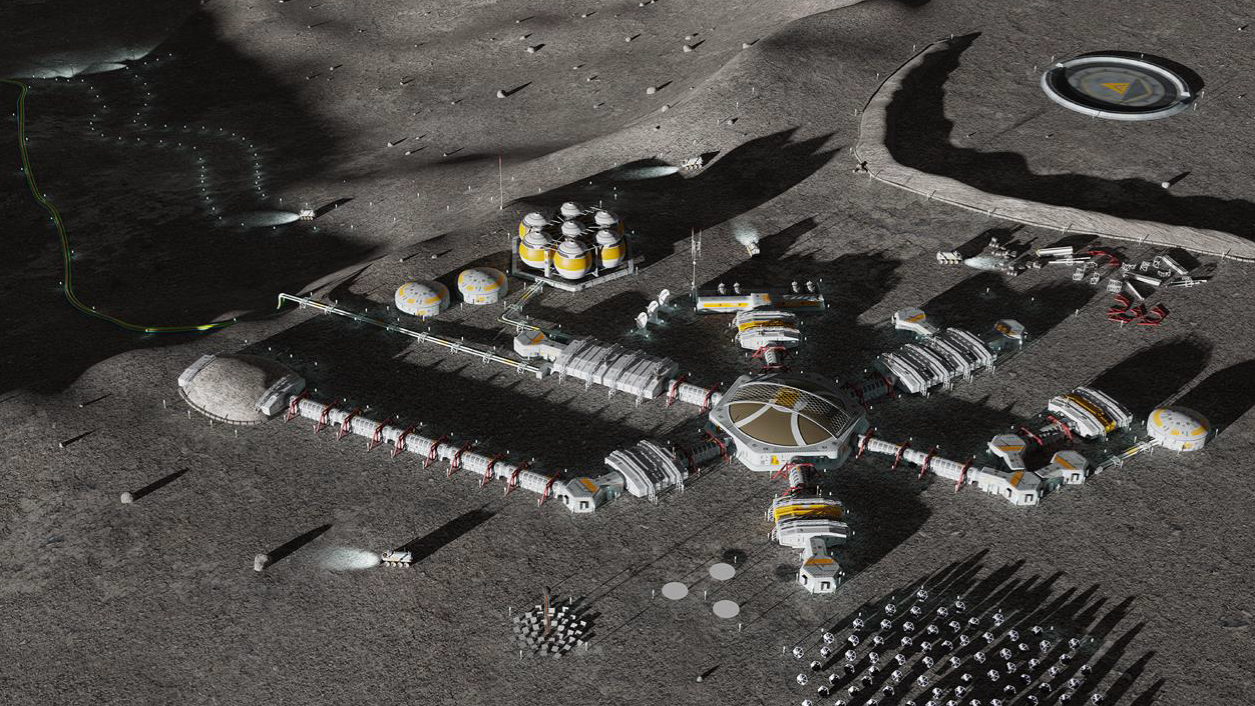

Surface Infrastructure

Johnson Space Center (JSC) is at the forefront of enabling a sustained human presence on the lunar surface (and one day Mars) through its development of surface infrastructure, including habitats, life support systems, power generation and storage systems, communication systems, surface transportation, resource utilization, research and medical science instruments, and processes, training and procedures to operate these systems. For example, JSC experts offer design, development and testing of robotic technology, providing key capabilities such as Robonaut and the Electric Dexterous Manipulator Testbed (eDMT), designed for testing robotic interfaces for future Moon and Mars exploration missions. Additionally, the 15-foot Dirty Thermal Vacuum Chamber and Dust Containment and Preparation Lab allows testing of hardware in relevant planetary surface conditions. From unpressurized and pressurized rovers to resource utilization and power systems, JSC is committed to providing the surface infrastructure necessary for sustainable human presence beyond our Earth. We invite our partners to leverage our robust capabilities in surface infrastructure to collectively advance and expand humankind’s presence in the solar system. With our expertise, together we can pioneer innovative solutions for sustainable surface infrastructure crucial for establishing and maintaining human settlements. Let’s collaborate to unlock the next chapter of space exploration and propel humanity’s journey into the cosmos.

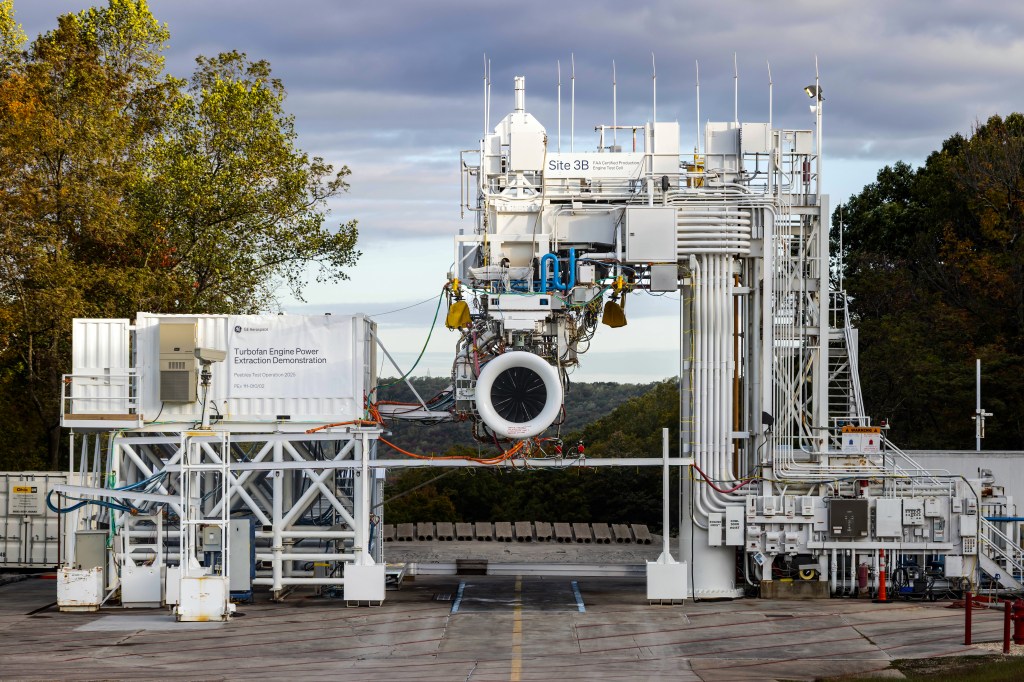

15-foot Dirty Thermal Vacuum Chamber

NASA JSC 15-foot dirty thermal vacuum chamber (TVAC) provides unique testing capabilities for dust and planetary surface environments. The 15-foot chamber is a spherical chamber designed to test advanced concepts, especially for ISRU, battery power systems, space vehicle actuators and auxiliary power units.

- 12.5-foot internal diameter spherical chamber with ~78-inch diameter clear entry for easy access

- Vacuum conditions: 1×10^-6 torr to 760 torr

- Thermal conditions: -185°C to +125°C

- Features: Air or GN2 repress options, Residual Gas Analyzer, particulate filtration for testing with regolith simulants, LN2 contamination scavenger plate, interior LED lighting and cameras

- Air, GN2 pressurization

- Feed-throughs for high-power electrical connections and high-channel count data

- Chamber platform and I-beam trolley rated for payloads up to 3,500 lbs

- Regolith bin and drill tube for design and test of excavation, processing, or construction technology

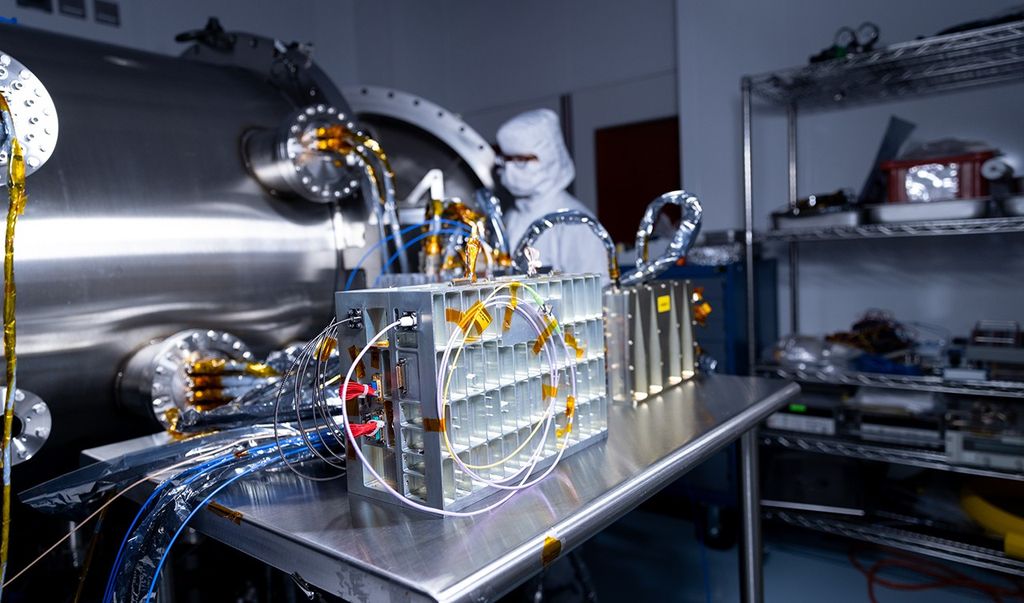

3-foot Dirty Thermal Vacuum Chamber

NASA JSC’s 3-foot dirty thermal vacuum chamber (TVAC) provides unique testing capabilities for dust and planetary surface environments. The 3-foot chamber is a 3ft x 3ft x 3ft cube designed to test component level concepts in a lunar simulated environment.

- 32” x 32” x 32” internal volume of the thermal shroud

- Vacuum conditions: 10^-7 torr to 760 Torr

- Thermal conditions: -185°C to +150°C

- Features: GN2 repress, oil-free vacuum system, particulate filtration for testing with regolith simulants, LN2 contamination coil

- Built-in thermal platen and shroud walls independently controlled for temperature conditioning if needed

Integrated Mobile Evaluation Testbed for Robotics Operations (iMETRO)

iMETRO is a NASA facility for functional testing of robotic hardware and software in realistic space exploration environments including simulation, indoor space vehicle and habitat mock-ups, and outdoor EVA proving grounds. Do you have a robotic or artificial intelligence (AI) technology that needs to be demonstrated in a relevant space environment? Are you looking for ways to advance the Technology Readiness Level (TRL) to level 4 and beyond for space exploration applications? If so, NASA JSC’s iMETRO facility has solutions for you. Whether you need to test a whole robot or a single hardware or software component, iMETRO has you covered with a variety of “house robots” to use for your test. Our JSC robotics engineers are ready to assist with any level of integration desired, for 1-hour consultations to extended test campaigns.

iMETRO Open-Source Software and Simulation

- The virtual facility includes open-source robot configurations (e.g., URDF) for iMETRO robots as well as models of mock-ups for space use cases, such as the crew access hatch and logistics stowage task trainer.

- ROS2 compatible software interfaces

You can check out the iMETRO open-source simulation assets, software, and documentation on Github at the link below. The iMETRO team is always making updates and adding new features:

https://github.com/NASA-JSC-Robotics/iMETRO

iMETRO Lab Facility Features

- The physical facility consists of many robots, space application mockups, and support instrumentation and computing. A variety of mock-ups and task trainers are available to use, and additional customized mockups can be designed and constructed by JSC staff for mission scenarios as needed.

- Overhead PTZ video cameras

- Remote operator situational awareness

- Optical tracking ground truth for pose estimation and navigation

- Isolated robot network with configurable latency and bandwidth restrictions (currently a future planned capability)

iMETRO Outdoor Rockyard Features

- Outdoor lunar and Mars yards

- Control station trailer

- Outdoor mobile dexterous robots

- Drone operations support

- Link to JSC Rock Yard maps: https://ntrs.nasa.gov/api/citations/20240002135/downloads/Rock_Yard_Map_Book.pdf

Robot Options

- Linear Rail-mounted Single Manipulator Arm

- Universal Robots UR10e

- Robotiq hand-E Gripper w/ Custom Fingers

- Vention horizontally mounted 2.0m linear rail

- Ewellix Telescoping Lift Kit with 700mm Stroke

- Intel® RealSense™ Wrist-Mounted Depth Camera

- Indoor Mobile Base with Dual Manipulator Arms

- Universal Robots UR5e (2x)

- Robotiq Hand-E Grippers with Custom Fingers

- Arms mounted to dual, independent lift-kits of 500mm Stroke

- Clearpath Ridgeback Wheeled Mobile Base

- Intel® RealSense™ Wrist-Mounted Depth Cameras

- Outdoor Mobile Base with Single Manipulator Arm (coming 2026)

- Universal Robots UR10e (Option for UR30)

- Robotiq hand-E Gripper w/ Custom Fingers

- Intel® RealSense™ Wrist-Mounted Depth Camera

- Bring Your Own Sensors and/or End Effectors

- Utilize standard interfaces

- Bring Your Own Robot

- Test custom configurations with space application mock-ups

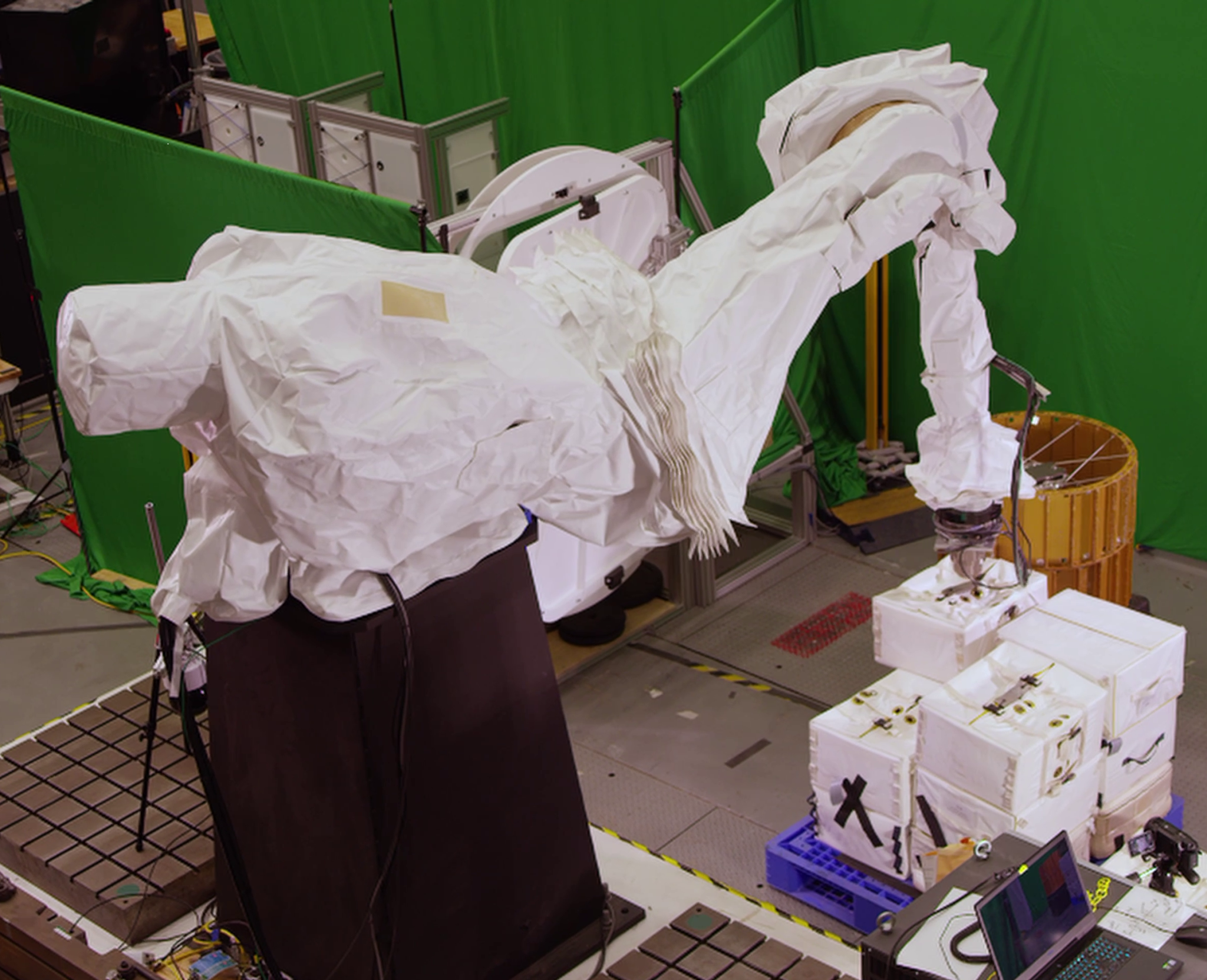

Electric Dexterous Manipulator Testbed (eDMT)

The Electric Dexterous Manipulator Testbed (eDMT) is used for testing space robotic payloads, interfaces, and concepts of operation for ISS and future Moon and Mars exploration missions. It consists of multiple Commercial Off-The-Shelf (COTS) serial manipulators. These manipulators can be used to perform a wide range of dynamic simulations and operational feasibility assessments. They range in size and payload capacity, so that smaller units can be relocated to other testing environments. Components have been designed to maximize compatibility in rugged, unstructured, and even vacuum environments.

Testbed Features:

- Closed-loop force and moment accommodation

- Detailed force and position metrology

- Mounted T-slot tables for mockup integration

- On-orbit Tool Change Mechanism Emulator (OTCME) end effector for grasping standard interfaces

- Optical motion tracking

Yaskawa Motoman ES165RD-II:

- 3 meter reach

- 165 kg payload capacity

- Permanent mount in facility

- ISS emulation end effector

Kuka KR70 R2100:

- 2.1 meter reach

- 70 kg payload capacity

- Fast response to sensor feedback, ideal for handling delicate payloads and testing autonomous operations

- Pedestal mounted in facility, but lightweight enough to transport via forklift for integrated testing

- Reconfigurable gripper interface

Surface Mating

On-site expertise available for on-surface docking/mating related mechanisms (latches, lockdowns, linear actuators, umbilical drives, et al) and successful on-surface Docking linear and non-linear contact dynamics modeling, loads analysis, docking simulations, and testing. Includes the development and maintenance of on-surface Docking Standards and cross-interface system engineering and integration.

- Design, Development, Test and Evaluation of surface mating systems

- Component, System and Vehicle-level Systems Engineering and Integration

- Analytical Simulation/Prediction, Independent Modeling and Model Validation

- Dynamic, Static, and Natural/Induced Environmental Testing

- System Management, Flight Hardware Acceptance, Joint Integrated Testing

- Standards and Specifications Development

- Avionics, Software and Controls

- Rapid Prototyping and Evaluation

- Contact Modeling and Simulation

- Collaborative Working Environment

Lunar Surface Element/Module/Cargo/Payload Offloading

On-site expertise available for surface related module payload offloading mechanisms used to take objects delivered to the lunar surface which need to be taken off the lander and placed on the surface via grappling, lifting, positioning, and release; or moved and repositioned with accuracy. Includes design, analysis, linear and non-linear dynamics modeling, loads analysis, simulations, and testing, and the development and maintenance of systems and cross-interface system engineering and integration.

Systems with mechanisms, latches, lockdowns, linear actuators, drives:

- Design, Development, Test and Evaluation of offloading systems

- Component, System and Vehicle-level Systems Engineering and Integration

- Analytical Simulation/Prediction, Independent Modeling and Model Validation

- Dynamic, Static, and Natural/Induced Environmental Testing

- System Management, Flight Hardware Acceptance, Joint Integrated Testing

- Standards and Specifications Development

- Avionics, Software, and Controls

- Rapid Prototyping and Evaluation

- Contact Modeling and Simulation

- Collaborative Working Environment

Related Patents

Connect With Us

Whether you are a public agency, private company, or academic institution, we look forward to hearing from you. Fill out the Statement of Interest form to submit your inquiry.