EVA Systems

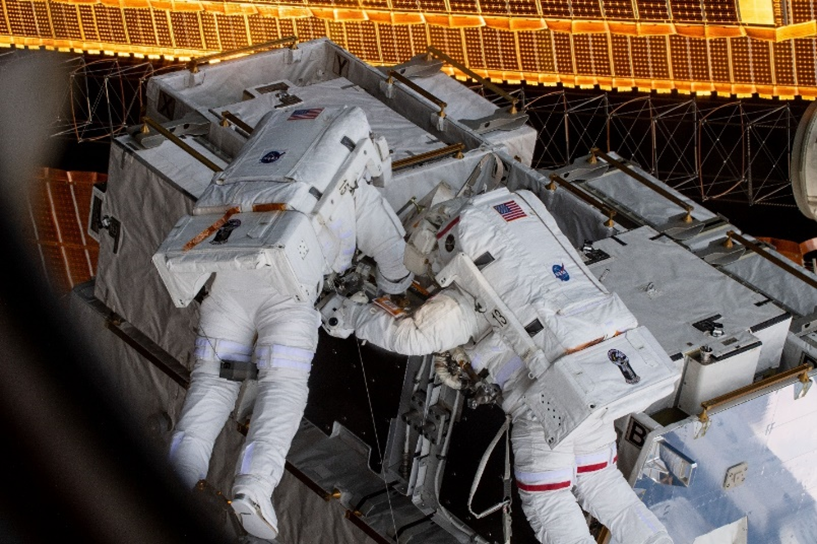

Extravehicular Activity (EVA) systems include space suits, tools and support systems for performing extravehicular activities in space. Space suits are unique meticulously engineered, miniature, customized spacecraft. Space suits act as a protective barrier, providing life support, thermal regulation, and shielding against the vacuum of space. Whether conducting repairs, performing experiments, or exploring celestial bodies, EVA space suits are indispensable, allowing astronauts to venture beyond the confines of their spacecraft, ensuring their safety and enabling the successful execution of critical tasks in the challenging environment of space.

The Johnson Space Center (JSC) features world class facilities and competencies to support the design, development, testing and verification, and implementation of Extravehicular Activity (EVA) systems. JSC personnel have a vast knowledge of the technical challenges associated with space suit technology, ranging from mobility, sizing, life support, ventilation, hydration, and waste management. JSC experience covers the full life cycle, starting from basic design through development, testing, and operational support. Explore the trove of EVA system capabilities below, as we invite you to join us in the exciting journey of space exploration at the forefront of discovery.

Space Suits

JSC personnel have a vast knowledge of the technical challenges associated with space suit technology, including mobility, sizing, life support, ventilation, hydration, and waste management. JSC experience covers the full life cycle, starting from basic design through development, testing, and operational support.

Space suits are unique in that they are miniature, customized spacecraft. They must provide environmental protection, mobility, and life support to the crewmember during spacewalks.

- Space suit design and development

- Pressure garment and glove design

- Mobility and sizing

- Helmet and visor design

- Life support umbilical design

- Suit maintenance and operations

- Portable life support technologies

- Thermal control

- Ventilation

- Oxygen systems

- Contaminant control

- Hydration

- Waste control

- Space suit testing, verification, and training

- Suit checkout

- Altitude testing

- Thermal vacuum testing

- Flight crew training

- System-level engineering insight into the Extravehicular Mobility Unit (EMU) hardware operational performance and detailed leadership into anomaly resolution

- Real-time mission support for on-orbit activities

- Ground training simulations for training and crew extraction from the Neutral Buoyancy Laboratory and vacuum chamber facilities

- Engineering risk-based guidance for management, sustaining and changes of the EMU hardware and forecast for long-term hardware lifecycle usage

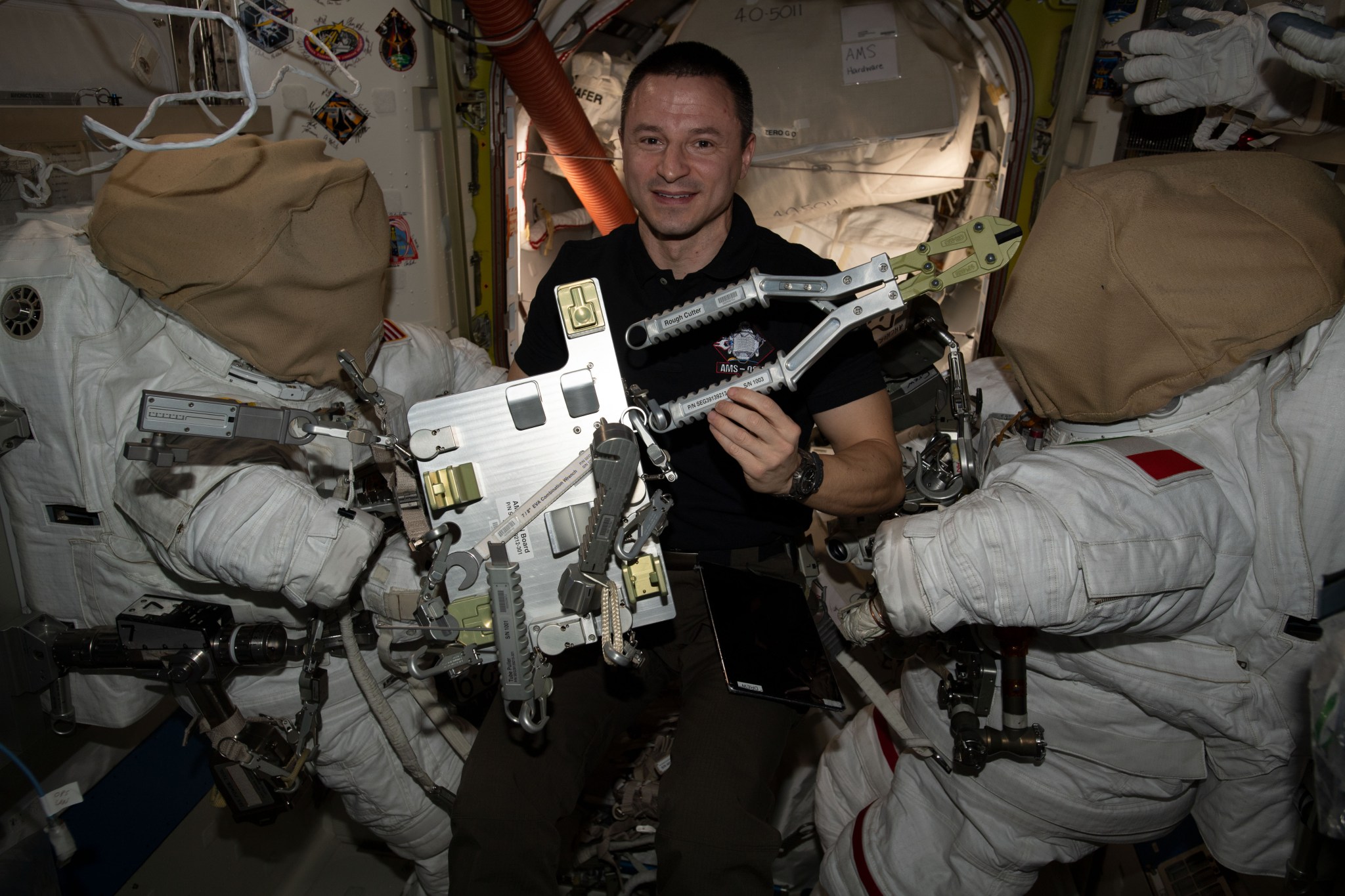

Extravehicular Activity Tools

JSC’s unique experience in Extravehicular Activity (EVA) tools covers the full hardware life cycle from worksite aids and restraints to unique tools for specialized maintenance and repairs. We cover the full spectrum of engineering space hardware from defining the problem to solve, to research and design, to rapid prototyping and development, to testing and operational support.

Flight Hardware Development

- Performance requirements and concept of operations development

- Prototype development including use of rapid manufacturing and 3D printing

- Fabrication, assembly, and testing

- Thermal and thermal vacuum testing

- Pressurized glove box testing

- Technology demonstrations

- Certification and integration support

- Pre–flight inspections, checkouts, packing and delivery for launch

Read more:

https://www.nasa.gov/extravehicular-activity-and-human-surface-mobility/spacewalking-tools

https://www.nasa.gov/gallery/eva-tools/

Softgoods and Materials Assessment

The Softgoods Lab (SGL) in the Engineering Design and Analysis Branch/EC2 of the Crew and Thermal Systems Division designs, develops, and manufactures flight softgoods products and components. The SGL also designs and fabricates ground support, test, and prototype softgoods products. The Advanced Materials Lab (AML) in the same branch provides testing for developing & evaluating textile fabrics and other non-metallic materials such as plastic, polymer films, foil, mylar, mesh, elastomers, and adhesives for NASA & industry applications. This lab is equipped to evaluate and certify softgoods materials and products for spaceflight.

The focus of the labs is developing customers’ needs and ideas into prototypes, which are then evaluated and customized to produce flight items that meet or exceed their requirements. Examples of softgoods products that are produced by the Softgoods Lab and evaluated by the Advanced Materials Lab: Components for spacesuits, softgoods containers for EVA and IVA operations, emergency masks, cargo stowage containers and kits, inflatable structures, bladders and liquid containment, contamination blankets, multi-layer insulation thermal blankets, crew clothing, and crew sleep accommodations.

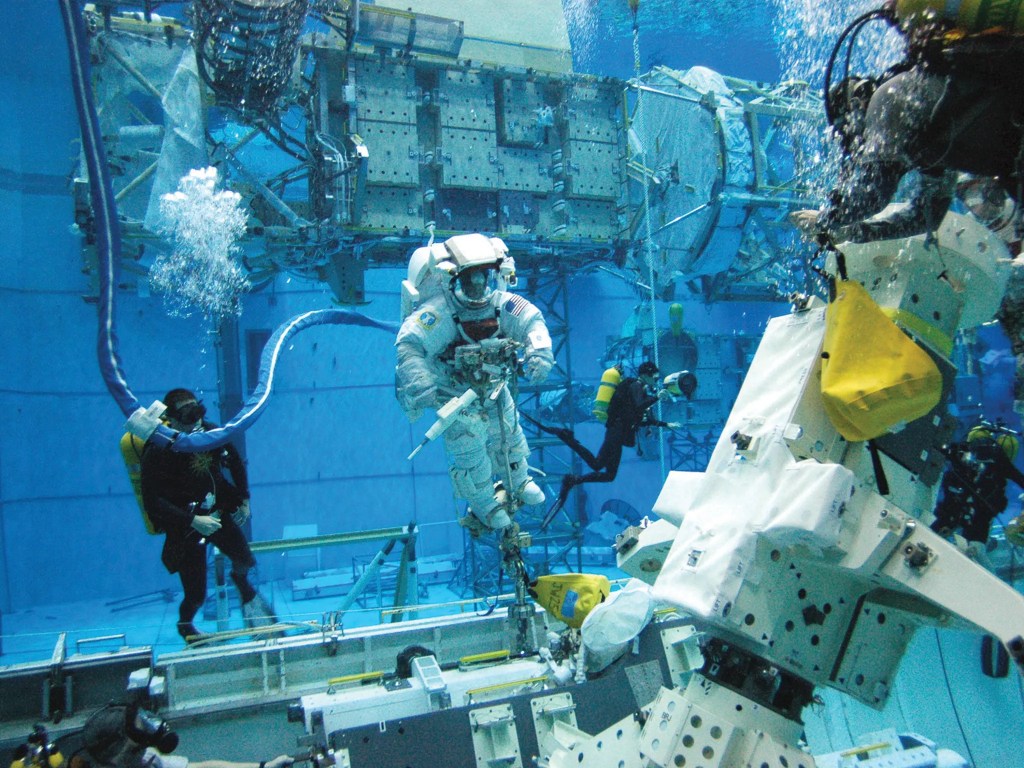

EVA and Environmental Physiology Laboratory

The EVA and Environmental Physiology Laboratory (EEPL) conducts operational research and technology development to support and enhance human health and performance in suited environments including during extravehicular activities (EVA). The EEPL leads research efforts focused on optimizing human health and performance during suited operations and in suited training environments such as the Neutral Buoyancy Lab (NBL) and Active Response Gravity Offload System (ARGOS). In addition, EEPL conducts hypobaric chamber research to characterize the risk of decompression sickness during spaceflight operations and develop, validate and test pre-breathe protocols. Furthermore, EEPL develops biomedical technologies and capabilities to enable future autonomous EVA for exploration class missions where real-time support and communication with the ground will not be available.

Tasks range from highly coordinated interdisciplinary suited research studies using ground-based suited analogs, such as ARGOS and NBL, to the development of an EVA-simulation environment that uses hybrid reality and high-fidelity informatics to represent the physical and cognitive workload associated with EVA.

- Develop, validate and conduct pre-breathe protocols for space suits

- Conduct pre-breathe protocol training for crewmembers

- Assess of metabolic cost of EVA during NBL training and inflight EVA

- Perform research studies to characterize and optimize human health and performance in spacesuits in various suited environments (i.e., chambers, ARGOS, NBL, etc.)

- Perform studies to assess CO2 washout capabilities of various suits

- Development of crewmember physiological and cognitive state predictive analyses and decision support tools

Simplified Aid for EVA Rescue (SAFER)

The SAFER is a miniaturized backpack connected to the EMU spacesuit providing stabilization, thrust and maneuverability for crewmembers back to safety in case of an emergency during EVA activities on ISS.

- Emergency/maneuverability hardware for an EVA crewmember providing self-rescue capability

- Miniaturized propulsion units (Composite Overwrapped Pressure Vessel (COPV))

- Electronic and software for guidance systems (Avionics/Inertial Measurement Unit (IMU))

- Virtual reality simulation/training

- Design and testing

- On orbit system management and maintenance

- EVA console support

- Verification & Validation

- Flight Certification

Active Response Gravity Offload System (ARGOS)

Active Response Gravity Offload System (ARGOS) is designed to simulate reduced gravity environments from earth gravity to microgravity. A continuous dynamic offload of a subject’s weight (or portion thereof) is maintained by a robotic motion control system that actively follows the subject’s motion within the system’s operational volume. ARGOS is capable of offloading humans (both in shirtsleeves and space suits), small rovers, and robots for testing, training, process development, and human research in simulated reduced gravity environments.

ARGOS 2 resembles an overhead bridge crane 41 x 24 x 25 feet in size. Sensors in the horizontal axes (X and Y) and vertical axis (Z) obtain displacement and force changes of the payload, allowing a computer-controlled winch to provide superimposed constant force offload above the payload’s center of mass.

ARGOS 2 Specifications

- 750lb offload capability

- 13’(X) x 30’(Y) x 15’(Z) workspace

- System wide communication for test subjects and support teams

- Motion tracking supported by AIBEL

- NASA Space suit support supported by Crew and Thermal Systems Division

- Pressurized breathing air

- Cooling water for suits

Motion capabilities

- Suited Configuration: 4 ft/s vertical, 6.5 ft/s horizontal

- Unsuited configuration: 11 ft/s vertical, 6.5 ft/s horizontal Variety of Gimbals (payload interfaces) to support suited, unsuited, and unmanned testing

Supported Test Types

- Suited or unsuited

- EVA in microgravity, Lunar, or Martian gravity environments

- EVA tools, process development

- Biometric studies in reduced gravity environments

- Robotic systems payloads New test types are possible

ARGOS technology is available in the NASA Patent Portfolio: https://technology.nasa.gov/patent/MSC-TOPS-60

Related Patents

Full-Size Reduced Gravity Simulator For Humans, Robots, and Test Objects