Ovens & Freezers

NASA Johnson Space Center (JSC) provides capabilities to handle unique needs for temperature extremes. The Cold Stowage team offers controlled environments to meet precise temperature requirements during ascent, on-orbit operations, and return of payloads and science experiments, enabling unique ISS science and research. Additionally, JSC provides access to advanced thermal chambers, including autoclaves and ovens. These facilities are essential for curing, baking-out, or thermally conditioning composite structures and material samples. We invite our partners to leverage these cutting-edge capabilities for their own spaceflight endeavors, ensuring the highest standards in temperature-controlled environments and material conditioning. Partner with us to advance your scientific and engineering missions.

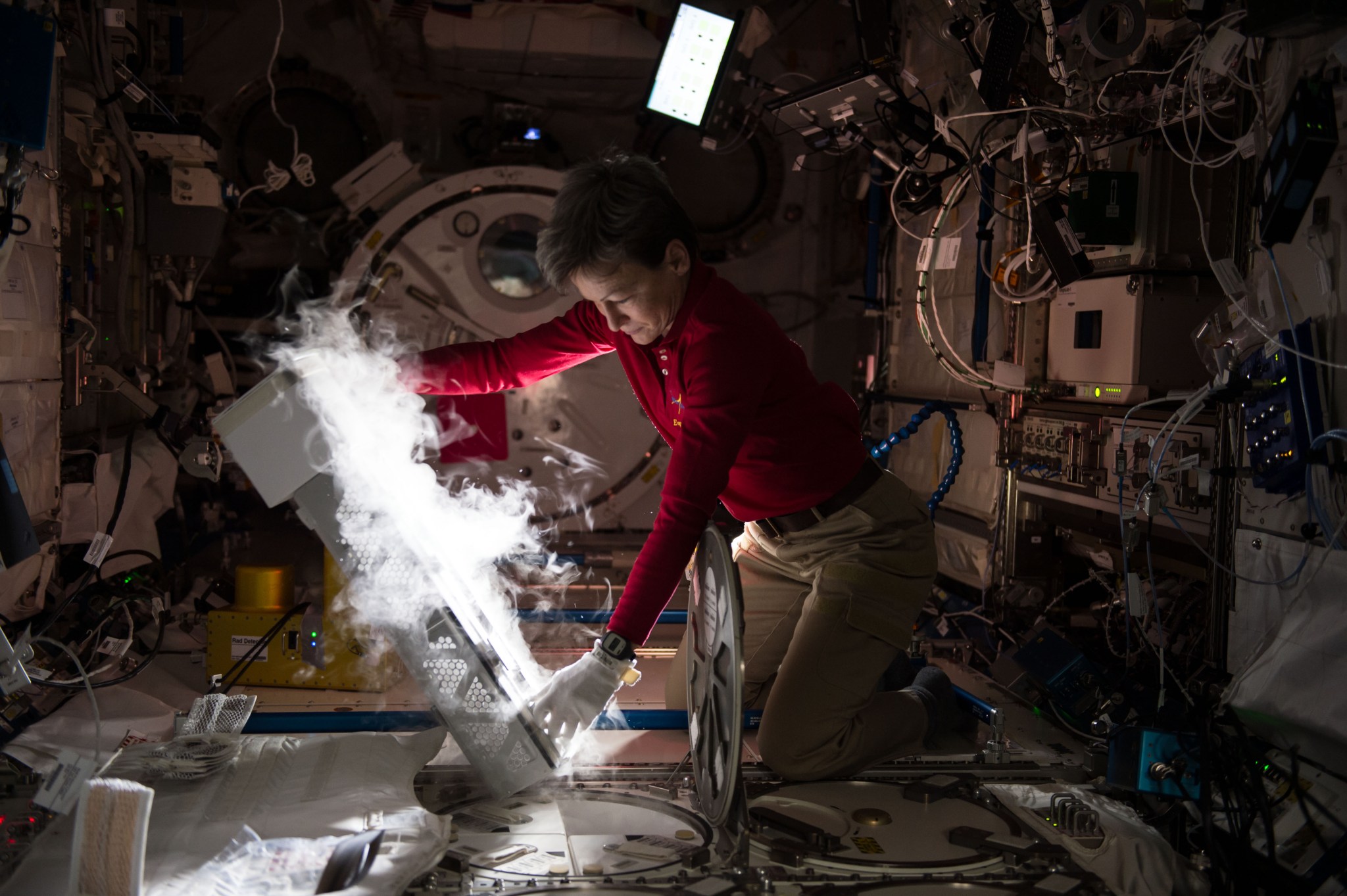

Cold Stowage

NASA’s vision for humans pursuing deep space flight involves the collection of science in low earth orbit (LEO). As a service to the science community, JSC has developed hardware and processes to preserve collected science in LEO and transfer it safely back to the Principal Investigators. These active and passive cold stowage systems include an array of freezers, refrigerators, and incubators. JSC’s Cold Stowage Lab can perform hold tests, fit checks, and thermal tests by request. Equipment in the lab allows the team to test articles at temperatures ranging between -196° C to +200° C. Cold Stowage also utilizes labs at Kennedy Space Center (KSC) and other vehicle processing locations. The team provides support to payload developers through launch, on-orbit operations, and landing. For further information see: Cold Stowage Poster

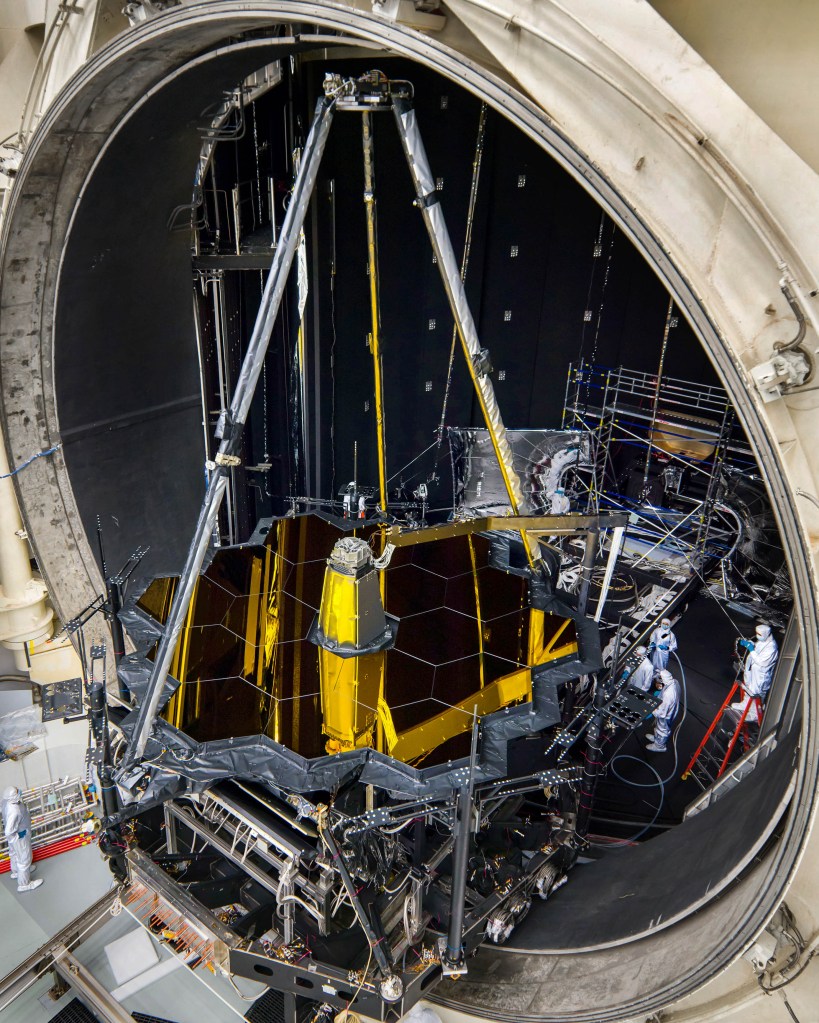

Autoclaves & Ovens

Autoclaves & ovens are thermal chambers used to cure, bake-out, or thermally condition composite structures and material samples.

Autoclaves are pressurized thermal chambers typically used for curing epoxies and resins in composite structures:

- One autoclave onsite at JSC

- Sample sizes up to 7’ X 16’

- Temperatures up to 600 degF

- Pressurized up to 30 PSI

Ovens are unpressurized and typically used for heat-treating metals and thermally conditioning any material sample:

- Two ovens onsite at JSC

- Sample sizes up to 4′

- Temperatures up to 2000 degF

Connect With Us

Whether you are a public agency, private company, or academic institution, we look forward to hearing from you. Fill out the Statement of Interest form to submit your inquiry.