Hazardous Testing

The Johnson Space Center (JSC) Energy Systems Test Area (ESTA) and White Sands Test Facility (WSTF) offer a highly specialized and comprehensive suite of engineering and hazardous testing capabilities critical for advanced aerospace systems. WSTF provides essential expertise in Composite Overwrapped Pressure Vessels (COPVs), Micrometeoroid and Orbital Debris (MMOD) hypervelocity impacts, oxygen systems and propulsion testing. JSC’s ESTA includes six remote hazardous test facilities and support services to provide hazardous test capabilities in the areas of propulsion and fluids, power and batteries, pyrotechnics and In-Situ Resource Utilization (ISRU) development for lunar and Martian applications.

Together, these facilities cover critical testing of key space components, from material compatibility and fluid analysis to high-energy propulsion and extreme environmental validation. We invite our partners to leverage this unique, flight-proven expertise and our state-of-the-art assets to accelerate their most challenging development, qualification, and testing programs.

White Sands Test Facility (WSTF)

Composite Overwrapped Pressure Vessels

White Sands Test Facility (WSTF) tests and evaluates composite overwrap pressure vessels (COPVs) and components through studying damage tolerance and stress rupture. It also offers leading expertise in both destructive and nondestructive evaluation, training, analysis, and development of life extension protocols for composite structures.

White Sands Test Facility (WSTF) offers leading expertise in the testing, nondestructive evaluation, training, and analysis of composite structures. WSTF engages in the test and evaluation of structures by performing mechanical damage tests, sustained load testing, material compatibility, and hydraulic and pneumatic burst tests to understand and evaluate environmental effects on pressurized systems.

Damage Detection Course

A two-day damage detection course is offered to qualify aerospace visual inspectors of flight composite pressure vessels and provides comprehensive working knowledge of composite overwrap pressure vessel (COPV) technology. The course focuses specifically on mechanical damage, safe life, sustained load, and propellant/fuel exposure effects on pressure vessels built using graphite/epoxy composite filament wound onto metallic liners.

Micrometeoroid and Orbital Debris (MMOD) Testing

The White Sands Test Facility’s Remote Hypervelocity Test Laboratory (RHTL) is an access‐controlled hazardous test area capable of simulating Micrometeoroid and Orbital Debris (MMOD) impacts. This unique NASA facility was designed to safely handle and test hazardous targets, and simulate impacts on shields, spacecraft, satellites, and spacesuits.

- Three different caliber gun ranges; 1 inch, .50 caliber, and .17 caliber guns able to propel single 0.05 mm to 22.2 mm diameter projectiles with velocities in excess of 7.5 km/s

- The facility is remotely located with access control protocols and underground bunkers for personnel protection

- Various high speed cameras are used, some capable of 200 million frames per second, to capture the target impact and debris cloud

- Ability to measure projectile velocity with laser intervalometers

- High-speed data acquisition to capture the diagnostic information from the light detectors and temperature, pressure, and shock measurement sensors

- Ability to test hazardous test articles (energized, pressurized, toxic materials, pyrotechnics, etc.)

Oxygen Systems Testing and Analysis

The Oxygen Systems Engineering Group (OSEG) at White Sands Test Facility (WSTF) specializes in all aspects of the performance and safety of oxygen systems. OSEG assists in the design and optimization of these systems for all applications through comprehensive analysis, modeling and materials testing in spaceflight environments.

Analysis and Design Capabilities

- Oxygen Compatibility Assessments

- Material and Components Compatibility

- Systems Safety Analysis

- Failure investigation

- Design assistance

- White Sands Test Facility (WSTF) also offers oxygen system training courses for designers, operators, and maintainers of oxygen systems

Test System Capabilities

- High flow, high pressure particle impact ignition testing, (subsonic and supersonic velocities)

- Flowing Oxygen Promoted Combustion testing

- Friction Ignition testing

- Laser Promoted Ignition testing

- Ultra-High Pressure Promoted Combustion Testing (up to 30,000 psi)

- Ability to provide Liquid Oxygen (LOX) for pumps, turbopumps, immersion tests, and various other LOX applications

- Various low-pressure cloth/fabric flammability test chambers (upward and downward flame propagation)

- Arc/Spark ignition test system

Propellants and Aerospace Fluids Testing and Analysis

White Sands Test Facility (WSTF) performs testing that enables aerospace fluid and propulsion system designers to evaluate the risks and hazards associated with potential and existing materials, components, and system configurations.

The White Sands Test Facility (WSTF) performs laboratory-scale experiments and tests to determine and verify the properties of aerospace fluids. Tests include micro-calorimetry and accelerated rate calorimetry, flash point, fire point, differential scanning calorimetry, inductively coupled plasma-mass spectroscopy (ICP-MS), Fourier transform infrared spectroscopy (FTIR), adiabatic compression, and thermal runaway. Testing is performed on exposed and nonexposed materials per applicable NASA, military, and American Society for Testing and Materials (ASTM) standards to determine how fluid exposure affects the material’s properties. Testing can consist of exposure to any of the fluids and properties can vary depending on the type of material being evaluated (soft good, metal, ceramic, lubricant, or other materials). Testing includes tensile strength, flexure, compression set, and hardness. Composition and glass transition temperature are tested when polymers are the subject material. Posttest analysis of fluids is performed after exposure to determine how material exposure may affect fluid specifications and performance. WSTF designs free-field blast experiments up to 230-kilogram (kg) trinitrotoluene (TNT) equivalency and small-scale experiments to assess the hazards associated with a variety of high-energy release mechanisms. These energy releases can be the result of thermochemical reaction, such as with explosives and propellants; the rupture of gas or fluid storage vessels at high pressures, or both. WSTF hydrogen test facilities are designed to allow gaseous tests to be conducted at pressures up to 6,000 psi and at flow rates up to 5 pounds per second. Materials and component tests can be conducted with hydrogen in both the gaseous and liquid state. WSTF can provide in-person training to personnel handling hypergolic propellants, oxygen, and hydrogen medias. Classes are tailored to the individual audience and can vary from intense classroom discussions of new chemical analytical techniques to field training with Level-A, totally encapsulating suits (TES).

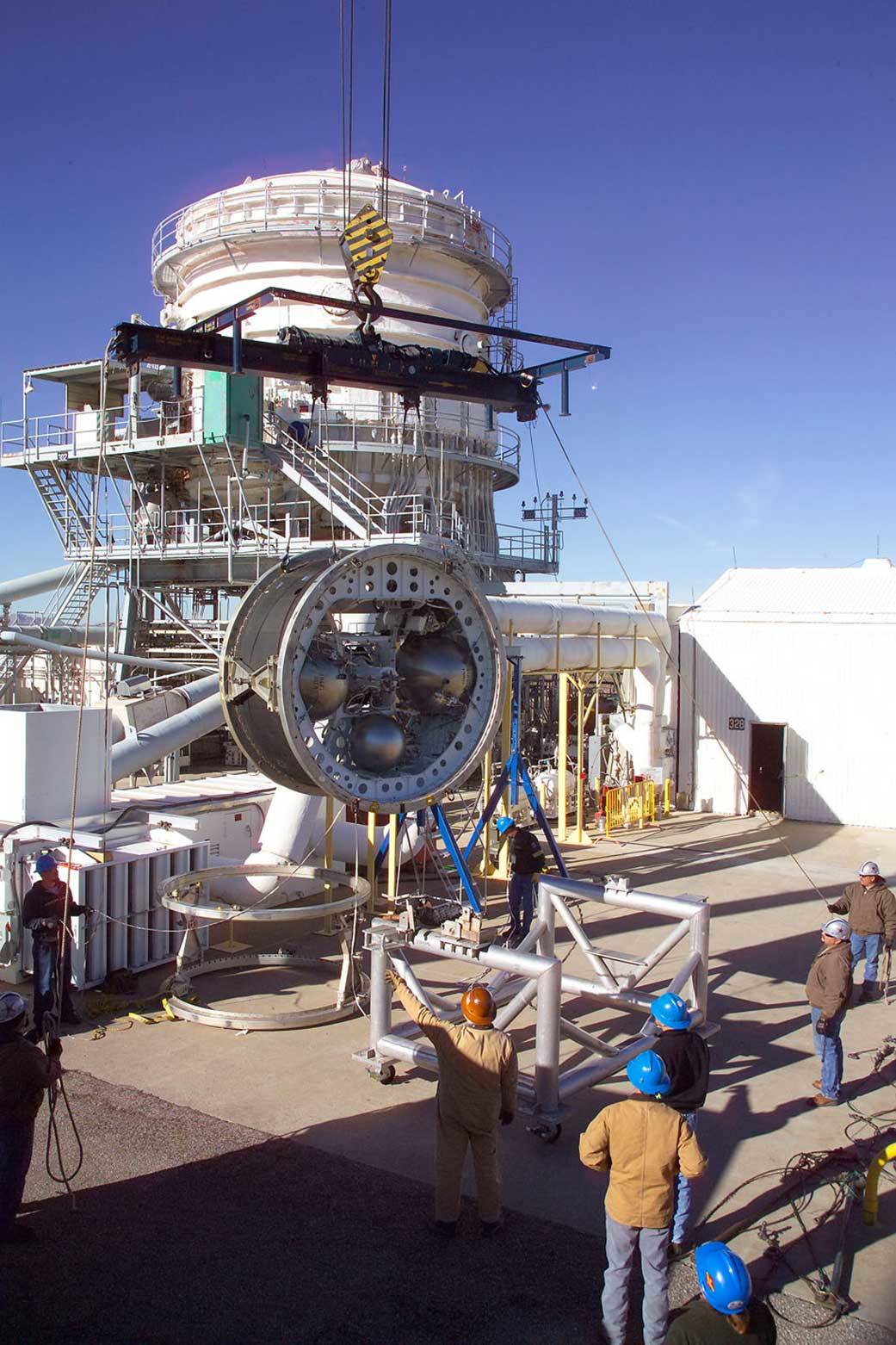

Propulsion Testing

White Sands Test Facility (WSTF) offers numerous ambient pressure and altitude simulation stands to test rocket propulsion systems, as well as single rocket engines. These facilities maintain extensive experience testing with hypergolic and liquid oxygen/hydrocarbon propellants over a wide range of operating conditions. Further information may be found at: https://www.nasa.gov/directorates/space-operations/rpt/propulsion-test-capabilities/

Altitude Testing: WSTF has six test stands that provide simulated altitude greater than 100,000 ft for engines and engine systems with thrust levels up to 25,000 pound-force (lbf). Horizontal and vertical firing configurations are available.

Ambient Testing: Three test stands at WSTF support ambient firing at 5000 ft (1500 m) above sea level. Rocket engines with thrust levels up to 60,000 lbf. (270 kN) can be tested. Horizontal and vertical firing configurations are available.

Propellants: Propellants available for testing at WSTF include liquid hydrogen, gaseous and liquid oxygen, hydrocarbon, hydrazine, Aerozine-50, monomethyl hydrazine (MMH), nitrogen tetroxide (N2O4), gaseous and liquid methane, and solid rocket propellants. Propellant saturation and temperature conditioning are available. Pressurants include nitrogen and helium.

Hypergolic Propellant Handling: WSTF can dispatch propellant handling teams to support projects at any location. Hypergolic propellants such as hydrazine, monomethyl hydrazine, nitrogen tetroxide, and unsymmetrical dimethylhydrazine have been used and stored at WSTF since 1964.

Rough Vacuum Chamber (“Pizza Oven”)

The White Sands Test Facility (WSTF) Rough Vacuum Chamber, nicknamed the “Pizza Oven”, is one of the many unique testing chambers at WSTF. The primary use is for large-scale flammability testing.

- Internal Dimensions: 7.75ft/2.36m Dia. x 6 ft/1.83m deep

- Vacuum Range: Rough Vacuum, 1×10-2 torr

- Temperature range: Ambient (No chamber temperature control)

- Volume: 283 ft3/ 8.01 m3

Spaceflight Component Processing

White Sands Test Facility (WSTF) Spaceflight Component Services Group provides support for flight, flight-like, and critical test components through fabrication, repair, refurbishment, acceptance testing, failure analysis, and decontamination processes.

Component/Test Article Decontamination Areas

- Two laboratory fume extraction hoods (one for fuel propellant & one for oxidizer propellant contaminated hardware)

- Three ISO 7 (Class 10,000) decontamination clean rooms with propellant vapor fume extractor systems for handling fuel & oxidizer propellant contaminated hardware

- Heated GN2 purge/drying system

- Deionized Water supply systems

- Portable deionized water pump/circulation system

- Portable process water catch/pump transfer system

Component Repair, Refurbishment, & Acceptance Testing

- Technical expertise in the processing of development, qualification, and flight hardware

- Personnel with hands-on experience in the processing (decontamination, failure analysis, disassembly, reassembly, repair, acceptance testing) of flight hardware ranging from Space Shuttle and International Space Station to other commercial vendor hardware

- Mono and hypergolic propellant & oxygen system expertise

- Test system design, fabrication, and operation

- Experience in the development of detailed processing & test procedures

- Borescope and microscope inspection equipment with digital recording capability

Flight Hardware Parts & Component Fabrication/Manufacturing

- Certified to manufacture flight hardware

- Foreign Object Debris (FOD) awareness training

- Technicians certified to IPC J-STD-001FS Space Applications Electronic Hardware Addendum to IPC J-STD-001F Requirements for Soldered Electrical and Electronic Assemblies

- NASA Standard STD-8739.1, Workmanship Standard for Polymeric Application on Electronic Assemblies

- NASA Standard STD-8739.4, Workmanship Standard for Crimping, Interconnecting Cables, Harnesses, and Wiring

- NFPA 70 National Electrical Code & NFPA 70E Standard for Electrical Safety in the Workplace

Bonded Storage Facility

- Procedures & systems in place for the controlled storage of critical hardware

JSC Energy Systems Test Area (ESTA)

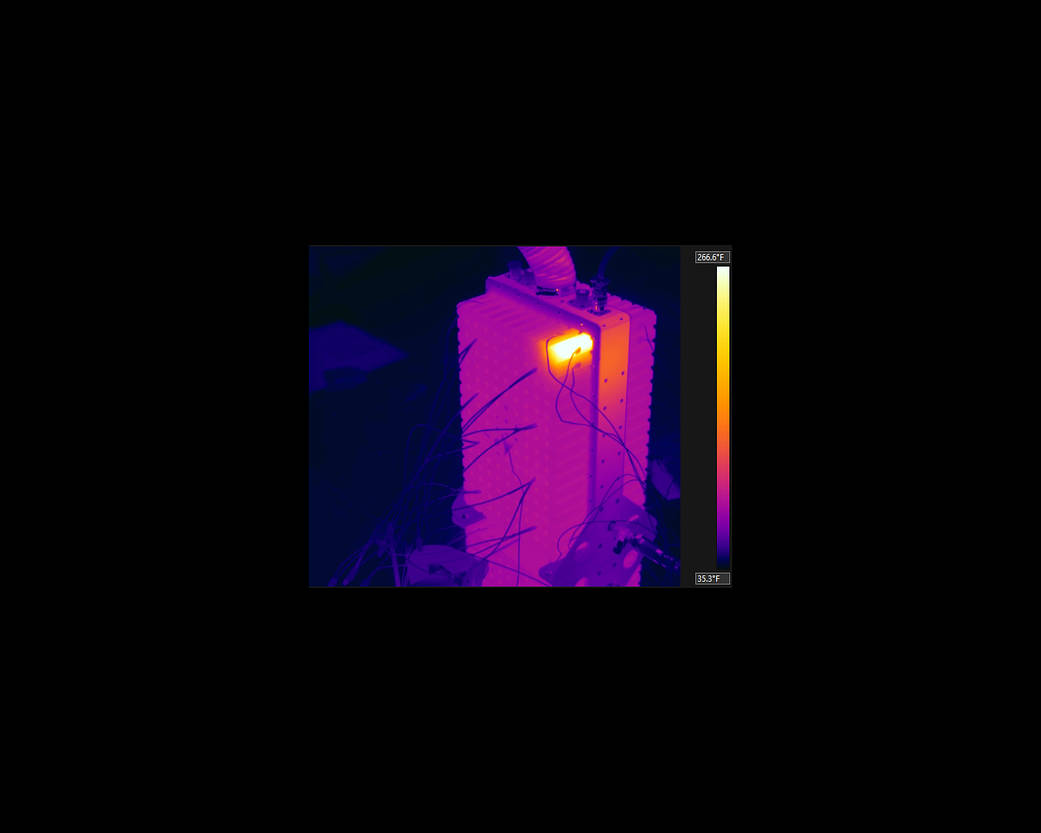

Battery Systems Test, Design, and Analysis

The development, engineering evaluation, acceptance, and flight qualification testing of dedicated high-spec batteries as needed for spaceflight is available.

- Capability to test a variety of battery Cell Chemistries (Alkaline, Li-on, NiMh, Pb-Acid)

- Battery Performance Testing and abuse testing including on-limit conditions and off-nominal failed or damaged conditions

- Battery thermal runaway propagation

Fuel Cell & Electrolysis Testing

NASA JSC has expertise in various (high & low temperature) electrochemistry, design, system integration and test of fuel cell & electrolysis systems.

- Balance of Plant Assembly

- System Operations

- Performance Evaluations in Relevant Environments

- JSC provides test facilities and services for fuel cell & electrolysis from subsystem/system testing through flight:

- Vibration

- Pyro Shock

- Thermal Vacuum

- Dust Exposure

- Oxygen and Hydrogen Testing

- Solid Oxide Fuel Cell System Performance

- Proton Exchange Membrane (PEM) Fuel Cell Performance

- Solid Oxide Electrolyzer System Performance

- PEM Water Electrolyzer System Performance

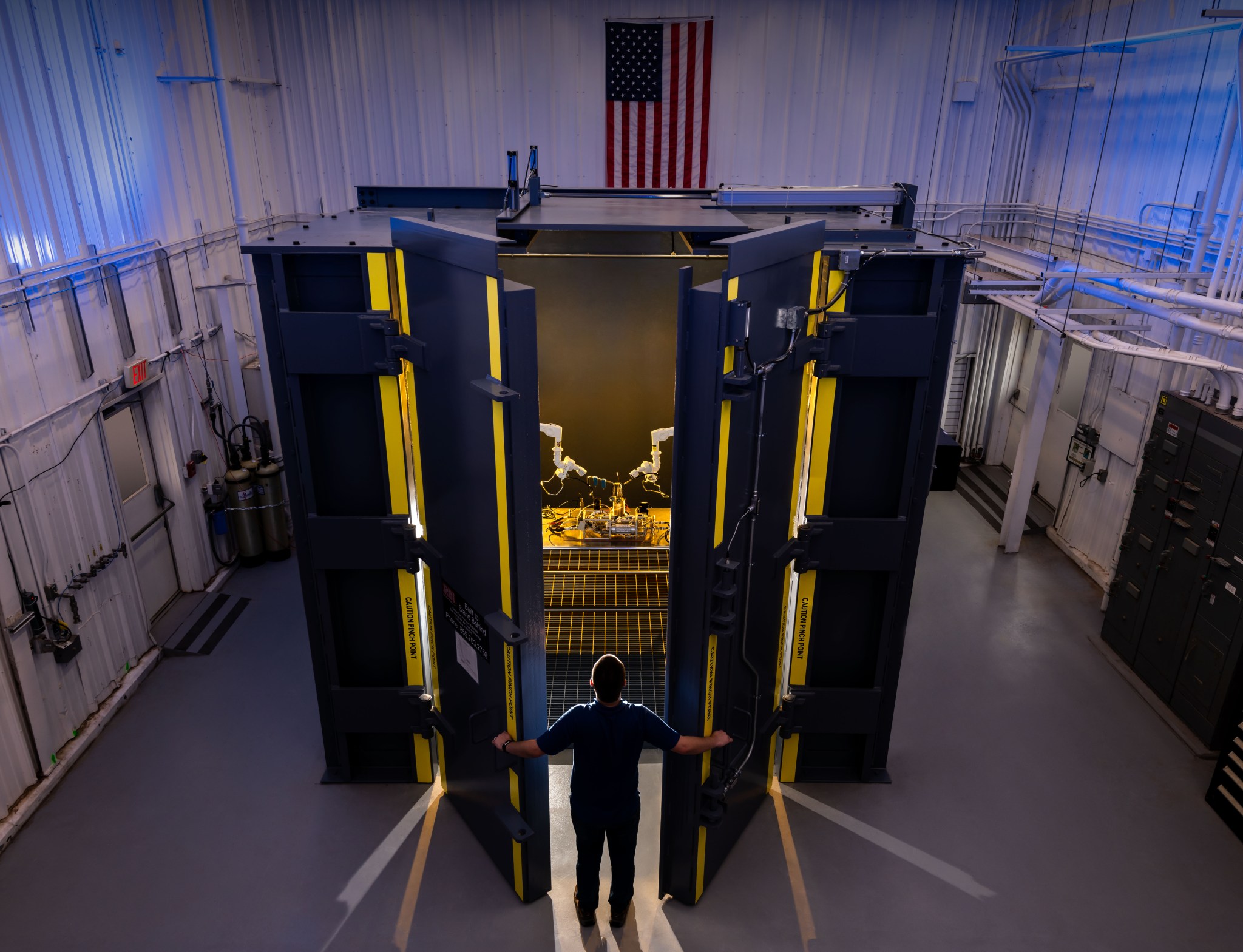

Hazardous Vibration & Shock Testing

The Pyrotechnics Test Facility includes the capability to subject hardware to vibration and pyroshock environments encountered during launches and landings.

- The Vibration Shaker System is capable of subjecting components and systems to random and sinusoidal vibration levels up to 26,000 g-lb, over a frequency range of 20 to 2000 Hz. The vibration table is located in a blast-resistant test cell capable of handling hazardous test articles.

- The test facility also houses two Pyroshock Test Stands, the pneumatically-operated Tunable Beam and the explosively-operated Resonant Plate Stand. Both test stands are regularly utilized for subjecting components to shock environments up to 10,000 g, over a frequency range of 100 to 10,000 Hz.

In-situ Resource Utilization (ISRU) Development and Testing

JSC has a long history of technology development of In-Situ Resource Utilization (ISRU) hardware and systems for use on the Moon and Mars.

JSC’s ISRU area of expertise:

- Various chemical conversion processes: Hydrogen Reduction of Lunar Regolith, Carbothermal Reduction of Lunar Regolith, Solid Oxide Electrolysis of Mars atmosphere

- Water evolution and capture from Lunar polar and Mars soils

- Product stream capture and purification including mixed gas separation, condensation and regenerative gas drying

- Water electrolysis and regenerative fuel cells

- Regolith sample transfer including weighing, manipulation and heating

JSC specializes in System Engineering and integration of ISRU systems:

- Modeling of complex chemical processes, regolith excavation and transfer systems, ISRU system sizing and scaling, architectural evaluations, and thermal conversion systems and the interactions between them

- Integration and evaluation of ISRU subsystems and systems

- Integration and execution of end-to-end system field test campaigns

JSC Test Facilities and services for ISRU hardware from concept development through flight:

- Vibration

- Pyro Shock

- Thermal Vacuum

- Dust Exposure

- Oxygen and Hydrogen Testing

- Solid Oxide Electrolysis Performance

- Water Electrolyzer Performance

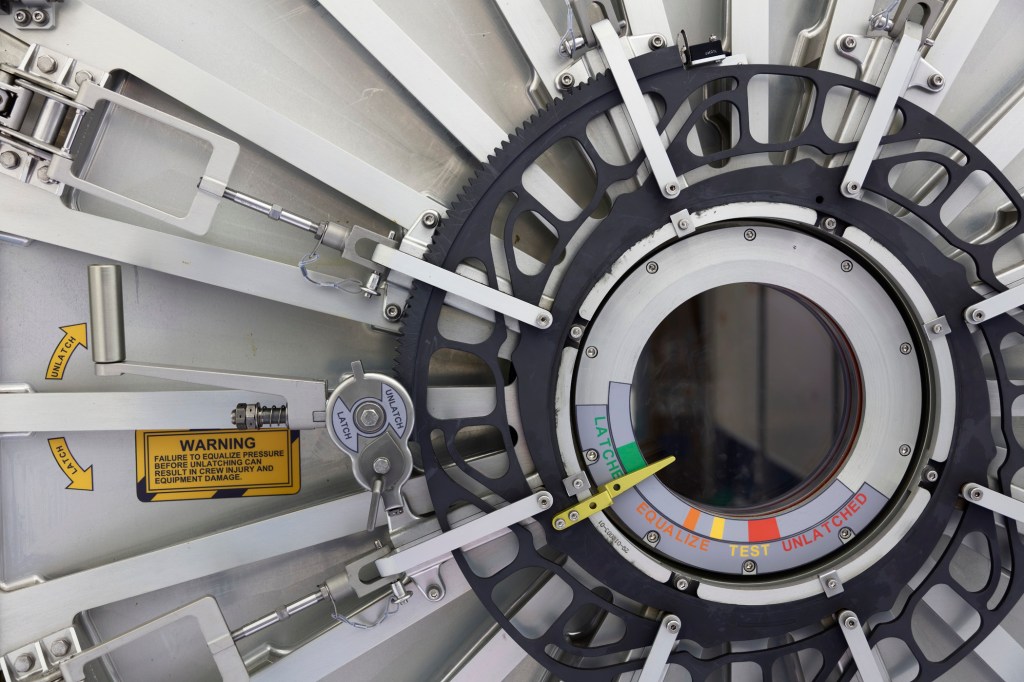

Pressure System Testing

NASA JSC has expertise in the design, fabrication, build, and test of vehicle-level integrated pressure systems.

- High-pressure hydrostatic proof and burst

- High-pressure pneumatic proof and burst

- Inflatable proof and burst

Pyrotechnics Testing

NASA JSC provides nondestructive and destructive testing of pyrotechnic hardware including initiators, detonators, gas generators, and linear explosives used in all phases of spaceflight.

- Test cells for destructive testing of pyrotechnic devices and full systems

- Non-destructive evaluation support (including X-ray), dimensional inspection, proof pressure, vacuum, and leak testing

- Thermal cycling and cryogenic (-452 °F) conditioning

- Loading of propellants, pressure cartridges, and explosive devices

- Pyroshock and vibration of hazardous test articles, including pressurized systems and explosive materials

- Internal ballistic analysis and data reduction

- Pyrotechnic storage

Self-Contained High Pressure Testing Enclosure

The “Boom Box” Pressure Test Enclosure is a high strength steel box designed to provide protection to personnel while performing high pressure testing up to 30,000 psig.

- Enclosure rated up to 30,000 PSI at 2 cu/ft volume (Ar, He or GN2)

- Hydrostatic pressure testing up to 30,000 psi

- Pneumatic pressure testing up to 15,000 psi at 4.5 cu/ft volume (Ar, He or GN2)

- 12’x12’x12’ interior work area

- 8’ x 12’ entry door area

- Data acquisition for pressure documentation

- Camera viewing and recording for remote observation

Wide Range Dedicated Battery Systems Testing Abilities

Dedicated as needed testing and evaluation of spaceflight battery systems for flight qualification, design evaluation, and other highly specialized needs.

- Low Current/Voltage to High Current/Voltage

- Constant Voltage, Current, and Power Modes Provided

- Long-term and Short-term cycling

- Determination of Optimal Charge and Discharge Rates

- Thermal Capacities/Vacuum Tolerance

- Hazardous Vibration test Stand

- High Temperature Exposure and Heat-to-Vent Testing

- Over Charge and Over Discharge Characterization

- Positive Temperature Coefficient Failure Testing

- Short Circuit Testing

- Crush and Drop Testing

- Destructive Physical Analysis

Connect With Us

Whether you are a public agency, private company, or academic institution, we look forward to hearing from you. Fill out the Statement of Interest form to submit your inquiry.