Gernod Dittel and Berthold Vogt

Dittel Engineering

The success of newcomer companies such as SpaceX shows one thing above all: there is a spirit of optimism in commercial space travel and there is one sector that will benefit from the growth of the aerospace market: cleanroom technology. Gernod Dittel and Berthold Vogt from Dittel Engineering talk about how the sectors works together.

Article courtesy of HPCi Media/Cleanroom Technology

Not only private companies, but also state space agencies have set themselves ambitious goals. According to forecasts by management consultants, the global market for space technology will increase tenfold in the next 20 years to 2,700 billion euros (2040).

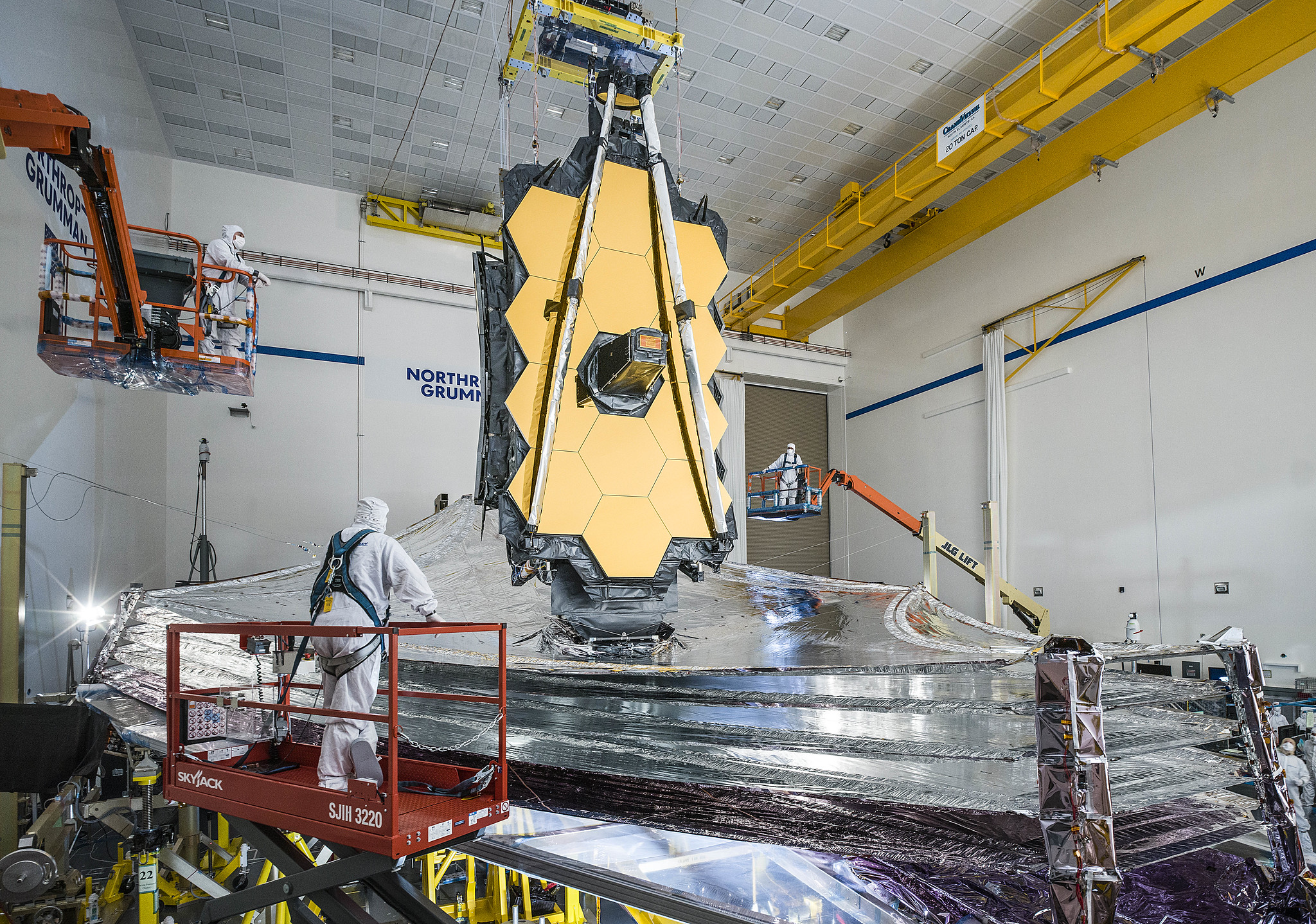

Many scientists, engineers, suppliers and service providers will benefit from this growth—and cleanroom technicians. Because almost all those involved in space travel have one thing in common: a cleanroom.

In space travel, it is the small things that make big projects fail. When an Ariane 4 was launched in 1990, it was a cleaning rag in a pipeline that caused the crash. In 1994 there were two false starts because dirt had paralyzed a turbo pump. This happens not only to the European Space Agency (ESA). NASA needed five repair missions to iron out a manufacturing defect in the Hubble telescope. The primary mirror was ground a few micrometers too flat. This was found out too late, namely only at the top.

The examples show the special nature of technical requirements in space travel: Aggregates and satellites must be and remain 100% functional when they arrive at the site of operation and are to be operational in orbit for several decades. Once in space, repair and cleaning are usually impossible.

Even small particles are capable of endangering missions. Smeared optics, dirty solder joints, unclean bearings are weak points that must be prevented. The engineers have learned this in a painful and costly way, through error analysis after accidents.

Automation offers no way out; satellite integration remains a manual task

The most important consequence of this learning curve is the continuously developed cleanroom. Even its creation is closely connected with space travel.

In order to further develop the German V2 rocket, the Americans built one of the first technical cleanrooms for the assembly of gyroscopic devices. Because the control and monitoring functions of airplanes and rockets were to become more and more precise, the need for precision in production also increased.

Thus the further development of cleanroom technology supported the aerospace industry, just as it set trends for the cleanroom guild with its requirements and budgets. Maximising reliability, i.e. reducing the failure rate for launchers and payloads, is the essential contribution of today’s cleanrooms to space travel. Satellites are created along a long cleanroom chain. This ranges from component production and integration to transport to the launch site and into space.

Apart from technology, the critical factor is always the human. He is the main source of contamination in the cleanroom, as he releases one to 30 million particles of the size >0.3 µm per minute. Therefore the personnel active in the clean area carries special protective suits. These protect the product rather than the personnel—unlike suits for space travelers.

Purity requirements between visual inspection and biohazard

The highest demands on purity are made by missiles that are to land on other celestial bodies. They must have neither particles nor germs on board. If spores or bacilli were to travel with them, they would falsify the measurements in the search for extraterrestrial life. They would also violate part of the Outer Space Treaty, signed in 1967 in the run-up to the Viking missions to Mars.

At that time, the U.S. and the Soviet Union agreed to exercise caution, at least on the other side of the world. No foreign planet should be influenced in its development by the entry of terrestrial flora and fauna.

Meanwhile, 110 space travelling nations have joined this principle. Because such missions only rarely take place, existing cleanrooms are converted for their integration.

During work breaks UV lamps kill germs in the air. Assemblies are radioactively irradiated, gassed with chlorine or heated above 140°C. Sterilisation measures are applied until a lower limit for the number of germs is reached. Completely germ-free integration is not possible. For this reason, comprehensive sterilisation is unavoidable for landing units.

At the other end of the spectrum of cleanliness requirements is the category “Visible Clean”. This lowest of all classes does not exist in any set of regulations of other industries, only in the space standard ECSS-Q-ST-70-01C (European Cooperation for Space Standardization—ECSS).

Visible Clean is a standard for development labs, not for integration. The personnel constantly change between laboratory and office, there is no airlock. A pressure control is also missing and the air flow in the room is not defined. Only direct contamination by street clothes is prevented. Rooms of this lowest permissible level can also be described as ISO class 9 or as a basically controlled area.

All higher-class cleanrooms are air-conditioned. Their temperature is usually 22°C (±3°C) and their relative humidity is 55 % (±10 %). Controlled humidity protects electronic components: Dry air can cause electrical flashovers. ESD (Electrostatic Discharge) floors also prevent flashovers. ESD equipment includes dissipative clothing, shoes and gloves, all suitable for preventing voltages above 100 volts.

Other equipment features include specially equipped cranes with encapsulated drive units and coated belts. This is because impellers generate abrasion while lubricated suspension ropes outgas.

Satellites that only have electronic components such as radar or communication systems on board have medium requirements. Most satellites originate from cleanrooms of ISO Class 7 and 8, but their sensitive components deserve more attention. These satellites are also equipped with star sensors for autonomous (self-sufficient) positioning, and with attitude control systems that operate with liquid or gas. The valves must be tight. Leakage shortens the service life. These components are usually covered during integration.

In ISO Class 8, an air exchange with conditioned filtered air takes place up to 40 times per hour. There is an overpressure of 20 to 30 Pascal in the room. Laser particle sensors monitor that no more than 3,520,000 particles of size 0.5 µm and 29,300 particles of size 5 µm per minute per m3; are in the air. ISO Class 7 shows 352,000 particles of size 0.5 µm and 2,930 particles of size 5 µm.

The cleanroom itself has requalification and calibration once a year.

Missions to other celestial bodies are rare so existing cleanrooms are converted for their integration

Cleanroom gowns or overalls, cleanroom shoes and headgear are mandatory, as is a beard bandage for beard wearers. Anyone handling the aircraft must wear gloves. Components only enter and leave the aircraft through airlocks. Although it is a cleanroom, the room is not dust-free and must be cleaned according to plan and regulations. Contaminants are deposited in quiet zones on the ground or on surfaces. Once a day a mop and distilled water is used to wipe the room.

Satellites with extremely sensitive optical systems, such as reconnaissance satellites, are integrated in a Class 5 cleanroom. Particles on optical surfaces increase the scattered light component, while molecular impurities cause spectral interference. Cleaning with a soft brush is time-consuming and can scratch the coating. After washing, streaks may remain. Priority is therefore given to trying to avoid all contamination. Thus, no silicone should be used in the cleanroom. Silicone evaporates in >20 years, thus releasing molecules.

Vapours during operation must be eliminated via the ventilation system. A vertical low-turbulence displacement flow from the ceiling to the floor is ideal.

Another possibility is a horizontal flow. The discharge surface consists of a grille with many Filter Fan Units with fan and terminal filter. Surfaces of workbenches/worktables are usually perforated to allow the air to flow through without creating disturbing turbulences. Employees enter the ISO 5 cleanroom via an airlock system of cleanroom classes ISO 7/8, where they adjust their clothing to the higher requirements.

Trends in future satellite integration rooms

When looking into the future of cleanrooms for space travel, the higher requirements and costs stand out. The integration of a satellite with a length of about 5 m requires an area of about 300 sqm. The price per sqm is based on a usage fee of several 100 euros per day. This means that the cleanroom costs alone already swallow up millions.

When dealing with these costs, it can be seen in commercial projects that tenants tend to choose a cheaper, i.e. too low cleanroom class or reduce the useful life. Automation offers no way out; satellite integration remains a manual task.

Especially optical systems increase the requirements for cleanrooms. They should look further and further into space or take more detailed pictures of the earth. Humans currently see only a fraction of the estimated 10 billion trillion stars. A deeper look into space requires more precise technologies.

One example of this is the ESA project ATHENA, an X-ray telescope with a mirror construction made of millions of micrometre-sized silicon wafers. Miniature satellites with edge lengths of just 10 cm also require higher cleanroom quality.

The more miniaturised the systems are, the more sensitive they are to dust. In the future, such satellites will have to be integrated in rooms of class ISO 5 or higher. This can be achieved in a cost-conscious manner by establishing a higher class only for a limited area.

Even this will not be enough for satellites with sophisticated optical systems. They no longer focus on particles alone, but on molecules (AMC—Airborne Molecular Contamination), especially organic components in the air.

If an employee even breathes on a solar panel, there is a measurable reduction in performance. This is permanent, and cleaning does not change this. Molecules can be filtered out with non-specific activated carbon filters for supply and circulating air. A standard that will soon be available in every cleanroom of ISO class 5. Stricter standards must also be applied to the measurement technology. Up to now, after several days of exposure to a sampler, only a subsequent analysis can be performed. In order to eliminate sources immediately, it would be necessary to measure in real time.

Transport in mobile cleanroom

Satellite integration requires many transports. The weakest link in the chain determines the final quality. Therefore, the conditions for transport must be the same as for integration. The transport container is in principle a robust mobile cleanroom of Class 8 including climate control.

It is often flooded with dry nitrogen and pressurised under slight overpressure. Before the satellite fuselage enters from above or from the side, the roughly pre-cleaned transport container is finely cleaned in an air lock.

The container only meets the satellite in the main airlock. Bulky attachments like solar collector and antennas travel separately. When transporting with a flatbed truck, shocks may only be transmitted in a damped manner. For this purpose, the container and the satellite’s supporting structure are decoupled by spring elements.

The satellite is put through its paces in test centres with large ISO Class 7 and 8 cleanrooms, which are not available at every integration site. Access to the test facilities, in which space conditions such as negative pressure, temperature scenarios and vibrations are simulated, is from a central cleanroom.

On the “shaker”, the satellite is shaken in the same way as during launch. If components break off in the process, the mountings can be reinforced or redesigned and dimensioned in good time. In order not to unnecessarily increase the quality requirements for the cleanroom, sensitive subsystems are covered. After successful tests, the satellites are brought directly to the launch site, usually by cargo plane. A transport container for air transport must meet the requirements of the IATA (International Air Transport Association). These include a bursting disk that ensures pressure equalisation when the cabin pressure drops.

Satellite integration requires many transports

Cleanroom quality must also be maintained at the launch site. Either the satellite is assembled in a cleanroom in a separate closed payload capsule. The advantage of the spatial separation of integration room and rocket is bought with an additional adapter. Another possibility is to mount the satellite directly on the carrier. In this case, the interface level of the carrier to the payload extends into a cleanroom where the satellite is placed and connected with a clamping ring. Before the outer hull (fairing) is closed, a check is made to see whether stowaways have crept in.

But not only these are responsible for contamination, the atmosphere itself is also responsible. In Internet forums, technicians report on geckos and spider webs that had to be prevented from travelling, whether by nitrogen flooding or with the help of a vacuum cleaner. When the outer shell is blown off at an altitude of 100 km, the atmosphere is so thin that there is no longer any risk of contamination from stowaways.

Journey from the cleanroom to the dump

As hard as humanity is trying to send up its sky messengers in a clean state, it is negligent with its satellites at the other end of the life cycle.

At the end of March 2020, 2,700 functional satellites were orbiting the earth, 1,300 of them from the U.S.

However, they are in the company of around 17,000 satellites that are either broken or no longer needed. The ESA model MASTER-2005 assumes that there are more than 600,000 objects with a diameter of more than 10 mm in orbits around the Earth. Other simulations estimate 150 million objects in mm size. The U.S. Space Surveillance System continuously keeps track of objects larger than 50 mm. When approaching, evasive manoeuvres are required and the International Space Station is also forced to make course corrections from time to time.

The ideas for a cleaning crew range from space vacuum cleaners to the shooting of space debris.

Whichever cleaning method is used, there is a lot of work waiting for the space nations if they want to clean up in Earth orbit. If they succeed in sweeping up in front of their doorstep, this would prove the effort of mankind to settle down in the solar system in the long run—in order to set off from here perhaps later to new worlds.