Electric Propulsion and Power Laboratory

The Electric Propulsion and Power Laboratory (EPPL) supports research and development of spacecraft power and electric propulsion systems. The staff of EPPL have been supporting electric propulsion and power system testing for over 40 years.

Facility Overview

The Electric Propulsion and Power Laboratory (EPPL), formerly known as the Electric Propulsion Laboratory (EPL), supports research and development of spacecraft power and electric propulsion systems.

EPPL features two very large space environment simulation chambers; intermediate and smaller environment simulation chambers suitable for testing small engines or components; bell jars used for development and small-scale component testing; and support areas including an electronics shop, machine shop, clean room, and office space.

The space simulation chambers have been enhanced to support the unique requirements of electric propulsion and power system testing. VF-5 cryopumps 3.5 million liters of air per second with its 33.5 sq meter of 6 K helium cryopanels. Several of the chambers have multiple air-locked access ports. These ports allow several tests to be conducted simultaneously in each chamber without cycling the chamber back to atmospheric pressure during introduction or removal of test hardware. Conditioned DC power is supplied to VF-5, VF-6 and VF-12 for powering ion, hall and MPD thrusters.

The staff of EPPL have been supporting electric propulsion and power system testing for over 40 years and have developed technology leading techniques with precision thrust balances, thruster erosion diagnostics, plume characterization, and EMI/EMC.

Quick Facts

The Electric Propulsion and Power Laboratory (EPPL) supports research and development of spacecraft power and electric propulsion systems. EPPL features two very large space environment chambers; intermediate and smaller environment simulation chambers for testing small engines or components; bell jars used for small-scale development and component testing; and support areas.

| Name | Electric Propulsion and Power Laboratory |

|---|---|

| Vacuum Facilities | VF-5 and VF-6: Very high pumping speed for electric propulsion testingSix intermediate chambers (VF-8, VF-12, VF-13, VF-17, VF-56, & VF-67) |

| Laboratory and Build-up area | 50,000 square feet |

- Take a virtual tour of our Electric Propulsion and Power Laboratory.

- The EPPL features space simulation chambers that have been enhanced to support the unique requirements of electric propulsion and power system testing.

- The EPPL can support all phases of propulsion or power system testing of flight ready hardware from TRL 2–7.

- The VF–5 cryopumps 3.5 million liters of air per second with its 33.5 sq meter of 6 K helium cryopanels.

- The EPPL has supported such programs as Prometheus, Energetic, the International Space Station (ISS) and the Jupiter Icy Moon Orbiter (JIMO).

- Several of the chambers have multiple air-locked access ports that allow several tests to be run simultaneously in each chamber without cycling the chamber back to atmospheric pressure during introduction or removal of test hardware.

Capabilities

General EPPL Capabilities

- Vacuum Chambers

- Two world-class facilities (VF-5, VF-6)

- Six intermediate facilities (VF-8, VF-12, VF-13, VF-17, VF-56, VF-67)

- Multiple vacuum bell jars.

- Building Features

- 50,000 square feet of laboratory and build-up area

- 340 sq ft of class 1000 Clean Room

- 15 Experimental Labs

- Central control room

- Machine shop

- Shared Facility Systems

- LN2supplied by a 55,000 gallon dewar

- Cooling tower water

- Closed-loop -45°C refrigeration 16 tons

- Distributed DC Power for EP Testing

- 200 KW (2000V, 100 A)

- 40KW (2000V, 20 A)

- 500KW (200V, 2500 A)

Vacuum Facility 5 (VF-5)

- High Power Electric Propulsion System Test Bed

- Dimensions

- Overall 4.6m diameter by 18.3m long

- Access 4m diameter by 9m long

- Vacuum System

- World-class pumping speed

- 700 kL/s Xenon @ 10-6 torr

- No Load Pressure 1 x 10-7torr

- Xe gaseous feed system

- Cryopumps

- 33.5 m2of helium panel

- 750 Watts @ 20 K

- Pumping Speed: 700 kL/s Xenon @ 10-6 torr

- Temperature Range 6 K to 20 K

- Diffusion Pumps

- (20) 32 inch diffusion pumps

- 250,000 l/s air @1 X 10-6torr

- Refrigeration system cooled chevron traps

- Multiple Test Ports

- 1.8m diameter by 2.4m long

- (2) 0.9m diameter by 0.9m long

- 0.3 m diameter by 0.3 m long

- Automatic, unattended operation controls

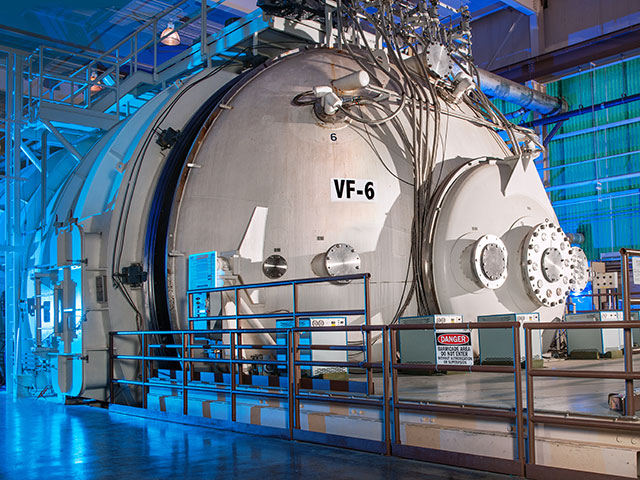

Vacuum Facility 6 (VF-6)

- Large scale thermal vacuum facility for power system testing and high power electric propulsion

- Xe gaseous feed system

- Dimensions

- Overall 7.6 m diameter by 21 m long

- Access 6.7 m diameter by 18.3 m long

- Vacuum System

- Pumping speed: 310 kL/s Xenon @ 10-6 torr

- Base (No Load) Pressure: 5 x 10-7torr

- (12) 54 in nude cryopumps

- (4) 3080-ft3/min root blowers

- (3) 850-ft3/min mechanical pumps

- 3 m diameter by 3 m long test port

- Thermal Simulation

- LN2cooled (77deg K) shroud

- 240-kW thermal rejection

- 300 m longitudinal shroud

- 6.6m diameter by 18m long max access

- Divided into three segments longitudinally

- Automatic, unattended operation

Vacuum Facility 8 (VF-8)

- Low Power Electric Propulsion Testbed

- Dimensions

- Overall 1.5m diameter by 4.5m long

- Access 1.3m diameter by 4.3m long

- Vacuum System

- Pumping speed: 120,000 l/s air @10-5torr

- 4 x 10-7torr base (no load) pressure

- (4) 35-inch diameter oil diffusion pumps

- (1) 3080 ft3/min root blower

- (2) 300 ft3/min mechanical pump

- Test Ports

- End port: 0.9m diameter by 0.8m long

- Side port: 0.6m diameter by 0.6m long

- Gaseous Feed Systems

- Nitrogen, XE

- Automatic, unattended operation

Vacuum Facility 12 (VF-12)

- Medium to High Power Electrostatic Thruster Testbed

- Xe gaseous feed system

- Dimensions

- Overall 3.0m diameter by 9.0m long

- Access 3.0m diameter by 5.0m long

- Vacuum System

- Pumping speed: 150 kL/s Xenon @ 10-6 torr

- 8 x 10-8torr base (no load) pressure

- Cryopanels 350 W @20K

- Automatic, unattended operation

Vacuum Facility 13 (VF-13)

- Liquid Nitrogen Cold Shroud

- Lunar Simulant Test Bed

- Dimensions

- Overall 1.5m diameter by 3.5m long

- Upper 2.75m is removable

- Vacuum System

- Pumping speed: 10,500 l/s air at 10-6torr

- 4 x 10-7torr base (no load) pressure

- 20 in. Cryopump and Turbo Pump

- Quick turnaround by isolating high vacuum pump system

- Automatic, unattended operation

Vacuum Facility 17 (VF-17)

- Base Pressure (no load):

- 5 x 10-7 torr

- Dimensions

- 2.2m long, 0.9m diameter

- Vacuum System

- 12 in. Cryopump

- Pumping Speed: 1400 liters per second

- Liquid Nitrogen Cold Shroud

Vacuum Facility 56 (VF-56)

- Base Pressure (no load):

- 5 x 10-6 torr

- Vacuum System

- Cryopump

- Pumping Speed: 400 liters per second

Vacuum Facility 67 (VF-67)

- Liquid Nitrogen Cold Shroud

- Dimensions

- Overall 1.0m diameter by 3.0m long

- Vacuum System

- Pumping speed: 10,000 l/s air @10-6torr

- 9×10-7torr base (no load) pressure

- 20-inch Cryopump

- Automatic, unattended operation

Contact

Electric Propulsion and Power Laboratory

Facility Manager: Ernest Williams

216-433-3554

ernest.t.williamsii@nasa.gov

Test Facility Management Branch

Branch Chief: Michael S. McVetta

216-433-2832

michael.s.mcvetta@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

Did you test in one of our facilities? Let us know about your experience by participating in our customer facility evaluation survey.

Gallery

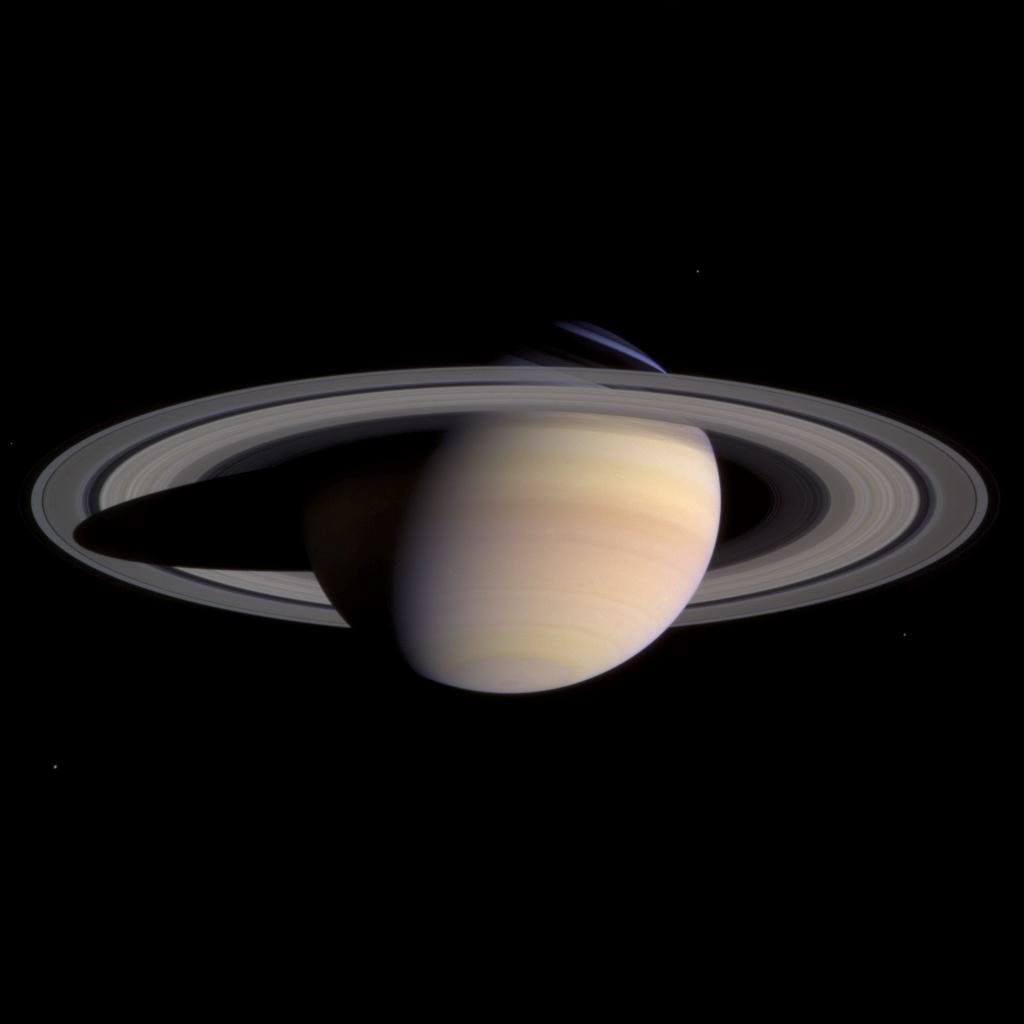

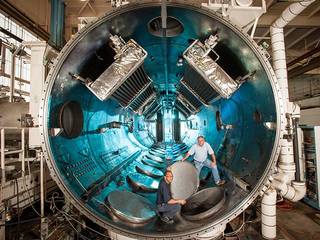

Thermal Vacuum Facility 5

Thermal Vacuum Facilities 5 is a part of NASA Glenn Research Center’s Electric Propulsion and Power Laboratory.

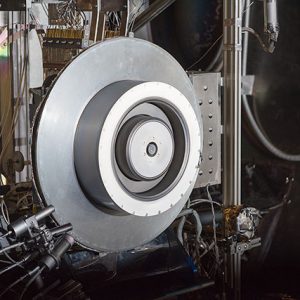

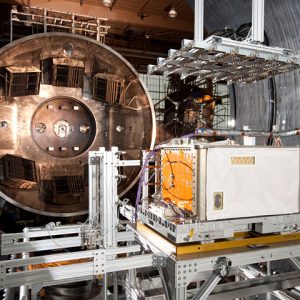

Post Vacuum Facility 5 Test

300M Magnetically Shielded Hall Thruster, Post Vacuum Facility 5, VF5 Tests.

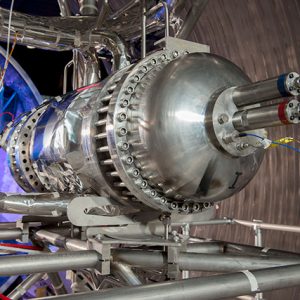

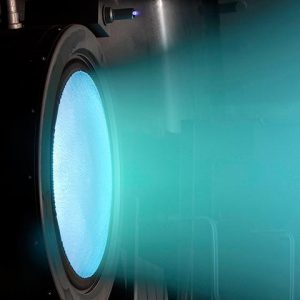

NASA’s Evolutionary Xenon Thruster

NASA’s Evolutionary Xenon Thruster (NEXT) Project has developed a 7-kilowatt ion thruster for deep space missions.

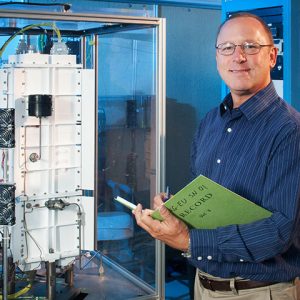

CoNNeCT

Communication, Navigation, and Networking Reconfigurable Test-bed (CoNNeCT) in the Electric Propulsion and Power Laboratory.