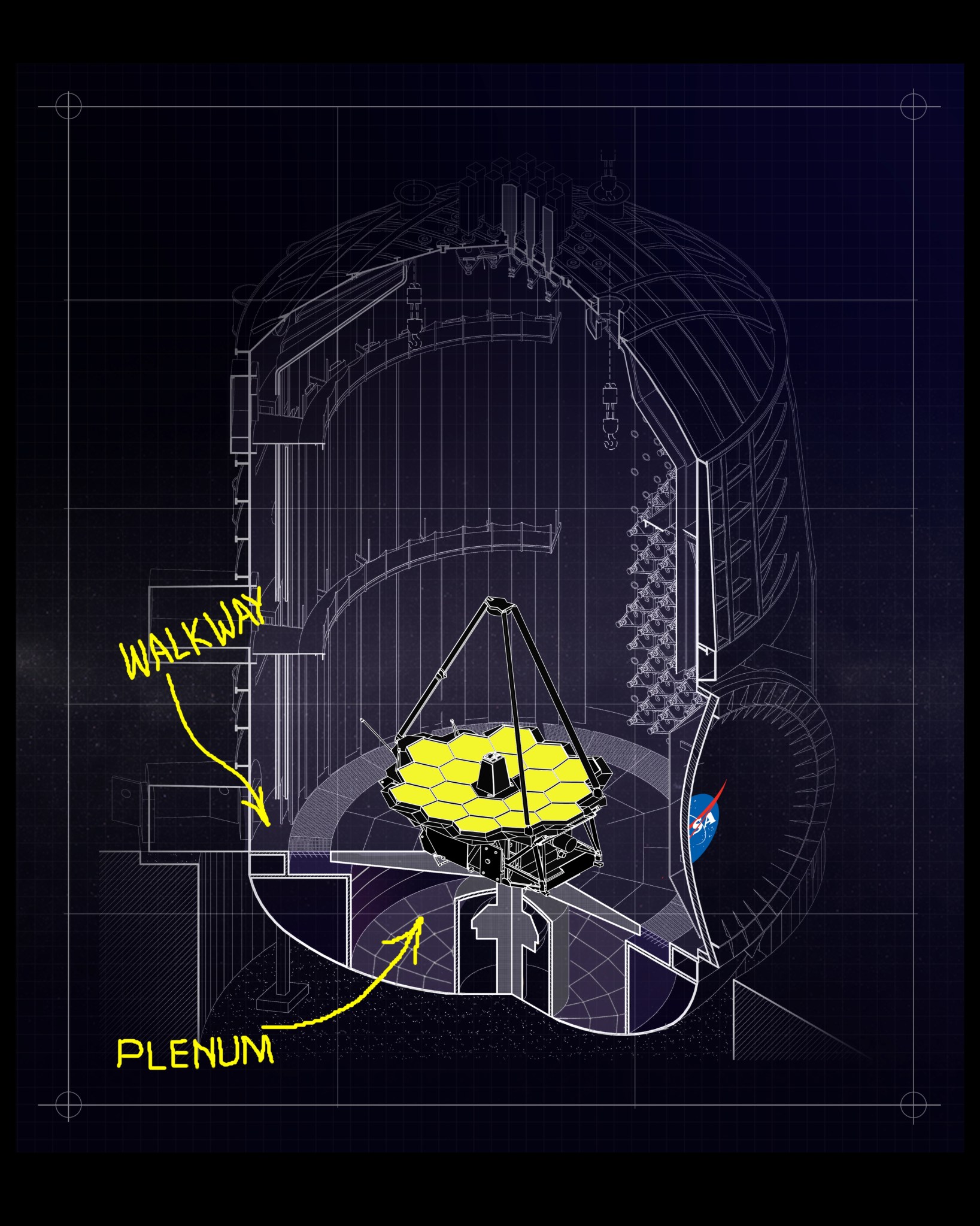

Hidden beneath Chamber A at NASA’s Johnson Space Center in Houston is an area engineers used to test critical contamination control technology that has helped keep NASA’s James Webb Space Telescope clean during cryogenic testing.

This voluminous area is called the plenum, and it supports the weight of the chamber above as well as houses some of the cabling and plumbing for it. Before Webb’s cryogenic testing in the chamber commenced, engineers ventured to the plenum’s depths to test NASA-developed technology designed to remove molecular contaminants from the air.

Catching contaminants

Nithin Abraham, a coatings engineer at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, is part of a contamination control team tasked with ensuring Webb remains as clean as possible during its testing in Chamber A. Abraham is the principal investigator of the coatings research team that has developed and tested a highly porous material called molecular adsorber coating (MAC), which can be sprayed onto surfaces to passively capture contaminants that could be harmful to Webb’s optics and science instruments.

Not to be confused with absorption, adsorption is the process in which microscopic materials (for example, atoms and molecules) adhere to a surface — in this case, to the surface of a panel coated with the MAC. The MAC panel secures contaminants released through outgassing, a process that occurs when gas that was dissolved, absorbed, or otherwise trapped within a substance is released into the surrounding environment. An example of this is the coveted “new car smell” of a freshly manufactured automobile.

Even minute amounts of outgassed material within the plenum could have posed a threat to Webb’s optics and science instruments located in Chamber A, so Abraham and her team — engineers turned spelunkers — descended into the cave-like space to place the MAC panels before cryogenic testing began.

To reach the plenum, the engineers walked single file along a narrow, mineshaft-like passageway between the helium shroud that surrounds the Webb telescope and the wall of the chamber, then descended a ladder into the cylindrical room. Light along the passageway and within the plenum is sparse, so the engineers donned headlamps before they made the journey. They also wore oxygen sensors to warn them if oxygen levels inside the plenum were getting low.

The MAC panels in the plenum primarily captured hydrocarbons and silicone-based compounds. These contaminants are ghosts of the Apollo era, when a mechanism within the central cylinder of the plenum rotated the floor of the chamber above. This rotation simulated the thermal roll used to evenly disperse heat on the Apollo spacecraft during their journeys to and from the Moon. Nithin and her team also placed MAC panels inside Chamber A, including on the outside of the helium shroud.

“We do a thorough analysis on the types of contaminants that were collected and how much,” said Abraham. “That data is very useful and shows that we are protecting [the telescope] from molecular contamination.”

Shielding the Webb telescope

MAC panels are only one type of contamination control protecting the Webb telescope from both microscopic and macroscopic threats. Engineers wear white cleanroom suits to prevent particles of skin, hair, and clothing fibers from depositing on the telescope. Similarly, Webb must move from cleanroom to cleanroom because the rooms are specially designed to reduce the amount of airborne particles present. Engineers enter the cleanrooms using airlocks, and the rooms have positive air pressure compared to their surrounding environment, so air flows out of the area and takes any potential contaminants with it.

Outgassing in space

When a spacecraft is exposed to the vacuum of space, outgassing occurs from epoxies, tapes, lubricants, plastics, and other materials used to construct it. For Webb, the biggest threat from outgassing comes early in its mission, shortly after launch when the telescope is cooling down but is still warm.

“Fortunately, warm things outgas but cold things not so much, so once the telescope and instruments go cold, the outgassing goes way down,” explained Lee Feinberg, optical telescope element manager for the Webb telescope at Goddard.

Engineers will control the temperatures of the different parts of the observatory as it cools so outgassed molecules from one part do not deposit elsewhere, such as on sensitive surfaces like the optics, but instead escape to space. Though the MAC is only being used terrestrially and peripherally for Webb, engineers are researching ways to apply the coating directly onto elements of future NASA spacecraft, as an added measure of protection.

After cryogenic testing at Johnson is complete, Webb’s combined science instruments and optics journey to Northrop Grumman in Redondo Beach, California, where they will be integrated with the spacecraft element, which is the combined sunshield and spacecraft bus. Together, the pieces form the complete James Webb Space Telescope observatory. Once fully integrated, the entire observatory will undergo more tests during what is called “observatory-level testing.” This testing is the last exposure to a simulated launch environment before flight and deployment testing on the whole observatory.

Credits: NASA’s Goddard Space Flight Center/Mike McClare

Webb is expected to launch from Kourou, French Guiana, in the spring of 2019.

The James Webb Space Telescope, the scientific complement to NASA’s Hubble Space Telescope, will be the premier space observatory of the next decade. Webb is an international project led by NASA with its partners, ESA (European Space Agency) and CSA (Canadian Space Agency).

For more information about NASA’s Webb telescope, visit: www.webb.nasa.gov or www.nasa.gov/webb

Read more about how we are keeping Chamber A free of contaminants: https://www.nasa.gov/feature/goddard/nasa-technology-protects-webb-telescope-from-contamination

By Eric Villard and Rob Gutro

NASA’s Goddard Space Flight Center