Astronaut ice cream may be an exotic treat for kids, but for real space explorers, a fresh, crunchy salad could sometimes really hit the spot. And the ability to grow food in space will prove crucial for longer-duration voyages envisioned over the next decades.

Growing plants in a spaceship, and one day on another planet, is a complicated endeavor. But one tool making it easier is a specially formulated fertilizer, developed years ago with NASA help, which has also drawn huge accolades from growers on Earth.

The fertilizer, created by Sarasota, Florida-based company Florikan, is coated in polymers that control when and how much of each ingredient is released over six months to a year.

“Having the ability to add a controlled-release fertilizer — which adds the right amount of nutrients over time without any mixing or any chemicals that you have to measure out — makes it much simpler,” explains Gioia Massa, science team lead for the NASA Veggie project at Kennedy Space Center.

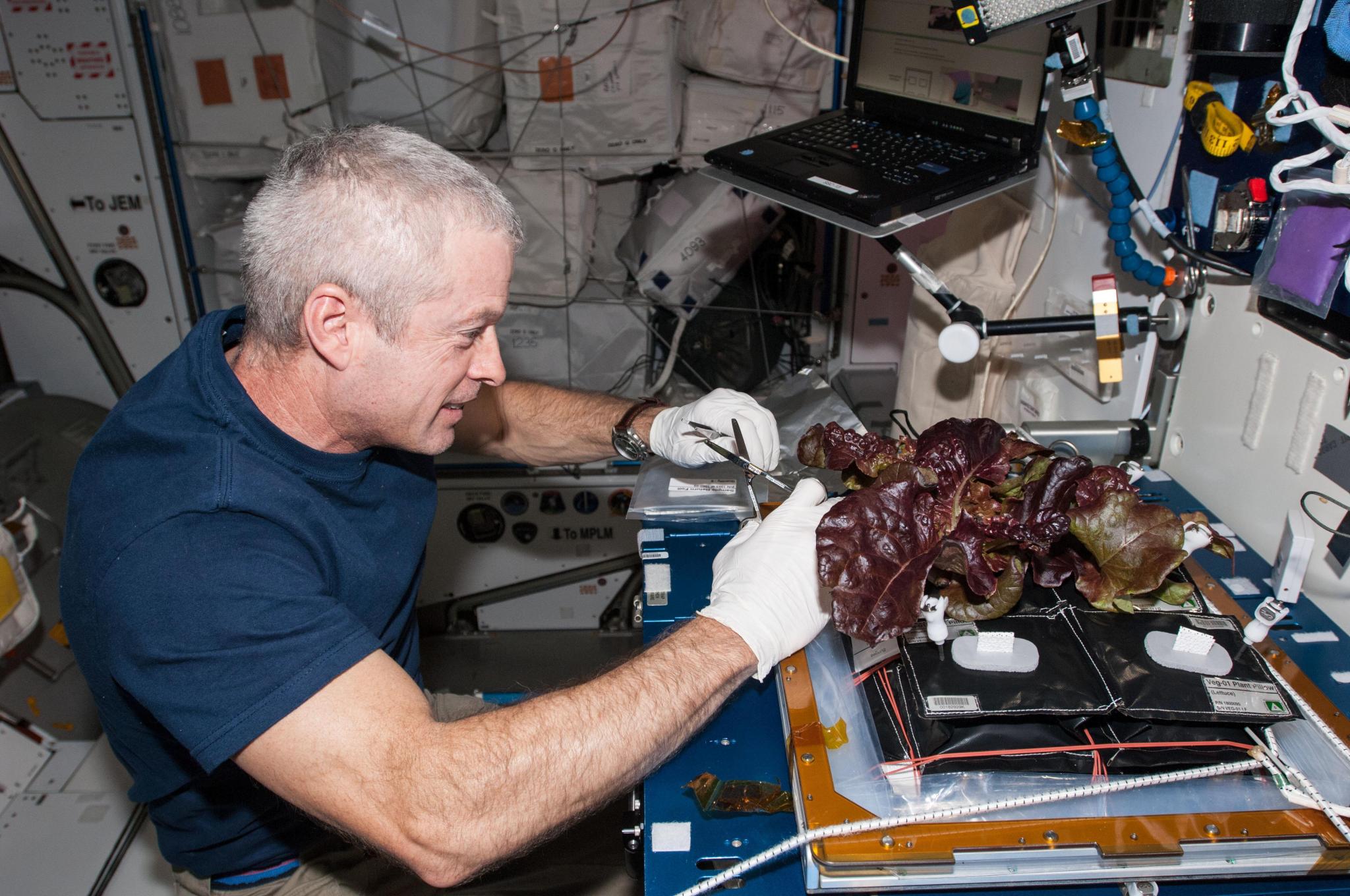

The team’s first major success, red romaine lettuce cultivated on the International Space Station in 2015, was the first produce ever grown and eaten in space.

Nutrients on Demand

Florikan founder Ed Rosenthal did not expect to help grow vegetables in space when he first began developing his award-winning fertilizer. He just saw an opportunity to improve how nutrients are delivered to plants.

Although not a chemist by training, by 2002 Rosenthal had spent decades working with fertilizers and polymers at Florikan and before that at a company that manufactured polymer-based plant containers.

“I wondered if I could separate each nutrient based on its relative solubility and when it was needed by the plant,” he says. Then he would coat each with different polymers with different-sized pores to control the rate at which water reached the nutrient.

That way, he thought, he could create a fertilizer that delivered exactly the right amount of each nutrient at exactly the right stage of growing.

Traditional fertilizers are often applied monthly — requiring huge amounts of fertilizer and a large workforce to apply it. But Rosenthal knew that much of that fertilizer was never actually absorbed by the plant.

As he told one grower friend, “I believe you’re wasting more than two-thirds of your nitrogen: it’s going straight into the groundwater.”

Florikan’s new staged-release fertilizer would get the same results with a third of the fertilizer, and it only needed to be applied once.

The product quickly found a market, but there was more work to be done, and in 2004, as a prize for winning an engineering award, Rosenthal got some high-level help from NASA.

The NASA consultants recommended a new approach: coat the nutrients in a single, impervious polymer, and then treat them with a chemical to open up pores to the exact specifications required. By 2008, Florikan had two patents, one for staged nutrient-release fertilizer and another for the polymer coating it was using.

Soon Florikan had enough business to open a coating facility in Florida, and later a second plant. Rosenthal has also sold his patents to agribusiness giant J. R. Simplot Company, which has introduced the technology across the western United States and overseas, though Florikan retains a license to manufacture and sell it in 32 eastern U.S. states.

A Boon for the Environment

The key advantage to Florikan’s staged nutrient-release fertilizer is that growers need to use far less of it, far less often than traditional formulations. That significantly reduces the harmful environmental impact of nutrient runoff, and it also means less labor and lower costs for growers.

Nitrogen, in particular, has been linked to harmful algal blooms, which can release toxins that harm, and even kill, marine wildlife, including dolphins, manatees and sea turtles.

One of Florikan’s early formulations — Florikan Nutricote 18-6-8, for its ratio of nitrogen, phosphate, and potassium — was designed specifically for ornamental plants. The company has since expanded its offerings, creating special blends for citrus groves and, more recently, sugar cane.

J. R. Simplot’s customers include large-scale nursery and turf growers across the western United States, as well as palm oil growers in Indonesia and Malaysia. Jeff Roesler, vice president for specialty business units, says the technology highlights two of Simplot’s core values: “respect for resources and spirit of innovation.”

And when NASA called Florikan for help with its Veggie project, Rosenthal created a new blend for flowering plants, like the tomatoes next heading up to the space station.

“NASA’s expertise helped us advance our development by years,” Rosenthal emphasizes. “We were happy to pay it back.”

NASA has a long history of transferring technology to the private sector. Each year, the agency’s Spinoff publication profiles about 50 NASA technologies that have transformed into commercial products and services, demonstrating the wider benefits of America’s investment in its space program. Spinoff is a publication of the Technology Transfer Program in NASA’s Space Technology Mission Directorate.

To learn more about this NASA spinoff, read the original article from Spinoff 2017.

For more information on how NASA is bringing its technology down to Earth, visit http://technology.nasa.gov.

Naomi Seck

Goddard Space Flight Center