Liquid rocket engine hardware components can take many months, and in some cases over a year, to procure and fabricate. One NASA project, called Long Life Additive Manufacturing Assembly (LLAMA), is testing 3D printing methods for building liquid rocket engine components that would save a considerable amount of time and money compared to traditional manufacturing methods. The advanced manufacturing methods employed by LLAMA can cut the time required for rocket engine nozzle production by more than half compared to traditional processes. It also significantly reduces the part count since less pieces need to be manufactured individually and then assembled.

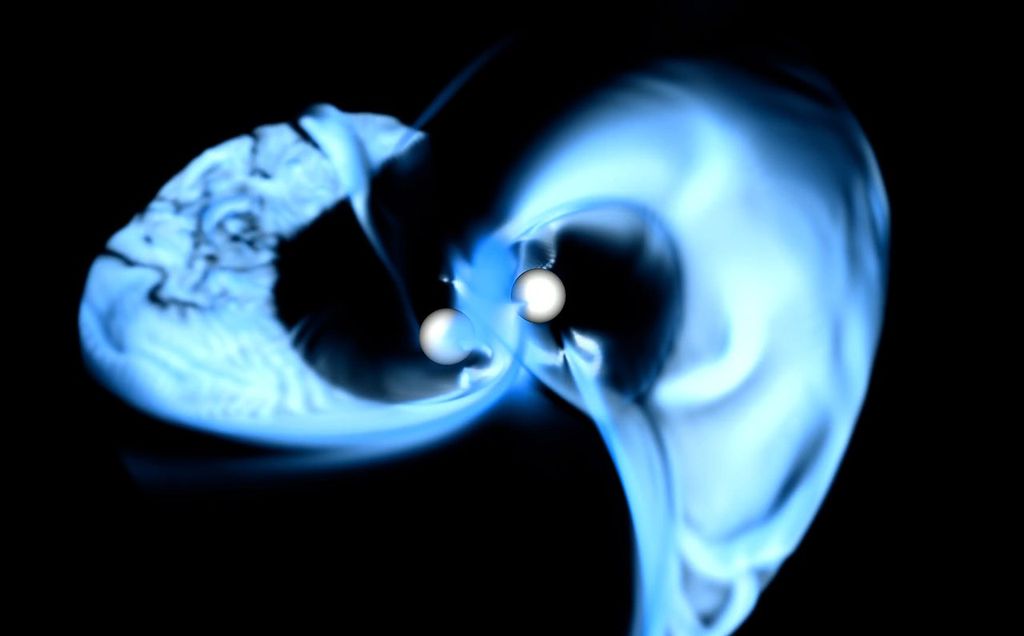

Combustion chambers and nozzles are two of the major components that make up a rocket engine. In liquid rocket engines, fuel and an oxidizer are mixed and burned inside the combustion chamber. This combustion produces hot exhaust, which passes through a nozzle to accelerate the flow and produce thrust. The LLAMA project is examining the performance of a 3D-printed copper alloy combustion chamber, two composite nozzles, and a high-strength metal alloy nozzle with hot-fire tests. Engines on future lunar landers could employ the manufacturing technology.

The composite nozzles being hot-fire tested under LLAMA can withstand much higher temperatures than traditional metallic nozzles, meaning their performance margin is greater. This testing is demonstrating the composite nozzles’ feasibility and the complex interface between the additively manufactured chamber and these nozzles.

“The objective is to demonstrate this hardware can support the agency’s Moon and Mars exploration goals,” LLAMA project manager John Fikes said. “The reusable and high-strength materials used in this additively manufactured hardware could significantly lower rocket engine production times and costs for all types of spacecraft and missions.

The type of hot-fire testing performed under LLAMA is a critical step in progressing these novel manufacturing processes for future widespread use. “To implement these advanced manufacturing methods for use on a large scale, we need to demonstrate the reliability and successful performance of each step, from the metal powder materials to the finished product,” Fikes said. “The LLAMA project tests will help us do that.”

Manufacturing the Hardware

The LLAMA copper combustion chamber is additively manufactured from an advanced Copper-Chromium-Niobium alloy, or GRCop-42, developed at NASA’s Glenn Research Center in Cleveland. This material enables the chambers to fire many times, has excellent thermal conductivity properties, and maintains its strength when exposed to scorching environments. The newly-designed and rapidly produced combustion chamber significantly reduces the number of parts and joints compared to traditional rocket engine chambers, potentially improving reliability.

The high-strength iron-nickel alloy nozzle tested under LLAMA is printed using laser powder directed energy deposition, which deposits and melts the metal powder to create freeform structures. This method allows for large-scale additive manufacturing, as demonstrated by NASA’s RAMPT project. The additional two composite nozzle extensions are made using carbon fiber reinforced materials densified with either carbon or silicon carbide. Additionally, the nozzle extensions are coated with ceramic materials that can also withstand extreme temperatures.

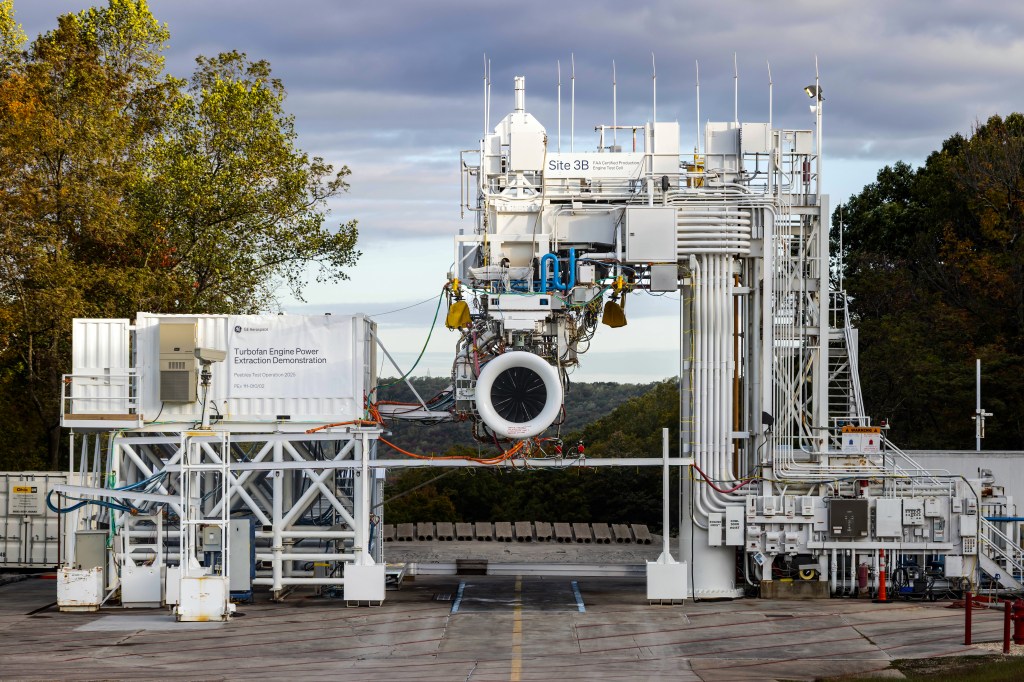

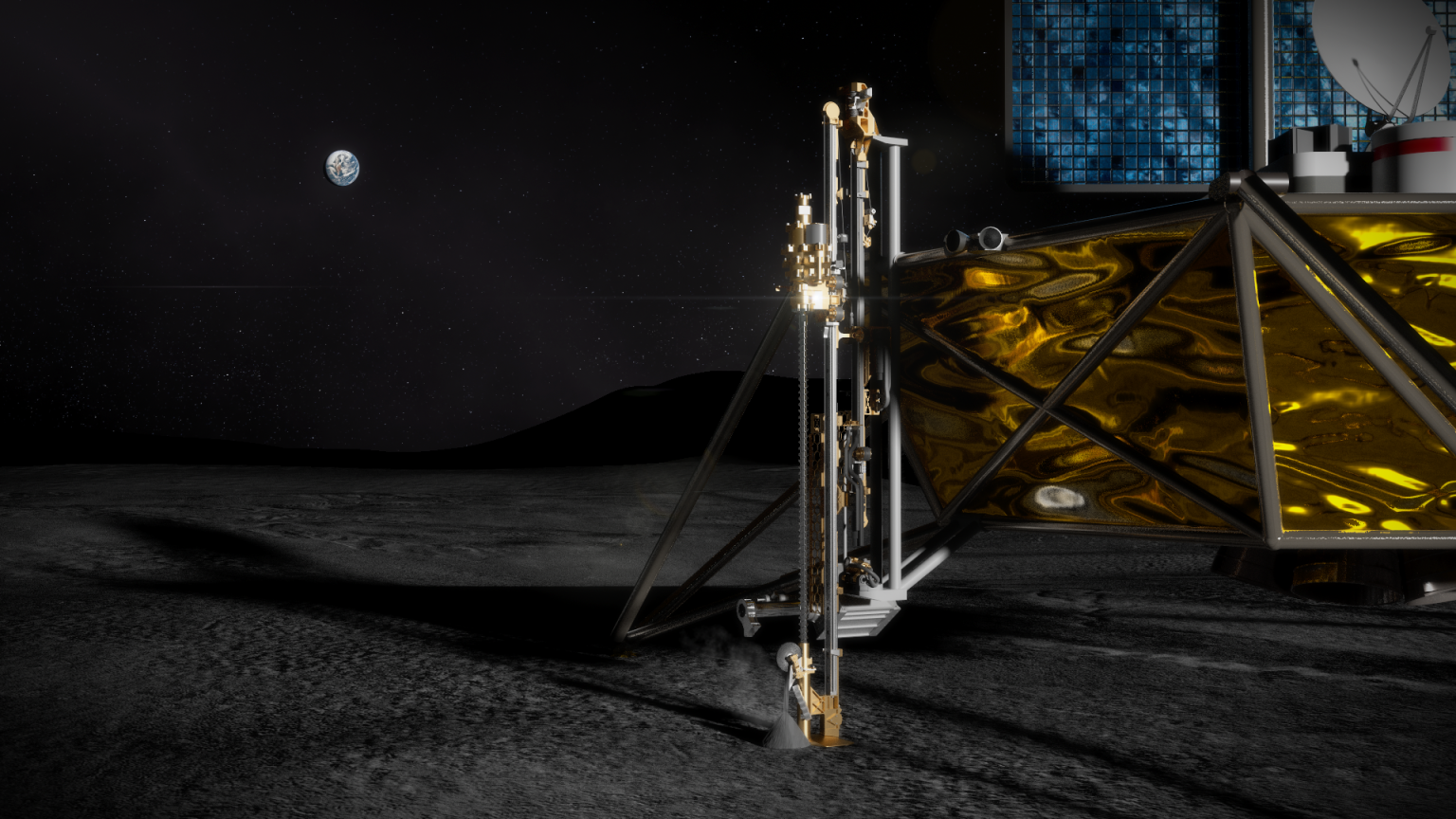

Testing the Hardware

The hardware has undergone hot-fire tests at NASA’s Marshall Space Flight Center in Huntsville, Alabama. During each test series, the engine was hot-fired 25 or more times, with combustion gases approaching 6000 degrees Fahrenheit. These durability test cycles will help determine whether or not the additively manufactured combustion chamber and nozzles could withstand extreme temperatures combined with structural and dynamic loads. The hardware needs to withstand these conditions to be able to undergo multiple firings for development, qualification and future flight. The LLAMA team plans to complete hot-fire tests in 2021.

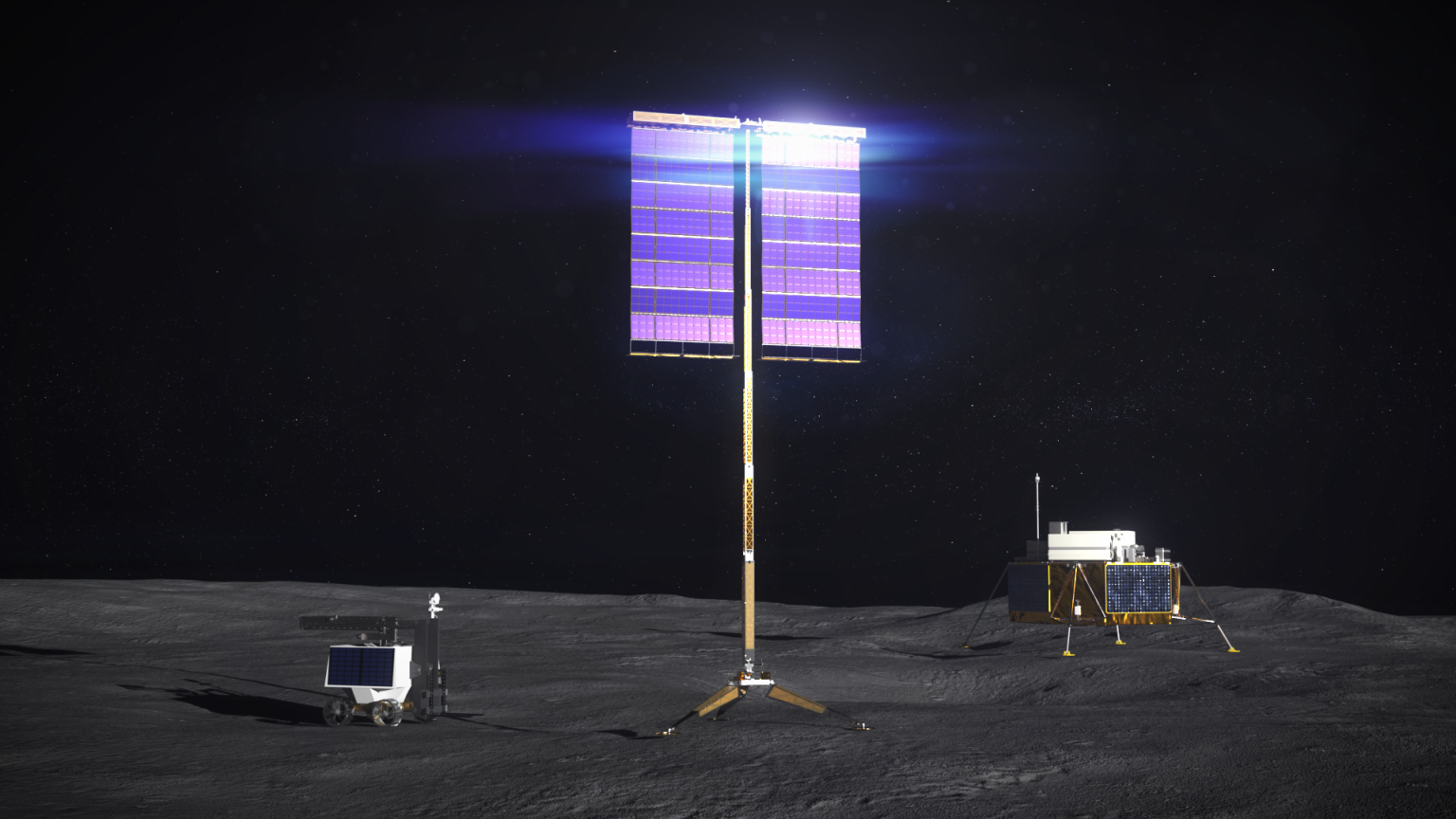

Using the Hardware

LLAMA’s advanced materials, combined with a commercial supply chain, could help this type of additive manufactured technology get infused into various NASA missions and the aerospace industry’s engine and lander concepts. LLAMA test data could help engineers tailor hardware designs that are less complex, which could make future missions safer and less expensive.

Partners:

- The LLAMA project is led by NASA out of Marshall with support from Glenn.

- LLAMA is working with Additive Manufacturing & Engineering (AME) of Huntsville, Alabama, and Elementum 3D of Erie, Colorado, for the GRCop-42 thrust chambers.

- Pressure Technologies (PTI) of Concord, Ohio, or Hot Isostatic Pressing (HIP), and PTR-Precision Technologies, Inc. of Enfield, Connecticut, are developing electron beam welding manifolds.

- Rem Surface Engineering of Brenham, Texas, is providing polishing of the external surfaces. Additionally, Carbon-Carbon Advanced Technology of Arlington, Texas, Northrop Grumman Innovation Systems of Promontory, Utah, and GE Aviation of Cincinnati, Ohio, are producing the high-temperature composite nozzles.

- RPM Innovations of Rapid City, South Dakota, is working on the actively-cooled NASA HR-1 nozzle, which was co-produced under the RAMPT project.