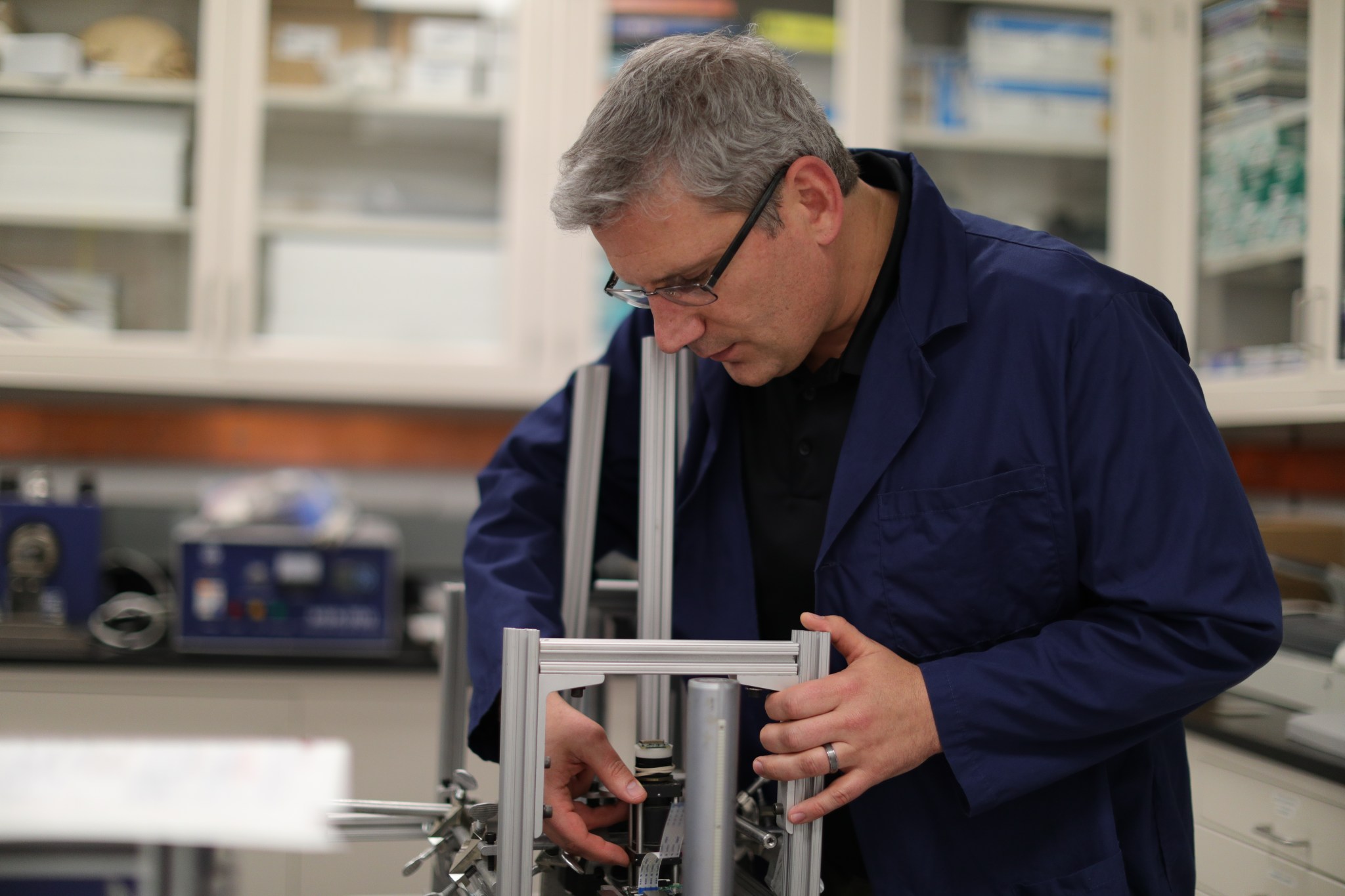

Electrostatics and Surface Physics Laboratory

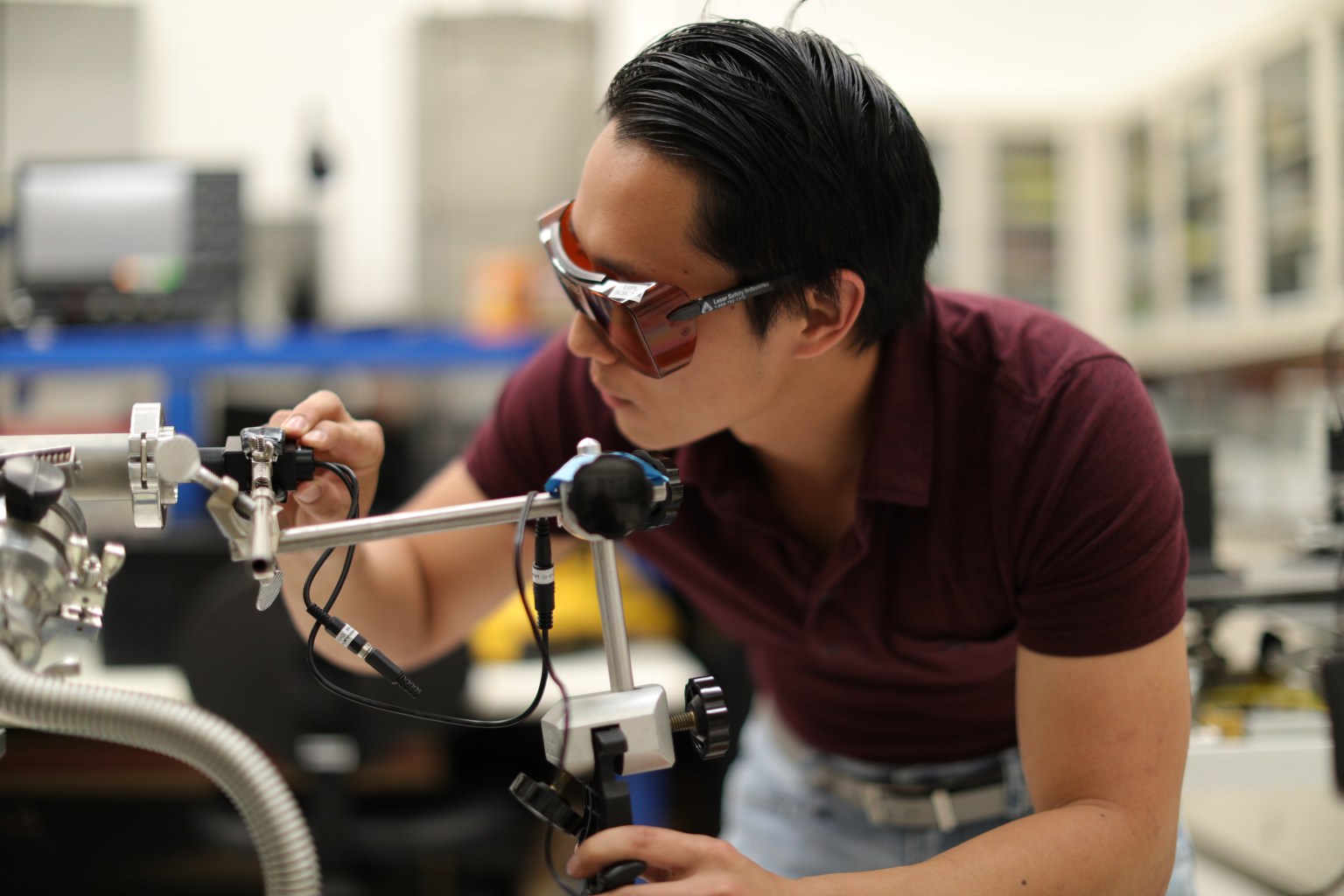

The Electrostatics and Surface Physics Laboratory (ESPL) is a research facility located at NASA’s Kennedy Space Center. The lab conducts scientific investigations to protect flight hardware and launch equipment from the phenomenon of electrostatic discharges, commonly known as sparks, since a spark near rocket propellant or other chemicals could be catastrophic. The lab studies lunar and Martian dust and the physics behind the particles’ dynamic electrical states. The lab also develops new technologies that leverage electrostatics to solve problems, such as filtering dust from air or repelling dust off surfaces using electrostatic forces.

History

The Electrostatics and Surface Physics Laboratory began operations in May 2000 to support the Space Shuttle Program. The ESPL provided electrostatic studies for a number of shuttle components, including hydrogen fuel lines, crew escape life preserver and life raft inflators, thrust vector control actuator blankets and thermal control system blankets. The lab also provided an electrostatic evaluation and some design change recommendations for the Hubble Space Telescope’s imaging spectrograph hardware.

The lab characterized lunar dust samples brought back from the Apollo 14 mission. The ESPL measured the moon dust’s dielectric properties, finding it to have low electrical conductivity.

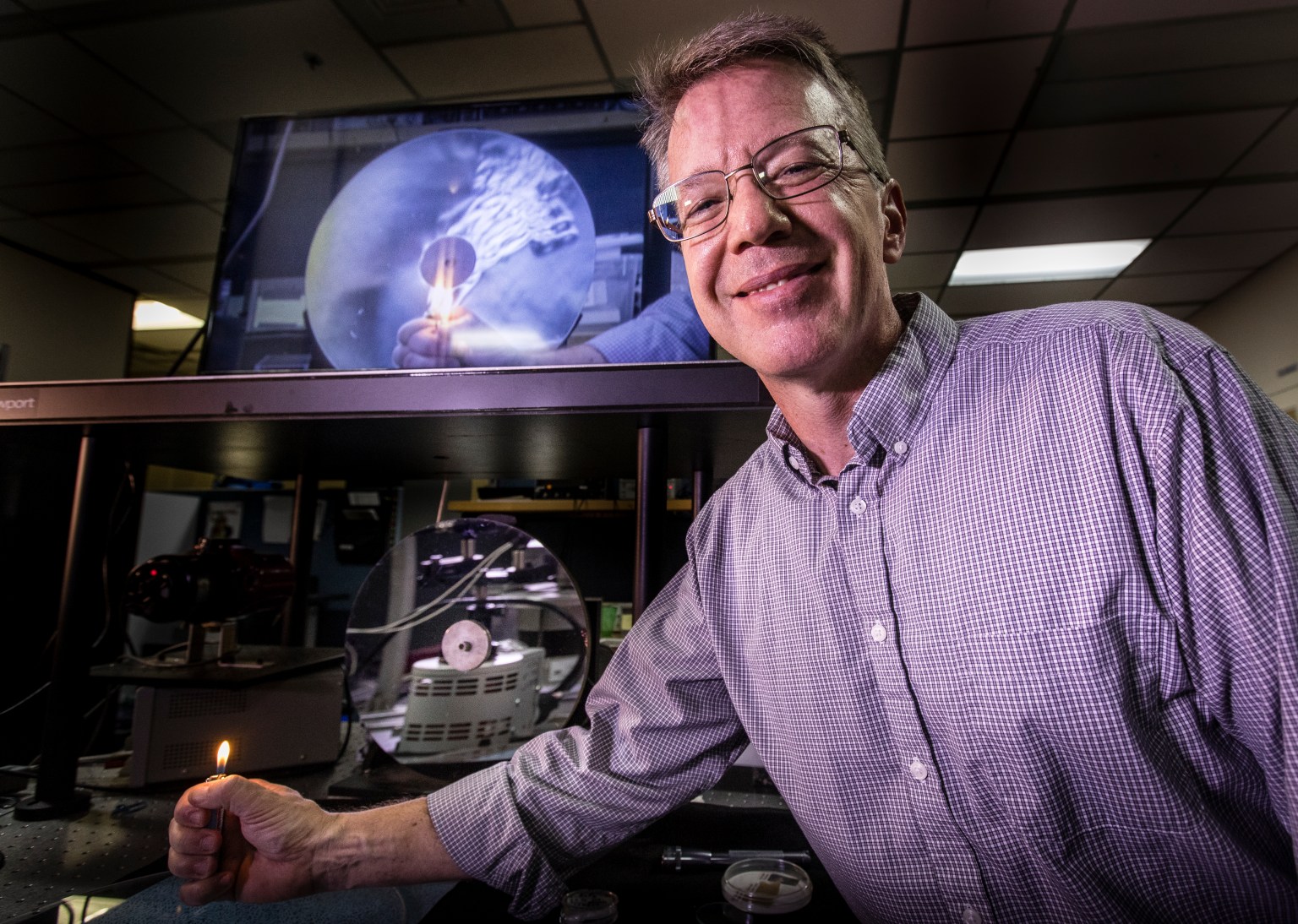

The ESPL developed a way to measure a dust particle’s diameter and electric charge using a laser and an applied electric field. This dust particle analyzer could potentially be miniaturized and sent to Mars as a science tool, or it could be used in the lab to study Martian samples if they are brought back to Earth one day.

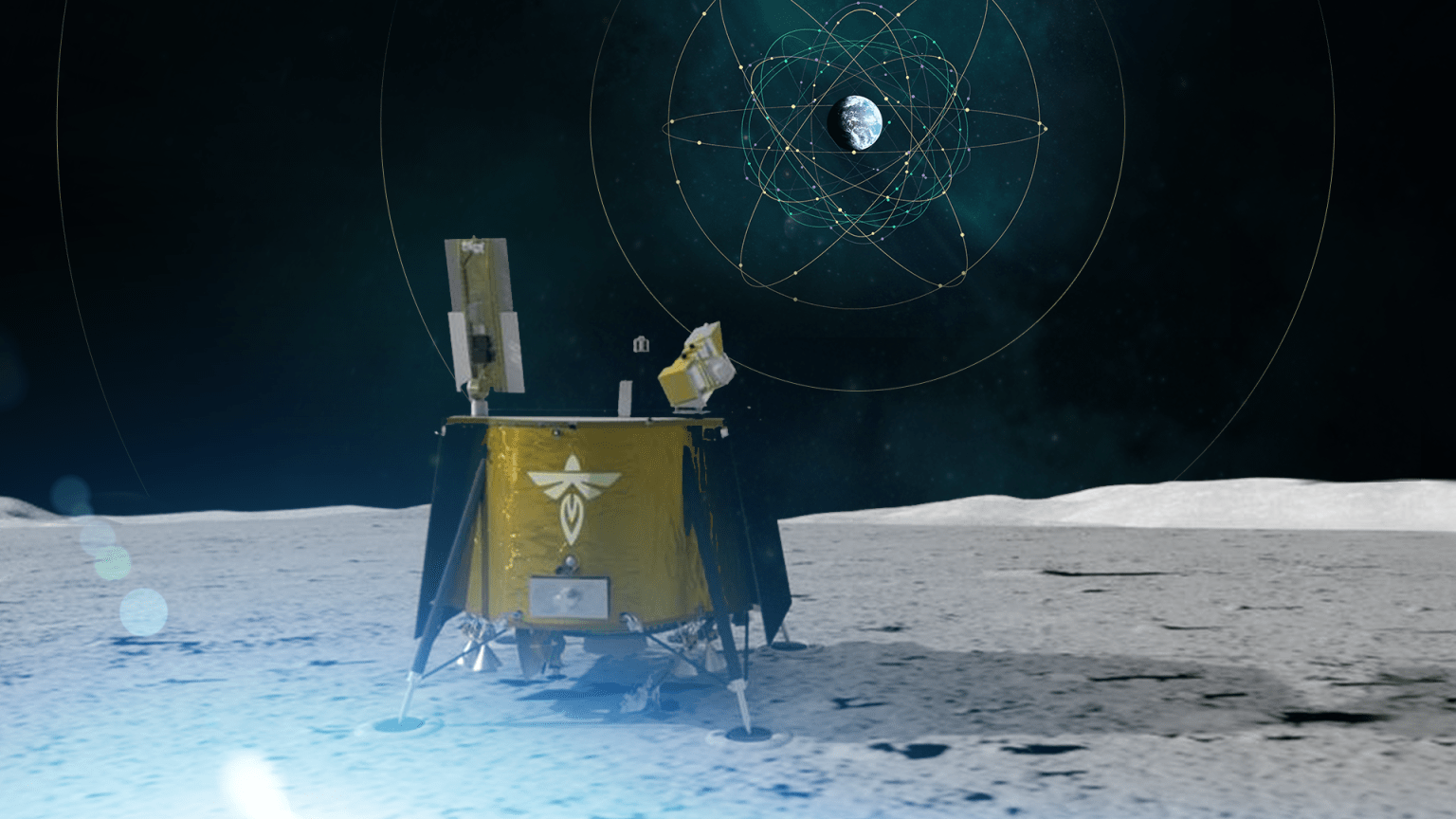

The lab designed the Mars Environmental Compatibility Assessment (MECA) Electrometer to characterize electrostatic and triboelectric properties of Martian soil, measure the electric field strength above the Martian soil, and measure atmospheric ion currents. The initial design was slated to fly on the 2001 Marie Curie Mars Lander, but that lander mission was canceled. Since then, the lab has developed more advanced variations of the electrometer that can be embedded in a rover wheel or installed on the end of a robot arm. The electrometer now is being proposed to perform measurements on lunar landing missions.

In 2012, the lab became part of Swamp Works and started focusing on more in-situ resource utilization (ISRU) work. For example, the ESPL worked jointly with the Granular Mechanics and Regolith Operations lab to test the idea of a heat shield made from space dirt. Making a heat shield in space instead of launching it from Earth could potentially save fuel and launch costs. The lab made rounded bricks out of a lunar simulant, then tested the bricks under extreme heat similar to what a payload would experience entering an atmosphere. The bricks stayed relatively cool on the back, showing that, with more investigation, space dirt might work as a material to thermally protect payloads.

Researchers Look to Alien Soils for Heat Shield

Researchers are looking to see whether a heat shield made from the soil of the Moon, Mars, or an asteroid will stand up to the searing demands of a plunge through Earth's atmosphere.

Read More

The lab also investigated graphene-based ultra-capacitors, which are lightweight energy storage devices made from a highly conductive form of carbon in a hexagonal lattice structure. They can operate for tens of thousands of cycles at high current and wide temperature ranges and, unlike lithium-ion batteries, aren’t at risk for catching fire. Remarkably, early prototypes showed almost no loss in performance after 30,000 charge/discharge cycles.

Current Work

Since 2003, the ESPL has been developing Electrodynamic Dust Shield technology to clear dust off a number of different materials including glass, plastics, metals, and potentially spacesuit fabrics. The dust shields are important for keeping solar panels, heat radiators, optical instruments and other equipment clean so they can operate properly.

The lab flew Electrodynamic Dust Shield experiments twice on reduced gravity flights. The testing showed the dust shields could operate using Martian dust simulant, lunar dust simulant, and actual Moon dust. They worked in lunar and Martian gravities and atmospheric pressures. Another experiment slated to fly on the International Space Station in 2019 will expose material samples and coatings to the harsh environment of space for a year. The experiment will provide data that will inform future dust shield designs.

Since about 2010, the lab has been developing a Mars-based electrostatic precipitator, a type of air filter that uses electric fields to remove the dust. This technology is important for ISRU plants pulling in the carbon dioxide-rich Martian atmosphere to produce commodities such as oxygen, water and methane. The air must be cleaned before it enters the reactor so dust doesn’t damage the equipment or make its way into final products, including breathing air, drinking water or rocket fuel.

Kennedy Scientists Developing Technology to Remove Martian Dust

NASA's Journey to Mars requires cutting-edge technologies to solve the problems explorers will face on the Red Planet. Scientists at the agency's Kennedy Space Center in Florida are developing some of the needed solutions.

Read More

Accomplishments

The Electrostatics and Surface Physics Laboratory has published more than 150 papers and journal articles. The lab has one patent with the University of Arkansas Little Rock on the Electrodynamic Dust Shield.