By Wayne Smith

Products and services that benefit life on Earth put a new spin on technology developed for space. This includes inventions at NASA’s Marshall Space Flight Center in Huntsville, Alabama.

NASA engineers and scientists often develop new technology during the course of their mission work. And while the origin of the technology is often to help explore the solar system and beyond, NASA’s Technology Transfer program is bringing them back down to Earth by licensing them to companies and entrepreneurs. The licensees then create new products and services, called “spinoffs” that benefit the economy, protect the environment, and even save lives.

There are more the 2,000 NASA spinoffs, with cellphone cameras, baby formula, and airplane winglets among the most common.

NASA’s Technology Transfer program has over 1,200 technologies available for licensing. Potential licensees can browse the entire portfolio online, where they are organized by categories such as communications, medical, environment, manufacturing and more. Inventors also share in royalties if the product is licensed.

“In Technology Transfer, we have the opportunity to work with NASA engineers and scientists, who are some of the most innovative people you’ll ever meet, and then we transfer their technologies to industry,” said Sammy Nabors, acting chief for the Technology Transfer branch at Marshall.

The 2022 edition of NASA’s Spinoff publication features 46 companies across 21 states in manufacturing, public safety, consumer products, and more. It also highlights two examples of technology available for licensing from Marshall – a more rugged infrared camera and a process for making stronger, less polluting concrete.

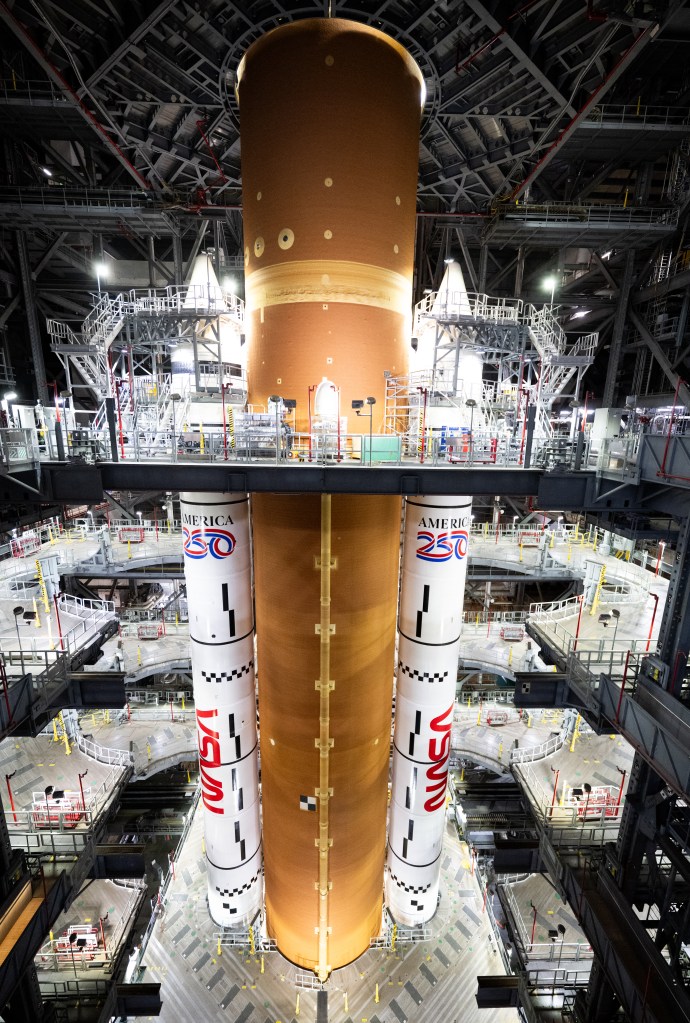

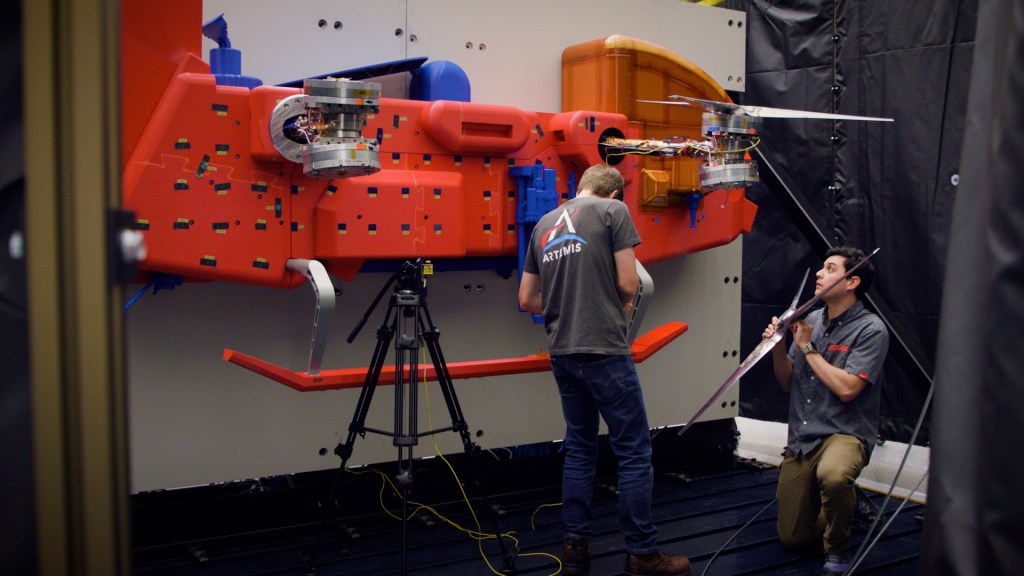

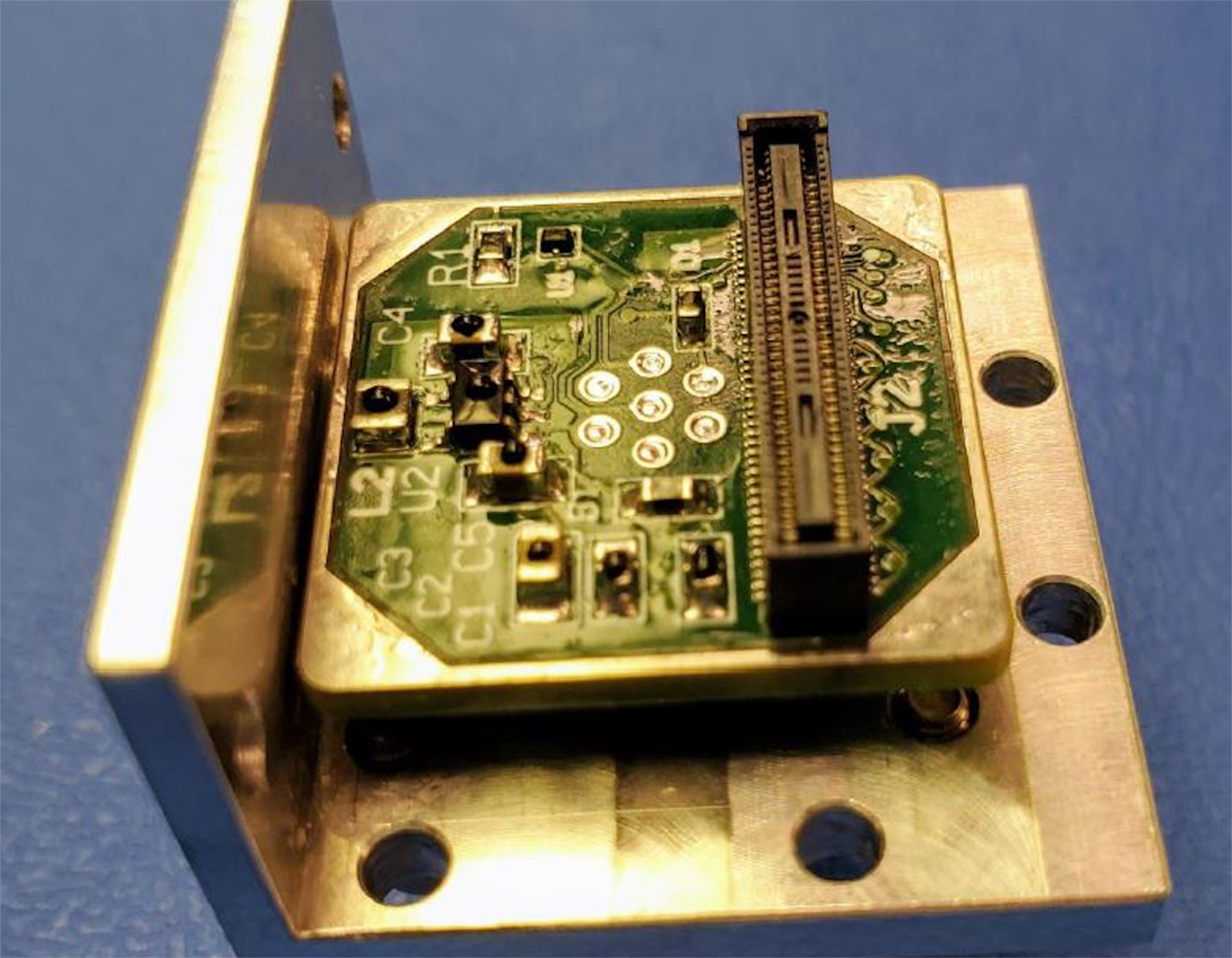

The ruggedized camera is a space-rated camera that meets NASA specifications for withstanding vibrations and radiation and removing heat. Current cost-effective commercial cameras can’t survive launch conditions. NASA will utilize the technology for the ruggedized camera imaging systems aboard the Space Launch System on future Artemis missions.

Marshall team members developing the technology included Brent Beabout, Jarret Bone, Jeremy Myers, and Jonathan Pryor. They developed modifications to a separate patent, the visible spectrum camera, to enable it for use in space. Marshall patented the invention, licensed it to Imperx Inc. of Boca Raton, Florida, and assisted with commercialization efforts.

This same team developed modifications to the infrared camera, enabling it to survive launch conditions and remove heat. In addition to its use for imaging systems in satellites and spacecraft, other practical uses of the technology include:

- Aerospace: aircraft-mounted cameras for surveillance and thermal analysis of aircraft engines.

- First responders: night vision and enhanced imaging capability in fog, rain, and smoke for search and rescue, firefighting, threat detection, and surveillance.

- Automotive: vision systems for autonomous vehicles.

Innovators at Marshall also developed a new cement composition and manufacturing method that reduces carbon emissions while making it stronger.

Companies and consumers can use the carbonated cement process in cement factories, reducing the carbon footprint, and in quick-mix cement kits. The cement industry is one of the highest producers of CO2 in the world.

The idea for the new manufacturing method was first constructed around the problem of reducing CO2 aboard NASA missions. Building on their expertise in life-support oxygen control systems for spacecraft, Morgan Abney of Marshall and Iowa State University professor James Alleman created a process that reduces carbon emitted during cement production, converting the carbon to a solid form. The carbon is then added to the cement product, making it more durable for construction materials.

Nabors said Marshall set a NASA center record with 50 licenses executed last fiscal year, with most being research licenses that could eventually turn into a commercial agreement. Across the agency, Nabors said a record 211 licenses were executed.

“There are a lot of different reasons why companies are interested in NASA’s inventions. Just the NASA name means a lot, too,” Nabors said. “Our goal is to ensure NASA technologies are broadly available to the public, which maximizes the benefit to our nation.”

For more on Marshall Space Flight Center, visit

https://www.nasa.gov/centers/marshall/home/index.html

Lance D. Davis

NASA’s Marshall Space Flight Center, Huntsville, Alabama

256-544-0034

lance.d.davis@nasa.gov