In This Week’s Star

- Director’s Corner: Staying Strong Through Adversity

- ‘We’re All in This Together, 6 Feet Apart’: Marshall, Huntsville Rally to Protect Jobs, Employees, Future Human Spaceflight Missions

- Take 5 With Katherine Van Hooser

- Artemis Update: A Year of Progress on Returning to the Moon

- Spinoff 2020: Marshall Inventions Improve Life on Earth

- Moon Thrusters Withstand Over 60 Hot Fire Tests

- This Week in NASA History: STS-6 Launches – April 4, 1983

Director’s Corner: Staying Strong Through Adversity

As NASA implements important measures across the agency to help slow the transmission of COVID-19 and protect our communities, the safety of our workforce is our top priority. I am proud of how you are adjusting to this temporary situation and working hard from wherever you are.

I also extend a big “thank you” to those necessary to maintain International Space Station science and the safety and security of NASA’s Marshall Space Flight Center, who are working on-site to carry on operations. We are grateful for your perseverance, courage and expertise to achieve what NASA could not pause or do remotely. I encourage each of you to speak up if you are concerned for your safety, or that of others, during this unprecedented time. I am proud of you and what you are doing not just for our agency, but for the betterment of our world.

To combat the spread of this invisible enemy, it will take everyone working together. We all will have to make sacrifices to win this battle. Due to the Stage 4 status of Marshall, Michoud Assembly Facility and Stennis Space Center, NASA has temporarily suspended production and testing of Space Launch System and Orion hardware at these locations.

This month, teams across the country would normally be preparing to travel to Huntsville for our annual spring STEM events — Student Launch, FIRST Robotics and the Human Exploration Rover Challenge. Instead, NASA made the difficult decision to cancel these local events, amend the contests as we could, and honor the efforts of our dedicated student participants with virtual award ceremonies.

I’m proud to say there have been no impacts to science on the space station to this point. The Payload Operations Integration Center at Marshall has done an excellent job of being resilient throughout this disruption to their normal work schedule. Although on-site work will be paused, I’m heartened to hear from many teams how they are leveraging any technology available to accomplish work that can be done from anywhere with agility.

As we work through this together, we are staying on top of guidance from the Office of Personnel Management and the Office of the Chief Human Capital Officer. Our Marshall procurement team has worked diligently to provide guidance to our on-site and off-site contractors about assuring pay for contracted employees who are unable to work or work remotely because of the coronavirus, work stoppages or because facilities are closed. NASA is expediting the review and approval of invoices to ensure payment to contractors. We are doing all we can to get information out in the timely manner and commit to keep sharing what we know as soon as we know it.

We are also evaluating how to best help not only our local community, but our national community in its time of need. Marshall team members have unique capabilities and gifts that can surely be a great asset during a time of crisis such as this. In coordination with NASA Headquarters, Marshall leadership is researching how we can legally and effectively be of service, whether that’s through subject matter expertise, technology or other areas.

I realize what is happening right now is challenging for many reasons, but I assure you that Marshall leadership is staying engaged in local emergency response plans, Centers for Disease Control and Prevention recommendations and agency guidance. We are also eager for a return to work on-site, but we prioritize protecting you and our Redstone Arsenal and Tennessee Valley communities.

I believe in you — the Marshall team — and I urge you to remain strong throughout this adversity we all face together. Remember that this too shall pass as we focus on achieving missions that will outlast any pandemic and inspire a new generation to follow in our footsteps.

‘We’re All in This Together, 6 Feet Apart’: Marshall, Huntsville Rally to Protect Jobs, Employees, Future Human Spaceflight Missions

By Rick Smith

As Alabama and the nation ride out the global COVID-19 pandemic, the top priority of Huntsville-area businesses, city and state officials and the leadership at NASA’s Marshall Space Flight Center remains the health and safety of employees and their families.

But eyes across the Rocket City still turn frequently to the stars.

With Marshall now in Stage 4 of NASA’s coronavirus response framework, and despite the temporary closing of statewide nonessential businesses by Alabama Gov. Kay Ivey, Marshall leaders remain confident about achieving their goals for completing the Space Launch System and pursuing Artemis-Generation missions to the Moon and beyond.

Pointing to the $2.2 trillion stimulus package signed March 27 by President Donald Trump — which includes benefits for small businesses — city officials share Marshall leaders’ optimism about safeguarding employees and jobs essential to the nation’s mission in space.

To protect the workforce and the community, Marshall has enacted Stage 4 directives, putting all buildings, operations and hardware in safe condition until on-site work can safely resume. Center-wide mandatory telework is in effect, except for designated personnel required to maintain the safety and security of the center, critical hardware and astronauts on the International Space Station. All business travel is suspended during the Stage 4 response.

“I know this creates an even more challenging situation as we work in new ways to deliver on our mission, but I am proud of our Marshall team and our agility,” Marshall Director Jody Singer said in a March 26 email to team members.

The status of the center, updates on leave and telework, and other pertinent information will be updated regularly and communicated to all employees and contractors, Singer added. Visit NASA People for the latest information.

To help team members adapt to the Stage 4 response, Marshall is broadening telework flexibility for its civil service employees, and working with contractors to ensure a seamless remote workflow. NASA, in cooperation with the Office of Personnel Management, also has issued guidance enabling excused leave for homebound employees caring for young children and other dependents.

On the business front, Marshall is working with on-site and off-site contractors to ensure all mission-essential work is safely transitioned to telework or remote operations. Contract payments will continue to be disbursed, ensuring funding for personnel and for their work. The center has sent guidance to its contractors on how to handle invoicing, and directed them to maintain readiness to return to normal operations as soon as the crisis passes.

“Marshall’s Small Business Office and the entire NASA procurement community are working to find ways for small businesses to keep supporting the mission through this crisis,” said Jason Detko, director of Marshall’s Office of Procurement.

Marshall consults regularly with partners across Redstone Arsenal and extending beyond Huntsville, he said — from NASA leadership in Washington to vested regional enterprises such as the Decatur/Morgan County Entrepreneurial Center in Decatur and the Jackson County Mountain Lakes Chamber of Commerce in Scottsboro.

“We’ve seen remarkable support across all levels of government,” Detko said. “The U.S. General Services Administration provided a list of businesses offering a wide range of services we may need during this situation, including cleaning services.” Marshall and other Redstone tenants also are teaming to meet key, short-notice facilities requirements as they arise. Detko’s team even received input from AbilityOne, the independent federal agency which hires people with disabilities, offering on-call support as needed.

NASA Administrator Jim Bridenstine and the agency’s procurement, engineering and science and technology teams are working to ensure NASA contractors, industry partners, grantees and Space Act Agreement partners receive adequate support to continue mission-critical work through the duration of the crisis.

“Our goal in all this is to ensure this crisis does not rob us of our most precious resource, our team,” Bridenstine told NASA team members in a March 25 email following a virtual “Ask the Administrator” Q&A. He, NASA Associate Administrator Steve Jurczyk and Dr. JD Polk, NASA’s chief health and medical officer, answered questions about the COVID-19 outbreak and NASA’s response. Watch the full video here.

Singer echoed Bridenstine’s pride in the NASA team — and emphasized that resources exist for Marshall team members dealing with stress or anxiety as a result of the pandemic. The Marshall Employee Assistance Program remains available. Learn more here, or contact program coordinator Terry Sterry at terry.w.sterry@nasa.gov.

Detko said the crisis response — among team members as well as government and business leaders — fills him with pride. “NASA is an agency of talented professionals who truly enjoy their jobs,” he said. “Working together, we will adapt to this new operating model and overcome hurdles to find unique solutions to our missions.”

Throughout the crisis, the Huntsville/Madison County Chamber of Commerce and Huntsville Mayor Tommy Battle, have hosted a daily web conference to share new developments with business stakeholders. The chamber and Battle stay in close communication with essential organizations and leaders, including Madison Mayor Paul Finley, Madison County Commissioner Dale Strong, the Alabama Emergency Management Agency, the Alabama Department of Public Health, area hospitals and city and county first responders, and representatives of federal agencies and contractors on Redstone Arsenal.

“We have a good crew working on this, all doing the jobs we’re supposed to do” in a crisis, Battle said.

On March 27, Battle and the chamber launched a citywide campaign — “We’re All in This Together… Six Feet Apart” — to help alleviate concerns about jobs, resources and community health and welfare. They’ve also opened the communications resources section of the chamber’s website, usually available only to chamber members, to all interested parties for the duration of the COVID-19 emergency.

“We want everyone to be safe,” said Lucia Cape, the chamber’s senior vice president of economic development, industry relations and workforce. “Whatever we can provide to support that, we’re honored to play that role.”

The chamber site’s one-stop coronavirus news page includes detailed economic insight for small and large businesses; updates from state leaders and members of Congress in Montgomery and Washington; where-to-turn directories and webinars to assist in obtaining financial relief; and networking solutions encouraging companies to help one another navigate the crisis.

Battle and the chamber encourage Alabama small businesses adversely impacted by the outbreak — including qualified government contractors and nonprofit organizations — to seek assistance via the U.S. Small Business Administration’s Economic Injury Disaster Loan program. The program offers up to $2 million in low-interest loans. Learn more at the Small Business Administration’s COVID-19 disaster assistance web page.

“We’re really proud of the Huntsville community,” Cape said. “We know so much of the work done here in service to America’s space program and other endeavors is critical — and will continue to be critical once this crisis is behind us.”

Her comment echoed Bridenstine’s words written earlier to the NASA team: “One of the key elements to maintaining resilience in the face of challenge is the ability to find meaning and purpose in the situation at hand. At NASA, our mission gives us that meaning and purpose.

“Let’s continue to take care of ourselves and one another as we work through this unprecedented situation,” he added.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Take 5 With Katherine Van Hooser

Katherine Van Hooser developed a passion for space in the sixth grade, as NASA prepared to launch the space shuttle for the first time. Ten years later, she was working at NASA’s Marshall Space Flight Center.

After helping design turbopumps for in-house programs and the space shuttle, Van Hooser became a chief engineer and held several leadership roles at Marshall. Today, she is Marshall’s Chief Engineer and leads 60 team members in assuring the technical excellence of all major Marshall-assigned programs and projects.

Marshall media specialist Brice Russ sat down with Van Hooser to discuss the Chief Engineer’s Office, the role chief engineers play across Marshall and her advice for future chief engineers.

Question: What part does the Chief Engineer’s Office play in landing on the Moon by 2024?

Van Hooser: The chief engineer for the Human Landing System, Rene Ortega, is working with engineers across the agency to set requirements and prepare to help the companies competing to land on the Moon so they have the best chance at success — but that’s just one of our programs!

We have chief engineers for the Space Launch System and all of the major programs managed by the Human Exploration Development & Operations and Science & Technology offices. Our office is instrumental in a large portion of Marshall’s portfolio.

Question: What makes the role of a chief engineer unique?

Van Hooser: Our jobs aren’t like anyone else’s. Some people confuse our role in Engineering Technical Authority with that of supervisors. I’ll clarify our roles in that regard.

Engineering supervisors make sure the models, assumptions, tests, etc., being used by their discipline are appropriate, and that results make sense for their discipline.

A chief engineer works across all engineering disciplines. If one discipline recommends a change to a piece of hardware, the chief engineer is responsible for ensuring that other disciplines in the system aren’t unacceptably adversely impacted by that change, and to lead the team in finding a system-level solution that’s best for the program.

Question: What’s a typical day like in the Chief Engineer’s Office?

Van Hooser: There is no such thing as a typical day! That’s one of the reasons I love this job.

We help program/project managers set strategic goals for their efforts and aid in defining the scope of work necessary to accomplish their goals. Chief engineers work with the team supporting each program — Engineering, Safety & Mission Assurance, and industry — in the identification and quantification of risks. We advise program managers about technical issues and appropriate solutions. This takes understanding of the system, technical skill, communication and negotiation prowess and knowledge of the risk posture and goals of the program.

It’s not our job to find a technically perfect answer to any question. It’s our job to find a technically adequate answer that meets the technical, cost and schedule needs of the program. Identifying that which is just adequate, just good enough, is the hardest part. We all want our products to be perfect, but perfect takes time and costs money. I think it’s the job of all engineers to present options — alternate tests, analytical assumptions, design shortcuts — that could lower cost or schedule. Then, it’s the chief engineer’s job to recommend a path to the program manager, describing associated risks. The program manager chooses a path. We describe the risks, but the program manager ultimately owns the baseline and risks.

Question: How does your office define and achieve success?

Van Hooser: When our programs and projects meet their goals, we have done our jobs. It’s critically important for us to continue to have tasks that develop our engineering skills, because we need to be really good engineers so we know the appropriate tools and techniques necessary to make our programs successful.

Often, we’ll point out that a piece isn’t going to last as long as it needs to or that the proposed testing isn’t enough. I’m most proud of our engineering team when we follow up identification of issues with solutions. When the solutions work and the program succeeds, we succeed.

Question: What advice do you have for early-career team members, or anyone at Marshall, looking to follow your career path?

Van Hooser: There are a lot of paths to get into the Chief Engineer’s Office. One of my role models was Otto Goetz, space shuttle main engine chief engineer. It never occurred to me I could possibly follow in his footsteps. I just worked hard trying to make whatever I was working on better. My skills were recognized, and I was asked to move to the Chief Engineer’s Office. To me, being outstanding at your job is the best way to open opportunities.

One of the reasons I love being at NASA is that we have world-class experts who’ve spent their entire careers advancing a discipline. We need those experts! But I don’t want somebody to work for 20 or 30 years in a very specific area and then realize, “I wanted to do something different and it never happened.” So, it’s important to have goals and discuss them with your manager. Also, be open-minded. Don’t set only one goal or you might never attain it. Be open to opportunities. Ask for feedback — know what you’re good at and where you can improve, and find opportunities that challenge and develop you.

Previous Take 5s

Bobby Watkins, manager of the Human Exploration Development & Operations Office at Marshall

Neil Rodgers, director of the Office of the Chief Information Officer at Marshall

Lisa Watson-Morgan, manager of NASA’s Human Landing System Program

Mary Beth Koelbl, deputy director of Marshall’s Engineering Directorate

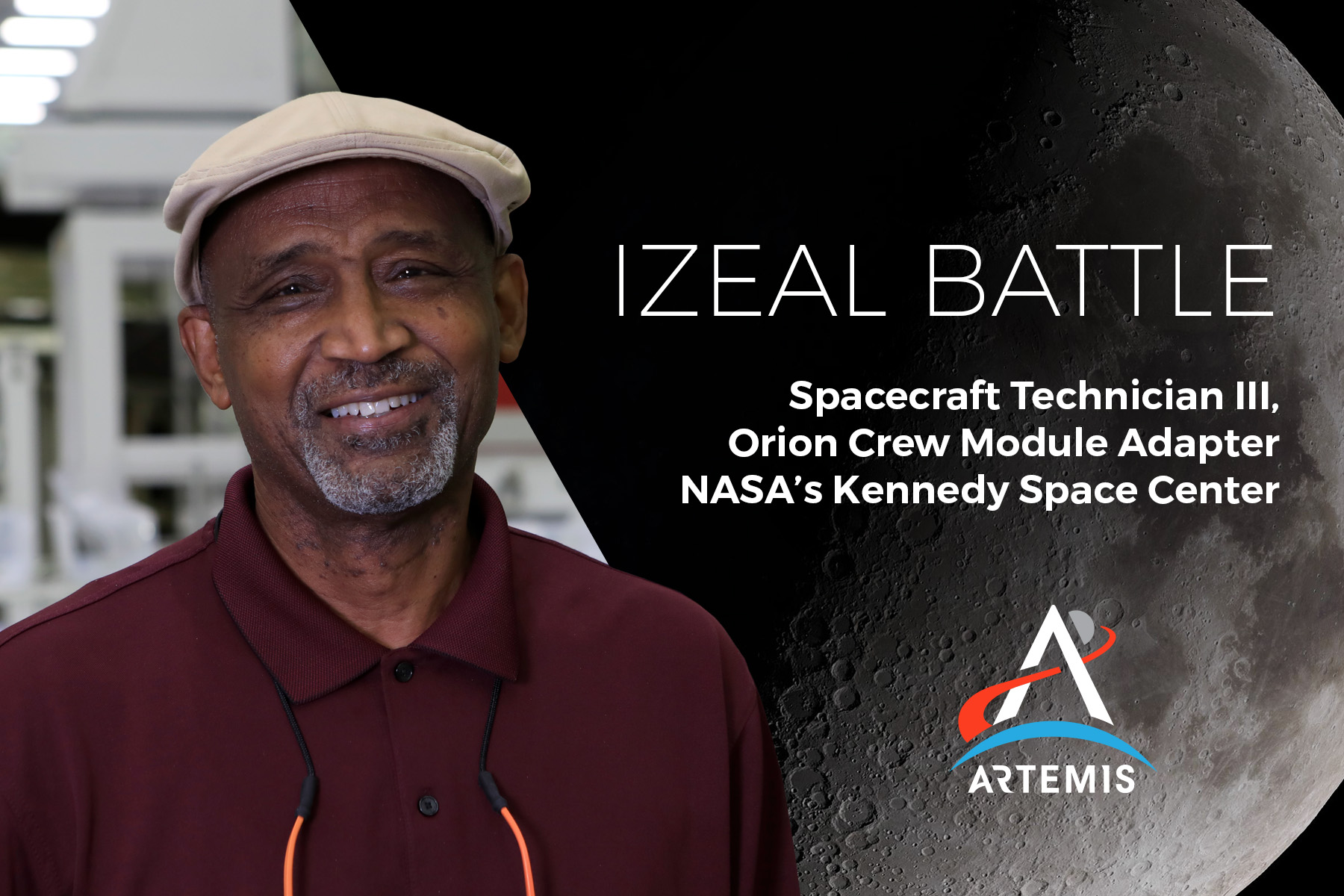

Artemis Update: A Year of Progress on Returning to the Moon

On March 26, 2019, during a National Space Council meeting at the U.S. Space & Rocket Center, Vice President Mike Pence announced that NASA’s Artemis Program will return U.S. astronauts to the surface of the Moon. Take a look at all the agency has accomplished since then, from testing the Orion spacecraft and building the Space Launch System rocket to graduating a new Artemis Generation class of astronauts and creating partnerships with private industry.

Spinoff 2020: Marshall Inventions Improve Life on Earth

By Will Bryan

Looking for something educational to do with the kids and family? Check out the new issue of Spinoff, a yearly NASA publication that presents 50 NASA technologies that are used in the commercial sector.

Included in the just-released 2020 issue are seven spinoffs from NASA’s Marshall Space Flight Center that improve the way the world operates and the way people relax.

Sometimes new technologies do not come as the result of trying to make something happen, but unexpectedly while solving a separate problem. A case in point is a new humidity sensor developed by Marshall engineers while they were creating a new high-capacity material to replace batteries. Marshall technologists teamed with Roscid Technologies of Woburn, Massachusetts, to test the material that uses nanotechnology and nontoxic ingredients. Roscid now uses that material in its line of humidity sensors.

Better ways to protect your mobile devices are also being developed. Former NASCAR driver Kevin Conway created the PHOOZY cell phone and mobile devices cases after his phone overheated. Incorporated in the cases is the metallized plastic material best known as space blankets. Conway’s team is also developing a small case made of their material to protect insulin, heat-sensitive medications and emergency epinephrine — EpiPens — to ensure their safety wherever their user takes them.

Truck drivers play a critical role in transporting heavy tanks of fuel across the country. Work done by Marshall technologists and Huntsville-based Cimarron Composites has resulted in a new composite overwrapped pressure vessel — essentially a gas tank — that is approved by the U.S. Department of Transportation for highway use.

Marshall technology doesn’t only support travel on the roads but also into space. Working with Virgin Orbit of Long Beach, California, engineers from Marshall and NASA’s Glenn Research Center experimented with and helped develop 3D-printed bimetallic combustion chambers for Virgin Orbit’s LauncherOne rocket. The rocket launches not from a launch pad but from the wing of a modified Boeing 747 airplane — named Cosmic Girl — taking small payloads into space.

Marshall expertise also has an important role in understanding how fluids flow through rocket engines. Through Denver-based Model Technologies Group, Marshall is making licenses for the Generalized Fluid System Simulation Program software available to business and educational institutions. The Marshall-developed software predicts how fluids flow through a system, such as rocket engine. It can determine the fluid’s behavior, even if that fluid changes speed, temperature and phase.

Aerojet Rocketdyne has decades of experience working on rocket engines, including with Marshall. The result of that work is used to help produce energy in cleaner ways. Gas Technology Institute in Des Plaines, Illinois, which bought Aerojet Rocketdyne’s energy portfolio in 2015, uses the knowledge of liquid rocket engine development — including the principle of gasification — to help developing countries use coal in a way that is less harmful to the environment.

A device that is helping on oil rigs is another Marshall spinoff. Following the tragic Deepwater Horizons oil spill in 2010, long-time NASA and Marshall contractor Bastion Technologies of Houston used their experiences and knowledge of propellants, mission safety and structural analysis to develop a new device to shear and seal an oil well’s drill pipe. The new apparatus aims to prevent future oil leak disasters.

Since 1976, NASA has published Spinoff, documenting thousands of technologies. See what else is in the new issue here. Download Spinoff here.

Bryan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

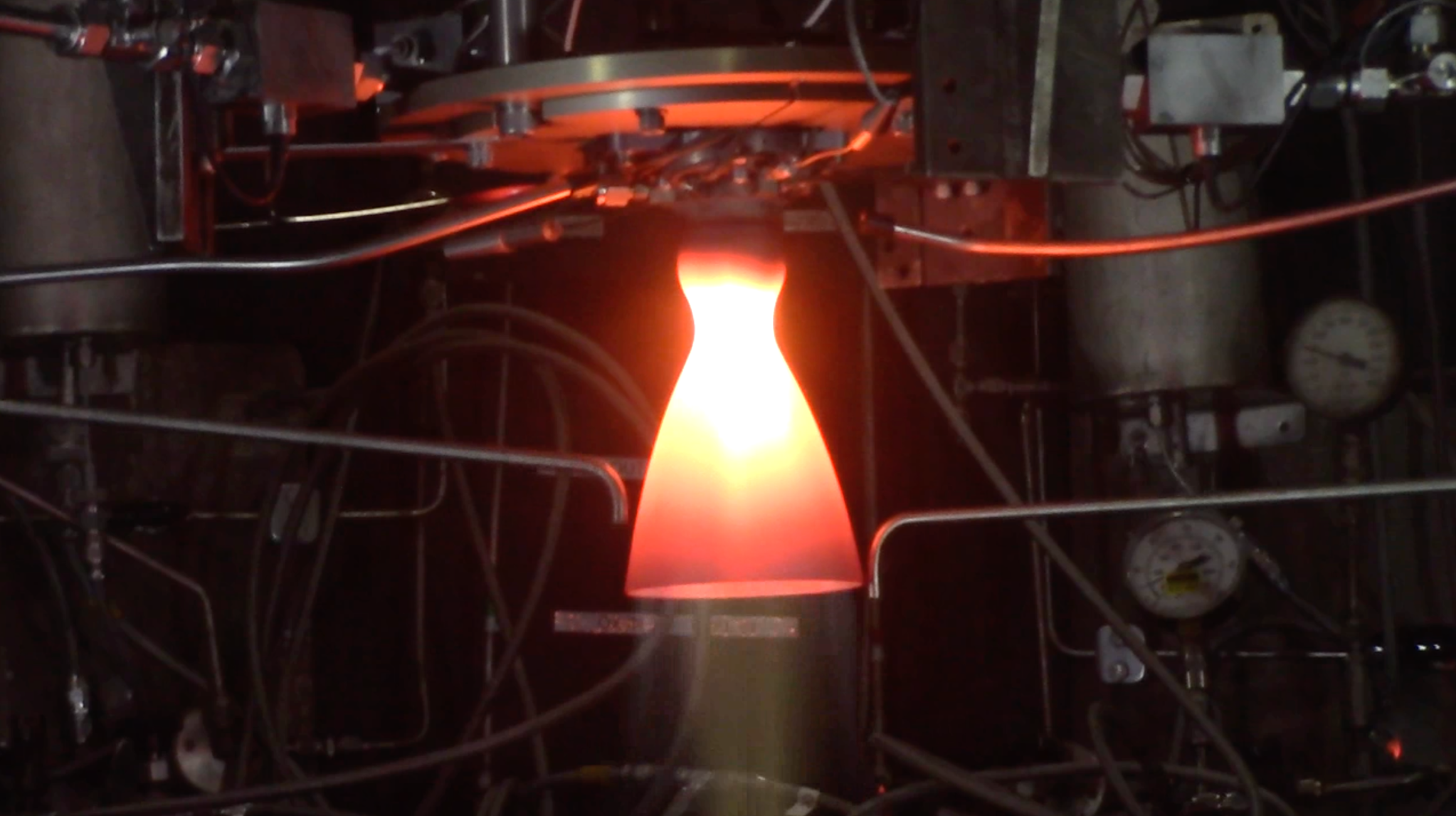

Moon Thrusters Withstand Over 60 Hot Fire Tests

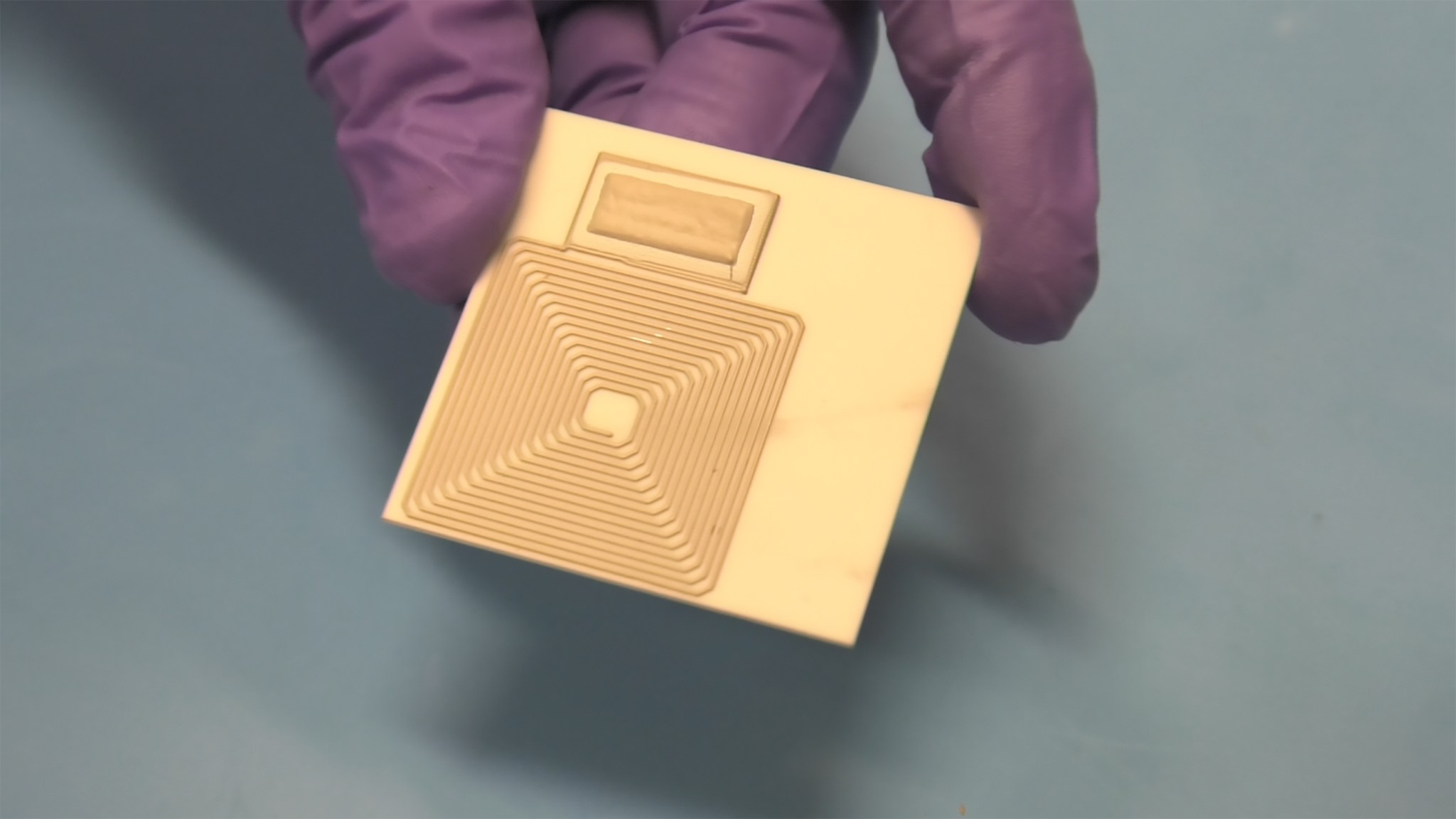

NASA and Frontier Aerospace of Simi Valley, California, completed approximately 60 hot fire engine tests on two lunar lander thruster prototypes March 16.

The thruster is being developed by Frontier Aerospace, as part of a project led and managed by NASA’s Marshall Space Flight Center.

Future Artemis Program lunar landers could use next-generation thrusters — the small rocket engines used to make alterations in a spacecraft’s flight path or altitude — to enter lunar orbit and descend to the surface. Before the engines make the trip to the Moon, helping deliver new science instruments and technology demonstrations, they’re being tested on Earth.

The tests occurred over the course of 10 days and took place in a vacuum chamber at Moog-ISP in Niagara Falls, New York, that simulates the environment of space. While replicating mission flight operations, engineers collected multiple data streams — including the pressure and stability of the combustion chamber and the pressure and temperature of the feed system, which delivers propellant from tanks to the thruster.

Being developed under NASA’s Thruster for the Advancement of Low-temperature Operation in Space project, the thrusters are designed to reduce spacecraft cost, mass and power — three things that constrain every space mission. Astrobotic Technology of Pittsburgh plans to use the new thrusters aboard their Peregrine lunar lander that will deliver science and technology payloads to the Moon for NASA in 2021.

The thrusters burn mixed oxides of nitrogen and monomethyl hydrazine propellants — MON-25/MMH — which are capable of operating at low temperatures for an extended period of time without freezing.

“TALOS is about leveraging the benefits of MON-25, which will reduce the amount of power needed for spacecraft when operating in extremely low temperatures,” said Greg Barnett, TALOS project manager at Marshall.

Although MON-25 has been tested since the 1980s, no spacecraft currently uses the propellant. TALOS is capable of operating at a wide propellant temperature range, between -40 and 80 degrees Fahrenheit. That’s compared to state-of-the-art thrusters of the same size that generally operate between 45 and 70 degrees Fahrenheit.

Because MON-25 does not need to be conditioned at extreme temperatures like other mixed oxides of nitrogen propellants, it will reduce power requirements for spacecraft operating in low temperatures — resulting in smaller, lighter and less expensive systems. Reducing power requirements for the spacecraft could potentially reduce the number of batteries and the size of solar panels needed to maintain the spacecraft.

“NASA will soon verify this versatile thruster design for space so that the agency and commercial companies can easily implement the technology in future missions,” Barnett said.

The TALOS project is slated to perform engine qualification testing in late summer to ready the thruster design for use on Astrobotic’s Peregrine lander. Astrobotic is one of several American companies working with NASA to deliver science and technology to the lunar surface through the Commercial Lunar Payload Services initiative — part of the Artemis Program.

In addition to sending instruments to study the Moon, NASA’s Artemis lunar exploration program will land the first woman and next man on the lunar surface by 2024 and establish a sustained presence by 2028. The agency will leverage its Artemis experience and technologies to prepare for the next giant leap — sending astronauts to Mars.

Once the TALOS design has been qualified for flight, Frontier Aerospace will build the thrusters for Astrobotic’s lunar lander under a project called Frontier Aerospace Corporation Engine Testing. The Game Changing Development program within NASA’s Space Technology Mission Directorate funds the technology development project.

Learn more about NASA’s investments in space technology at www.nasa.gov/spacetech.

This Week in NASA History: STS-6 Launches – April 4, 1983

This week in 1983, space shuttle Challenger, mission STS-6, launched from NASA’s Kennedy Space Center. Challenger carried the Tracking and Data Relay Satellite-1. Started in the 1970s, the Tracking and Data Relay Satellite comprises the space segment of the Space Network, a communications network of ground and space components for mission support. The current Tracking and Data Relay Satellite configuration consists of 10 orbiting satellites. Tracking and Data Relay Satellite-1, which was retired in the fall of 2009, is seen here in Challenger’s cargo bay. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)