In This Week’s Star

- Take 5 with Mary Beth Koelbl

- Televised Agencywide Town Hall Set for Dec. 3

- NASA Certifies SLS Rocket Laboratory to Test Flight Software for Artemis I

- NASA Chief Technologist to Deliver Talk Dec. 3

- From Wind to Data, in No Time Flat: Accelerating Spacecraft and Aircraft Design

- NASA Opens Previously Unopened Apollo Sample Ahead of Artemis Missions

- Over 900 Free Packages Featured in New NASA Software Catalog

- This Week in NASA History: Launch of Spacelab-1 – Nov. 28, 1983

Take 5 with Mary Beth Koelbl

Growing up in Iowa City, Iowa, Mary Beth Koelbl never dreamed of working for NASA. Fast forward to today, and she’s a 33-year agency veteran whose engineering expertise has been vital to multiple programs and projects at Marshall Space Flight Center, including the Space Launch System, the Commercial Crew Program and the Space Shuttle Program.

Koelbl was appointed deputy director of Marshall’s Engineering Directorate in July. She helps oversee the center’s largest organization, with more than 2,000 team members. The Engineering Directorate leads the design, testing, evaluation and operation of flight hardware and software associated with space transportation, spacecraft systems, science instruments and payloads in development at Marshall.

Marshall Star Editor Daniel Boyette recently sat down with Koelbl to discuss various aspects of the Engineering Directorate, her influences and her unexpected journey to Marshall.

Question: What is the team environment like in the Engineering Directorate, and how do you encourage collaboration and integration across such a large and diverse organization?

Koelbl: Our engineers like to collaborate on project teams. We work across disciplines to support the project offices and make our missions succeed. On specific projects, like the Space Launch System, Commercial Crew or IXPE, the team dynamic across engineering is strong. When you’re a matrix org as big as Engineering, cross-discipline works well, but it’s all aligned to a project. Our management focus is on trying to share best practices or lessons learned across project teams.

We also encourage collaboration and integration from a management perspective. We organize field trips where our leadership team visits a lab, manufacturing area, test environment, mock-ups, etc. The project teams present their work and it often triggers ideas for managers from other areas regarding future collaboration and teaming. We also have a standing meeting where engineers share cross-cutting topics, innovative ideas, process improvements and technology advancements to the engineering management team, which often spurs further collaboration and integration.

Question: What sort of partnerships is your team pursuing to help the agency and the nation put the first woman and next man on the Moon by 2024?

Koelbl: We collaborate with our industry partners, other centers and academia, and sometimes with the Department of Defense. Our cooperative agreement notice process allows us to work with industry or academia to make advancements for technologies we’re interested in. We do a lot of work with industry partners through Space Act Agreements or other contracting mechanisms, where a partner wants to use our test stand or use some expertise we have. We really encourage those collaborations. We’ve recently done some work with the DoD, for example, where they tested launch abort motors for us. We detailed one of our engineers to the Army side at the Redstone Test Center as a form of collaboration.

For the Human Landing System Program, our industry partners propose plans on how they collaborate with the government, so we have points of contact across the organization who meet with them, understand their needs and how we can best collaborate to help make them successful.

Question: How does the Engineering Directorate define and achieve mission success?

Koelbl: Mission success is different for every project we work. Some projects are high-risk, so we know that there’s a chance they’ll fail. But we do the best we can to help make sure they succeed within the budget and schedule. With programs and projects at the other end of the spectrum like SLS, where we’re eventually flying astronauts, mission success is more focused on minimizing the high-risk items. We also do a really good job of verification – making sure all the requirements we set out for SLS are met. Nothing in our industry is risk-free, but we try to put our resources, our time and our talent on the highest-risk items to help minimize that risk. We also look at potential hazards and failure modes and how to best mitigate those and put controls in place so that, if you do have an anomaly, there are some checks and balances in the design to mitigate the adverse effect. Mission success ultimately is successfully achieving the aims of the mission, within the budget and schedule constraints, whatever the project.

Question: Who are some of the people who have influenced your career, and how?

Koelbl: Rex Bailey was subject matter expert in the branch I started in – turbomachinery and combustion devices. He was a great mentor. He challenged you, yet made you feel safe to make a mistake. You wanted to please him, but he wasn’t intimidating. Early in my career, I thought I wanted to be Rex. It turned out that I took a different path than he did, but I still try to emulate the qualities that he had — being open, mentoring, approachable and genuine. Rex always had a little humor at work, too, which I value.

Another is Otto Goetz, who was the chief engineer for Space Shuttle Main Engine. He challenged you to be better. He always asked leading questions that I was pretty sure he knew the answer to, but he made you realize that you didn’t think of everything you should have. Even if he got a little frustrated with you in a meeting, afterward he would always say, ‘Hey, that wasn’t personal, but I think you can do better.’ He really made you try to do your job better.

Question: What’s something about you most people don’t know?

Koelbl: I got into engineering by accident. In high school, I liked math and logic, a little bit, but I didn’t really know what I wanted to do. When I applied to the University of Iowa, I put law, medicine and engineering on my application. I got a letter in the mail saying I had been accepted to the College of Engineering, and I freaked out. I was like, ‘Wait, I’m not ready to do that.’ The academic advisor told me that I should stay in engineering because it’s easier to get in right after high school, and that I could change majors if I didn’t like it. I liked it enough to never change my major.

Some people have their whole life planned out. I’m more of a wing-it kind of person. I didn’t really plan out that I was going to become an engineer and work at NASA. It just kind of happened. Life is funny sometimes.

Televised Agencywide Town Hall Set for Dec. 3

NASA Administrator Jim Bridenstine and Douglas Loverro, NASA’s new associate administrator for the Human Exploration and Operations Mission Directorate, will answer questions from the agency workforce during a televised town hall, originating from NASA Headquarters, at 11 a.m. on Dec. 3. NASA’s Marshall Space Flight Center team members can view the town hall in Building 4200’s Morris Auditorium, on NASA TV or on the agency’s website. To submit a question, visit here, enter your center, click “Ask” or, if your question is already on the list, vote it up the list by clicking the arrow on the left. Loverro, who begins his role Dec. 2, will oversee the development of human spaceflight systems for the Commercial Crew and Artemis programs. Loverro previously spent three decades in the Department of Defense and the National Reconnaissance Office developing, managing and establishing national policy for the full range of national security space activities. (NASA)

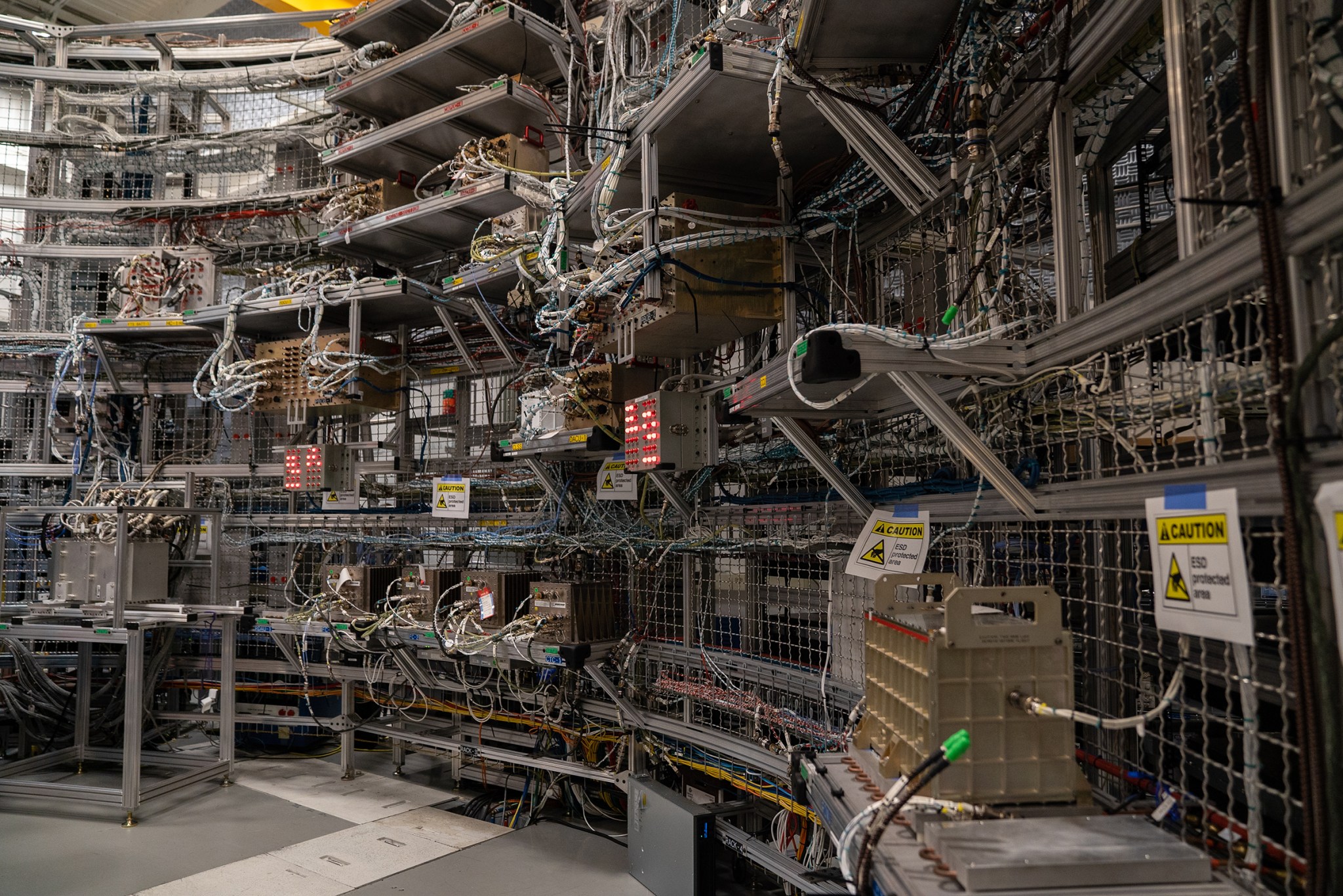

NASA Certifies SLS Rocket Laboratory to Test Flight Software for Artemis I

To launch the Artemis I Moon mission, NASA’s powerful Space Launch System rocket must go from zero to more than 17,000 miles per hour. The rocket’s flight software and avionics systems control all that power during launch and flight to ensure the rocket and NASA’s Orion spacecraft make it to space. The SLS avionics and flight software came a step closer to the Artemis I mission when NASA certified the Systems Integration Laboratory for final integrated avionics and flight software testing Nov. 14.

“The System Integration Lab’s test environment is the most accurate representation of the rocket’s entire avionics and software system,” said Dan Mitchell, lead SLS integrated avionics and software engineer. “Certification means the lab has completed a series of tests and analyses to assert that the facility, its simulation environment and the avionics and flight software have been properly integrated and ready for formal system verification testing.”

This lab at NASA’s Marshall Space Flight Center not only includes the flight computers and avionics identical to the core stage avionics but also includes emulators for the rocket’s boosters and engines, the Launch Control Center and Orion. Now that the lab is ready, software engineers can test the software both under normal and unplanned scenarios.

Using unique software programs, engineers in the lab create real-time launch vehicle simulations for the rocket’s extensive and incredibly intricate flight software and avionics hardware. These simulations include numerous nominal and off-nominal real-time pre-launch and ascent SLS mission scenarios.

Equipped with two propellant tanks that can hold a combined 733,000 gallons of fuel and four RS-25 engines, the 212-foot-tall core stage serves as the powerhouse of the rocket. The core stage, along with the two, five-segment solid rocket boosters, produces more than 8.8 million pounds of thrust to launch it and Orion to the Moon.

The internal flight software and avionics outfitted throughout the boosters and core stage operate with three SLS flight computers and interface with the avionics systems to control all that power and safely guide the rocket beyond Earth’s orbit. The software also works with software for the Exploration Ground Systems team at NASA’s Kennedy Space Center.

“The flight software and avionics systems are considered the brain and nervous system of the rocket,” Mitchell said. “They control the rocket from launch through the first eight minutes of flight, and the test scenarios we create in the lab can simulate any part of an SLS rocket’s launch or even the entire mission.”

In the same room as the lab, the Software Integration and Test Facility integrates and tests hardware for the avionics systems in the core stage of the rocket. These two facilities provide a comprehensive scope of the rocket’s “internal organs” as teams of engineers run hundreds of virtual launches to verify the rocket’s thousands of functional lines of code to evaluate how it will perform in space.

The facilities contain a complete set of avionics and software for the rocket’s core stage, boosters and engines to support end-to-end avionics and software system testing.

“Across the lab in roughly the same positions as they would be inside the core stage, SLS avionics boxes are mounted around a cylinder frame that matches the size of the rocket,” said Lisa Espy, SLS core stage avionics lead. “Inside the skeleton of the rocket, the boxes are even connected with the same sized cables and connectors that will be used on the flight vehicle itself.”

With the certification of the lab complete, formal system testing will be conducted in two phases. First, engineers and developers will focus on the critical avionics hardware and software for flight. Following that, testing will be conducted on the engineering and developmental data acquisition hardware and the hardware for the imagery and flight safety systems.

Although manufacturing hardware generally garners the most attention, development and testing of the flight software are two of the more technically challenging aspects of the rocket’s design.

NASA Chief Technologist to Deliver Talk Dec. 3

Douglas Terrier, NASA chief technologist, will deliver a talk on fostering a culture of innovation in the agency Dec. 3 at 1 p.m. in Morris Auditorium at NASA’s Marshall Space Flight Center. Terrier serves as NASA’s principal advisor and advocate on technology policy and programs, helping plot the strategic direction of the agency’s space technology program. The talk is hosted by the Marshall Center Chief Technologist’s Office. (Credit: NASA)

From Wind to Data, in No Time Flat: Accelerating Spacecraft and Aircraft Design

By Abby Tabor

NASA is preparing to send Artemis astronauts to explore the Moon’s south pole within the next five years. Knowing time is of the essence, aerospace engineer Nettie Roozeboom at NASA’s Ames Research Center had an idea that could significantly speed up the design of rockets, lunar landers and other spacecraft to support lunar exploration.

By linking in real time two NASA facilities — one for advanced aeronautics testing, the other for powerful analysis of results — her method could define a new way of doing business in the world of spacecraft and aircraft design. She recently showed how it could work during the latest tests of NASA’s Space Launch System.

“This could be a tremendous benefit for programs early in the design cycle,” said Thomas Steva, an aerodynamics engineer on the SLS team at NASA’s Marshall Space Flight Center who supported Roozeboom’s project along with researchers at NASA’s Langley Research Center. “That’s a time where high-fidelity data is typically sparse.”

In the wind tunnels at Ames, Roozeboom bridges the worlds of testing rocket designs and crunching data, helping NASA, government and commercial aerospace designers study their vehicles’ performance by simulating conditions expected in flight. From an experimental green aircraft concept designed by Boeing to reduce emissions and noise, to a launch abort system that would carry astronauts to safety if needed, Roozeboom has helped many designs get on their way. Her neighbors at Ames’s nearby NASA Advanced Supercomputing facility work with computer simulations and analyze complex data sets using one of the world’s most powerful supercomputers.

Traditionally, design teams carry their data from a wind tunnel test back to their workplace on a stack of hard drives, where it can take months to analyze. The wind tunnels are in such high demand that if more data is needed, she may not secure another test slot for them until 2021. With NASA’s schedule to land the first astronauts on the Moon in 2024, she knew this two-year cycle wouldn’t fly.

That’s especially critical with all the new traffic she anticipates in the wind tunnels. NASA is working with nine American companies on delivery services to the lunar surface, and Roozeboom expects they’ll all come through the Ames facility.

“The way I see it is: We, NASA, have asked you to do this, so how can we help you get there?” Roozeboom said. “I take it as my responsibility to go create the tools, help them connect to the right talent, and together we can save time.”

In September, Roozeboom put her plan to the test with SLS, set to send the Orion spacecraft to the lunar Gateway, from which the first woman and next man will head to the Moon’s surface on a human landing system. Roozeboom’s job is to measure shaking caused by strong, quickly changing air pressure, such as a vehicle experiences during launch to space.

During the tests, high-speed cameras captured the changing glow of a high-tech paint that reveals rapidly fluctuating pressure during the rocket’s simulated ascent. The data was saved to a rack of hard drives but, for the first time, it didn’t stop there.

The demonstration, which Roozeboom named Red Rover in a nod to the children’s recess game, sent as much as 400 terabytes of data straight from the wind tunnel to the supercomputer. That’s 800 times more than the laptop used to type this story can hold, and a record for live transfer of such data for immediate processing.

The experts at the NASA Advanced Supercomputing facility had taken the wind tunnel experts’ usual software for processing pressure-sensitive paint data and optimized it for real-time visualization. The supercomputer churned through the incoming data and revealed a visualization of the results, practically on the spot. Watching in real time, the SLS design team immediately consulted with experts at Ames. When test conditions didn’t provide precisely the information needed, they made quick adjustments and new data was collected. All without further ado or delay.

Working closely with SLS team members at Marshall and Langley, Roozeboom will determine how the data should be processed and packaged to best meet their customers’ needs — helping develop a new state of the art for NASA and commercial aviation and spacecraft design.

Tabor is a science communication specialist at NASA’s Ames Research Center. Read her original NASA feature story here.

NASA Opens Previously Unopened Apollo Sample Ahead of Artemis Missions

NASA scientists opened an untouched rock and soil sample from the Moon returned to Earth on Apollo 17, marking the first time in more than 40 years a pristine sample of rock and regolith from the Apollo era has been opened.

This allows scientists to practice techniques in studying future samples collected on Artemis missions. The sample — opened Nov. 5 in the Lunar Curation Laboratory at Johnson Space Center — was collected by astronauts Gene Cernan and Jack Schmitt in December 1972 by driving a tube into the surface of the Moon. The sample was opened as part of NASA’s Apollo Next-Generation Sample Analysis initiative.

“We are able to make measurements today that were just not possible during the years of the Apollo program,” said Sarah Noble, Apollo Next-Generation Sample Analysis program scientist at NASA Headquarters. “The analysis of these samples will maximize the science return from Apollo, as well as enable a new generation of scientists and curators to refine their techniques and help prepare future explorers for lunar missions anticipated in the 2020s and beyond.”

Since the Apollo era, all samples that were returned to Earth have been carefully stored in the laboratory to preserve them for future generations. Most samples have been well studied, and many are the subject of ongoing research. However, NASA made the decision to keep some samples completely untouched as an investment in the future, allowing them to be analyzed with more advanced technologies as they are developed.

Advances in techniques such as non-destructive 3D imaging, mass spectrometry and ultra-high resolution microtomy will allow for a coordinated study of these samples at an unprecedented scale.

Samples 73002 and 73001 are part of a 2-foot-long “drive tube” of regolith — rock and soil — that collected from a landslide deposit near Lara Crater at the Apollo 17 site. The samples preserve the vertical layering within the lunar soil, information about landslides on airless bodies like the Moon and a record of the volatiles trapped within lunar regolith — perhaps even those escaping from the Moon along the Lee-Lincoln Scarp, a fault at the Apollo 17 site.

During the preliminary examination, multiple generations of scientists, engineers and curators will work together to study the samples. Team members who have long NASA experience, some of whom were part of the original teams to first study Apollo samples, will work with younger team members in a true collaboration between past and present generations of lunar explorers. Schmitt, the lone geologist among the Apollo astronauts and lunar module pilot of Apollo 17, is also actively involved in the science team.

Since these samples were collected, NASA has continued to study Earth’s nearest neighbor through missions like the Lunar Reconnaissance Orbiter and now has an incredible amount of data about the lunar surface, environment and composition. Under Artemis, the agency will send a suite of new science instruments and technology demonstrations to study the Moon ahead of landing astronauts on the lunar surface by 2024 and establish a sustained presence by 2028. The agency will build on its past to leverage its Artemis experience to prepare for the next giant leap — sending astronauts to Mars.

Over 900 Free Packages Featured in New NASA Software Catalog

Whether NASA is landing humans on the Moon or rovers on Mars, every space mission requires advanced software. With a variety of technical applications, NASA software can also benefit users outside of the agency.

NASA has released its 2019-2020 software catalog, which contains more codes than ever before. Available in print and online, the fourth edition of the publication provides hundreds of new software packages to the public for free, without any royalty or copyright fees.

“These tools were developed to support NASA missions, but they can be utilized in academic research, engineering development and other settings,” said Jim Reuter, associate administrator of NASA’s Space Technology Mission Directorate at the agency’s headquarters. “We also see potential business applications for those looking for a unique, competitive advantage in today’s marketplace.”

The latest edition of the catalog contains 976 software packages, including business systems and project management, design and integration tools, data and image processing, data server processing and handling, environmental science and more. Among the packages included in the catalog for the first time are:

- A virtual reality platform designed with off-the-shelf hardware and game engine software to create digital training environments where engineers can practice procedures for current and future operations.

- An application that lets users explore the diverse ecosystem of experiments being researched on the International Space Station — both completed and ongoing.

- A mobile, low-cost, scalable and accurate system for autonomous navigation and localization.

The software catalog is a product of NASA’s Technology Transfer program, managed for the agency by the Space Technology Mission Directorate. The program ensures technologies developed by and for NASA are broadly available to the public, maximizing the benefit to American taxpayers. NASA’s Technology Transfer program also updated the process for downloading software to make it easier and faster. Interested users can initiate a software request with a click of the button and, in many cases, download code within minutes.

“NASA was the first federal agency to publish a comprehensive list of its available software and make it easy for the public to access,” said Daniel Lockney, executive of the agency’s Technology Transfer program, which manages the distribution of NASA software. “Our latest catalog and website make it simpler than ever to search for, acquire and use NASA-developed code.”

Access restrictions apply to some software that may be limited for use by U.S. citizens or for U.S. government purposes only.

Print and digital versions of NASA’s 2019-2020 software catalog are available at http://software.nasa.gov.

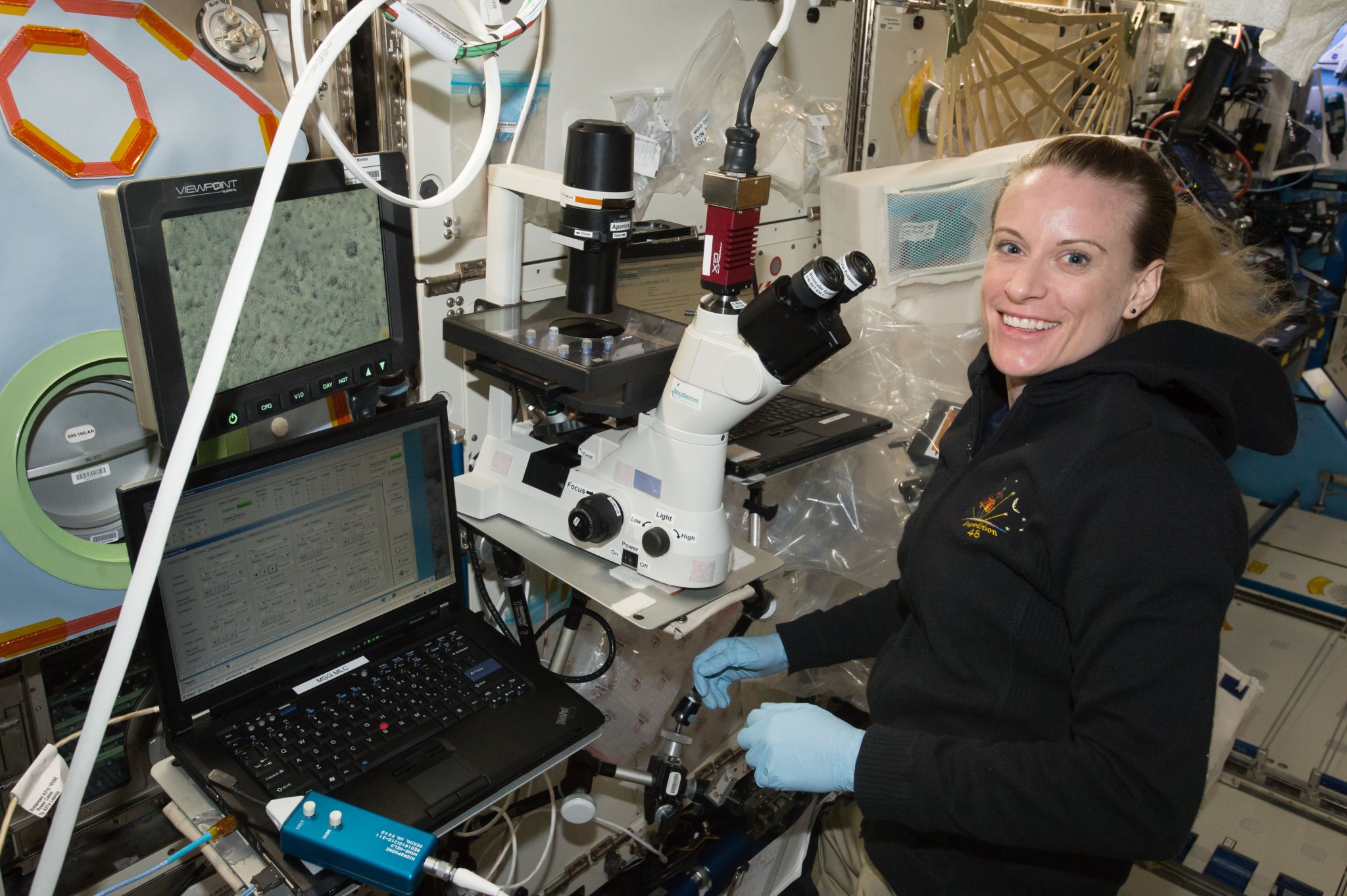

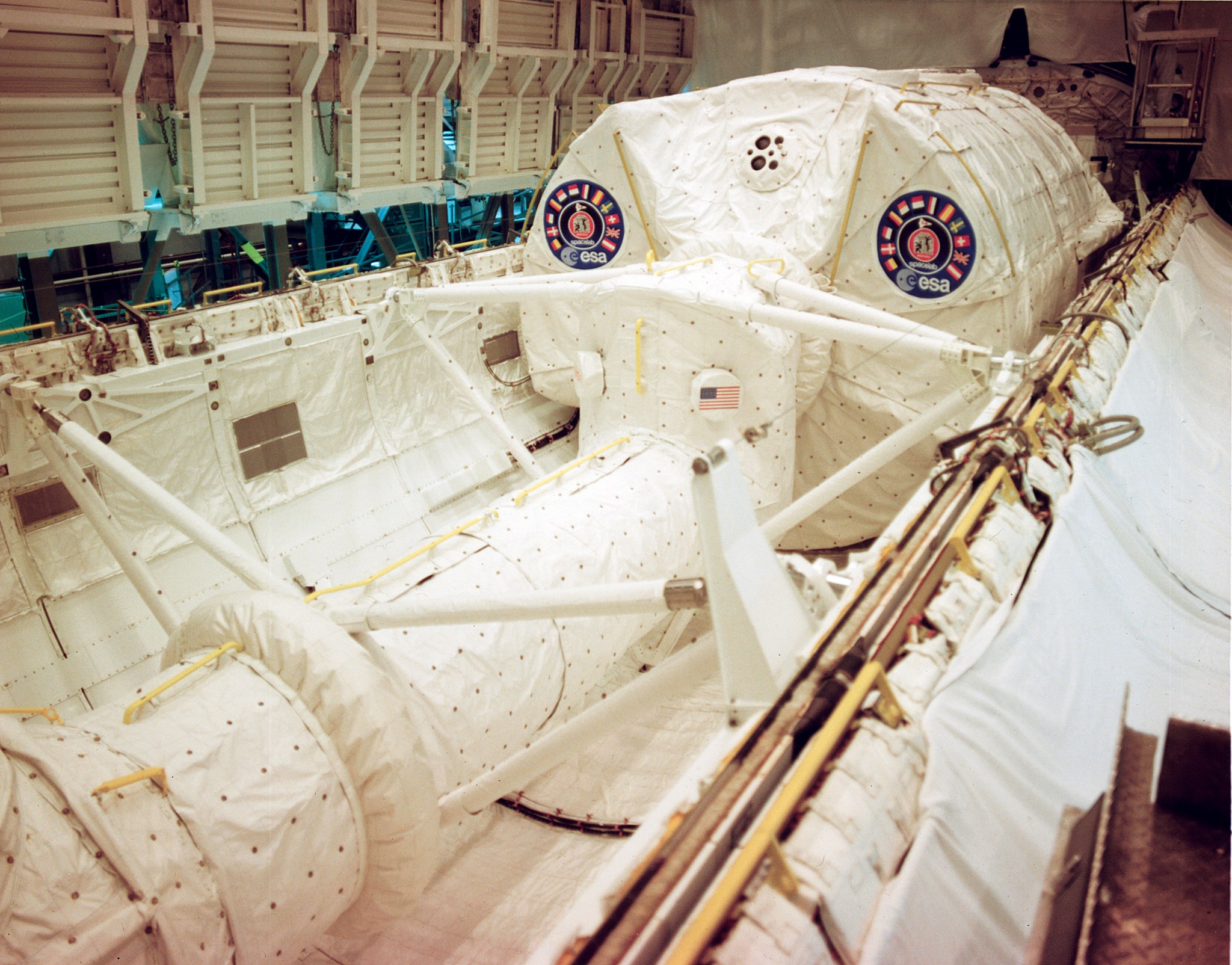

This Week in NASA History: Launch of Spacelab-1 – Nov. 28, 1983

This week in 1983, space shuttle Columbia, mission STS-9, launched from NASA’s Kennedy Space Center carrying Spacelab-1. Here, the Spacelab-1 module and access tunnel are being installed in the cargo bay of Columbia. The orbiting laboratory, built by the European Space Agency, was capable of supporting many types of scientific research best performed in space. The overall goal of the mission was to verify Spacelab performance through scientific experiments focused on astronomy and solar physics, Earth observations, space plasma physics, materials sciences, atmospheric physics and life sciences. NASA’s Marshall Space Flight Center was responsible for managing the Spacelab missions. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)