In This Week’s Star

January

- Marshall Team Moves Closer to Building a 3-D Printed Rocket Engine

- Second SLS Test Stand Begins to Rise at Marshall

- New Space & Rocket Center Exhibit Focuses on NASA’s Support of Science from the Ground

- SLS’s First Flight to Send Small Sci-Tech Satellites Into Space

February

- Todd May Named Marshall Space Flight Center Director

- Work Begins on NASA SLS Core Stage Pathfinder

- NASA Data Used to Track Groundwater in Pakistan

- Jody Singer Named Deputy Director of NASA’s Marshall Space Flight Center

March

- Flight SLS Engine Section Completes Welding at Michoud

- NASA Astronaut Scott Kelly Returns Safely to Earth After One-Year Mission

- Marshall Supports 15 Years of International Space Station Discoveries

- RS-25 Engine Test Marks Major Milestone on NASA’s Journey to Mars

- Marshall and Alabama Legislature Celebrate NASA and State’s Enduring Relationships

- NASA Spacecraft to Test ‘Green’ Propellant Passes Major Pre-flight Milestone

- Precision Meets Progress in Welding on SLS Liquid Oxygen Tank Hardware

- SLS Avionics Get in the Ring for the Journey to Mars

April

- NASA Rocket Fuel Pump Tests Pave Way for Methane-Fueled Mars Lander

- NASA Begins Testing of Revolutionary E-Sail Technology

- Rover Challenge Event Rolls Out Another Successful Year

- New Test Structures Will Have SLS Hardware Feeling the Force

- Astronaut Kjell Lindgren Credits Marshall for Successful Mission

- NASA Tests Earthquake Mitigation System at the University of Alabama in Tuscaloosa

- 2016 Student Launch Challenge Has Teams Soaring for Science

- NASA Helps Forecast Zika Risk

May

- Earth’s New Lightning Capital Revealed

- Marshall Scientist Andrew Molthan Honored by President at White House Event

- Marshall and Louisiana Legislature Celebrate State’s Continuing Role in Human Space Exploration

- ‘Greening’ of Marshall Continues: Center Operations Teams Move Into Building 4260

- Space Station Completes Milestone Orbit

- Final Space Shuttle Tank Arrives in California to Educate and Inspire Future Explorers

- NASA Marshall Wins Fifth Small Business Administrator’s Cup

- International Partners Provide Science Satellites for First Flight of SLS

June

- NASA Completes Test Version of SLS Launch Vehicle Stage Adapter

- Marshall Hosts Teen Winner of Space Tool Challenge

- Marshall Hosts ‘NASA in the Park’ in Downtown Huntsville

- SLS Hardware Delivered to Marshall Ahead of Big Test Series

- SLS Booster Fires Up for Last Test Before Flight

July

- Specialized Transporters Delivered for SLS

- NASA, USAID Open Environmental Monitoring Hub in West Africa

- Marshall Personnel Play Important Role in IMAX Film

- NASA Completes First Round of Composite Shell Buckling Tests with a Bang

- Scientists Gather in Huntsville to Guide the Future of Space Station Discoveries

August

- Marshall Engineers Improving Life Support on International Space Station and for Deep-Space Exploration

- Perseid Meteors Light Up Night Sky Aug. 11–12

- SLS Gets Updated Adapter for Journey to Mars

- ‘NASA Mars Day’ Highlights Progress on Getting to the Red Planet

- Welders Complete Final Plug Fusion Welds on SLS Liquid Hydrogen Tank

- NASA’s Juno Successfully Completes Jupiter Flyby

September

- NASA’s OSIRIS-REx Speeds Toward Asteroid Rendezvous

- NASA Awards $750K in Sample Return Robot Challenge for Autonomous Technology

- Welding Complete on SLS Flight Liquid Hydrogen Tank

- Nearly 150 Racers Compete in 2016 Racin’ the Station Duathlon

- Major Construction Completed on First of Two New Marshall Test Stands for Space Launch System

- Work Underway on Hardware to do Double Duty on First SLS Flight

October

- Skywatchers of All Ages Enjoy International Observe the Moon Night

- Launch Vehicle Stage Adapter Goes in Test Stand at Marshall

- NASA Awards $150,000 to Top 5 Teams in Third Round of Cube Quest Challenge

- NASA’s Journey to Mars Highlighted During Von Braun Symposium

- Apollo 17 Astronaut Harrison Schmitt Visits Marshall

- NASA Administrator Bolden Praises Progress on Programs, Thanks Marshall Team

November

- Hardware Does a ‘Flip’ for First Flight of SLS Rocket

- NASA and University of Alabama Sign Space Act Agreement, Partner to Advance CubeSat Propulsion Technology

- SLS Propulsion System Joins Stack in Test Stand

- Marshall Celebrates NASA’s Agency Innovation Mission Day

December

- Space Station Crew Grows Another Edible Crop in Orbit

- Major Assembly Complete on System That Will Pack a Powerful Push for Orion

- Jonathan Pettus Named Marshall Center Associate Director

- Cosmic ‘Winter’ Wonderland

- Wind Tunnel Testing Underway for Next, More Powerful Version of SLS

- Marshall Engineers Test Combustion Chamber to Advance 3-D Printed Rocket Engine Design

Director’s Corner

First, I want to acknowledge how important your contributions were to my first year as center director. I’ve been a part of the NASA Marshall Space Flight Center family for a long time — about 26 years — so I was well aware of what this team is capable of when we work together. But, from this vantage point, my sense of awe and pride about the work you do was renewed. Every decision I make is underwritten by my confidence in your ability to get the job done. I’ve said it before, and I’ll say it again, you make my job easy. I know that you are up to any challenge thrown our way.

What you accomplished in 2016 makes the most compelling case for the immense value of this team. Last year you:

- Advanced 3-D printing and other innovative manufacturing technologies as part of NASA’s effort to leverage these applications to build better, more cost-effective rocket engine parts and other components for space exploration. This work included 12 test firings of 3-D printed parts that are paving the way for the agency’s advanced manufacturing program.

- Moved the nation’s next-generation rocket for deep space — NASA’s Space Launch System — closer to the launch pad by successfully reaching a series of critical milestones that are laying the groundwork for Exploration Mission-1. You built the core stages of SLS using NASA Michoud Assembly Facility’s state-of-the-art facilities, erected crucial testing infrastructure for SLS hardware and validated the performance of the rocket’s engines and boosters.

- Fostered international cooperation and science by continuing to expertly manage payload operations on the International Space Station. Your work helps make this living laboratory an asset for our ongoing research and development into life support, human factors and other key challenges that will impact future human missions to Mars and other deep-space destinations.

- Expanded the world’s scientific knowledge through amazing discoveries about the universe via the NASA’s Chandra X-Ray Observatory — further underscoring Marshall’s role as a center of expertise for X-ray astronomy.

- Fueled economic growth and innovation through cooperative research and development with our partners in industry and the academic community, as we worked to tackle the challenges of 21st century space exploration.

- Showed some of the nation’s most influential voices the progress this nation has made on the Journey to Mars. NASA Mars Day, the Journey to Mars Event at Michoud in September, showed the world that America’s space program is on track to put human boot prints on the Red Planet by the 2030s,

- Participated in another successful Wernher Von Braun Symposium — this forum once again demonstrated the value of Marshall’s thought leaders in the areas of space exploration and science. There was nothing but positive feedback from our stakeholders.

And these highlights are really just a small sample of the constellation of achievements that can be attributed to Marshall in 2016.

We are at the epicenter of this nation’s push to lay the groundwork for a sustainable and viable human deep-space exploration program. The American people called upon Marshall to develop the vehicles, landers and other transformative technology needed to enable human explorers to reach the surface of the moon. Today, we are being called upon to lead a new transformation — one that will put Mars, and destinations around the outer solar system, within reach of humankind.

Success will hinge on more than just our ability to build the vehicles, lander technology and other hardware necessary for a crew to safely reach these destinations and then return home. Success will demand organizational excellence — the capacity to adapt to new challenges and effectively respond when the status quo simply can’t get the job done. This is about making Marshall a place capable of realizing the full potential of its outstanding workforce — a center that is a true partner to its stakeholders and continues to be a leader and innovator for the entire space program.

Our efforts to realign Marshall with the future in mind began in 2016 — my goal was to do everything within my purview to ensure this team can be positioned for even greater things in 2017. I believe these changes are going to ensure the center can most effectively leverage the talent and know-how found between its walls. Ultimately, organizational changes are only half the solution.

It’s up to us to continue to work together and do great things. You’ve done nothing less over the course of my career at Marshall, so moving forward with realignment was a no-brainer. And considering we started 2017 with the Agency’s Astrophysics Explorers Program announcement that it selected Marshall’s Imaging X-ray Polarimetry Explorer for its next mission, it’s safe to say we’re off to a tremendous start.

So, Happy New Year and welcome back Marshall Team — I can’t wait to see what you achieve in 2017!

January

Marshall Team Moves Closer to Building a 3-D Printed Rocket Engine

A team at NASA’s Marshall Space Flight Center moved step closer to building a completely 3-D printed, high-performance rocket engine in January by manufacturing complex engine parts and test firing them together with cryogenic liquid hydrogen and oxygen to produce 20,000 pounds of thrust. (NASA/ MSFC/Emmett Given)

Second SLS Test Stand Begins to Rise at Marshall

A crane moves the first steel tier to be bolted into place on Jan. 6, for welding of a second new structural test stand critical to development of the Space Launch System at Marshall. Construction began on the stand in Marshall’s West Test Area, where the 215-foot-tall towers of Test Stand 4693, which will conduct similar structural tests on the SLS core stage’s liquid hydrogen tank, is located. (NASA/MSFC/Fred Deaton)

New Space & Rocket Center Exhibit Focuses on NASA’s Support of Science from the Ground

The new Science On Orbit exhibit at the U.S. Space & Rocket Center was opened to the public Jan. 26 in Huntsville, featuring a mock-up of NASA’s Payload Operations Integration Center at NASA’s Marshall Space Flight Center — science mission control for the International Space Station. The museum replicated this smaller version of the science command center for NASA to educate the public and Space Camp attendees. Flight controllers and other Marshall employees who work with space station crews helped the visitor’s center with the details featured in the exhibit. (NASA)

SLS’s First Flight to Send Small Sci-Tech Satellites Into Space

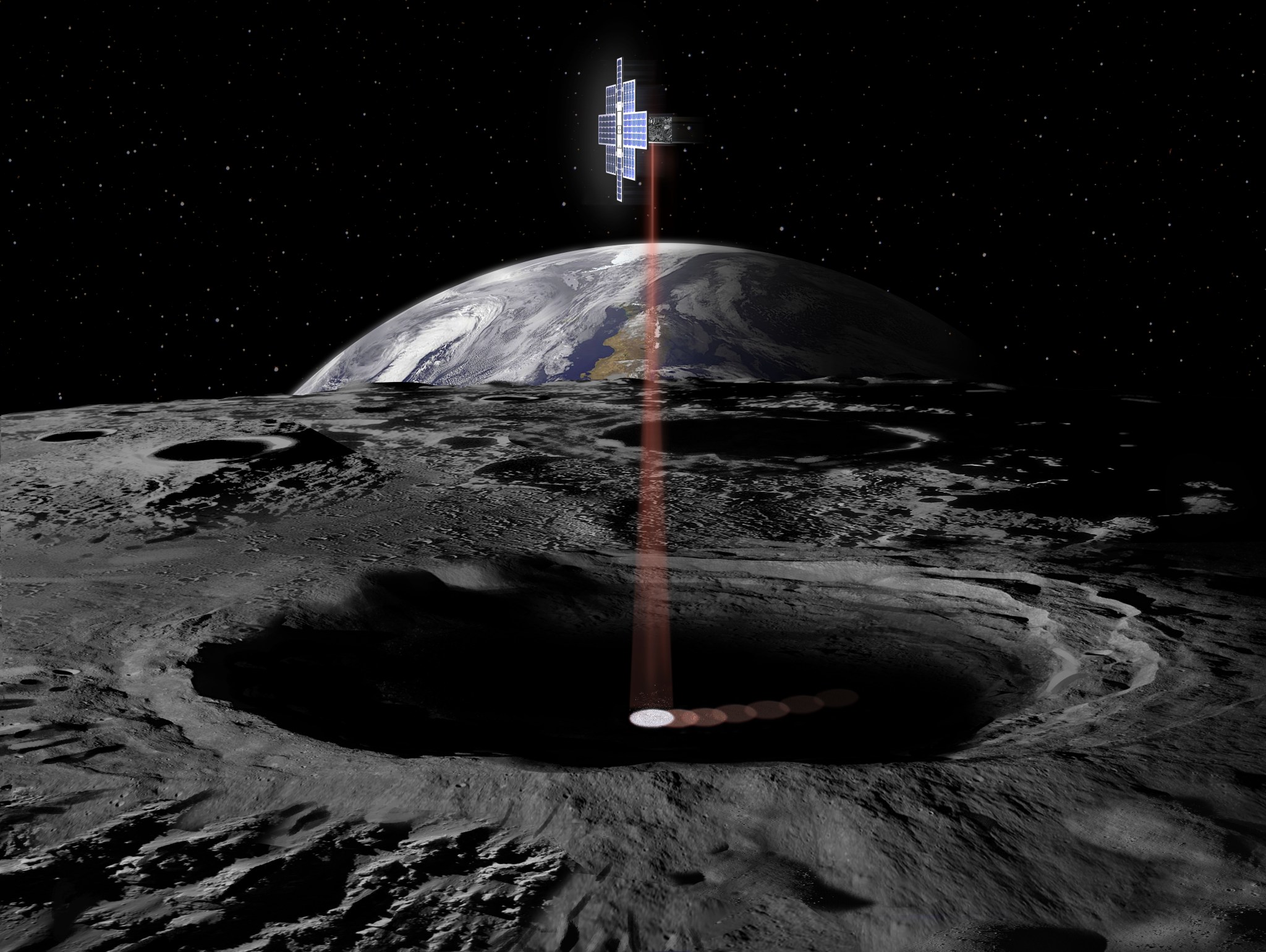

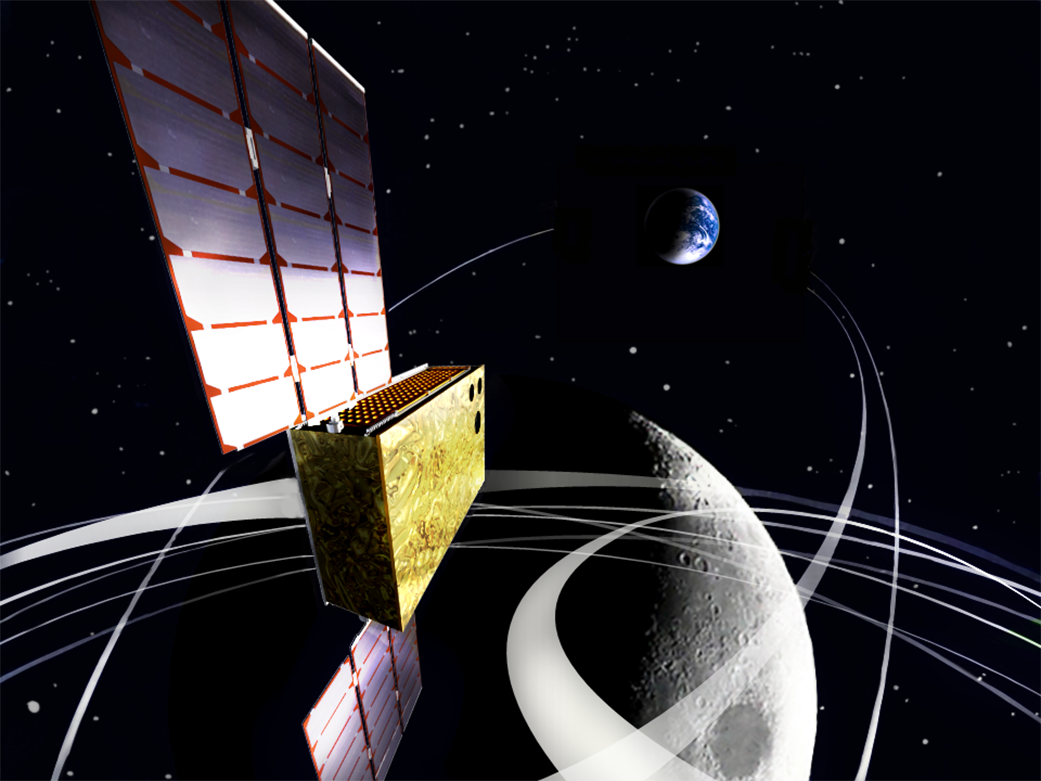

In January, NASA announced the first flight of the agency’s new rocket, the Space Launch System, will carry 13 CubeSats to test innovative ideas in 2018. These small satellite secondary payloads will carry science and technology investigations to help pave the way for future human exploration in deep space, including the Journey to Mars. (NASA)

February

Todd May Named Marshall Space Flight Center Director

On Feb. 1, Todd May was named Marshall center director. He was appointed deputy director of Marshall in August 2015 and had served as acting director since the November 2015 retirement of Patrick Scheuermann. As center director, May manages a broad range of propulsion, scientific and space transportation activities contributing to the nation’s space program. (NASA/MSFC)

Work Begins on NASA SLS Core Stage Pathfinder

In February, major work began in three Alabama communities on a 213-foot, 230,000-pound simulation of the SLS core stage. The steel mockup, designed by Marshall engineers, will demonstrate core stage operations and transportation, including routes for testing, assembly and launch. (NASA/MSFC)

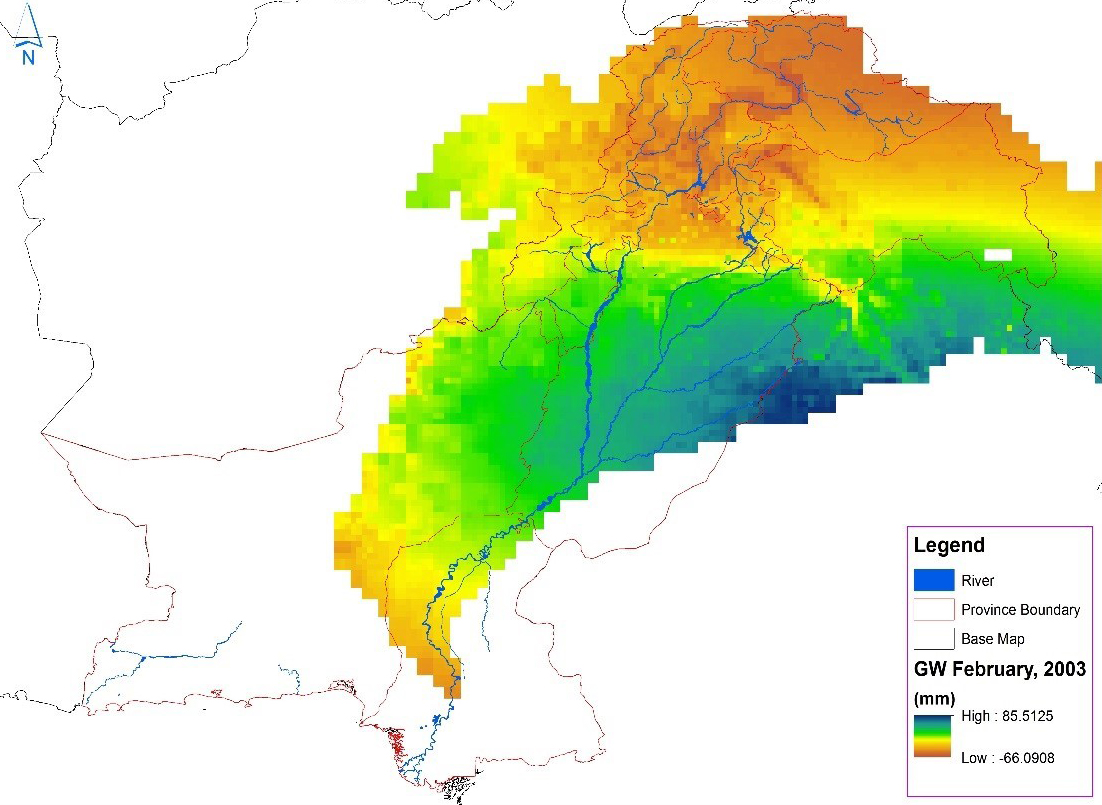

NASA Data Used to Track Groundwater in Pakistan

Thanks to a collaboration led by the University of Washington with the University of Houston, Ohio State University, SERVIR, and NASA Applied Sciences Program Water Resources application area, Pakistan’s water managers are using NASA satellites to help them more effectively monitor and manage the precious resource. SERVIR — managed by Marshall — is a joint initiative of NASA and the U.S. Agency for International Development to use the vast amount of data and observations collected by Earth-orbiting satellites for greater good. (NASA)

Jody Singer Named Deputy Director of NASA’s Marshall Space Flight Center

Joan A. “Jody” Singer was appointed Marshall’s deputy Feb. 29. Over a more than 30-year career with NASA, Singer has held leadership positions in a variety of engineering, propulsion and spaceflight development programs. (NASA/MSFC)

March

Flight SLS Engine Section Completes Welding at Michoud

The SLS engine section finished final welding in March at Michoud. The engine section was the first major SLS flight component to finish full welding on the Vertical Assembly Center. The engine section is located at the bottom of the rocket’s core stage and will house the four RS-25 engines for the first flight of SLS with NASA’s Orion spacecraft in 2018. (NASA/Michoud)

NASA Astronaut Scott Kelly Returns Safely to Earth After One-Year Mission

NASA astronaut Scott Kelly completed a historic 340-day mission aboard the International Space Station when he landed with his Russian counterpart Mikhail Kornienko March 1 in Kazakhstan. The pair spent nearly a year in space to help researchers better understand how the human body reacts and adapts to long-duration spaceflight. This knowledge is critical as the agency looks toward human journeys deeper in the solar system, including to and from Mars. Dozens of flight controllers at Marshall’s Payload Operations Integration Center worked around the clock with these space station crew members and scientists worldwide, contributing to the success of the mission. (NASA)

Marshall Supports 15 Years of International Space Station Discoveries

The team of flight controllers at Marshall’s Payload Operations Integration Center marked 15 years of around-the-clock support of scientific activities on the International Space Station, collaborating with crew members and hundreds of scientists around the world. Experts in disciplines including engineering, math, science, logistics, computer programming and communications manage and monitor investigations 24 hours a day, 365 days a year. Three members of the original team, who were on console when the Payload Operations Integration Center first began support of the station, were photographed in March 2001 (inset) and again 15 years later — from left, Payload Rack Officer Brian Little, Ground Training Integrator Ola Myszka, and Payload Rack Officer Aris Tanone. (NASA/Fred Deaton)

RS-25 Engine Test Marks Major Milestone on NASA’s Journey to Mars

NASA engineers conducted a successful test firing of the RS-25 engine March 10 on the A-1 Test Stand at NASA’s Stennis Space Center. The hot fire marked the first test of an RS-25 flight engine for SLS. (NASA/Stennis)

Marshall and Alabama Legislature Celebrate NASA and State’s Enduring Relationships

On March 10, the Alabama State Legislature welcomed Marshall officials to NASA Day at the Alabama State House in Montgomery. Marshall officials were at the capital March 8-10 during the Aerospace States Association’s Alabama Aerospace Week, to spread the word about Alabama’s role in NASA’s Journey to Mars and to inspire the next generations of engineers, scientists and explorers. (NASA/MSFC/Brian C. Massey)

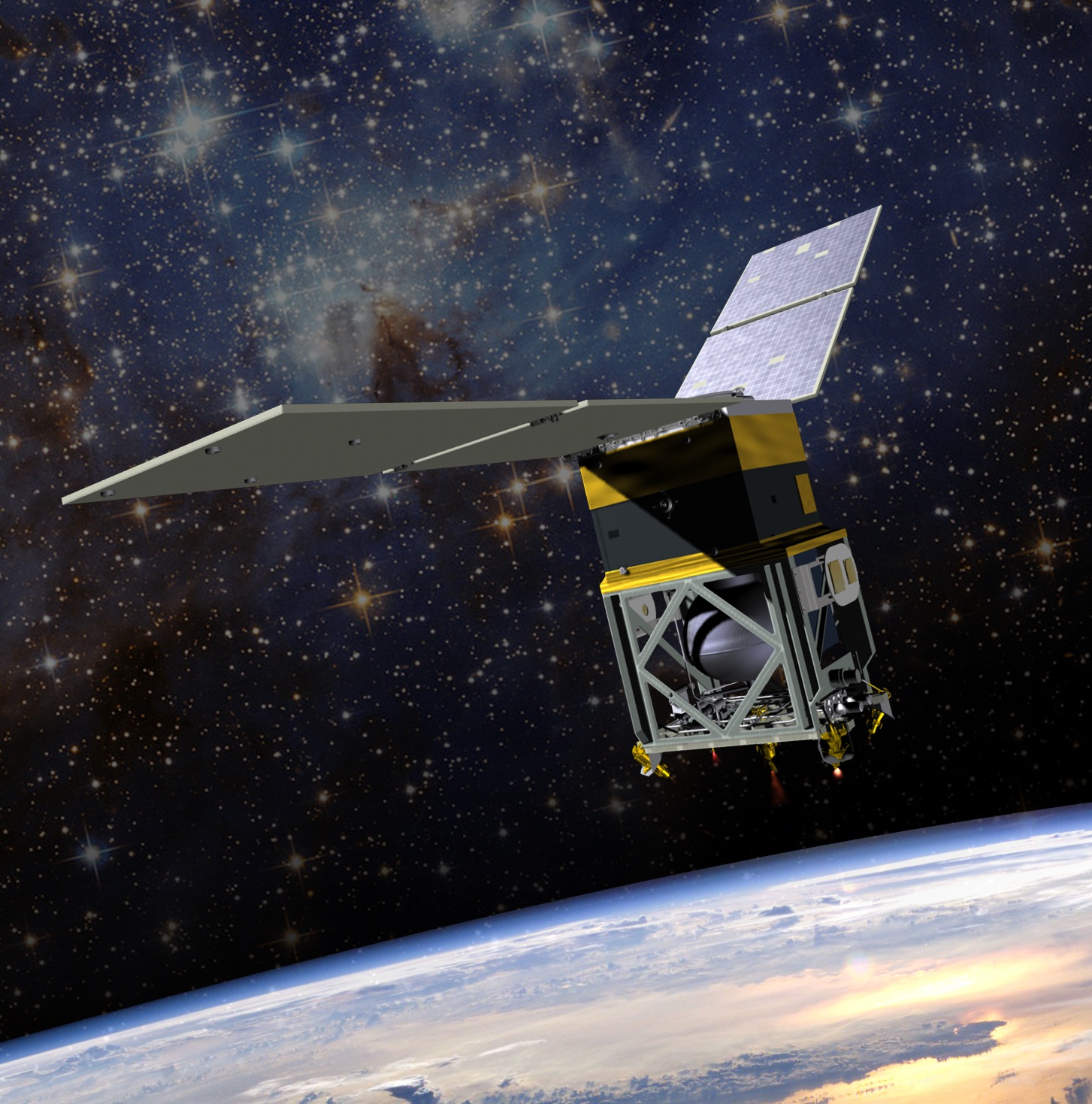

NASA Spacecraft to Test ‘Green’ Propellant Passes Major Pre-flight Milestone

NASA’s Green Propulsion Infusion Mission took a major step in March toward demonstrating the capabilities of a new propellant that is safer to handle on the ground and more efficient for thrusters in space. The GPIM spacecraft passed a major flight readiness milestone marking the successful completion of functional and environmental testing of its systems and software, and is on track for launch. GPIM is managed by the Technology Demonstration Missions program office at Marshall, and funded by NASA’s Space Technology Mission Directorate. (NASA)

Precision Meets Progress in Welding on SLS Liquid Oxygen Tank Hardware

A liquid oxygen tank confidence article for NASA’s new rocket, the Space Launch System, completed final welding on the Vertical Assembly Center at NASA’s Michoud Assembly Facility in March. This was the first glimpse of what one of the two tanks will look like that make up the SLS core stage. Towering more than 200 feet tall with a diameter of 27.6 feet, the core stage will store cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines. Confidence hardware verifies weld procedures are working as planned and tooling-to-hardware interfaces are correct. (NASA/Michoud/Steven Seipel)

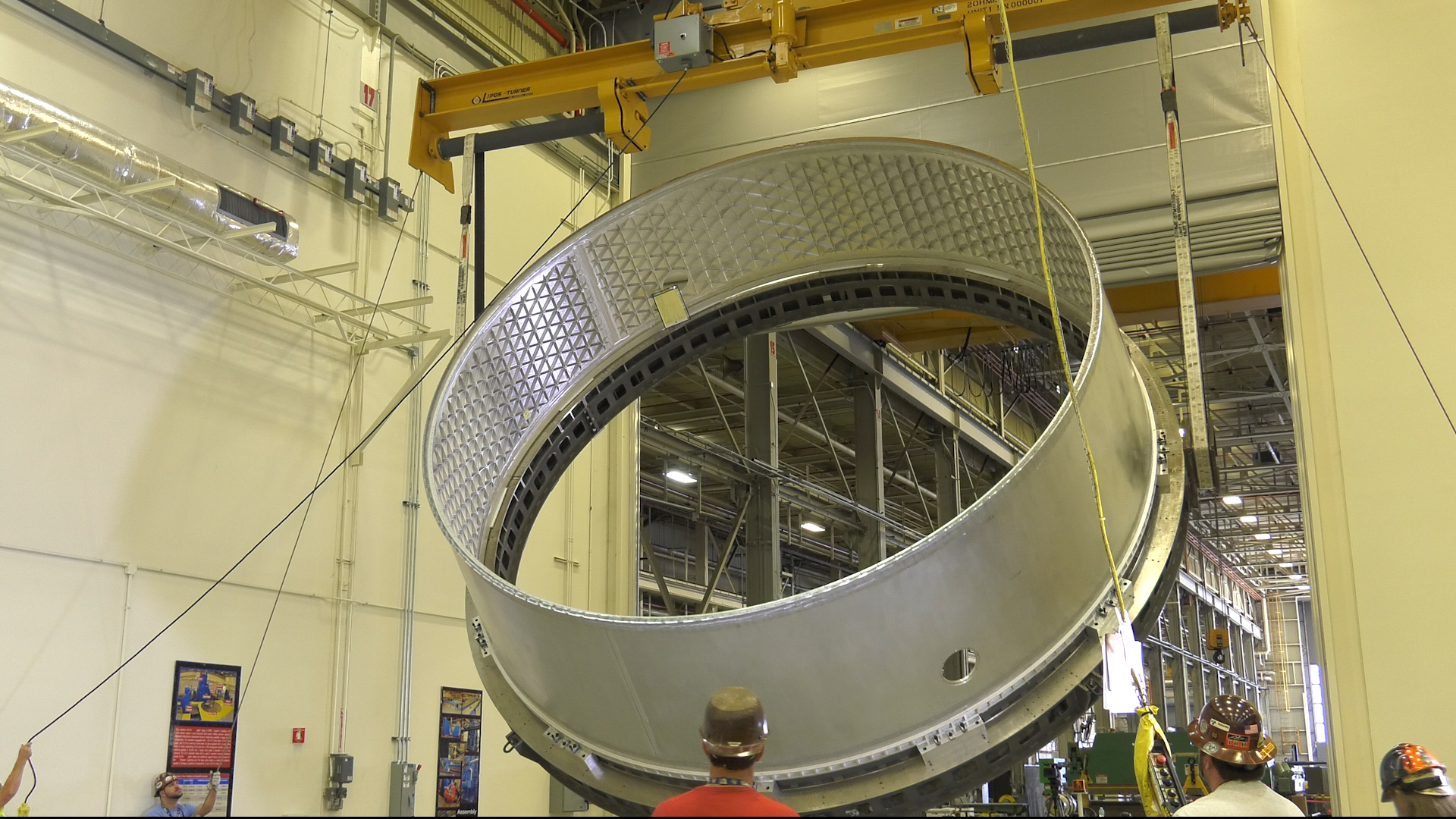

SLS Avionics Get in the Ring for the Journey to Mars

Qualification testing began March 30 at Marshall on the avionics system that will guide SLS on deep-space missions. The testing is an important step in ensuring the system is “go for launch” for the first flight of SLS in 2018. The complex avionics system, housed in the SLS core stage, is made up of computers, software and related hardware systems. (NASA/MSFC/Fred Deaton)

April

NASA Rocket Fuel Pump Tests Pave Way for Methane-Fueled Mars Lander

NASA tested a 3-D printed rocket engine turbopump with liquid methane — an ideal propellant for engines needed to power many types of spacecraft for NASA’s journey to Mars. The turbopump was tested at full power, pumping 600 gallons of liquid methane per minute, enough to power an engine capable of generating 22,500 pounds of thrust. (NASA/MSFC/Emmett Given)

NASA Begins Testing of Revolutionary E-Sail Technology

Testing started at Marshall on a concept for a potentially revolutionary propulsion system that could send spacecraft to the edge of our solar system, the heliopause, faster than ever before. The test results will provide modeling data for the Heliopause Electrostatic Rapid Transit System. The proposed HERTS E-Sail concept, a propellant-less propulsion system, would harness solar wind to travel into interstellar space. (NASA/MSFC)

Rover Challenge Event Rolls Out Another Successful Year

Purdue University Calumet – Team 1 of Hammond, Indiana, navigates the lunar obstacle on their way to winning first place in the college division of the 2016 NASA Human Exploration Rover Challenge April 8-9 at the U.S. Space & Rocket Center in Huntsville. Nearly 80 student teams from 18 states and Puerto Rico, as well Germany, India, Mexico, Italy and Russia designed, constructed and raced human-powered rovers through an obstacle course simulating the types of terrain potentially found on deep-space destinations. (NASA/MSFC/Fred Deaton)

New Test Structures Will Have SLS Hardware Feeling the Force

Construction began in April at Marshall’s Building 4619 on steel reaction towers and fixturing that will be used for structural loads testing on the SLS core stage intertank and engine section. The intertank is the connection component between the liquid hydrogen and liquid oxygen tanks, and the attachment point for the rocket’s two, five-segment solid rocket boosters. The engine section structure houses the rocket’s four RS-25 engines. For testing, hydraulic cylinders will be electronically controlled to push, pull, twist and bend the test articles with millions of pounds of force. (NASA/MSFC)

Astronaut Kjell Lindgren Credits Marshall for Successful Mission

NASA astronaut Kjell Lindgren, left, visited Marshall on April 14 to speak with the workforce and share his experiences during his five-month stay on the International Space Station in 2015. “We worked every day with the dedicated professionals here in the Payload Operations Integration Center, and it’s that partnership that makes science on orbit successful,” Lindgren said, referring to the flight controllers in NASA’s mission control for science in Building 4663. Lindgren also spoke with students who were at Marshall for the NASA Student Launch program, including Midshipman Zenas Yun, above, of the U.S. Naval Academy in Annapolis, Maryland. Lindgren encouraged students to continue their journey of aerospace education, saying a member of the audience could be the first person to walk on the surface of Mars. (NASA/ MSFC/Emmett Given)

NASA Tests Earthquake Mitigation System at the University of Alabama in Tuscaloosa

Officials from the University of Alabama in Tuscaloosa and Marshall gathered April 14 at the university’s Large Scale Structures Laboratory to demonstrate a disruptive tuned mass system’s ability to mitigate a building’s response to earthquakes. Originally developed to solve vibration issues encountered during a rocket launch, the disruptive tuned mass system has potential applications across multiple industries to improve damper systems on ships, automobiles, airplanes, helicopters, bridges and much more. (NASA/MSFC/Brian C. Massey)

2016 Student Launch Challenge Has Teams Soaring for Science

Nearly 50 middle and high school, college and university teams from 22 states competed in the 2016 NASA Student Launch challenge April 13-16 near Marshall. Each team designed, built and launched rockets to demonstrate advanced aerospace and engineering skills related to those needed for NASA’s Journey to Mars. (NASA/MSFC/Fred Deaton)

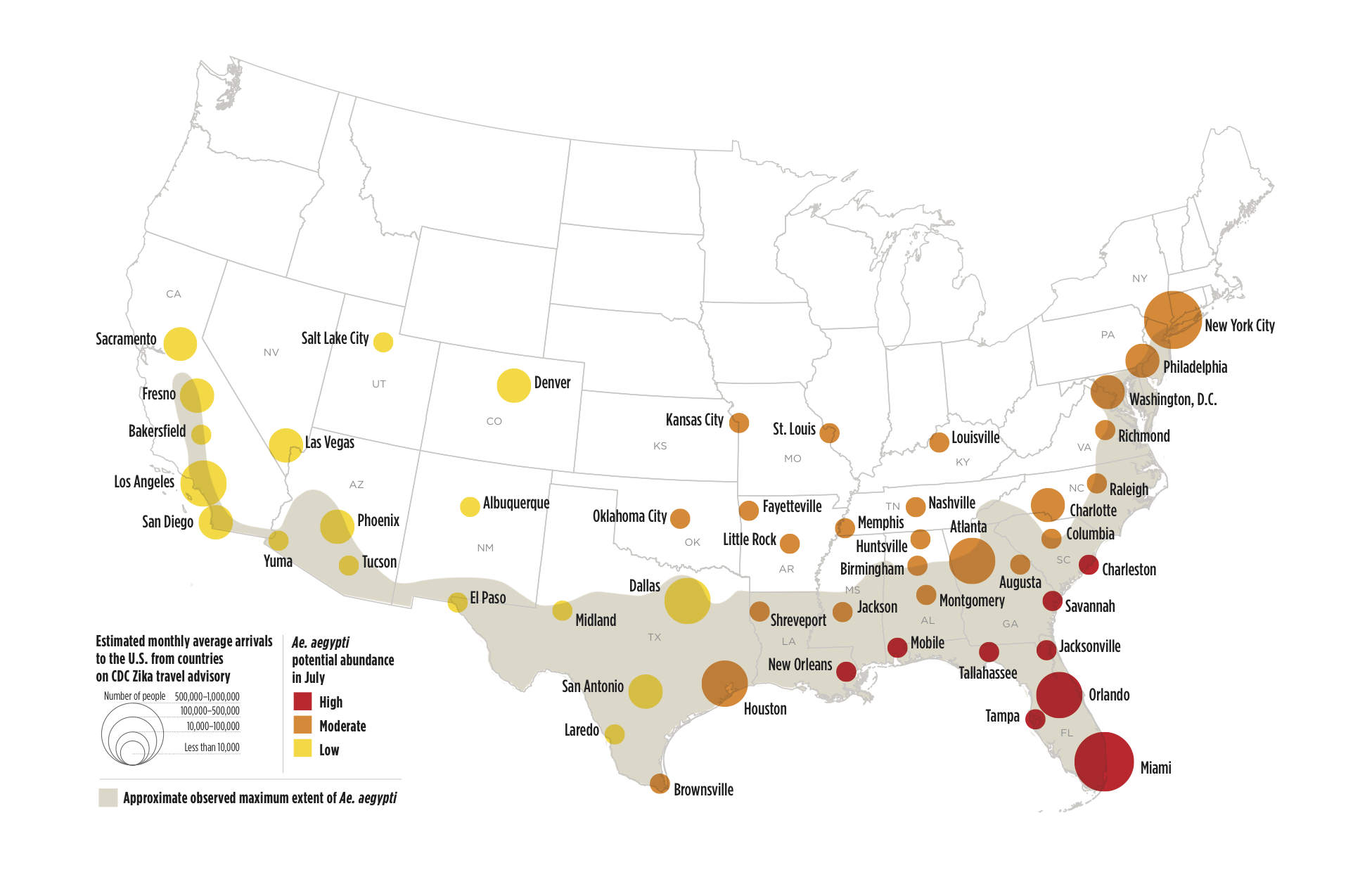

NASA Helps Forecast Zika Risk

NASA assisted public health officials, scientists and communities to better understand Zika virus and try to limit the spread of the disease it causes. Scientists at Marshall partnered with the National Center for Atmospheric Research in Boulder, Colorado, and other institutions to forecast the potential spread of Zika virus in the United States. The research team looked at key factors — including temperature, rainfall and socioeconomic factors — that contribute to the spread of Zika virus to understand where and when a potential outbreak may occur. (UCAR)

May

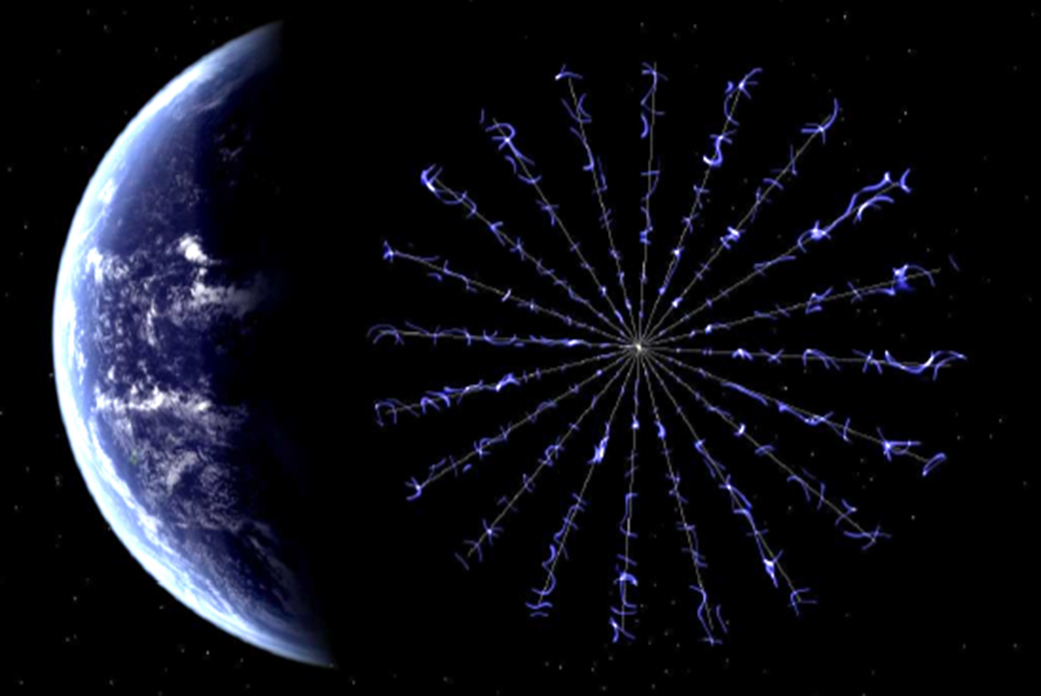

Earth’s New Lightning Capital Revealed

NASA announced in May that Earth has a new lightning capital, according to a recent study using observations from the Lightning Imaging Sensor onboard NASA’s Tropical Rainfall Measurement Mission. Lake Maracaibo in Venezuela earned the top spot, receiving an average rate of about 233 flashes per square kilometer per year, according to the study. Developed at Marshall, the Lightning Imaging Sensor detects the distribution and variability of total lightning — cloud-to-cloud, intracloud and cloud-to-ground — that occurs in the tropical regions of the globe. (NASA)

Marshall Scientist Andrew Molthan Honored by President at White House Event

Andrew Molthan, third row, sixth from right, a research meteorologist in Marshall’s Earth Science Office, was recognized May 5 by President Barack Obama, second row, center, as a recipient of the Presidential Early Career Award for Scientists and Engineers. Molthan was honored for his “outstanding leadership in cloud microphysics, weather forecast modeling and innovative cloud-computing technologies for worldwide distribution of satellite data; and for the development of unique products used by a variety of government agencies in support of disaster response and assessment.” (White House)

Marshall and Louisiana Legislature Celebrate State’s Continuing Role in Human Space Exploration

NASA celebrated the Louisiana workforce’s participation on the Journey to Mars at NASA Day in Baton Rouge at the Louisiana State Capitol on May 5. The Space Launch System — NASA’s next human exploration class rocket — will stand nearly as tall as the Capitol. The core stage of SLS is being built at Michoud. (NASA/MSFC/Will Bryan)

‘Greening’ of Marshall Continues: Center Operations Teams Move Into Building 4260

Marshall’s latest green facility opened for business in May, as Building 4260 on Rideout Road became home to about 100 Office of Center Operations team members. The new facility offers similar high-tech benefits used in Building 4220 and other new structures: state-of-the-art heating, ventilation and air conditioning; water-saving plumbing fixtures; and a retention pond to assist in stormwater quality control. The new building also includes two electric-vehicle charging stations for government vehicles — a pilot program to help meet new government emissions restrictions. It also offers special parking for certified, low-emission personal vehicles. (NASA/MSFC/Emmett Given)

Space Station Completes Milestone Orbit

The International Space Station completed its 100,000th orbit of Earth on May 16. The Zarya control module, launched from Russia in November 1998, was the first piece of the space station placed in orbit. A rotating international crew has conducted thousands of hours of science for more than 15 years, traveling at a speed of 5 miles per second — 17,500 miles per hour — and orbiting Earth every 90 minutes. That adds up to traveling more than 2.6 billion miles — 10 round trips between Earth and Mars. (NASA)

Final Space Shuttle Tank Arrives in California to Educate and Inspire Future Explorers

ET-94 arrived this morning to Marina Del Ray, Calif. Credits: Dennis Jenkins

The last external tank from the Space Shuttle Program, ET-94, embarked on its final mission to commemorate past achievements in space, to educate and inspire future generations of explorers as part of a permanent shuttle exhibit at the California Science Center in Los Angeles. The tank left Michoud by barge April 12, and arrived at the California Science Center May 19. With the addition of ET-94, the California Science Center’s Samuel Oschin Air and Space Center will be the only place in the world to view a complete shuttle stack in launch configuration. (Dennis Jenkins)

NASA Marshall Wins Fifth Small Business Administrator’s Cup

NASA Administrator Charles Bolden awarded the 2016 Small Business Administrator’s Cup to the Marshall Small Business Program Office May 20, marking the second straight year, and fifth time in the award’s eight-year history Marshall has received the award. From left are Todd May, Marshall Center director; Robin Henderson, Marshall Center associate director; Steve Miley, Marshall Office of Procurement director; David Brock, Marshall small business specialist; Glenn Delgado, NASA Office of Small Business Programs associate administrator; Bolden; and David Iosco, Marshall Office of Procurement deputy director. (NASA/MSFC/Fred Deaton)

International Partners Provide Science Satellites for First Flight of SLS

On the first flight of SLS, NASA will take advantage of additional available mass and space to provide the rare opportunity to send more than a dozen small satellites, called CubeSats, to conduct experiments beyond low-Earth orbit. In addition to the 10 CubeSats announced in February, NASA announced in May three more from international partners will also be aboard the maiden SLS mission. (JAXA/University of Tokyo)

June

NASA Completes Test Version of SLS Launch Vehicle Stage Adapter

In June, the structural test article of the launch vehicle stage adapter completed final manufacturing on a 30-foot welding tool at Marshall. The LVSA will connect two major sections of the upper part of SLS — the core stage and the interim cryogenic propulsion stage — for the first flight of the rocket and Orion. (NASA/MSFC/Emmett Given)

Marshall Hosts Teen Winner of Space Tool Challenge

Robert Hillan, a sophomore engineering student at the University of Alabama in Huntsville, watches from NASA’s Payload Operations Integration Center as NASA astronaut Jeff Williams displays a tool that Hillan designed as part of the Future Engineers Space Tool Challenge. The tool had just been printed on the International Space Station’s Additive Manufacturing Facility. Part of his prize for winning the student competition was going behind the scenes at Marshall’s POIC — mission control for space station science. (NASA/MSFC)

Marshall Hosts ‘NASA in the Park’ in Downtown Huntsville

More than 7,500 people attended Marshall and Downtown Huntsville, Inc.’s third annual celebration of NASA and the community June 18. This year, the event moved to Huntsville’s Big Spring Park, becoming “NASA in the Park.” The celebration featured fun for all ages, live music performed by Marshall team members and a special appearance by NASA astronaut Don Thomas. (NASA/MSFC/Emmett Given)

SLS Hardware Delivered to Marshall Ahead of Big Test Series

A key piece of SLS hardware completed a five-hour journey by barge June 19 from United Launch Alliance in Decatur, Alabama, to Marshall. The transported hardware is a prototype of the interim cryogenic propulsion stage, and will be tested in early 2017 with other structural test articles and simulators that make up the upper portion of the rocket. (NASA/MSFC/Emmett Given)

SLS Booster Fires Up for Last Test Before Flight

IA booster for SLS successfully fired up June 28 for its second qualification ground test at Orbital ATK’s test facilities in Promontory, Utah. This was the last full-scale test for the booster before SLS’s first uncrewed test flight with NASA’s Orion spacecraft in late 2018, a key milestone on the Journey to Mars. (NASA)

July

Specialized Transporters Delivered for SLS

In July, four transporters for the SLS core stage were delivered to Michoud. The transporters were designed and built by Wheelift of Waterloo, Iowa, where they were named Elpis, Novus, Pandora and Aegis through a company-hosted contest. The transporters will carry the core stage down roads and on and off the Pegasus barge for shipping to test and launch sites. (NASA/MAF/Steven Seipel)

NASA, USAID Open Environmental Monitoring Hub in West Africa

NASA and the U.S. Agency for International Development opened a new environmental monitoring program in West Africa July 14. The new program will enhance the role of space-based observations in the management of climate-sensitive issues facing the world today. SERVIR-West Africa, based in Niamey, Niger, is one of four NASA-USAID-sponsored centers operating in developing regions of the world. This SERVIR center is the newest facility for a growing global community of scientists and decision-makers who are using publicly available data from space to manage climate-sensitive issues, such as food security, water resources, land use change and natural disasters. (USAID/Sharon Kellman Yett)

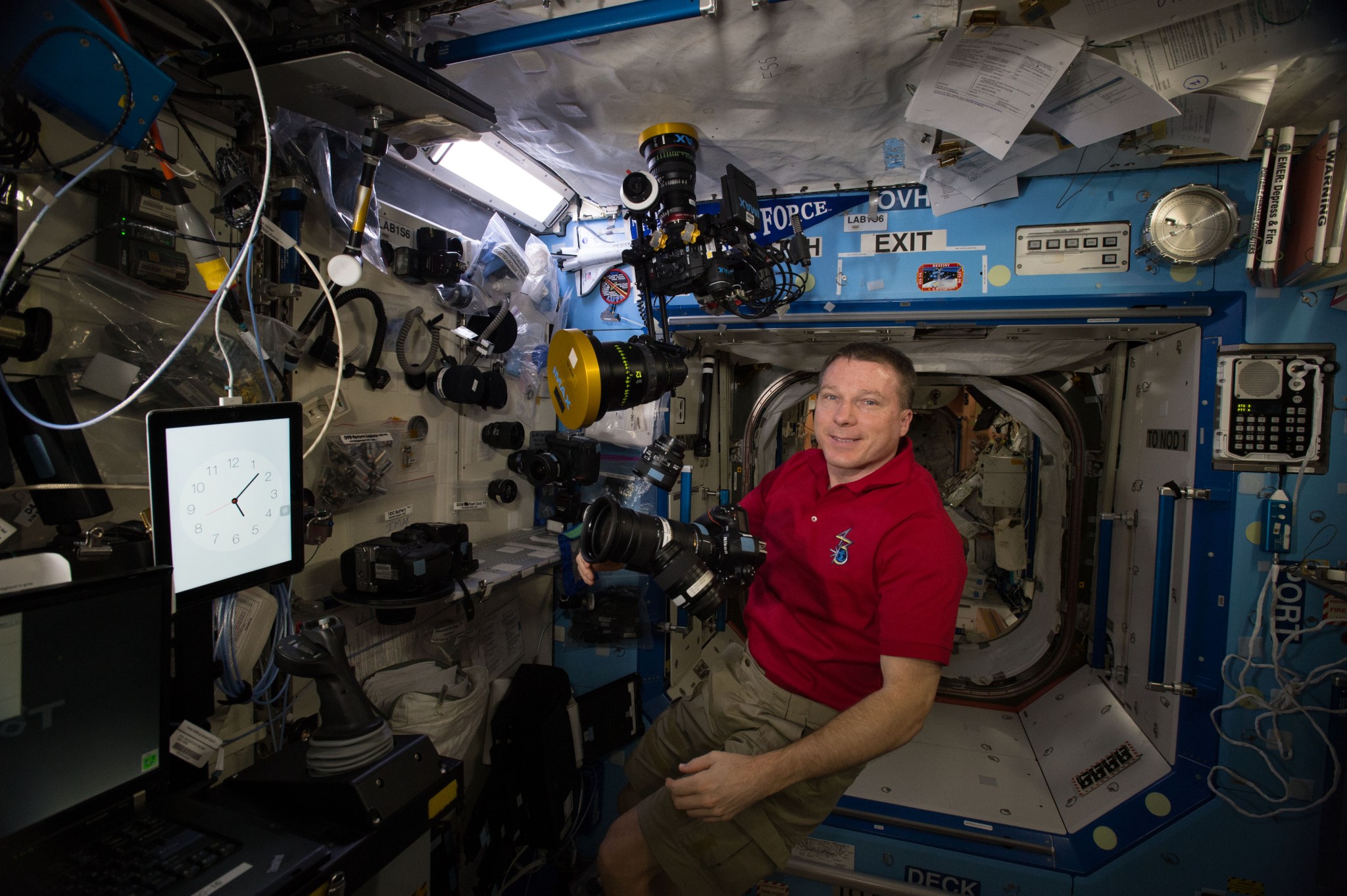

Marshall Personnel Play Important Role in IMAX Film

NASA astronaut Terry Virts records footage using a special IMAX camera during his stay on the International Space Station in May 2015. He, along with other crew members, trained to use the complex IMAX camera and worked with flight controllers at Marshall’s Payload Operations Integration Center. A little over a year later, on July 20, 2016, he joined many of those Marshall team members for the premiere of the film “A Beautiful Planet” at the U.S. Space & Rocket Center in Huntsville. (NASA)

NASA Completes First Round of Composite Shell Buckling Tests with a Bang

NASA successfully completed the first series of high-tech composite tests in as a large cylindrical barrel was tested to failure, in the name of building lighter, stronger primary structures for future launch vehicles. During the testing for the Shell Buckling Knockdown Factor Project at Marshall, force was increasingly applied to the top of a composite barrel to evaluate the structural integrity of the test article. (NASA/MSFC/Emmett Given)

Scientists Gather in Huntsville to Guide the Future of Space Station Discoveries

NASA astronaut Kjell Lindgren discusses his recent stay on the International Space Station and the future of human research in orbit during the semi-annual Payload Operations Integration Working Group meeting July 26-28 in Huntsville. The gathering of scientists from around the world and flight controllers from the Payload Operations Integration Center was held at Campus No. 805 in Huntsville. Updates were presented on payloads currently in orbit and investigations planned for the coming year were previewed. (NASA/Rachel Hobson)

August

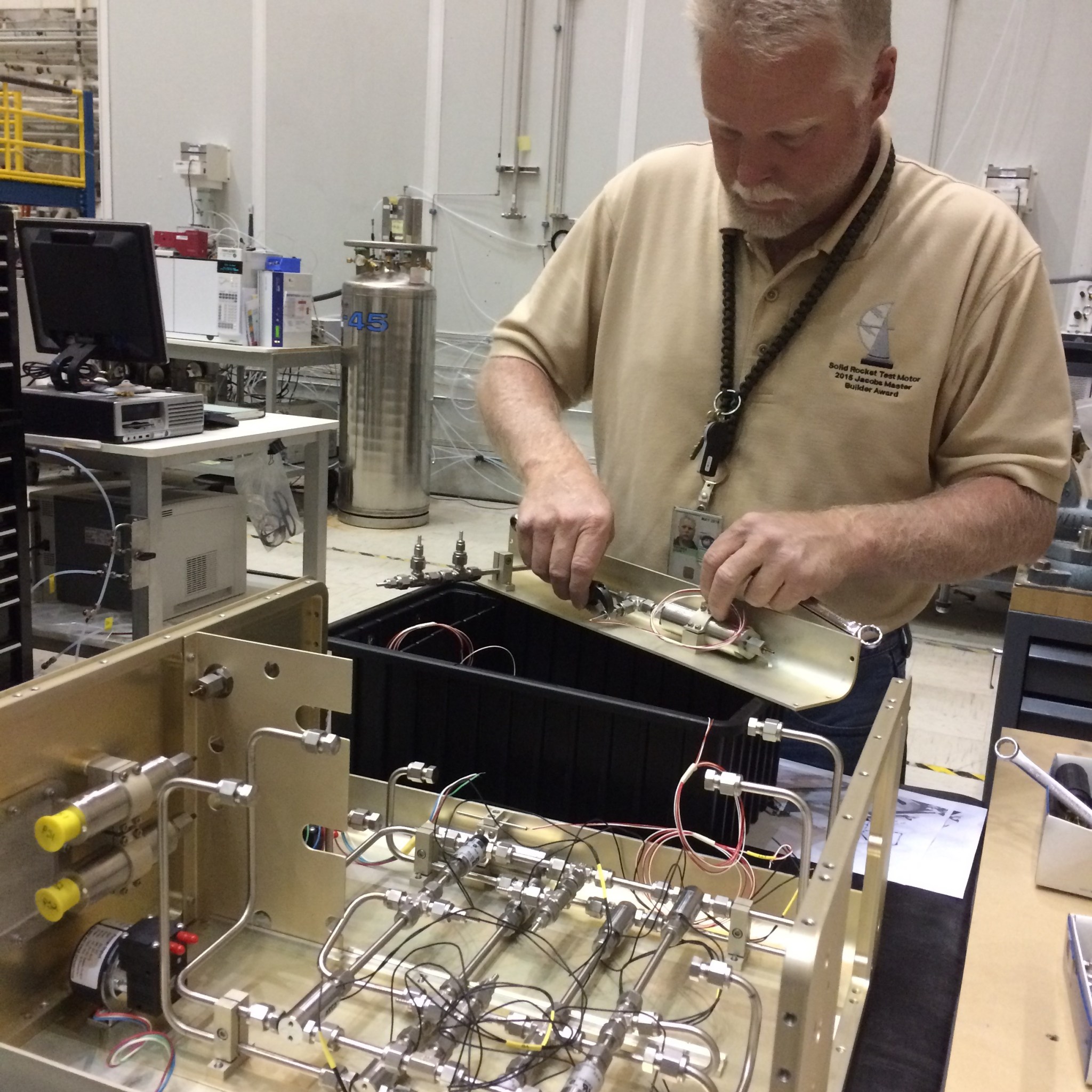

Marshall Engineers Improving Life Support on International Space Station and for Deep-Space Exploration

The Long Duration Sorbet Testbed was installed and activated on the International Space Station Aug. 3. The testbed — designed and built at Marshall — is helping study materials that will help scientists build a more efficient life support system for flights in to deep space. The life support system on the space station currently uses a silica gel to remove humidity or water from the air, allowing another piece of hardware to more efficiently scrub carbon dioxide from the air, keeping it from becoming toxic. Here, John Thomas, lead mechanical designer for the LDST investigation at Marshall, prepares the hardware assembly for the July 18 SpaceX resupply launch. “Exposure to the unique environment in the space station can change the way materials behave,” said David Howard, program manager of the investigation at Marshall. “This includes what we use to filter air and water, so we need options for systems we create for the future.” (NASA)

Perseid Meteors Light Up Night Sky Aug. 11–12

The annual Perseid Meteor Shower peaked Aug. 11-12 with double the normal rate of meteors, reaching 200 per hour under perfect viewing conditions. Astronomers with the Meteoroid Environment Office, located at Marshall, hosted a Facebook Live event to explain how and why NASA tracks and monitors meteor showers. (NASA)

SLS Gets Updated Adapter for Journey to Mars

In August, it was announced that NASA’s Glenn Research Center will lead the design and development of a universal stage adapter on behalf of the SLS Program. The adapter will connect the exploration upper stage — planned for future configurations of the rocket — and the Orion spacecraft. (NASA)

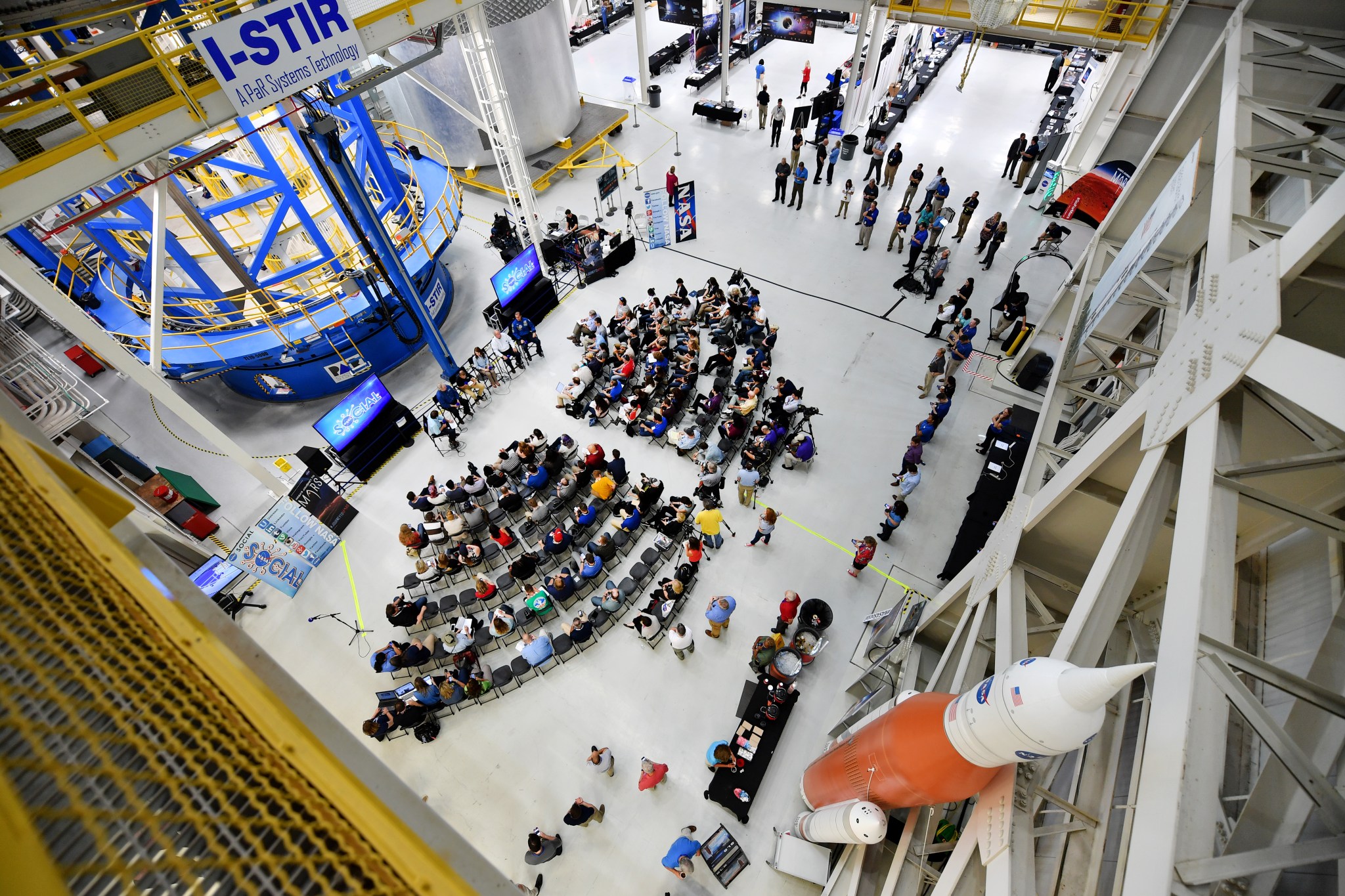

‘NASA Mars Day’ Highlights Progress on Getting to the Red Planet

It was all Mars, all day Aug. 18 at Marshall, Michoud and Stennis. Dubbed “NASA Mars Day,” the event gave hundreds of people, including members of the media and 85 NASA Social participants, a behind-the-scenes look at progress on the agency’s Journey to Mars. Guests got to take tours of Michoud and see a RS-25 engine test at Stennis. (NASA)

Welders Complete Final Plug Fusion Welds on SLS Liquid Hydrogen Tank

In August, welders completed plug fusion welds inside a large SLS liquid hydrogen tank. The fusion welds plug holes left after the tank is assembled using frictional heating and forging pressure. Friction stir welding produces high-strength bonds virtually free of defects. The photo of the work was featured in Aviation Week and on the White House Instagram account. (NASA/Michoud/Steven Seipel)

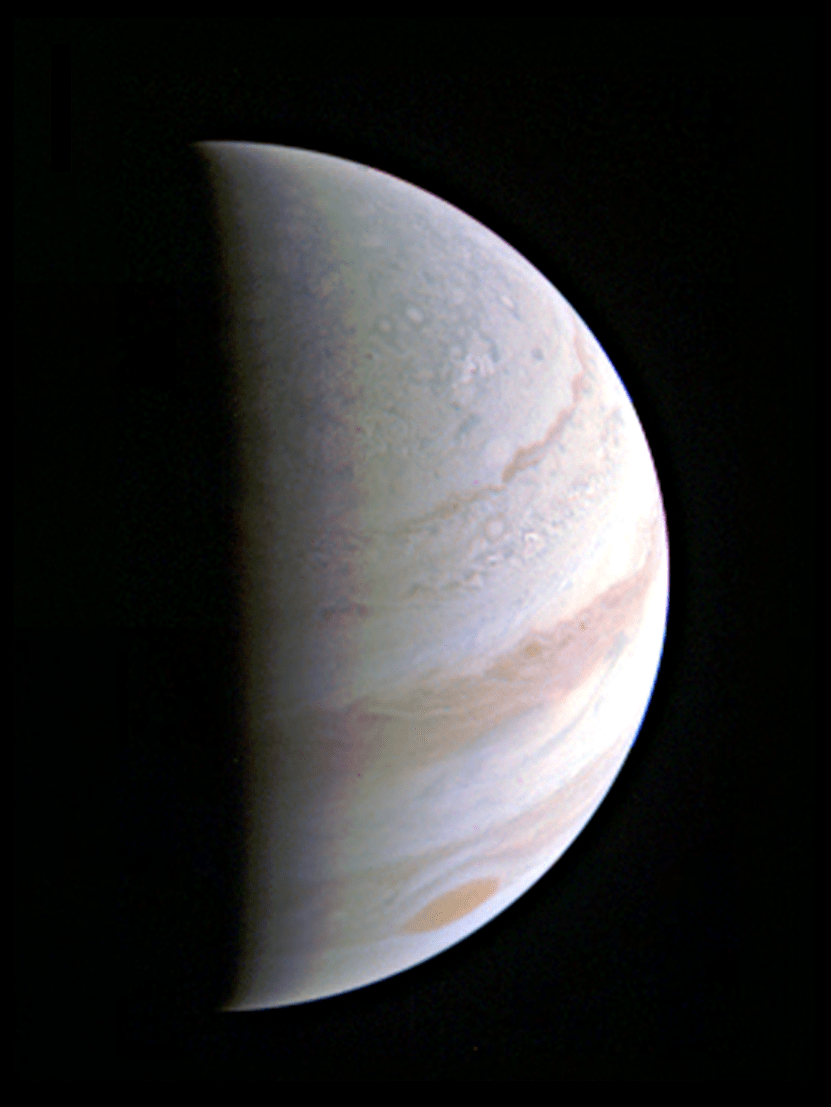

NASA’s Juno Successfully Completes Jupiter Flyby

NASA’s Juno mission successfully executed its first of 36 orbital flybys of Jupiter Aug. 27. The closest approach with the gas-giant world was about 2,600 miles above Jupiter’s swirling clouds. At the time, Juno was traveling at 130,000 mph with respect to the planet. This flyby was the closest Juno will get to Jupiter during its prime mission. The Juno spacecraft launched Aug. 5, 2011, from Cape Canaveral and arrived at Jupiter July 4, 2016. Juno is part of NASA’s New Frontiers Program, managed at Marshall. (NASA)

September

NASA’s OSIRIS-REx Speeds Toward Asteroid Rendezvous

NASA’s first asteroid sampling mission launched into space Sept. 7 from Cape Canaveral, beginning a journey that could revolutionize our understanding of the early solar system. The Origins, Spectral Interpretation, Resource Identification, Security-Regolith Explorer, or OSIRIS-REx, spacecraft is designed to rendezvous with, study and return a sample of the asteroid Bennu to Earth. OSIRIS-REx is the third mission in NASA’s New Frontiers Program. Marshall manages the agency’s New Frontiers Program for its Science Mission Directorate. (NASA)

NASA Awards $750K in Sample Return Robot Challenge for Autonomous Technology

The West Virginia University Mountaineers of Morgantown took home $750,000 at NASA’s Sample Return Robot Centennial Challenge. The team built a robot that autonomously navigated a city park and collected enough samples to win the prize purse, the largest amount ever awarded at this event. The competition began in 2012, and West Virginia University has been the most successful team, taking home $105,000 for their efforts in 2015. (NASA/Joel Kowsky)

Welding Complete on SLS Flight Liquid Hydrogen Tank

In September, welding was completed at Michoud on the liquid hydrogen tank that will provide the fuel on the first flight of SLS with Orion. Standing more than 130 feet tall, the liquid hydrogen tank is the largest cryogenic fuel tank for a rocket in the world. (NASA/Michoud/Steven Seipel)

Nearly 150 Racers Compete in 2016 Racin’ the Station Duathlon

A model rocket launch acts as the “starting pistol” for the 2016 Racin’ the Station duathlon at Marshall on Sept. 24. Participants were invited to run and bicycle a custom course — a 3.14 kilometer run, followed by a 23 kilometer bicycle ride, and another 3.14 kilometer run — in the same amount of time it takes the International Space Station to complete one orbit of Earth — just over 90 minutes. (NASA/MSFC/Emmett Given)

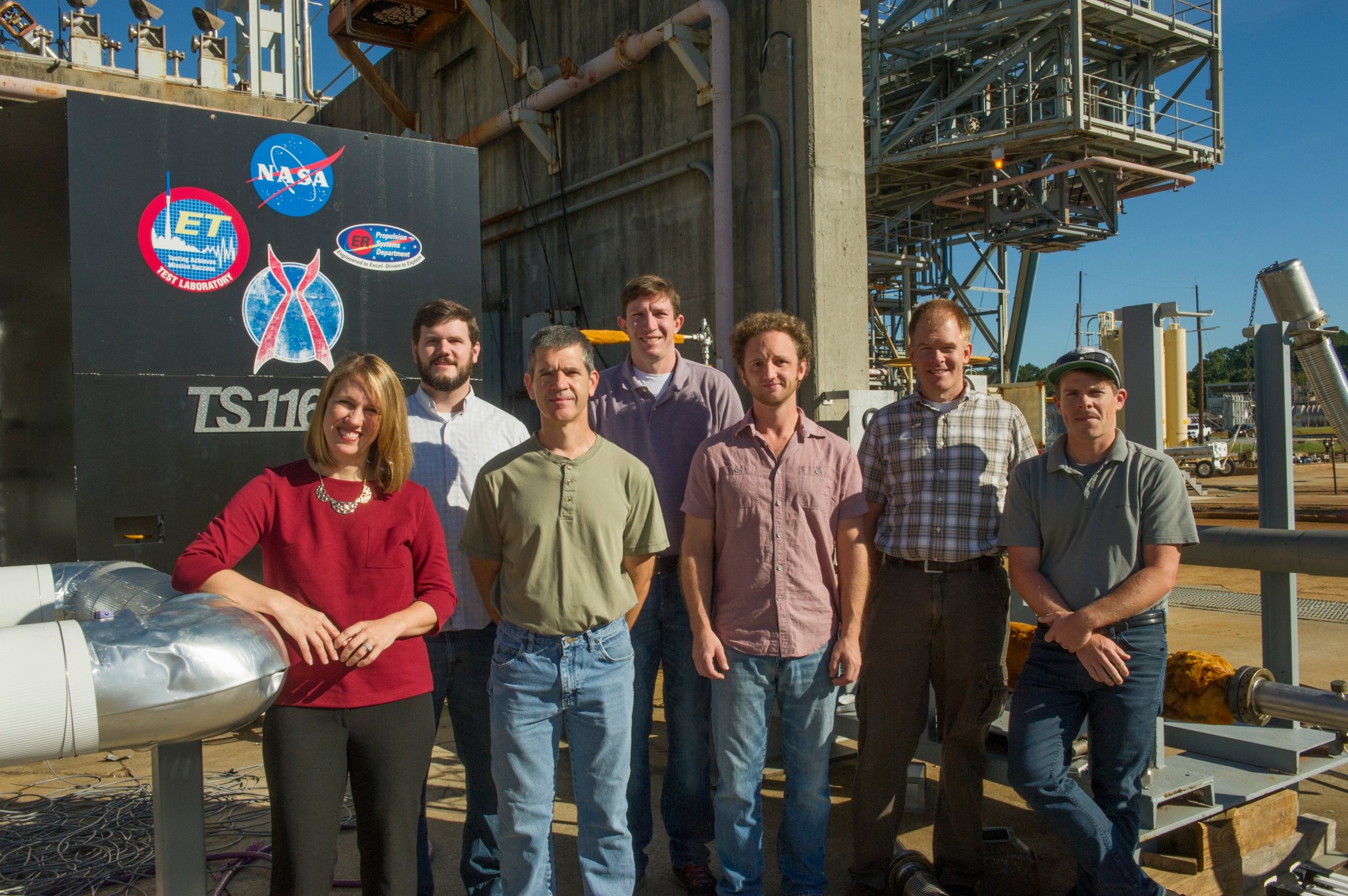

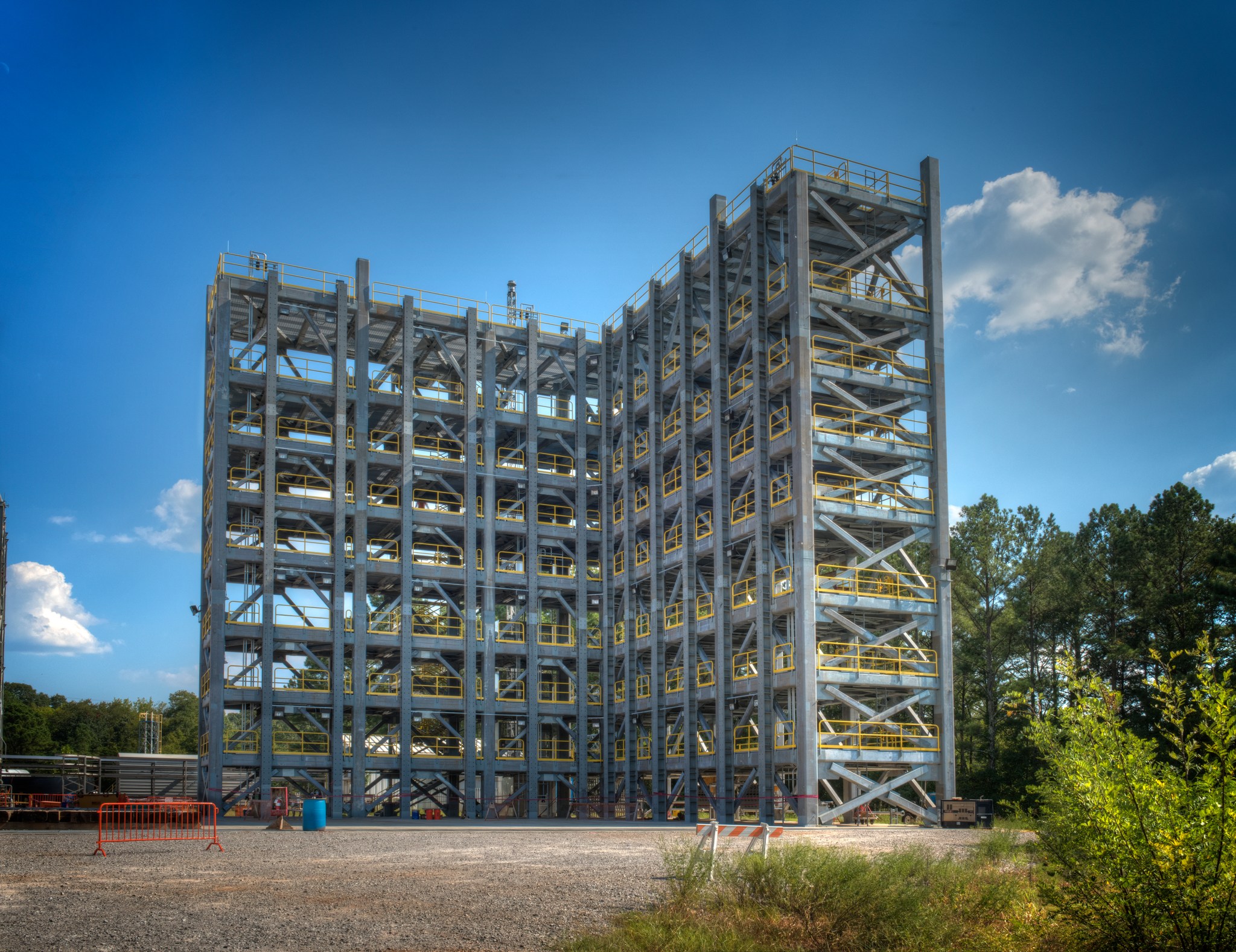

Major Construction Completed on First of Two New Marshall Test Stands for Space Launch System

Workers at Marshall completed the construction phase of Test Stand 4697 in September and began installing special equipment and instrumentation to prepare for testing. Test Stand 4697 will subject the 196,000-gallon cryogenic liquid oxygen tank in the massive core stage of NASA’s Space Launch System to the tremendous forces it will endure in launch and flight. (NASA/MSFC/Fred Deaton)

Work Underway on Hardware to do Double Duty on First SLS Flight

In September, major work began on the flight Orion stage adapter at Marshall. The adapter will connect Orion to the interim cryogenic propulsion stage for the first flight of SLS with Orion in late 2018. The adapter also will carry 13 CubeSats that will perform science and technology investigations. (NASA/MSFC/Emmett Given)

October

Skywatchers of All Ages Enjoy International Observe the Moon Night

Astronomers of all ages celebrated International Observe the Moon Night Oct. 8 at the U.S. Space & Rocket Center in Huntsville with moon-related exhibits, hands-on activities and several large telescopes for viewing the moon, stars and planets. A special guest panel featured Marshall scientists including Mitzi Adams, a NASA solar physicist; Barbara Cohen, a NASA planetary scientist; Bill Cooke, manager of NASA’s Meteoroid Environment Office at Marshall; and Renee Weber, a NASA planetary scientist. (NASA/MSFC/Emmett Given)

Launch Vehicle Stage Adapter Goes in Test Stand at Marshall

A test version of the SLS launch vehicle stage adapter goes into a Marshall test stand Oct. 12. Two simulators and four qualification articles of the upper part of the SLS will be stacked in the stand and tested using forces similar to those experienced in flight. (NASA/MSFC)

NASA Awards $150,000 to Top 5 Teams in Third Round of Cube Quest Challenge

NASA awarded $30,000 to each of five top-scoring teams in Ground Tournament-3 of the agency’s small satellite Cube Quest Challenge. Winning teams were Team Miles, Cislunar Explorers, CU-E3, KitCube, above, and SEDS Triteia. Cube Quest is a $5 million competition to design, build and deliver flight-qualified CubeSats capable of advanced operations in space. The competition continues in 2017, with the fourth and final Ground Tournament in March, followed by two in-space flight competitions. (NASA)

NASA’s Journey to Mars Highlighted During Von Braun Symposium

Discussions about the benefits, challenges and opportunities in advancing space activities as well as highlights of recent progress in science, engineering and technology, were the focus of the ninth annual Wernher von Braun Symposium Oct. 25-27. Held on the campus of the University of Alabama in Huntsville, the symposium was hosted by the American Astronautical Society and Marshall. (NASA/MSFC/Emmett Given)

Apollo 17 Astronaut Harrison Schmitt Visits Marshall

While in town for the Von Braun Symposium, Apollo 17 astronaut Harrison Schmitt, right, the only scientist to walk on the moon, toured Marshall. Schmitt first visited Marshall as a young scientist in the 1960s as he prepared for his lunar mission. He drew comparisons between the two visits while speaking with reporters. “I remember being extraordinarily impressed, as I was today, with the scale of the operation here. It’s just unbelievable, the things human beings are putting together and put together then for the Saturn V,” he said. “The Saturn V was clearly the enabling technology for the Apollo Program and for sending astronauts to the moon. And SLS is the enabling technology for ultimately putting people on Mars.” (NASA/MSFC/Emmett Given)

NASA Administrator Bolden Praises Progress on Programs, Thanks Marshall Team

NASA Administrator Charles Bolden talked with Marshall team members in Morris Auditorium during an all-hands meeting Oct. 27. Bolden praised the progress he’s seen on the Space Launch System and other programs during his seven years as administrator — milestones delivered by the workforce at Marshall and agency wide. “I wanted to thank all of you,” he said. “We’re the best space program in the world. I could not be more confident.” On stage with Bolden are, from right, Marshall Director Todd May, NASA Associate Administrator Robert Lightfoot and Deputy Administrator Dava Newman. (NASA/MSFC/Fred Deaton)

November

Hardware Does a ‘Flip’ for First Flight of SLS Rocket

In November, Marshall engineers flipped the flight Orion stage adapter, which will be an important piece of connector hardware for SLS. The adapter will join the NASA’s Orion Spacecraft to the rocket’s interim cryogenic propulsion stage. The adapter also will carry 13 CubeSats to perform science and technology investigations that will help pave the way for future human exploration in deep space, including the Journey to Mars. The flip was an important next step in evaluating the machining and drilling work on the flight hardware. (NASA/MSFC)

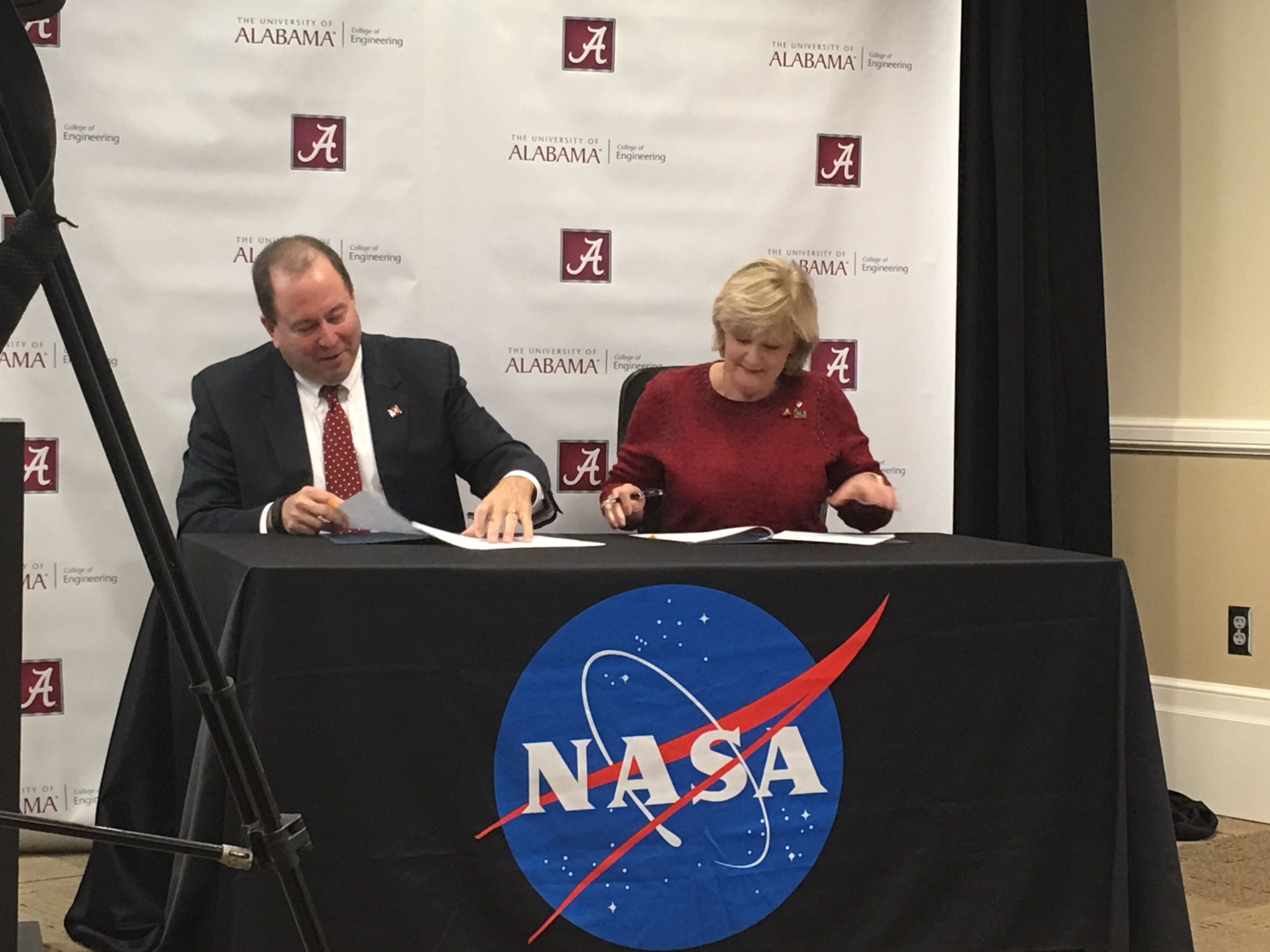

NASA and University of Alabama Sign Space Act Agreement, Partner to Advance CubeSat Propulsion Technology

Jody Singer, deputy director of Marshall, right, and Carl Pinkert, vice president for research and economic development at the University of Alabama in Tuscaloosa, sign a Space Act Agreement between the university and NASA Nov. 10. The pact formally begins work between Marshall and the university in enhancing the understanding of propulsion systems for small satellites - CubeSats. (NASA/MSFC/Mike Kynard)

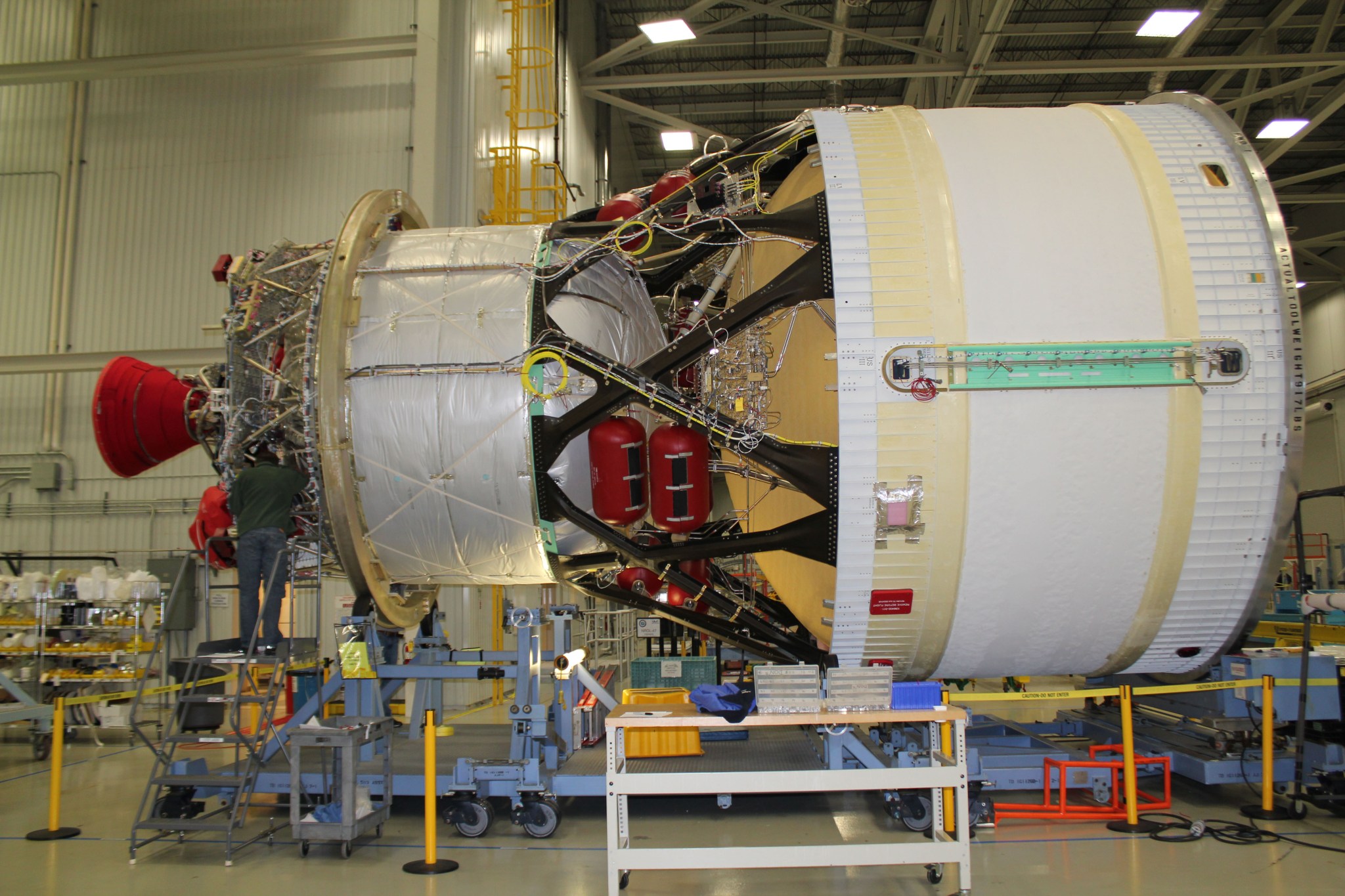

SLS Propulsion System Joins Stack in Test Stand

The interim cryogenic propulsion stage structural test article is loaded into the test stand Nov. 17 ahead of structural loads testing on the upper part of the SLS rocket. The ICPS joins the core stage simulator and launch vehicle stage adapter, which were loaded into the test stand earlier in the fall. Testing is scheduled to begin in early 2017. (NASA/MSFC/Brian C. Massey)

Marshall Celebrates NASA’s Agency Innovation Mission Day

The NASA FIRST 2016 Leadership Program hosted Agency Innovation Mission Day at Marshall Nov. 1. Throughout the day, Marshall team members connected with each other and with other centers via an internal television network to learn about NASA technologies. The first of its kind, this agency-wide initiative served as an opportunity to capture and celebrate the innovation of all NASA employees. (NASA/MSFC/Emmett Given)

December

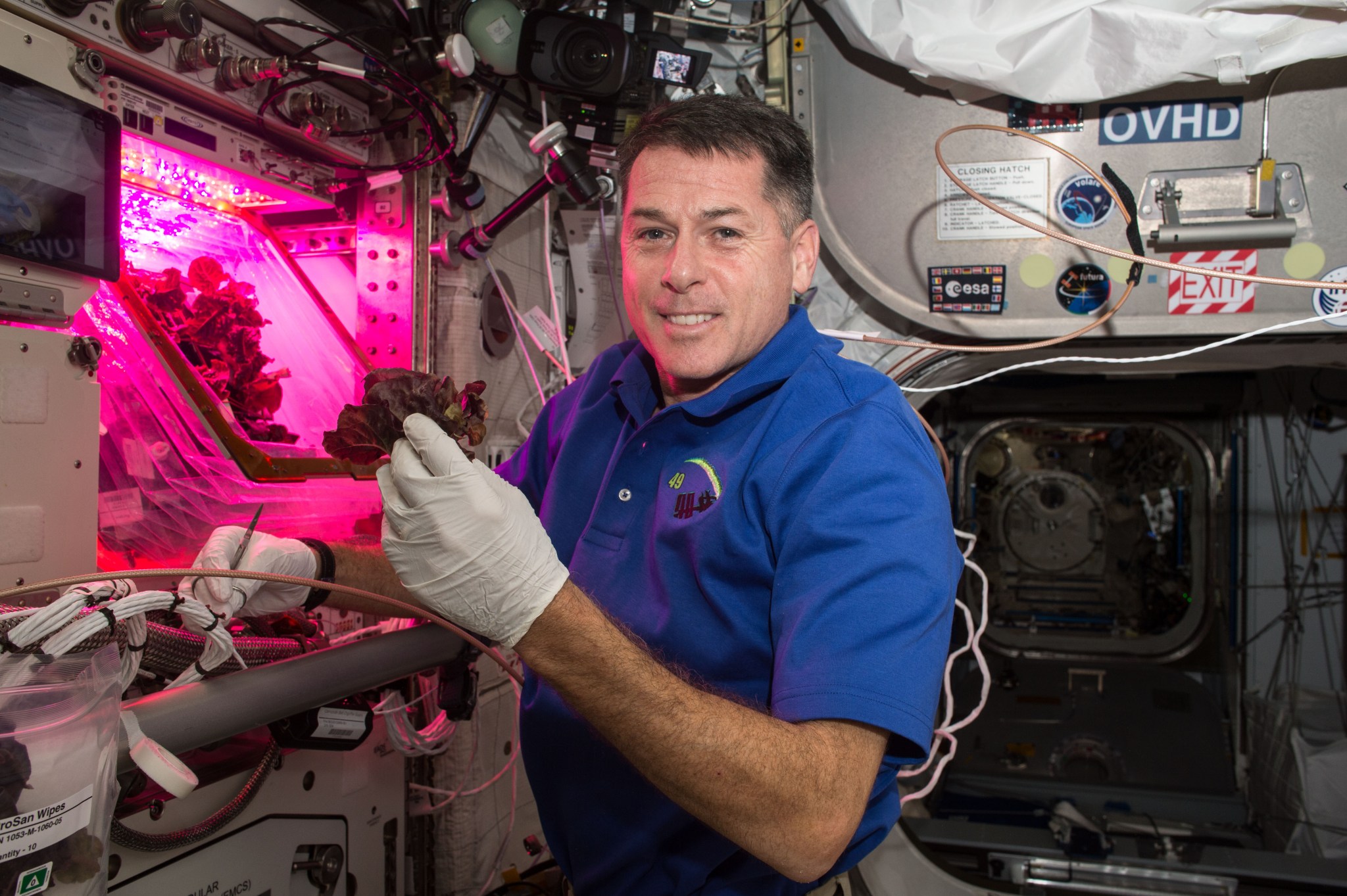

Space Station Crew Grows Another Edible Crop in Orbit

NASA astronaut Shane Kimbrough exercised his green thumb, harvesting fresh red romaine lettuce leaves on the International Space Station on Dec. 2 as part of the Veggie investigation. The lettuce was soon consumed by crew members as part of their evening meal. Future long-duration space missions will require crew members to grow their own food. Understanding how plants respond to microgravity is an important step. Crew members on the station have previously grown lettuce and flowers in the station’s Veggie facility — a low-maintenance, low-energy system that provides lighting and necessary nutrients for plants to grow in microgravity. (NASA)

Major Assembly Complete on System That Will Pack a Powerful Push for Orion

The propulsion system that will give the Orion spacecraft the in-space push needed to travel thousands of miles beyond the moon and back completed major assembly in December at United Launch Alliance in Decatur, Alabama. The Boeing-designed interim cryogenic propulsion stage is a liquid oxygen/liquid hydrogen-based system that will give Orion an extra punch of power on the first, uncrewed flight of the spacecraft with SLS in late 2018. With major assembly now complete on the flight hardware, the ICPS has several more steps to go, including avionics installation at the ULA-Decatur factory; barge and road transport to the Delta Operating Center at Cape Canaveral, Florida, for avionics and system-level testing; and delivery to NASA in mid-2017. (ULA)

Jonathan Pettus Named Marshall Center Associate Director

Jonathan Pettus was named associate director of NASA’s Marshall Space Flight Center, where he will be responsible for leading the institutional operations of one of NASA’s largest field installations. Pettus succeeded Robin Henderson who retired Dec. 31 after 33 years of service. (NASA/MSFC)

Cosmic ‘Winter’ Wonderland

Although there are no seasons in space, this cosmic vista invokes thoughts of a frosty winter landscape. It is, in fact, a region called NGC 6357 where radiation from hot, young stars is energizing the cooler gas in the cloud that surrounds them. This composite image contains X-ray data from NASA’s Chandra X-ray Observatory and the ROSAT telescope (purple), infrared data from NASA’s Spitzer Space Telescope (orange), and optical data from the SuperCosmos Sky Survey (blue) made by the United Kingdom Infrared Telescope. (NASA/CXC/PSU/L. Townsley et al/UKIRT/JPL-Caltech)

Wind Tunnel Testing Underway for Next, More Powerful Version of SLS

NASA engineers began tests in December in supersonic wind tunnels at NASA’s Langley Research Center and Ames Research Center to develop the next, more powerful version of the world’s most advanced launch vehicle capable of carrying humans to deep space destinations. Scale models of the upgraded SLS rocket in crew and cargo configurations were carefully positioned in wind tunnels for test programs to obtain data needed to refine the design of the rocket and its guidance and control systems. (NASA/Ames/Dominic Hart)

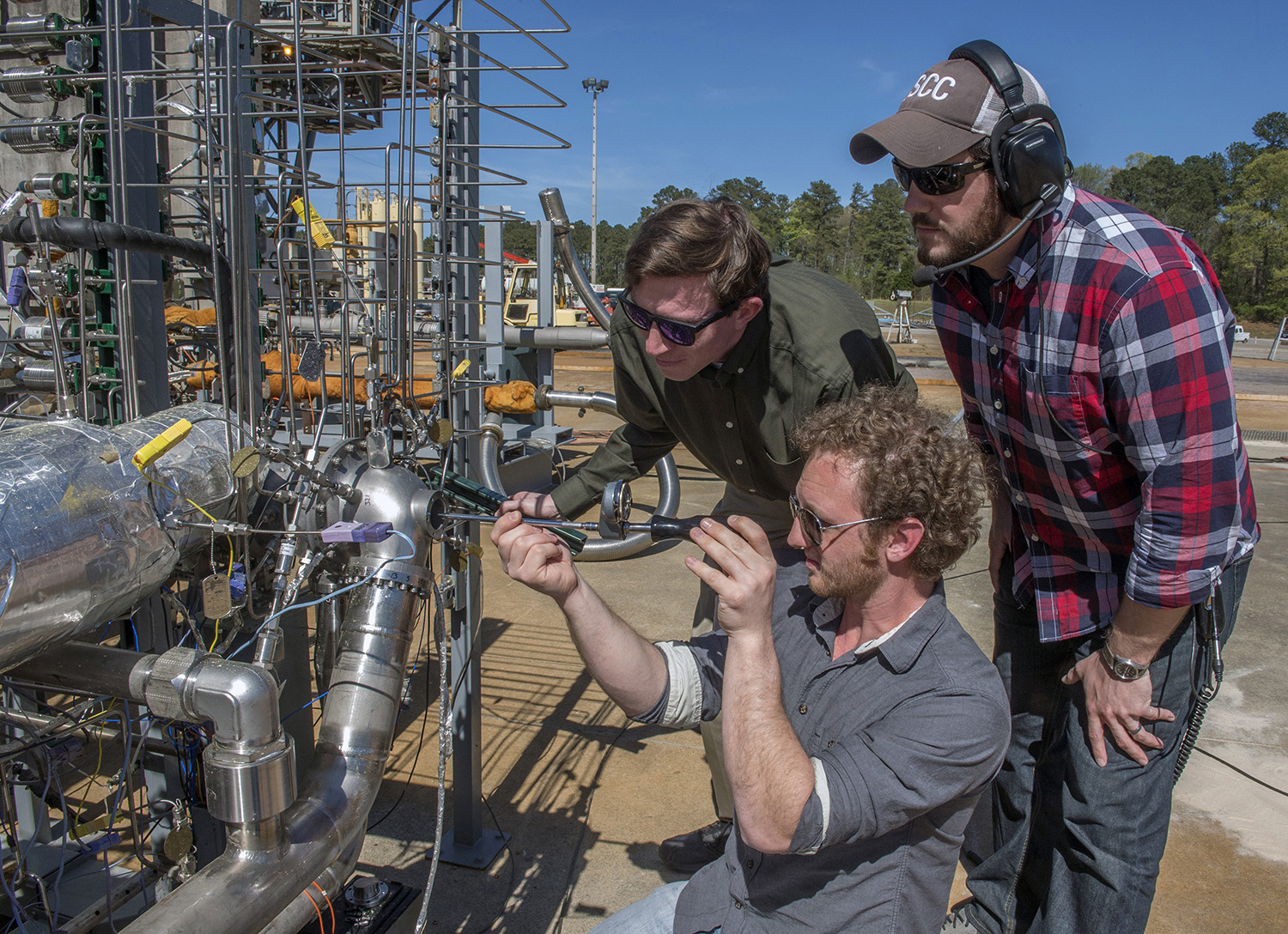

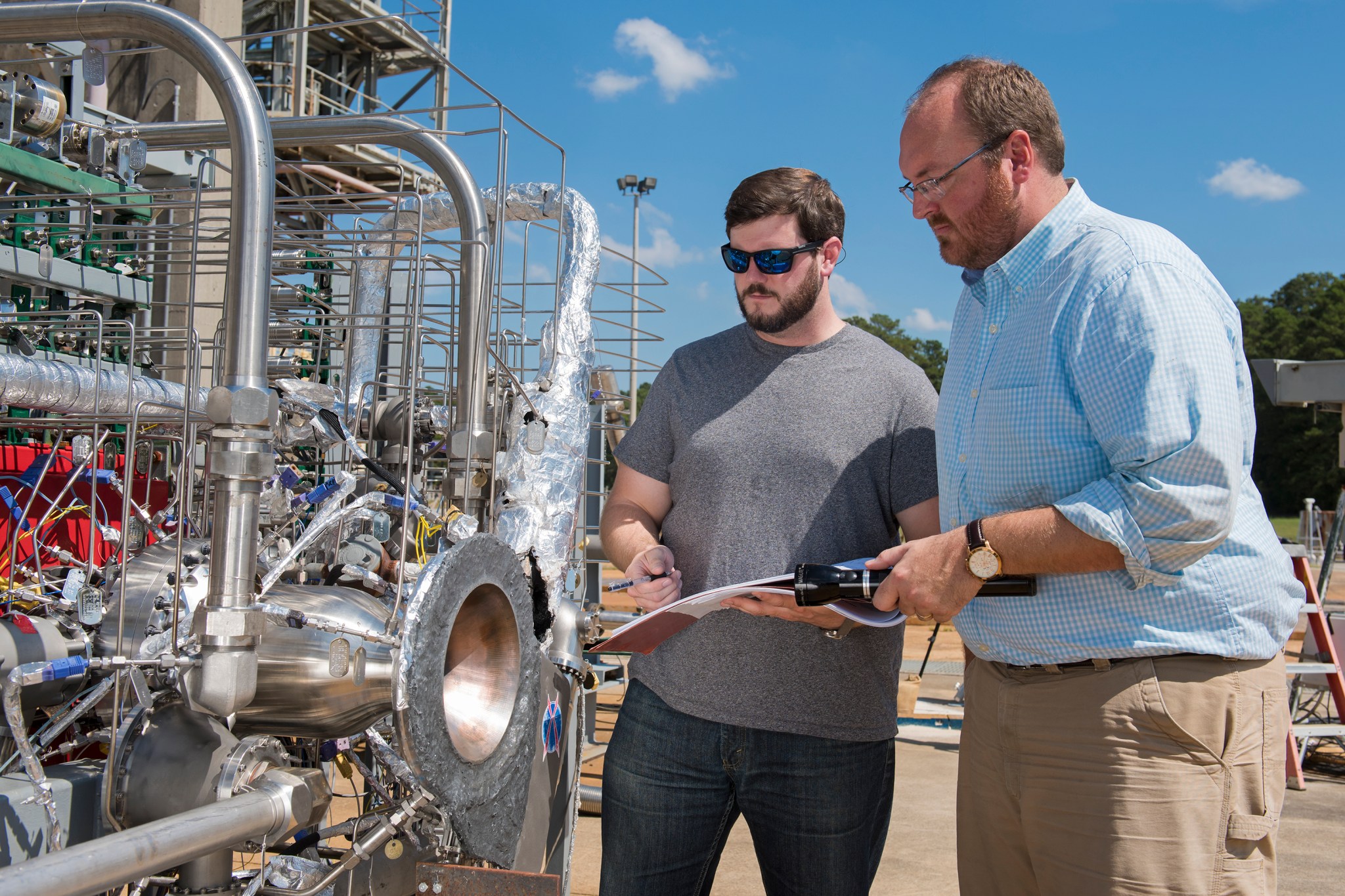

Marshall Engineers Test Combustion Chamber to Advance 3-D Printed Rocket Engine Design

Marshall engineers tested an additively manufactured demonstration breadboard engine. Graham Nelson, right, is the project manager, and Andrew Hanks is test lead for the project, in which engineers are designing components from scratch to be made entirely by 3-D printing. A series of test firings in the fall brought them closer to that goal — all the main engine components were 3-D printed, with the exception of the main combustion chamber, allowing engineers to proceed with testing nearly all the pieces of their demonstrator engine design in place, yielding valuable data about how the 3-D printed components perform as a system. (NASA/MSFC/Charles Beason)