In This Week’s Star

- Director’s Corner: Harnessing the Tide of Change

- Marshall Experts to Share Total Solar Eclipse In-person, on Television

- Marshall to Celebrate Total Eclipse with Team Event Aug. 21

- NASA on a Strong Roll in Preparing Space Launch System Flight Engines

- NASA’s Archinaut Project Conducts First Large-Scale Additive Manufacturing Build in Space-like Environment

- NASA Cargo Launches to Space Station on SpaceX Resupply Mission

- SLS Manager John Honeycutt Receives Alumni of Achievement Award

- NASA Fellow Karen Son Helps Improve Air Quality for Space Travel at Marshall

- Marshall Hosts Mentor-Protégé Agreement Signing Between CH2M Inc. and Alcyon Inc.

- NASA Awards Acquisition, Business Support Services Contract

- This Week in NASA History: The First Saturn Rocket Arrives at Kennedy – Aug. 15, 1961

- RS-25 Engine Test Highlighted on ‘This Week @NASA’

- Obituaries

Director’s Corner: The Big Moments Belong to You

With summer winding down and a busy fall ahead, it’s a great time to take a deep breath — then exhale — and think about where Marshall is as a center, and a team. It’s not just about assessing progress made and opportunities won and lost; it’s about making course corrections, when and where necessary, without slowing our momentum. If you’ve been part of NASA for long enough, you know that challenges — both expected and not — are inevitable in our line of work. It’s our job to not only respond effectively to adversity, but be ready and able to do so. The same is true when it comes to new opportunities – near- and long-term.

With this is mind, I want to highlight a key element of our Plan to Thrive: Bi-Modal Operations. The bimodal operations concept was born in the information technology industry, as a way for companies that develop software applications and other IT products to stay competitive in a highly dynamic business environment. Essentially, it’s an approach that enables an organization to simultaneously operate in two different modes. Mode I, which is traditional and sequential, and Mode II, which is exploratory and non-linear. In other words, it’s a way to keep doing what you do well now, while pursuing new opportunities that better align your organization with the future. This model has clear applications for our portfolio of work at Marshall.

Bimodal operations can enable us to maintain our critical commitment to safety and mission success, while seeking new and innovative ways of doing business when the potential benefits clearly outweigh the risks. Across the center, we must identify areas where risk is acceptable and manageable to operate in Mode II. Likewise, in each of our organizations there are areas where risk must be minimized at all practical costs, so we must operate in Mode I to ensure mission success and continuity.

Marshall’s proud legacy speaks for itself, but we need to recognize that space exploration — from national and global priorities to the industries and technologies that enable it — in the 21st century is rapidly evolving with the tide of change. Simply put: We can either harness these powerful undercurrents for our future, or let the tide force our hand.

This is perfect segue for a few words about the 2017 Federal Employee Viewpoint Survey, because this is another powerful tool that Marshall can use to shape its future for the better. Last year, you set a new Marshall record when more than 77 percent of the team responded to the survey, so I challenged you to do it again in 2017 and get our response rate to an even 80 percent. And you didn’t just step up to the plate, you knocked it out of the park with a final 2017 survey response rate of 82.2 percent! This is only going to make us stronger as a center and Team.

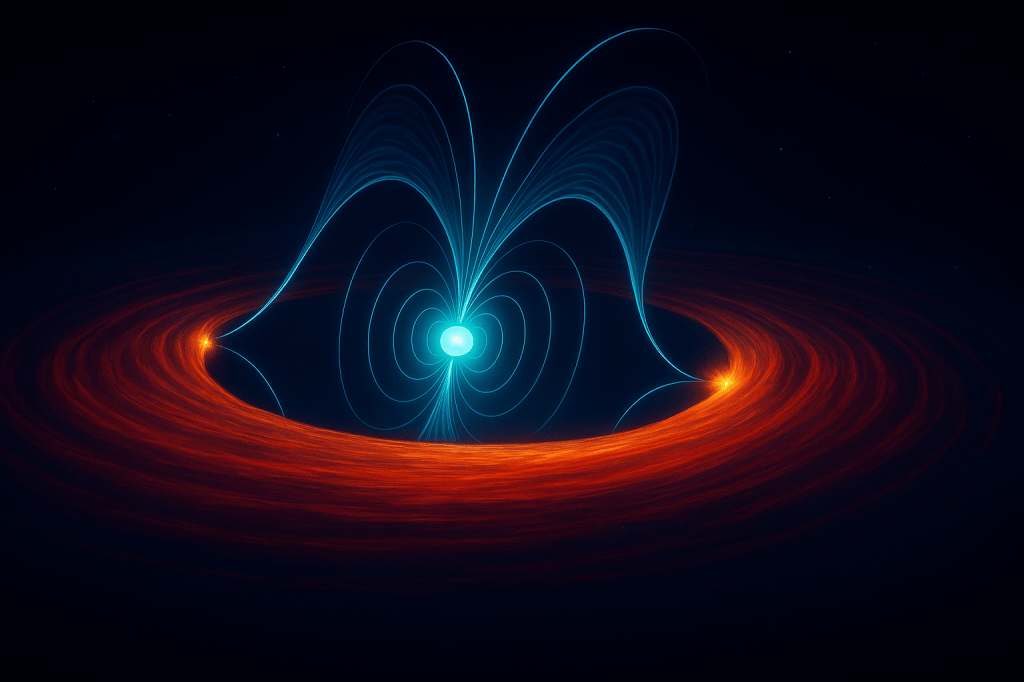

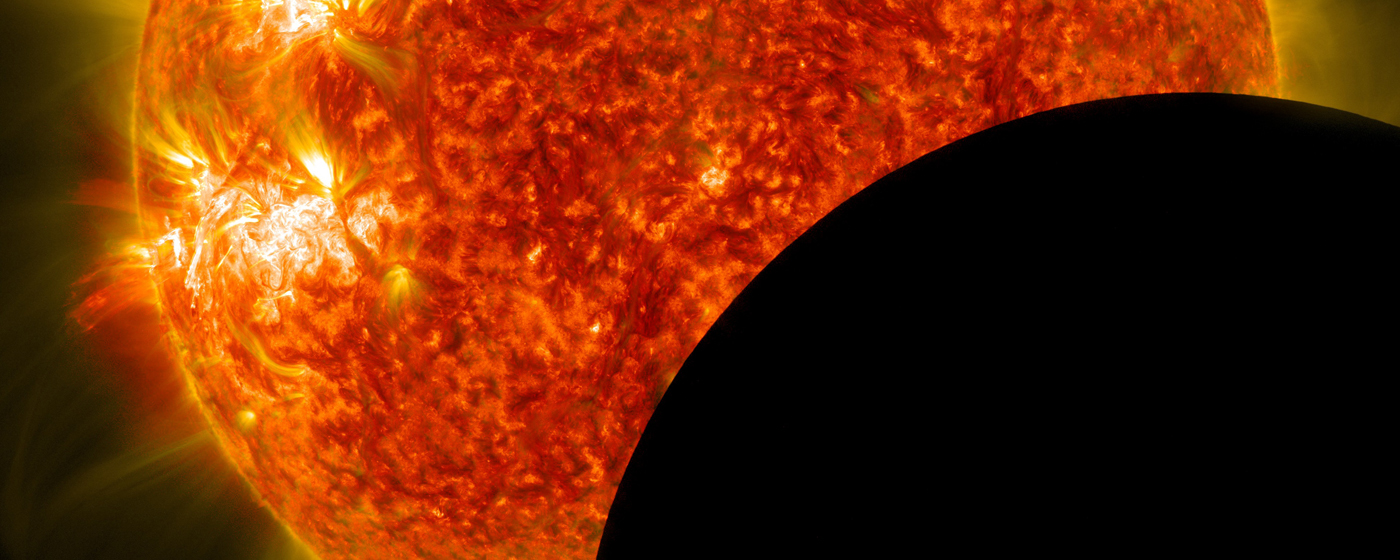

Finally, I hope you have the opportunity to share in the experience of the Total Solar Eclipse on Aug. 21. For the first time in almost 100 years, a total solar eclipse will cross the entire continental United States, with the path of totality crossing right through our neighbor to the north: Tennessee. In fact, Deputy Director Jody Singer and Associate Director Jonathan Pettus are participating in eclipse-viewing events in Nashville and Gallatin, respectively. This is one of those unique events that not only offers a rare glimpse of a spectacular natural phenomenon, but also highlights NASA and Marshall’s role in advancing the science of the sun, Earth and moon. Whether you step outside and watch the eclipse here in northern Alabama — where about 97 percent of the sun will be covered — or travel to a location somewhere in the path of totality, be safe, and enjoy the moment!

Marshall Experts to Share Total Solar Eclipse In-person, on Television

By Brian Massey

On Aug. 21, for the first time in almost 100 years, all of North America will be treated to an eclipse of the sun. Those in the path of totality, running from Oregon to South Carolina, will experience one of nature’s most awe-inspiring events — a total solar eclipse.

Scientists, researchers and experts from NASA’s Marshall Space Flight Center will mobilize to experience the eclipse and share it with others. They will join participants from across the agency for a multi-hour broadcast, titled Eclipse Across America: Through the Eyes of NASA, to offer unprecedented live video of the celestial event, along with coverage of activities in parks, libraries, stadiums, festivals and museums across the nation, and on social media.

“It’s going to be a spectacular event,” said Marshall Chief Scientist James Spann. “We’ll be sharing our research and work with people and letting them know how to safely view the eclipse, not only at the events in the path of totality, but also worldwide online and on NASA Television. Excited doesn’t begin to describe how our team feels right now. It truly will be breathtaking, and we can’t wait.”

Marshall experts will be located at two of the broadcast’s 15 locations — Hopkinsville, Kentucky, and Austin Peay State University in Clarksville, Tennessee.

Located 185 miles from Marshall, Hopkinsville has been coined Eclipseville, as the point of greatest eclipse. The celestial geometry of the sun-Earth-moon system lines up perfectly for Hopkinsville, where the axis of the moon’s shadow is closest to Earth’s center.

Marshall planetary scientist Renee Weber and other NASA experts will be on hand at for the broadcast from Orchardale Farms in Hopkinsville. The working farm offers open acreage, elevated viewing and an eclipse that will last just over 2 minutes and 40 seconds.

In Clarksville, 40 miles south of Hopkinsville, Marshall solar astronomer Mitzi Adams and other NASA experts will work with Austin Peay’s Department of Physics and Astronomy to inspire and educate students from the U.S. Space & Rocket Center in Huntsville, NASA’s INSPIRE Project, the University of Alabama in Huntsville, and others in the STEM fields of science, technology, engineering and mathematics. The students will receive hands-on science experiences with lectures, scientific balloon launches, agricultural observations and more.

The two broadcast locations will not be the only viewing opportunities Marshall experts will attend. Experts also will share the experience with eclipse viewers at the Adventure Science Center in Nashville, Tennessee; the St. Louis Science Center in Missouri; the Total Eclipse Music Festival in Adams, Tennessee; Clingmans Dome in Smokey Mountain National Park in Tennessee; Volunteer State Community College in Gallatin, Tennessee; and the University of Tennessee Space Institute in Tullahoma.

The public can get updates, links to the live broadcast, photos and other eclipse information on Marshall’s Facebook and Twitter accounts. NASA also has an eclipse gallery on Flickr and is encouraging the public to share their eclipse experience through imagery, video and artwork.

Massey, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall to Celebrate Total Eclipse with Team Event Aug. 21

By Rick Smith

For NASA’s Marshall Space Flight Center team members who can’t journey north Aug. 21 to watch the total solar eclipse from beneath the path of totality, an on-site Marshall celebration will bring workers together to experience the phenomenon.

The event will be held in Activities Building 4316 from 11 a.m. to 3 p.m. Team members will be able to try out a powerful telescope, ask eclipse-related questions of Marshall solar scientist Robert Wilson and watch continuous, live coverage of “Eclipse Across America: Through the Eyes of NASA” on NASA TV.

Robert Devlin, deputy director of Marshall’s Office of Center Operations, will make opening remarks. Former Spacelab 1 mission scientist Rick Chappell also is scheduled to speak. Chappell, who served as associate director for science at Marshall from 1987 to 1997, is now a research professor of physics at Vanderbilt University in Nashville.

A limited number of free eclipse-viewing glasses will be provided at the door, and free Italian ice treats, provided by the Marshall Exchange, will be offered starting at 12:30 p.m. Both items will be available while supplies last.

The Marshall Food Truck Corral will extend its business hours for the occasion, from 11 a.m. until 2 p.m. Follow the Food Truck Corral on Facebook for updates.

Marshall researcher Bill Cooke, who heads the NASA Meteoroid Environment Office, is optimistic that Marshall skywatchers will enjoy the eclipse, despite the fact that Huntsville is south of the path of totality.

The most important thing to remember, Cooke stressed, is eye safety. “Totality is the only safe time to remove protective glasses,” he said. “Watchers in this area won’t experience totality, so keep eye protection in place at all times while observing the sun.”

People should resist the temptation to stare at the sun for any long duration, Cooke said — even with protective glasses in place. “Put on your safety glasses and look for a couple minutes when it starts, as the moon begins to creep across the sun’s surface,” he said. “Turn away for a few minutes, and then take another look.” Complete information about viewing the eclipse safely is available here.

For Huntsville, the period when the sun will appear most fully eclipsed is from approximately 1:30-1:48 p.m. Even if busy Marshall team members can’t break away for the celebration in Building 4316, Cooke urged them to take a few minutes to share the experience.

“The view in Huntsville won’t be quite the same as that seen from the path of totality, but it’s still a rare opportunity to witness a natural phenomenon like no other,” he said. “Don’t miss out!”

The Aug. 21 total solar eclipse, the first to traverse most of the continental United States in nearly a century, will begin near Lincoln City, Oregon, at 12:15 p.m. CDT and will end near Charleston, South Carolina, at 1:48 p.m. CDT.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

NASA on a Strong Roll in Preparing Space Launch System Flight Engines

NASA is on a roll when it comes to testing engines for its new Space Launch System rocket that will send astronauts to deep-space destinations, including Mars. Just two weeks after the third test of a new RS-25 engine flight controller, the space agency recorded its fourth full-duration controller test Aug. 9 at NASA’s Stennis Space Center. Engineers conducted a 500-second test of the RS-25 engine controller on the A-1 Test Stand at Stennis. The test involved installing the controller on an RS-25 development engine and firing it in the same manner, and for the same length of time, as needed during an actual SLS launch. The test marked another milestone toward launch of the first integrated flight of the SLS rocket and Orion crew vehicle, Exploration Mission-1. EM-1 will be an uncrewed mission into lunar orbit, designed to provide a final check-out test of rocket and Orion capabilities before astronauts are returned to deep space. (NASA/Stennis)

NASA’s Archinaut Project Conducts First Large-Scale Additive Manufacturing Build in Space-like Environment

By Rick Smith

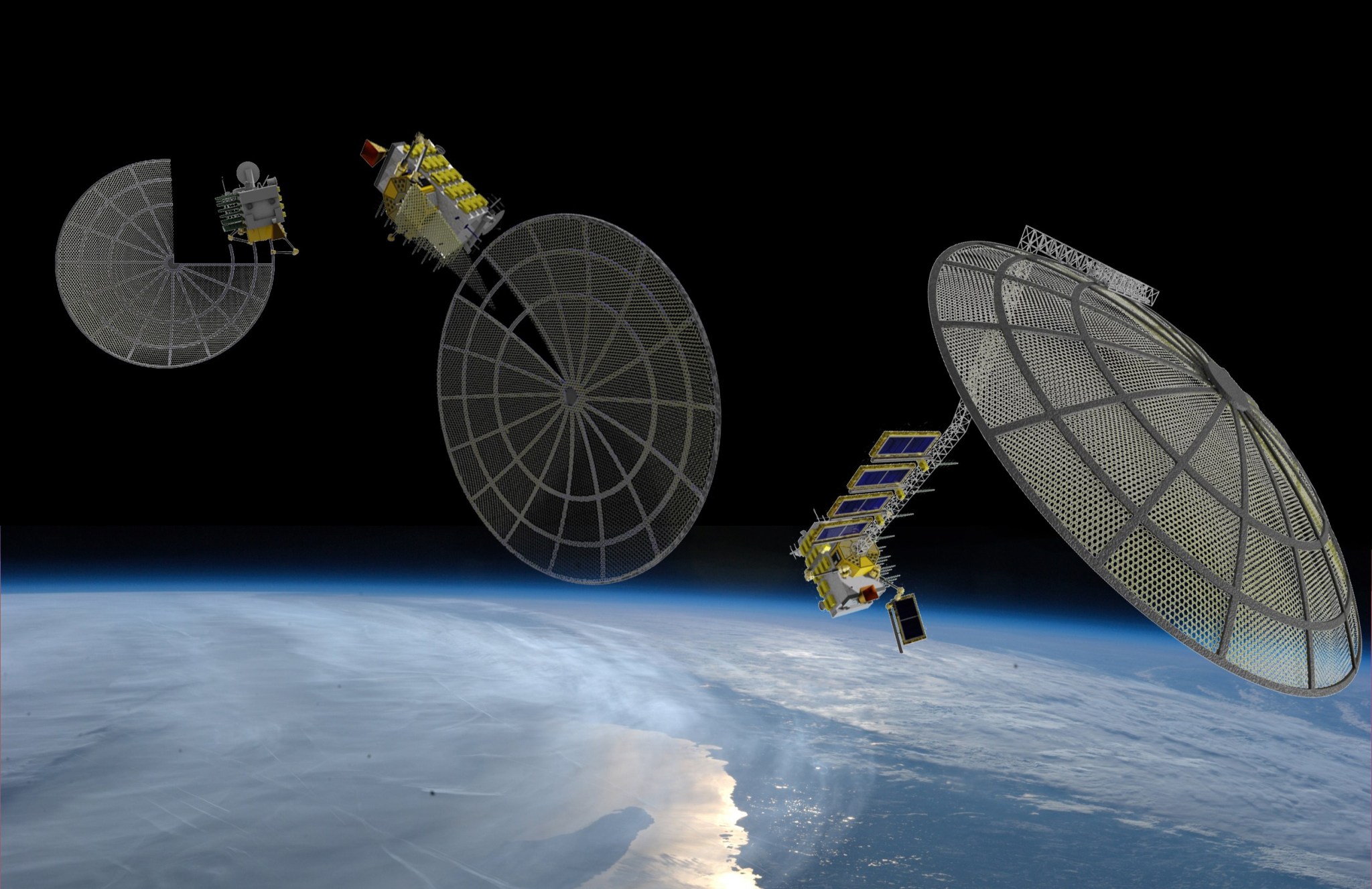

Archinaut, a NASA Technology Demonstration Mission project developing cutting-edge technology to build and assemble complex hardware and supersized structures on demand in space, achieved an unprecedented milestone this summer.

“To our knowledge, this is the first time additive manufacturing – better known as 3-D printing — has been successfully tested on such a large scale in the vacuum and temperature conditions of space,” said Eric Joyce, Archinaut project manager for Made In Space Inc. of Mountain View, California, which spearheads the project for NASA.

The Archinaut test series, using Made In Space’s innovative Extended Structure Additive Manufacturing Machine, was conducted in a vacuum chamber in the Engineering Evaluation Laboratory at NASA’s Ames Research Center.

The team conducted hundreds of hours of testing to complete the series. Working around the clock for much of June, they printed large beam segments — similar to those used to construct a variety of current space structures — and subjected 3-D printing equipment and printed hardware to the pressures, temperatures and other rigors of deep space.

“This was a big step for us,” Joyce said. “It advances the technology — and gives us real confidence that the hardware will do the job in space that it does here on the ground, enabling us to print sturdy, reliable structures of unlimited size.“

Archinaut is one of three tipping point projects NASA is funding under the umbrella of TDM’s In-space Robotic Manufacturing and Assembly project, sponsored by NASA’s Space Technology Mission Directorate. Tipping point projects help NASA determine whether technologies have been sufficiently matured to pursue flight demonstrations or for infusion into future exploration missions. NASA’s Marshall Space Flight Center leads the TDM program for the agency.

“We couldn’t be more pleased about Archinaut’s successful demonstration,” said Trudy Kortes, TDM program executive at NASA Headquarters. “In-space robotic manufacturing and assembly technologies are destined to be key building blocks for a thriving space infrastructure, and will enable robust future exploration missions across the solar system. Milestones such as this one are crucial steps toward that future.”

Additive manufacturing could offer solutions for quickly and cheaply mounting new space infrastructure missions. Combined with robotic manufacturing and assembly, the technology could help NASA and its commercial partners remotely construct new habitats and hardware in space — without the costs or risks associated with flying heavy materials or structures via rocket from Earth to space.

Just as crucially, building to order in space frees future missions from the limitations of conventional spaceflight. “Until now, everything we have sent to space has been constrained by the volume available on various launch vehicles,” Joyce said. “That fundamentally limits the size and geometry of anything we send up.”

Additive manufacturing would nullify that obstacle, according to Joyce. “Instead of launching a rocket with a complete vehicle crammed on board, what if we just launch feedstock — raw material — and do all manufacturing and assembly in space?” he added. “All the constraints go away, and rockets become more efficient at delivering cargo to space.”

Another test series in early 2018 will further hone the capabilities of the 3-D printer and refine Archinaut’s robotic manipulator. Ultimately, Archinaut could evolve into a build-to-order space platform. Vehicles or satellites could dock to enable construction, assembly and integration of whatever space-optimized hardware or systems they require, Joyce suggested — permanently rewriting the way humans travel to space.

The Archinaut team includes lead subcontractor Northrop Grumman Corp. of Falls Church, Virginia; Oceaneering Space Systems of Houston; and Ames Research Center.

Read NASA’s complete Archinaut web feature here.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

NASA Cargo Launches to Space Station on SpaceX Resupply Mission

Experiments seeking a better understanding of Parkinson’s disease and the origin of cosmic rays launched to the International Space Station on a SpaceX Dragon spacecraft Aug. 14.

Carrying more than 6,400 pounds of research equipment, cargo and supplies, the spacecraft lifted off on a Falcon 9 rocket from NASA’s Kennedy Space Center at 11:31 a.m. on the company’s 12th commercial resupply mission. It arrived at the space station the morning of Aug. 16, when astronauts Jack Fischer of NASA and Paolo Nespoli of the European Space Agency captured the capsule using the space station’s robotic arm.

Flight controllers at the Payload Operations Integration Center — mission control for space station science, located at NASA’s Marshall Space Flight Center — will work with astronauts to conduct the numerous science investigations carried to the station.

Research materials flying inside the Dragon’s pressurized area include an experiment to grow large crystals of leucine-rich repeat kinase 2, or LRRK2, a protein believed to be the greatest genetic contributor to Parkinson’s. Gravity keeps Earth-grown versions of this protein too small and too compact to study. This experiment, developed by the Michael J. Fox Foundation, Anatrace and Com-Pac International, will exploit the benefits of microgravity to grow larger, more perfectly shaped LRRK2 crystals for analysis on Earth. Results from this study could help scientists better understand Parkinson’s and aid in the development of therapies.

The Kestrel Eye investigation, known as NanoRacks-KE IIM, is a microsatellite carrying an optical imaging payload, including a commercially available telescope. This investigation, sponsored by the U.S. National Laboratory, tests the concept of using microsatellites in low-Earth orbit to support critical operations, such as lowering the cost of Earth imagery in time-sensitive situations — like tracking severe weather and detecting natural disasters.

Another experiment will measure the charges of cosmic rays using the Cosmic Ray Energetics and Mass instrument, which will be attached to the Japanese Experiment Module Exposed Facility on the space station. The data collected from its three-year mission will address fundamental questions about the origins and histories of cosmic rays, building a stronger understanding of the basic structure of the universe.

Dragon is scheduled to depart the space station in mid-September, returning more than 3,300 pounds of science, hardware and crew supplies to Earth.

For more than 16 years, humans have lived and worked continuously aboard the International Space Station, advancing scientific knowledge and demonstrating new technologies, making research breakthroughs not possible on Earth to enable long-duration human and robotic exploration into deep space. A global endeavor, more than 200 people from 18 countries have visited the unique microgravity laboratory that has hosted more than 1,900 research investigations from researchers in more than 95 countries.

Get breaking news, images and features from the station on Instagram and Twitter.

SLS Manager John Honeycutt Receives Alumni of Achievement Award

By Martin Burkey

An engineering family, an inclination to tinker with cars and simply growing up in the “Rocket City” led John Honeycutt from the University of Alabama in Huntsville campus to the top job leading the development of NASA’s new rocket to deep space.

Honeycutt received a Bachelor of Science in mechanical engineering in 1990 and was one of four “Alumni of Achievement” recently honored by the UAH Alumni Association.

Since October 2015, Honeycutt has been the program manager of NASA’s Space Launch System Program at NASA’s Marshall Space Flight Center. He leads a nationwide workforce of more than 4,200 civil servants and contractors with an annual budget of $2.15 billion to design, build, test and fly NASA’s newest launch vehicle.

Honeycutt is in charge of all facets of the program — planning, procurement, development, testing, evaluation, production and operation of SLS. “I couldn’t do that without an incredibly talented team,” he said. “It’s a challenging job, but it’s also an exciting time to be part of what I believe will be NASA’s greatest adventure yet.”

Until his senior year at UAH, Honeycutt attended college part time and worked several jobs, including managing a small grocery store, working on cars, managing a gas station and working in a hardware store. It was that part of his youth he credits for his people skills and at least some of his mechanical insight. It wasn’t long, though, until he became part of the space program.

After completing his senior year as a full-time UAH student, he joined Rockwell International of Huntsville as a lead test engineer on the Space Shuttle Propulsion Program, and also worked on other Rockwell propulsion development projects. Honeycutt later worked for Boeing North America on qualification, proto-flight and acceptance testing hardware for the International Space Station.

After joining NASA in 1999, he continued in leading roles in propulsion design, systems integration, test planning and more. Before being appointed to the top rocket job, he was deputy manager of the SLS stages office, SLS deputy chief engineer, and SLS deputy program manager.

In his management role today, Honeycutt is seldom required to do any of the hands-on engineering he trained for. But the knowledge and discipline instilled in Honeycutt at UAH remains the foundation for his ability to probe into issues. He credits UAH and its professors for the discipline and inquiring nature required for his career.

“There’s nothing like managing the design, manufacturing and operation of space hardware to introduce even the smartest person to the concept of ‘life-long learning.’ So, I’ve had the chance to continue the education that began at UAH,” said Honeycutt.

He’s received numerous awards for his work, including a NASA Exceptional Achievement Medal in 2011. In 2004, he received a Space Flight Awareness Award and a Center Director’s Commendation in 2000. In 1999, the NASA astronaut corps presented him with their Silver Snoopy Award for his contributions to the success of human spaceflight missions. In July 2017, he received NASA’s Exceptional Service Medal for his leadership critical to the success of both the Space Shuttle and Space Launch System programs. But that’s all history.

“My number one goal now is to fly our first mission successfully and then fly the second mission as soon as possible,” he said. “My long-range goal is for everybody working on this program to look back and say it’s the best thing they’ve ever done.”

Burkey, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

NASA Fellow Karen Son Helps Improve Air Quality for Space Travel at Marshall

By Amanda M. Adams

Preserving air quality inside NASA’s space systems is vital to space habitation. Karen Son, a NASA Space Technology Research Fellow from Purdue University in West Lafayette, Indiana, is working with NASA’s Marshall Space Flight Center to help the agency improve the carbon dioxide removal system used aboard the International Space Station and in future deep-space explorations.

The current carbon dioxide removal system on the space station, the Carbon Dioxide Removal Assembly, contains beds filled with thousands of tiny beads called adsorbents. These beads act as a filter to remove, or scrub, carbon dioxide from the air as part of a larger process called atmospheric revitalization, providing clean air for astronauts.

“Atmospheric revitalization is important anytime we have an enclosed structure without ventilation. We must remove the carbon dioxide so we can continue to use the oxygen,” said Son. “Space habitats, submarines and even some airplanes have atmospheric revitalization systems to purify the air we breathe.”

One way NASA is looking to improve this system is by researching different sorbents to find the most efficient type, and to increase the reliability of the system, reducing the amount of sorbent needed. “When we go to Mars, we need more efficient systems that require less maintenance,” said Son. Son’s work is focused on testing different types of sorbents in a virtual laboratory to determine which is most effective at removing carbon dioxide from the atmosphere.

“Right now, we are in low-Earth orbit and if we have a system failure, we have launch vehicles that can send backup parts for maintenance, or in a worst-case scenario, astronauts can return to Earth,” said Jim Knox, an aerospace engineer for the Environmental Control Life Support Systems department at Marshall. “Once we are headed to Mars, we don’t have the option of resupply or return until we make the loop around Mars, which can take up to two years. It’s like backpacking — whatever we take up is what we have for the trip.”

Knox spent the last two years working with Son during her fellowship. “Karen is highly motivated and curious about how things work,” said Knox. “She is very detailed in her documentation and the virtual test models she creates help us understand how much we can trust our test data.”

Son presented her research to the Marshall community in a crowded conference room of Building 4220 on Aug. 14. She will soon return to Purdue University to continue her work and complete her dissertation for graduation from the doctoral program in 2018. During Son’s time at Marshall, John Sharp, branch chief for the Spacecraft and Vehicle department, served as her research collaborator for the fellowship program. Knox, along with Greg Schunk, technical assistant for the Spacecraft and Vehicle department, acted as her day-to-day technical mentors.

NASA fellows perform innovative, space-technology research at their respective universities, NASA centers or at nonprofit U.S. research and development laboratories. Awards are made as training grants to the fellow’s university on behalf of the individual pursuing a master’s or doctoral degree, with the faculty advisor serving as principal investigator. For more information on the NASA Space Technology Research Fellowship program, contact hq-nstrf-call@mail.nasa.gov.

Adams, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Hosts Mentor-Protégé Agreement Signing Between CH2M Inc. and Alcyon Inc.

Executives of technology firms CH2M Inc. of Denver, and Alcyon Inc. of Huntsville signed a NASA Mentor-Protégé agreement Aug. 15 at NASA’s Marshall Space Flight Center. The agreement, the 16th Mentor-Protégé agreement between a Marshall prime contractor and a protégé, is the first with a certified small disadvantaged business.

Executives in attendance were J.P. Martin, vice president and NASA account manager of CH2M; Debbie Matthews, Marshall contracting officer; Autumn Sellars, security and professional services and vice president of operations of Alcyon; Roy Malone, Marshall Center Operations director; Robert Devlin, deputy director of Marshall Center Operations; Joyce Meier, Marshall’s logistics services contracting officer; Farley Davis, manager of Marshall’s Logistics department; David Brock, Marshall small business specialist; Edwin Jones, CH2M deputy program manager; Angela Lugo, CH2M business operations manager of Marshall logistics support services; and Michael Vanhooser, NASA business development director for Alcyon.

CH2M specializes in program/project management, operations management, consulting and construction management. Alcyon specializes in logistics, engineering services, laboratory services and information technology. Under the agreement, CH2M will provide Alcyon developmental assistance with their fleet and property management system, and market assessment and strategies related to the commercial and government sectors.

The NASA Mentor-Protégé Program, established in 2008 by NASA’s Office of Small Business Programs, allows NASA prime contractors opportunities to enter into mentor-protégé agreements with small businesses and historically black colleges and universities/minority-serving institutions under their subcontracting programs to establish long-term relationships, enhance technical capabilities and enable protégé companies to successfully compete for larger, more complex prime contract and subcontract awards. Marshall oversaw NASA’s first Mentor-Protégé signing agreement in February 2008.

To learn more about NASA’s Office of Small Business, click here.

Follow NASA’s Office of Small Business on Social Media at: https://www.facebook.com/NASASmallBusiness and https://twitter.com/NASA_OSBP.

NASA Awards Acquisition, Business Support Services Contract

NASA has awarded a contract to Paragon TEC Inc. of Cleveland, Ohio, to provide acquisition and business support services at the agency’s Marshall Space Flight Center and its Michoud Assembly Facility.

The performance-based, firm-fixed-price, indefinite-delivery/indefinite-quantity contract has a maximum potential value of $75.8 million. The contract begins Sept. 1 with a one-year base period, followed by four, one-year options.

Support services provided under this contract include: contract management and control; plans and reports; accounting and resource management operations; budget integration and analysis; business best practices; procurement administrative services; acquisition policy services; procurement operations support; procurement source selection office support and paralegal support.

This Week in NASA History: The First Saturn Rocket Arrives at Kennedy – Aug. 15, 1961

This week in 1961, the first Saturn I rocket, SA-1, arrived at NASA’s Kennedy Space Center. The SA-1 mission was used to demonstrate the validity of the clustered engine concept as well as test the aerodynamic and structural design of the Saturn I booster. Here, the S-1 stage for the SA-1 mission is being installed on the launch pad for its Oct. 27, 1961, launch. Today, Marshall is developing NASA’s Space Launch System, the most powerful rocket ever built that will be capable of sending astronauts deeper into space than ever before, including to Mars. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)

RS-25 Engine Test Highlighted on ‘This Week @NASA’

The latest test of the RS-25 engine for NASA’s Space Launch System is featured in the most recent edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

On Aug. 9, engineers at NASA’s Stennis Space Center conducted another hot-fire test of an RS-25 engine flight controller. The objective of the test was to “green run” or flight certify the engine controller — which is the brain of the engine. Once proven flight-worthy, the controller will be installed on an RS-25 engine that will help power the first integrated flight of the SLS rocket with NASA’s Orion spacecraft, known as Exploration Mission-1. SLS is designed to power astronauts deeper into the solar system than ever before.

NASA’s Marshall Space Flight Center manages the SLS Program.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.

Obituaries

Robert O. Bowen, 92, of Huntsville, died Aug. 8. He retired from the Marshall Center in 1994 as an engineer.