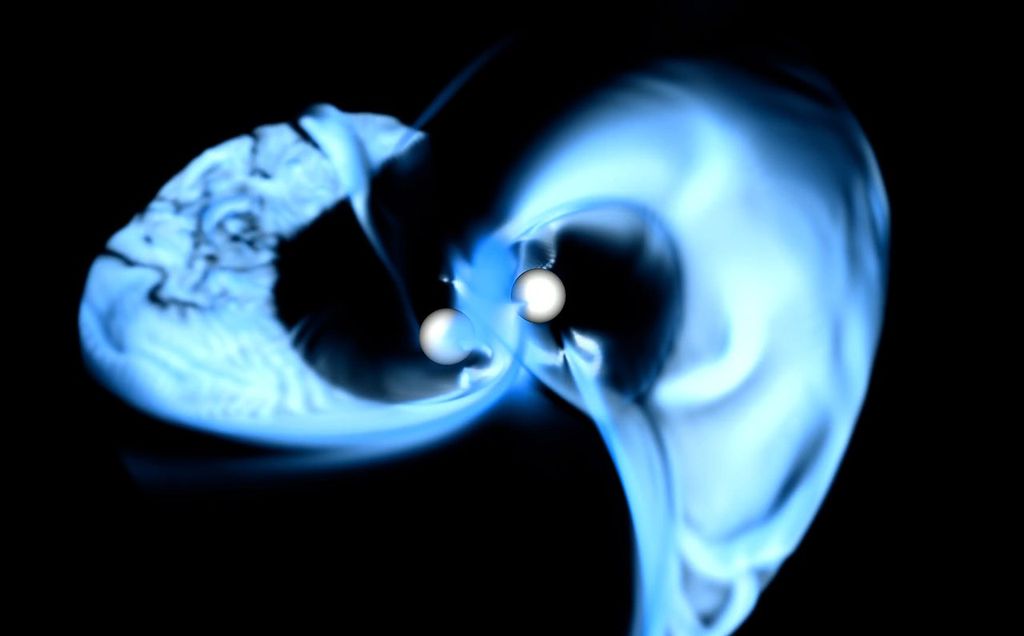

Panel Test Facility

The Panel Test Facility (PTF) operates with a 20-MW constricted arc heater that is coupled with a semielliptical nozzle. The heater operates at pressures from 1 to 9 atm and enthalpy levels from 7 to 35 MJ/kg (3000 to 15000 Btu/lb). The test stream generated is suitable for the simulation of boundary layer heating environments on a flat panel sample of approximately 355 mm by 355 mm (14” by 14”). However, it is possible to test sample sizes of 406 by 406 mm (16” by 16”).

The testing features include:

- 20-MW Ames-designed constrictor arc heater

- Semi-elliptic Mach 3.5 nozzle

- Test samples up to 355 by 355 mm (14-in by 14-in)

- -4 to +8 degree inclinations of the surface of test sample to the flow

- Run durations up to 30 minutes possible

- Cold wall, full catalytic heat flux from 6 to 350 kW/m2 (0.5 to 30 Btu/ft2-s)

- Surface pressures from 66 to 4700 Pa (0.0006 to 0.05 atm)

TRUNCATED PANEL TEST FACILITY (TPTF)

The modified facility, TPTF, uses the throat and first portion of the exit nozzle from the PTF. The result is a lower Mach number, higher surface pressure, higher heat flux and higher shear onto a smaller test sample, compared to the original configuration.

The testing features include:

- 20-MW Ames-designed constrictor arc heater

- Semi-elliptic nozzle

- Test samples up to 100 by 100 mm (4-in by 4-in)

- -5 to +4 degree inclinations of the surface of test sample to the flow

- Cold wall, full catalytic heat flux from 200 to 2000 kW/m2 (20 to 180 Btu/ft2-s)

- Surface pressures to 0.28 atm