Atmosphere Revitalization

Developing new regenerable systems for maintaining air quality in space

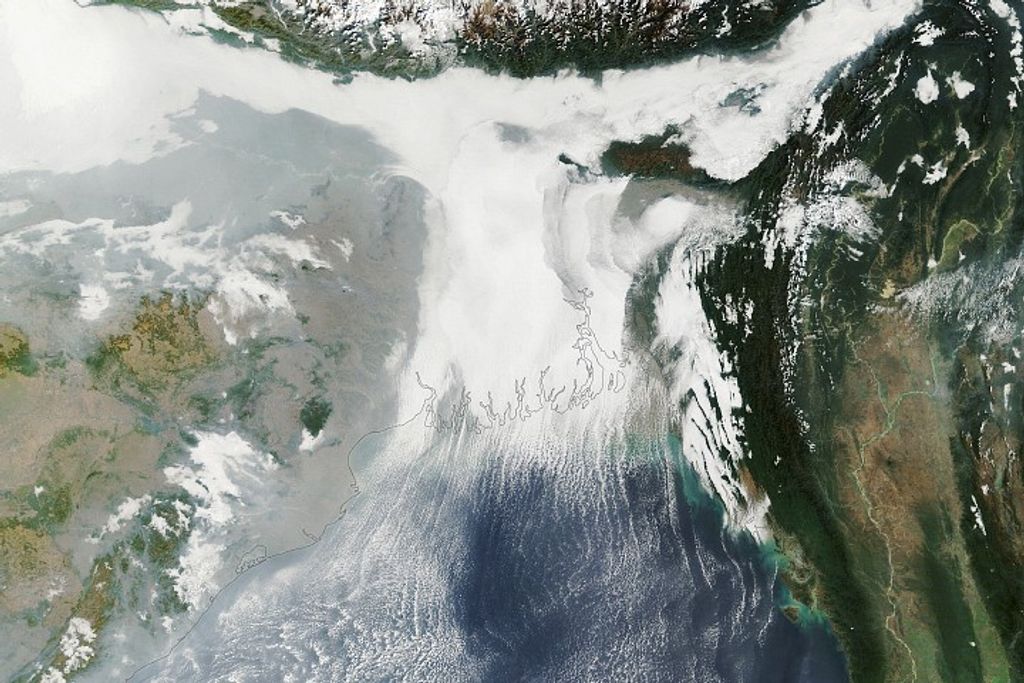

On Earth, humans live in an ecosystem where we co-exist with nature. For example, we need oxygen (O2) to breathe, and we exhale carbon dioxide (CO2). Plants and the environment keep these chemicals in balance. When humans go to space, we can’t bring enough plants with us yet to keep this balance. Spacecraft use their own artificial ecosystems to maintain the air as part of a life support system.

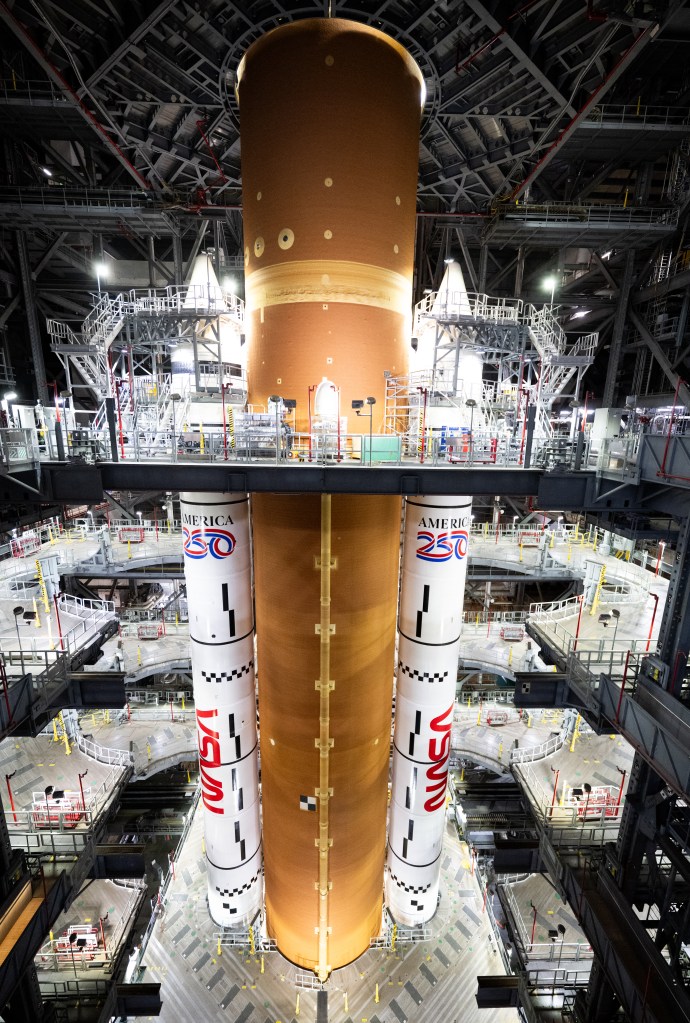

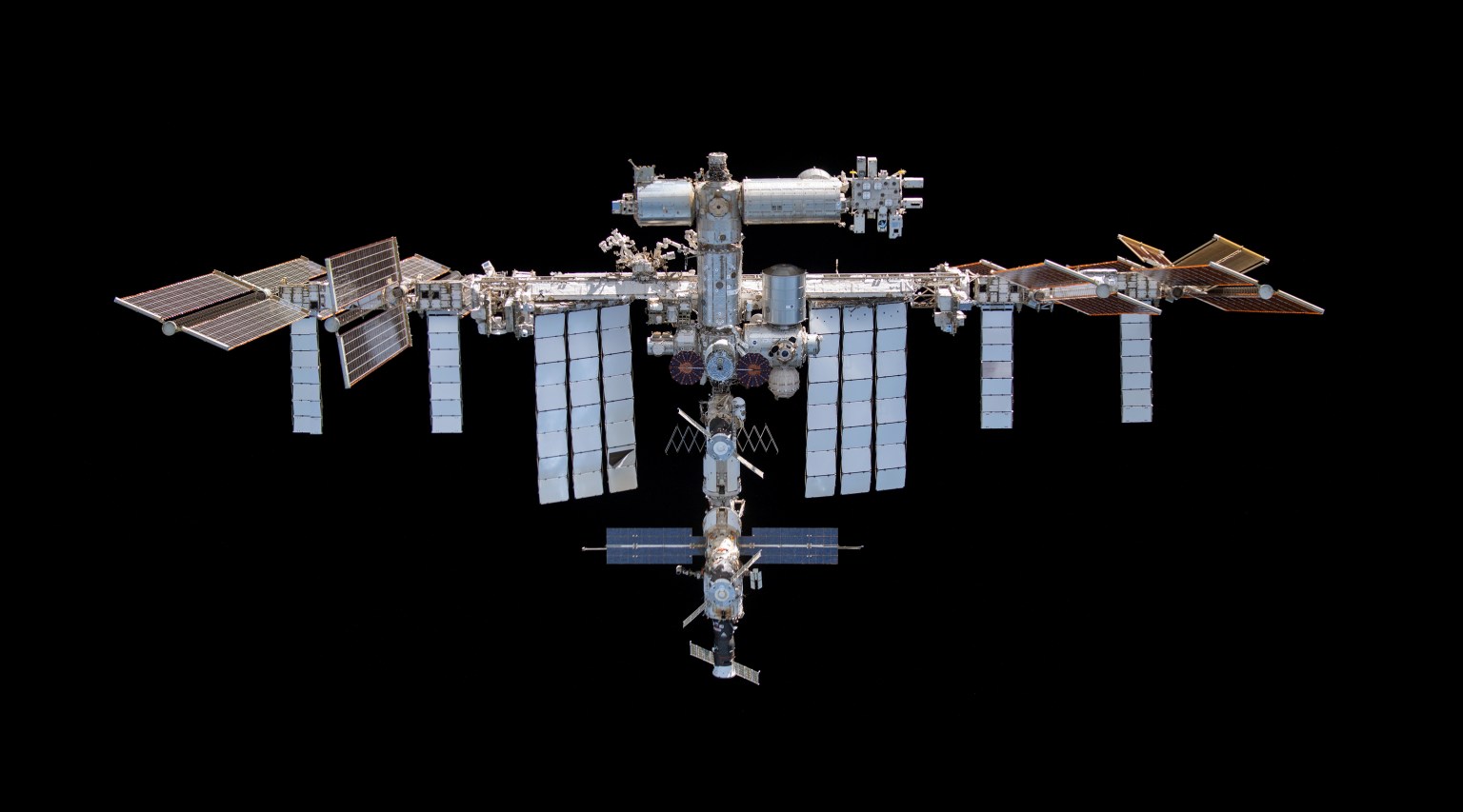

Currently, physio-chemical methods are used to remove CO2 and other contaminants from the air on the International Space Station (ISS). However, the life support system loop is not closed, meaning ISS needs regular resupply from Earth to get more O2. The CO2 removal system itself also requires regular maintenance, meaning it needs to be turned off temporarily so parts can be replaced. When humans want to travel beyond low earth orbit, like to the Moon or Mars, we can’t on resupply missions from Earth. Life support systems will need to both close the life support loop and require no maintenance to keep spare parts to a minimum.

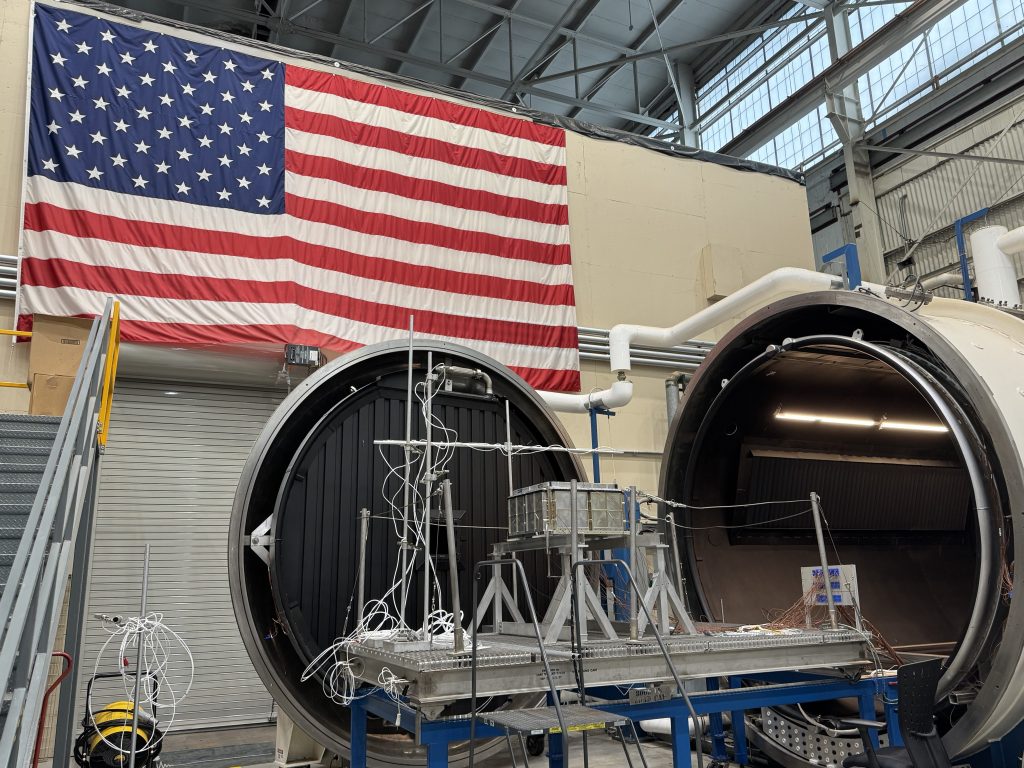

Here at Ames Research Center, the Air Revitalization team is developing new physio-chemical technologies to remove CO2 and other contaminants such as volatile organic compounds, manage water vapor, and prepare the CO2 for recovering the O2. The technologies are for Moon or Mars spacecraft, space station, and surface habitat environments. The technologies must be able to perform in microgravity, partial gravity, or Earth gravity, and at Earth atmospheric pressure or reduced pressure.

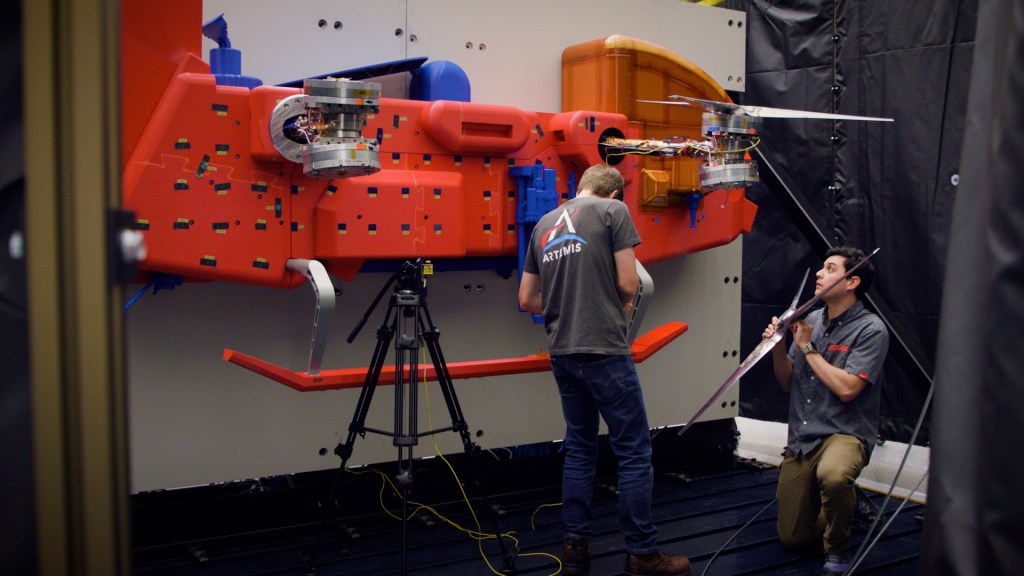

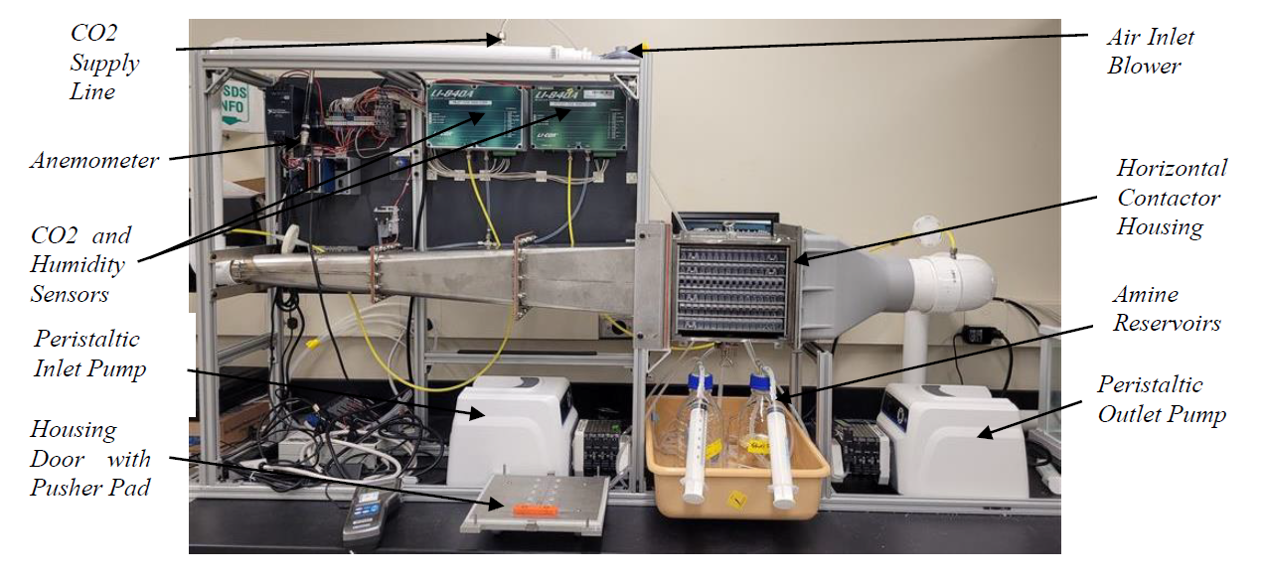

Technologies we develop use a wide array of physio-chemical methods, from solid sorbents like the ones in use on ISS today, liquid sorbents like the ones in use on Earth today for flue gas scrubbing, other newly-developed sorbents, and sorbent-less thermal methods, like cold surface capture. The Multifunctional Sorbent Devices (MultiSORB) project aims to produce additively manufactured solid sorbent systems

The Air Revitalization Team develops technologies from the idea phase, such as characterizing newly created sorbents to see if they would work in a spacecraft environment, to building benchtop experiments, prototyping subscale hardware, and then demonstrating full-scale, fully-functional systems to prove their reliability. We have also used flight experiments to test how new methods work in microgravity, such as the CapiSorb Visible System.

To enable the team to work on a range of development phases, we have a wide array of expertise and capabilities. Various equipment to support our work include methods to simulate spacecraft environments, controls and sensors, and prototyping equipment such as 3D printers. We also have extensive analytical capabilities to make and test sorbents, such as gravimetric and volumetric methods to generate isotherms, FTIR, Raman, NMR, viscometry, etc.