Space Suits

NASA’s Johnson Space Center (JSC) offers world-leading expertise in the full lifecycle of space suit systems, covering both Extravehicular Activity (EVA) spacewalk suits and crew survival suits for launch and entry. Our teams manage everything from the initial design of pressure garments, helmets, and portable life support systems to the complex testing, verification, and real-time mission support for these miniature, human-rated spacecraft. To ensure these systems are ready for flight, we utilize our unique facilities—like human-rated thermal-vacuum chambers and the Active Response Gravity Offload System (ARGOS)—to conduct high-fidelity testing in simulated space and reduced-gravity environments. We invite partners to collaborate with us and utilize these specialized capabilities to develop the next generation of space suit and crew survival technologies.

Space Suit Systems

JSC personnel have a vast knowledge of the technical challenges associated with space suit technology, including mobility, sizing, life support, ventilation, hydration, and waste management. JSC experience covers the full life cycle, starting from basic design through development, testing, and operational support.

Space suits are unique in that they are miniature, customized spacecraft. They must provide environmental protection, mobility, and life support to the crewmember during spacewalks.

- Space suit design and development

- Pressure garment and glove design

- Mobility and sizing

- Helmet and visor design

- Life support umbilical design

- Suit maintenance and operations

- Portable life support technologies

- Thermal control

- Ventilation

- Oxygen systems

- Contaminant control

- Hydration

- Waste control

- Space suit testing, verification, and training

- Suit checkout

- Altitude testing

- Thermal vacuum testing

- Flight crew training

- System-level engineering insight into the Extravehicular Mobility Unit (EMU) hardware operational performance and detailed leadership into anomaly resolution

- Real-time mission support for on-orbit activities

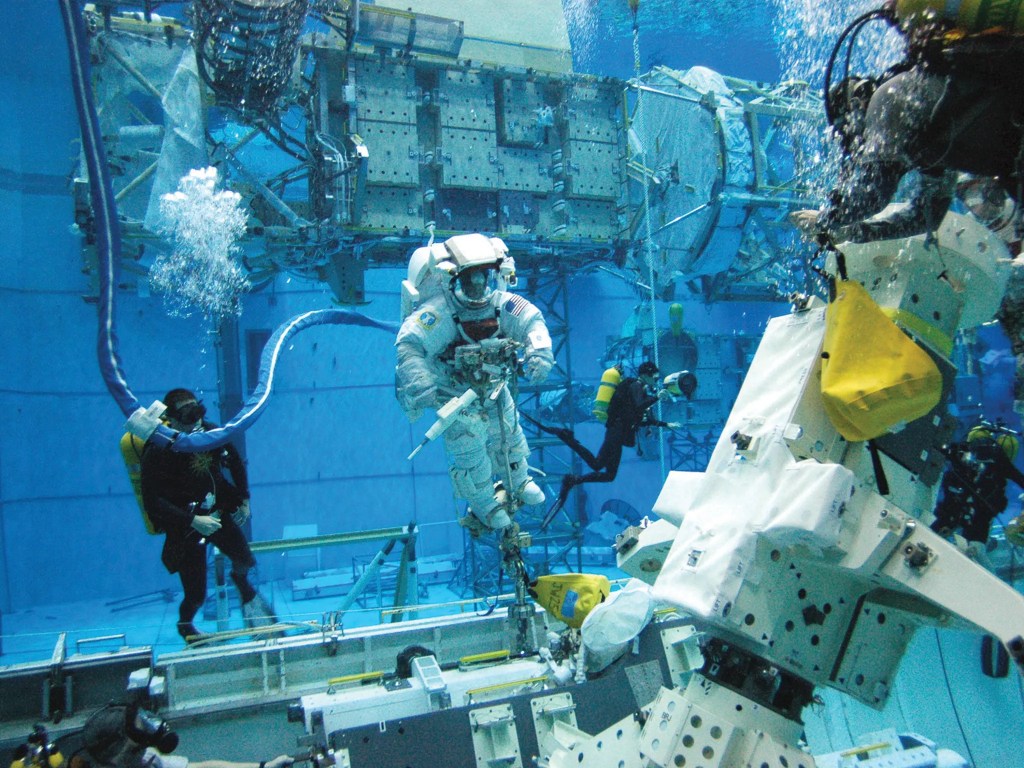

- Ground training simulations for training and crew extraction from the Neutral Buoyancy Laboratory and vacuum chamber facilities

- Engineering risk-based guidance for management, sustaining and changes of the EMU hardware and forecast for long-term hardware lifecycle usage

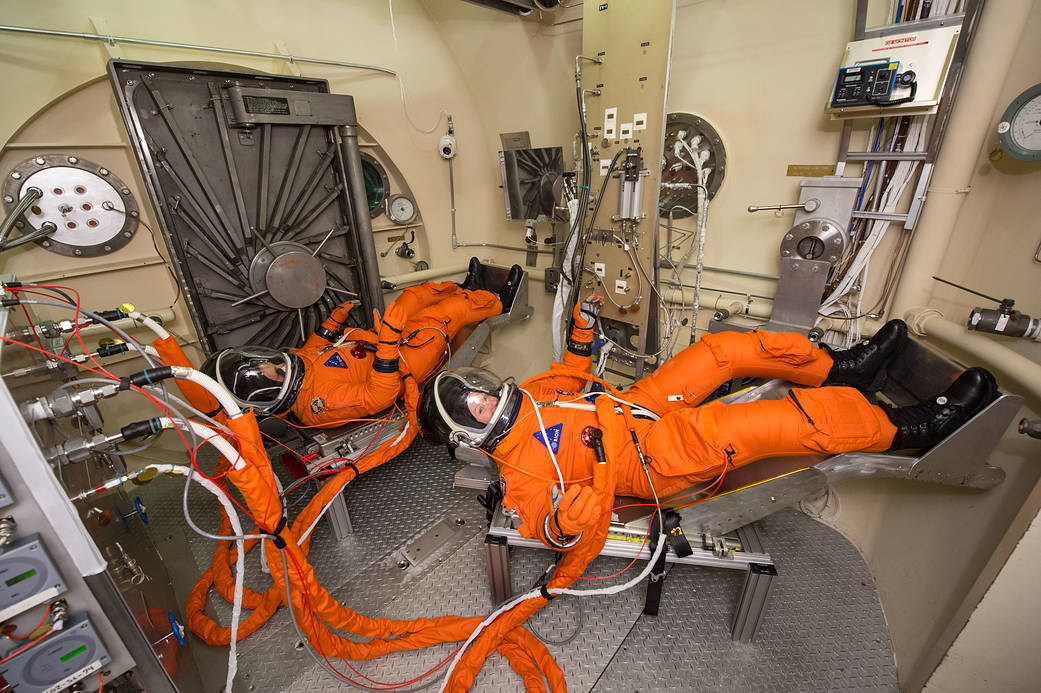

Crew Survival Suit and Equipment

The launch and entry suit provides a survivable environment for the crewmember during launch and landing mission phases and emergency survival and escape hardware to aid in emergency events from bailout to search and rescue anywhere on the planet.

- Crew survival suits and equipment design, development, testing, analysis, certification, and failure investigation

- Launch and entry pressure suits

- Vehicle seats

- Occupant protection systems

- Survival radios

- Life rafts

- Emergency breathing systems

- Automatic inflation life preservers

- Metabolic load physiological limitation studies to determine crewmember heat stress under multiple suit configurations

- Carbon Dioxide (CO2) buildup and washout testing and analysis to disperse helmet CO2 and prevent hypercapnia

- Occupant protection impact testing

- Suit material outgas investigation at vacuum

- Oxygen flammability assessment for emergency breathing hardware

- Multiple crewmember life raft stability studies

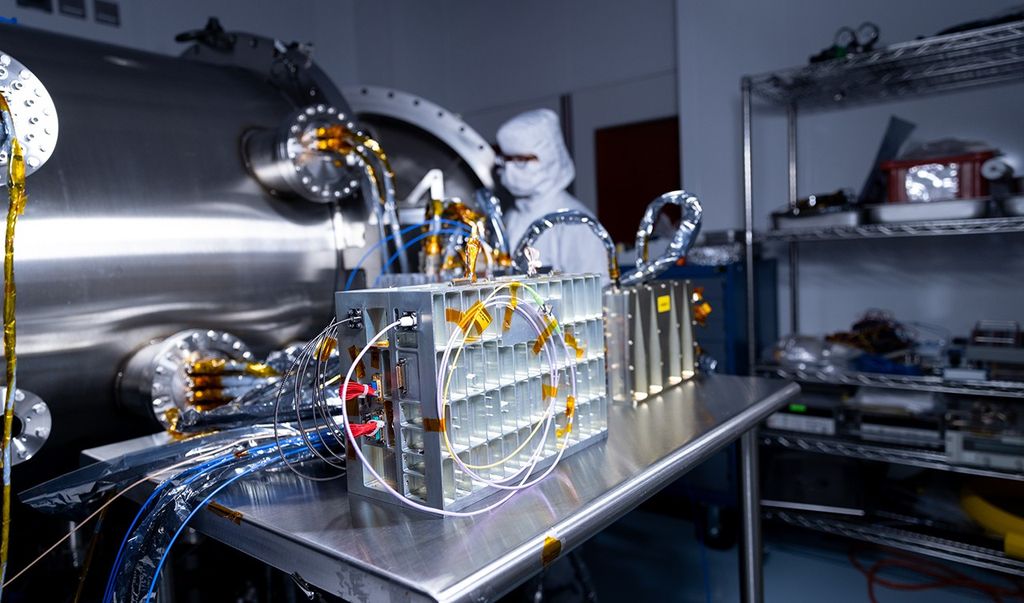

JSC Chamber B

Chamber B is used for human testing in a vacuum environment and for crewed space operations testing. NASA JSC Chamber B provides space environmental testing with vacuum thermal conditions. Chamber B is a human-rated chamber equipped with a traversing monorail that provides weight relief to one suited crew member at a time. The chamber also has dual crew airlocks to provide easy access to the test articles as well as a means of transporting test crew members to the test environment and back during tests. Chamber B has an internal volume of 7.6 m (25 ft) diameter x 7.9 m (26 ft). Its usable test volume and high-fidelity space simulation capabilities are adaptable for thermal vacuum testing of a wide variety of test articles. The low temperature range of the chamber is -300° F. The pressure range of the chamber is from 1×10-6 torr to 760 torr.

Thermal-Vacuum Human-Rated Testing

Johnson Space Center (JSC) is the world leader in human-rated testing in a simulated space environment, offering human testing in vacuum, thermal– vacuum, and vibration environments. JSC offers a collection of unique knowledge and experience as to what works well within the hostile environment of space and what does not. This knowledge is available to support crewed spacecraft and space system hardware design reviews and flight– like simulation of Extravehicular Activity (EVA) operations in pressures ranging from vacuum to one atmosphere.

- Human-rated hardware testing in vacuum and thermal–vacuum environments

- Space suit development testing

- Flight crew training

- Environmental control and life support system testing

- Metabolic loading to life support systems

- Parametric testing

- Emergency and mobility accommodations of suited crew person

- Human-in-the-loop air revitalization system testing

- Carbon dioxide (CO2) removal or reduction testing

- Oxygen (O2) generation testing

- Trace contaminant control testing

- Human-rated vibration testing

- Thermal analysis, including human thermal modeling

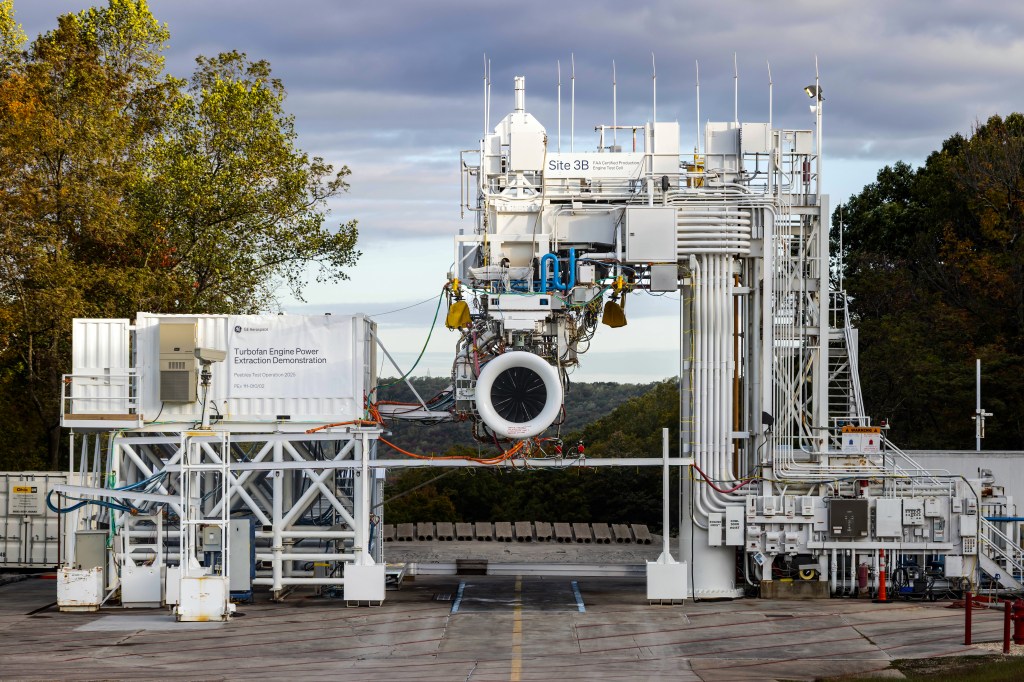

Vacuum Test Facilities (Altitude Chambers)

Johnson Space Center (JSC) provides a wide array of space environment simulation test capabilities. The altitude chambers are used primarily for development, certification, and parametric testing of life support systems for humans in the hostile environment of space. Each altitude chamber is configured for a particular type of testing; however, within the chamber’s capabilities, the chamber complex may be used to perform other types of tests. JSC offers a collection of unique knowledge as to what works well within the harsh environment of space and what does not. Test capability is available for both manned and unmanned test environments.

- Human-rated testing in a vacuum environment

- Space suit development testing

- Flight crew training

- Environmental control and life support system testing

- Metabolic loading to life support systems

- Parametric testing

- Emergency and mobility accommodations of suited crewmember

- Air Revitalization system testing

- Carbon dioxide removal or reduction

- Oxygen generation

- Trace contaminant control

- Materials and hardware testing in a vacuum environment

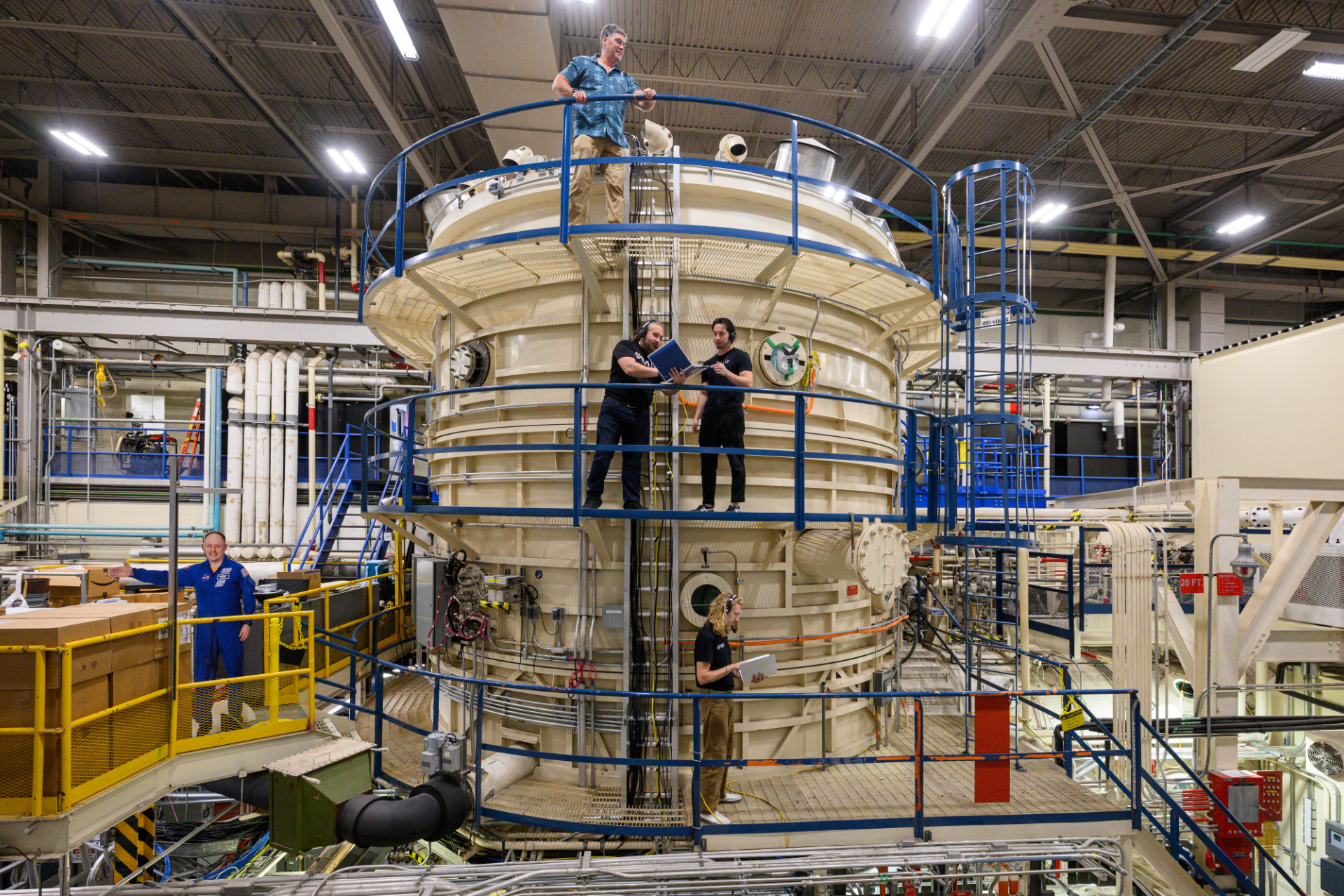

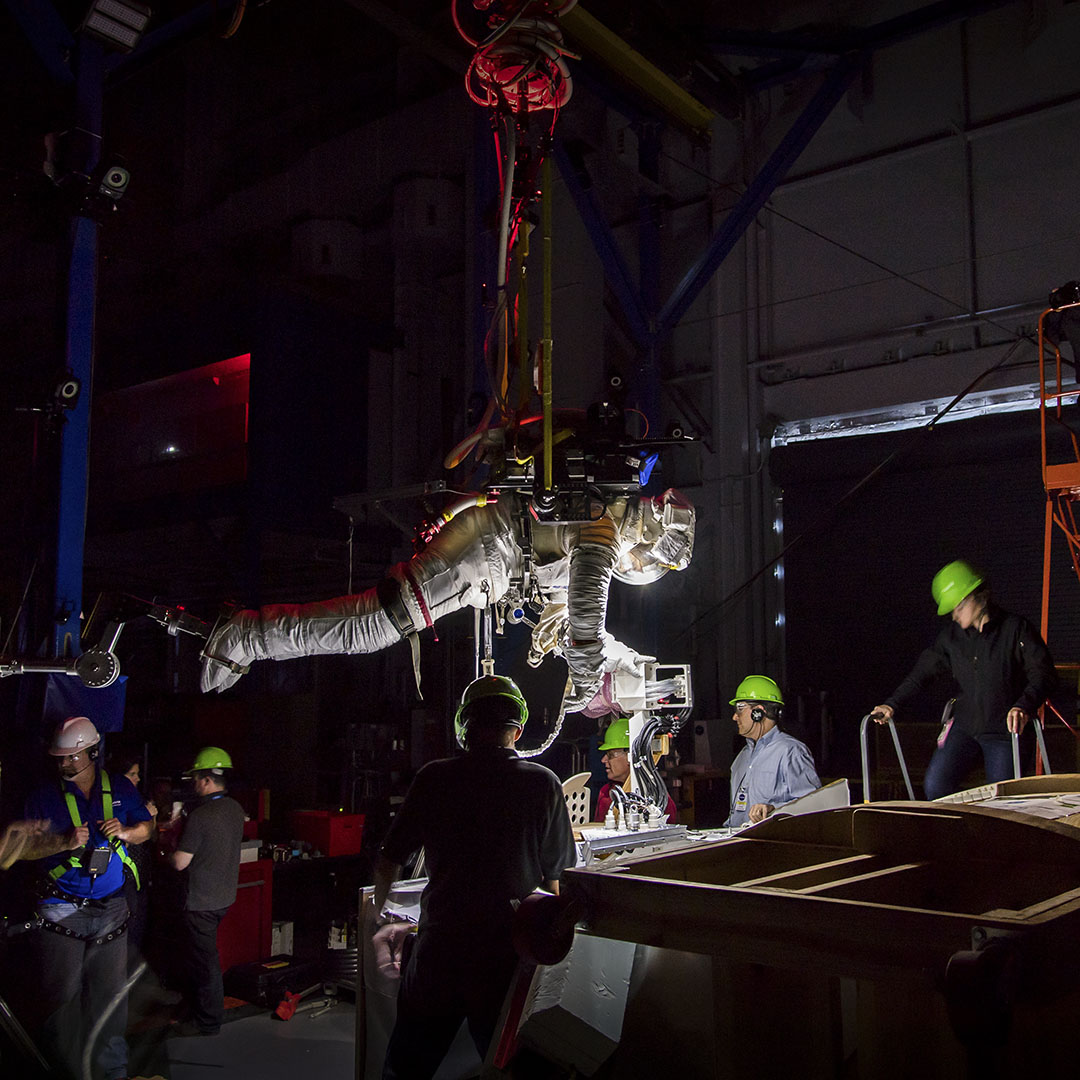

Active Response Gravity Offload System (ARGOS)

Active Response Gravity Offload System (ARGOS) is designed to simulate reduced gravity environments from earth gravity to microgravity. A continuous dynamic offload of a subject’s weight (or portion thereof) is maintained by a robotic motion control system that actively follows the subject’s motion within the system’s operational volume. ARGOS is capable of offloading humans (both in shirtsleeves and space suits), small rovers, and robots for testing, training, process development, and human research in simulated reduced gravity environments. ARGOS 2 resembles an overhead bridge crane 41 x 24 x 25 feet in size. Sensors in the horizontal axes (X and Y) and vertical axis (Z) obtain displacement and force changes of the payload, allowing a computer-controlled winch to provide superimposed constant force offload above the payload’s center of mass.

- ARGOS 2 Specifications

- 750lb offload capability

- 13 feet(X) x 30 feet(Y) x 15 feet(Z) workspace

- System wide communication for test subjects and support teams

- Motion tracking supported by AIBEL

- NASA space suit support supported by Crew and Thermal Systems Division

- Pressurized breathing air

- Cooling water for suits

- Motion capabilities

- Suited Configuration: 4 ft/s vertical, 6.5 ft/s horizontal

- Unsuited configuration: 11 ft/s vertical, 6.5 ft/s horizontal Variety of Gimbals (payload interfaces) to support suited, unsuited, and unmanned testing.

- Supported Test Types

- Suited or unsuited

- EVA in microgravity, Lunar, or Martian gravity environments

- EVA tools, process development

- Biometric studies in reduced gravity environments

- Robotic systems payloads

- New test types are possible

ARGOS technology is available in the NASA Patent Portfolio: https://technology.nasa.gov/patent/MSC-TOPS-60.

Related Patents

Full-Size Reduced Gravity Simulator For Humans, Robots, and Test Objects

Connect With Us

Whether you are a public agency, private company, or academic institution, we look forward to hearing from you. Fill out the Statement of Interest form to submit your inquiry.