Thermal

Contents

Introduction

Thermal testing is critical for designing spaceflight hardware to ensure its resilience and functionality in the extreme temperature variations encountered in outer space. Johnson Space Center (JSC) Thermal-Vacuum Test Facilities provide thermal-vacuum chamber test operations for both crewed and uncrewed test environments. The facilities offer a wide range of performance capability, which can be matched to the individual test requirements of smaller test articles or large test article components and subsystems. Typical uses of these chambers have included development, engineering evaluation, and qualification testing of spacecraft components, subassemblies, and experiments; and preflight thermal-vacuum conditioning of flight hardware.

JSC is also home to the Radiant Heat Test Facility, originally constructed to perform development and certification tests for the Space Shuttle thermal protection system (TPS). Two test chambers are equipped with vacuum pumps and heater assemblies to produce a variable pressure profile and heat fluxes for simulating atmospheric re-entry conditions. We invite customers to leverage our diverse range of thermal testing capabilities in order to pursue our collective exploration of the solar system.

Capabilities

JSC Chamber A

Overview | Chamber A is the largest of the thermal-vacuum test facilities at JSC. The chamber’s usable test volume and high-fidelity space simulation capabilities are adaptable for thermal-vacuum testing of a wide variety of test articles, including entire space vehicles.

Details | NASA JSC Chamber A provides a high vacuum thermal chamber with a usable test volume and space simulation capabilities that are adaptable for testing entire space vehicles. The chamber can simulate low temperatures of deep space (35K) within a 55 feet diameter by 80 feet tall shroud volume. The pressure range of the chamber is from 1×10^-6 torr to 760 torr. Additional test support equipment includes mass spectrometers, infrared cameras, and television cameras. The numerous flanges at all levels provide ample pass-throughs for electrical, instrumentation, and gasses to support large systems.

JSC Chamber B

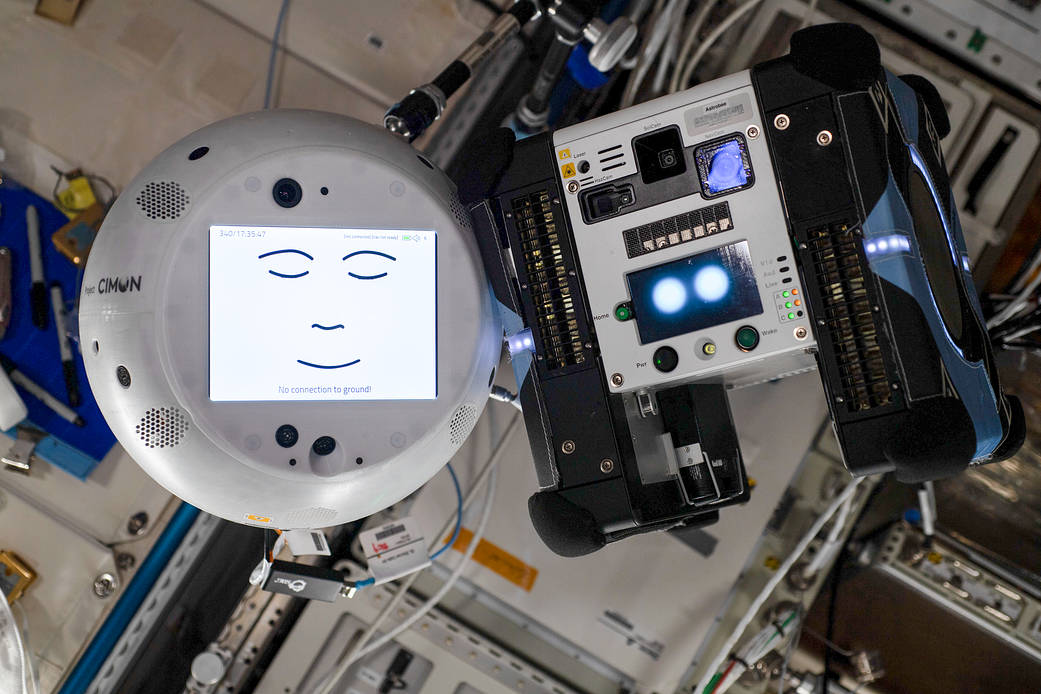

Overview | Chamber B is used for human testing in a vacuum environment and for crewed space operations testing.

Details | NASA JSC Chamber B provides space environmental testing with vacuum thermal conditions. Chamber B is a human-rated chamber equipped with a traversing monorail that provides weight relief to one suited crew member at a time. The chamber also has dual crew airlocks to provide easy access to the test articles as well as a means of transporting test crew members to the test environment and back during tests. Chamber B has an internal volume of 7.6 m (25 ft) diameter x 7.9 m (26 ft). Its usable test volume and high-fidelity space simulation capabilities are adaptable for thermal vacuum testing of a wide variety of test articles. The low temperature range of the chamber is -300° F. The pressure range of the chamber is from 1×10^-6 torr to 760 torr.

Thermal-Vacuum Human-Rated Testing

Overview | Johnson Space Center (JSC) is the world leader in human-rated testing in a simulated space environment, offering human testing in vacuum, thermal– vacuum, and vibration environments. JSC offers a collection of unique knowledge and experience as to what works well within the hostile environment of space and what does not. This knowledge is available to support crewed spacecraft and space system hardware design reviews and flight– like simulation of Extravehicular Activity (EVA) operations in pressures ranging from vacuum to one atmosphere.

Details |

- Human-rated hardware testing in vacuum and thermal–vacuum environments

- Space suit development testing

- Flight crew training

- Environmental control and life support system testing

- Metabolic loading to life support systems

- Parametric testing

- Emergency and mobility accommodations of suited crew person

Human-in-the-loop air revitalization system testing

- Carbon dioxide (CO2) removal or reduction testing

- Oxygen (O2) generation testing

- Trace contaminant control testing

Human-rated vibration testing

- Thermal analysis, including human thermal modeling

Specialized Chambers and Environmental Test Complex

Overview | Contains a collection of chambers of varying thermal & thermal/vacuum environment capabilities configured for testing hardware ranging from flight (qualification) to development hardware in support of JSC Government Furnished Equipment (GFE) activities.

Details |

- Temperature and humidity cycling

- Accurate determination of design factors

- Operating temperatures

- Changes in absorptive or emissive properties of thermal coating

- Changes in electrical or mechanical properties of materials

- Accelerated electrical or electronic components burn-ins and life-cycle testing

- Environmental cycling (thermal and humidity) for materials survivability

Thermal Vacuum Testing

Overview | Johnson Space Center (JSC) Thermal Vacuum Test Facilities provide thermal vacuum chamber test operations for both manned and unmanned test environments. The facilities offer a wide range of performance capability, which can be matched to the individual test requirements of smaller test articles or large test article components and subsystems. Typical uses of these chambers have included development, engineering evaluation, and qualification testing of spacecraft components, subassemblies, and experiments; preflight thermal– vacuum conditioning of flight hardware; development and calibration of instruments for use in the large chambers or in– flight; spacecraft seal studies; photographic film emulsion studies; and optical surface contamination studies.

Details | Human-rated space environmental testing

- 12.5-foot internal diameter spherical chamber with ~78-inch diameter clear entry for easy access

- Materials outgassing evaluations

- Accelerated electrical and electronic component burn-ins and life-cycle testing

- Environmental cycling (thermal and humidity) for materials survivability

- Materials and hardware testing in extreme environments (manned and unmanned)

- Determination of design factors

- Operating temperatures

- Combined thermal and pressure-load distortions of dimensionally critical structural elements

- Fluid and gas leak rates

- Changes in absorptive or emissive properties of thermal coating

- Evolution of harmful or undesirable offgassing products

- Presence of conditions conducive to electrical arc or corona discharge

- Thermal analysis, including human thermal modeling

Thermal Testing

Overview | Johnson Space Center (JSC) thermal test facilities offer a wide range of performance capability, which can be matched to the individual test requirements of smaller test articles or large test article components and subsystems. Typical uses of these chambers have included development, engineering evaluation, and qualification testing of spacecraft components, subassemblies and experiments, and preflight thermal conditioning of flight hardware.

Details | Temperature and humidity cycling

- Accurate determination of design factors

- Operating temperatures

- Changes in absorptive or emissive properties of thermal coating

- Changes in electrical or mechanical properties of materials

- Accelerated electrical or electronic components burn-ins and life-cycle testing

- Environmental cycling (thermal and humidity) for materials survivability

- Battery performance and abuse testing

- Thermal analysis, including human thermal modeling

- Subscale evaluation of thermal components

15-foot Dirty Thermal Vacuum Chamber

Overview | NASA JSC 15-foot dirty thermal vacuum chamber (TVAC) provides unique testing capabilities for dust and planetary surface environments. The 15-foot chamber is a spherical chamber designed to test advanced concepts, especially for battery power systems, space vehicle actuators and auxiliary power units.

Details |

- 12.5-foot internal diameter spherical chamber with ~78-inch diameter clear entry for easy access

- Vacuum conditions: 1×10^-6 torr to 760 torr

- Thermal conditions: -196°C to +120°C

- Air, GN2 pressurization

- Feed-throughs for high-power electrical connections and high-channel count data

- Control automation enabling low-cost operations

- Ambient dust containment room for regolith control and testing

- Hardware exposure testing to dust / regolith

- Regolith bin for design and test of excavation, processing, or construction technology

Regolith Simulant Component Test Lab

Overview | The Component Test Lab offers multiple small vacuum environments for testing in simulant and a simulant dispersal test box with ambient dispersal capabilities.

Details |

- Multiple 1’-3’ thermal vacuum bell jars for testing with simulant

- Ambient 2’ x 2’ x 3’ dust box for quick and easy functional testing with fan-blown simulant

Radiant Heating Test Facility (RHTF)

Overview | The Radiant Heat Test Facility (RHTF) provides for simulation of the heating experienced by spacecraft as they enter planetary atmospheres. The facility provides the capability to perform multi-zone, high-temperature, radiant heat testing of large spacecraft thermal protection systems and associated structures in a controlled pressure environment to simulate entry thermal profiles, thermal gradients, and pressures.

Details |

- Basic material testing and screening

- Development testing – gaps, seals, and attachments

- Clipped hardware

- RCS nozzles, antennas, instrument penetration, windows, and hatches

- Sustaining Engineering

- Orbital debris

- Design changes

- Recertification of materials

- Simulation

- Ascent heating and pressure decay

- On-orbit cold soak

- Reentry heating and pressure

- Uniquely shaped large scale system tests

- Nose cap

- Wing leading edge

- Small scale tests

- Materials screening

- Conductivity testing

- Advanced materials