Robotics

Robotics are critical for human spaceflight as they enhance mission success by enabling dexterous manipulation, autonomous vehicle operation, and efficient system management, thereby reducing human risk and expanding the capabilities for exploration in the challenging environments of space. Johnson Space Center (JSC) provides research, engineering, development, integration and testing of robotic hardware and software technologies for robotic systems applications in support of human spaceflight. Advanced robotic systems technology efforts include both remotely controlled robots for space and terrestrial application and intelligent robotics for high value functionality. JSC technology development laboratories have produced the Robonaut, an anthropomorphic robot with dexterity close to that of humans, and the Lunar Electric Rover.

JSC’s capabilities encompass a wide range of expertise in robotics and vehicle development. We focus on the design and development of highly dexterous manipulators, including aspects such as force-controlled manipulation, variable stiffness joints, human-like end effectors, integrated machine vision, and human-compatible robot operations. We also design and develop electric vehicles for use in extreme environments, whether on Earth or in outer space, addressing features like active suspension systems, efficient transmissions, vehicle autonomy and navigation, efficient motor control, and high voltage DC systems. Additionally, JSC’s capabilities extend to the design of robotic interfaces, free-flying robotic micro/nanosatellite-class platforms, analysis of capture and berthing of free-flying vehicles, simulation and verification of robotic workstation interfaces, physical emulation of robotic devices, development of intra-vehicular robotics concepts for crew-tended spacecraft, and the creation of vehicle systems management concepts with a focus on operational autonomy through a distributed, hierarchical architecture with clear interface definitions and redundancies for data in case of failure or degradation.

We invite our partners to unlock the future of innovation and efficiency by leveraging our unparalleled robotics services and expertise tailored to meet your specific needs.

Robotics Testing & Analysis

Dexterous Robotic Team

The Dexterous Robotics Team (DRT) combines expertise in advanced robotics hardware and software, high-performance avionics, embedded systems, and mechatronics for spaceflight and terrestrial applications. The goal of the team is to bridge the gap between advanced robotic technologies and the unique requirements for space exploration and any application where robots can reduce danger to humans or enhance human team effectiveness in operational environments. The DRT has a proven track record of rapidly developing, integrating, and deploying robotic systems in partnership with commercial industry to meet complex stakeholder needs. In addition, the DRT specializes in designing custom electronics, actuators, mechanisms, and fixtures. Collaboration is central to their mission, working closely with other government agencies, academic institutions, and commercial industry partners large and small.

- Industry-led Technology Partnerships

- Space application consultations for companies considering the space market

- Partnership development and teaming with startups, small businesses, and established technology providers

- Technology partnerships with businesses seeking to apply NASA technologies to terrestrial use cases, such as oil & gas, chemical processing, hazardous environments, subsea, and many more

- Advanced Robotics Software and Simulation

- ROS / ROS 2

- Robotic Manipulation

- Perception Systems (Cameras, LiDAR, RADAR, OpenCV, etc.)

- Task & Motion Planning (MoveIt, OMPL, PDDL, MTC)

- Advanced Robotics Control

- Robotic Mobility, Navigation, Mapping and Obstacle Avoidance (NAV2, OCTOMAP, etc.)

- Robotics Engineering Simulations (Gazebo, MuJoCo, Omniverse)

- High-Performance Avionics & Embedded Systems

- PCB & Electronics Design

- Motor Control Systems

- Firmware Development (FPGA & MCU)

- Custom EtherCAT Solutions for Space Applications

- High-Performance Spaceflight Computer (HPSC) Development on RISC-V

- Complex Automation and Mechatronics

- Mechanical Design & Development

- Turnkey Mechatronic / Electromechanical Systems

- Actuator Sizing & Custom Actuation Design

- System Identification & Characterization

- Rapid, Iterative Prototyping & Development

Check out our Github projects at the following link:

https://github.com/NASA-JSC-Robotics

Humanoid Robotics

Johnson Space Center (JSC) provides research, engineering, development, integration and testing of robotic hardware and software technologies for robotic systems applications in support of human spaceflight. Advanced robotic systems technology efforts include both remotely controlled robots for space and terrestrial application and intelligent robotics for high value functionality and their interoperability. JSC technology development laboratories have produced anthropomorphic robots with dexterity close to that of humans, Robonaut and Valkyrie.

- Design and development of highly dexterous manipulators

- Force-controlled manipulation

- Variable stiffness joints

- Human-like end effectors

- Integrated machine vision

- Human-compatible robot operations

- Design and development of robotic interfaces

- Robotic interface and system requirements definition and verification

- Simulation and verification of robotic workstation interfaces

- Physical emulation of robotic devices with motion platforms

Robotics Human Machine Interface Development

JSC provides expertise in software and displays for robotics operations both on-orbit and in Mission Control Center (MCC) that maximizes safety and increases automation in robotics operations.

- Develop displays and video overlays that present the crew with vehicle telemetry in intuitive ways

- Creation of a software development environment that assists operators and flight-controllers in the development of automation products such as scripts, procedures, and command plans

Robotics Sustaining Engineering for Human-Rated Space Vehicles

Expertise is available in maintaining a safe efficient robotic capability to maximize science and robotic operational life and sustaining engineering and systems management for on-orbit robotics, including these on ISS, Gateway, and Low-Earth Orbit vehicle providers.

- Robotic Mission Planning Review (Procedure review/update, Flight Rules, etc.)

- Real-time robotics system expertise for nominal and off-nominal operations

- Anomaly investigation and resolution of technical issues with robotic systems and interfaces to dependent systems

- Define, update, and maintain robotic system requirements and verifications

- Review change proposals, waivers, deviations, and exceptions

- Perform trending of robotics systems health

- Integration support with external equipment

- Provide software build feature/capability priorities to robotic SW designers (in house or out)

- Testing and evaluation of payloads for robotic compatibility (including Flight Support Equipment and latching)

- Perform Berthing Camera/Target System implementation tasks for Visiting Vehicles and payload, including overlay development

- Visiting Vehicle robotic development support

- Integration of payloads as pertains to robotic compatibility

- Development of robotics requirements for payload handling

- Review exceptions to requirements and initial verification products

- Coordinate issues/concerns/questions with SMEs

- Review verification submittals

- Coordinate operations

- Robotics Human-Machine Interface

- Develop some integrated SW that utilizes vehicle telemetry to report data to users in intuitive ways

- Develop SW to assist operators in development of on-console products

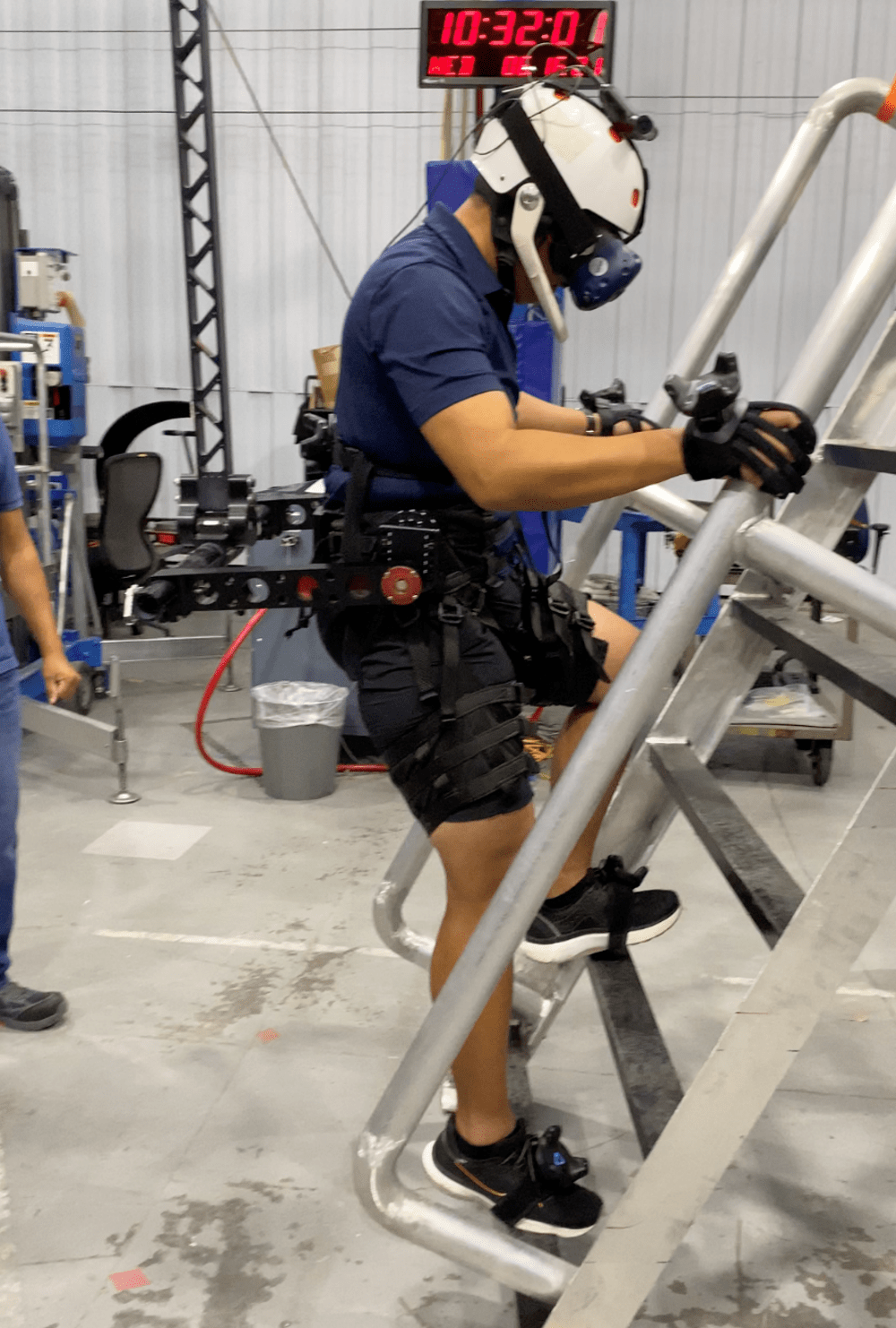

Technology Development for Human Health and Performance (Wearable Robotics)

Johnson Space Center’s (JSC’s) HumanWorks Lab provides human health and performance technology development, incubation, and integration for human spaceflight.

- Provides tools to address human health and performance gaps while collaborating with external partners

- Wearable robotics for assistance, exercise, rehabilitation

- Physiology sensing technologies

- Human health data applications

- Gamification of training and exercise

- General prototyping, innovation, collaboration

Robotics Performance Analysis

JSC provides robotics analysis for multi-system studies for robotically capturing space vehicles and docking them to a host vehicle.

- Expertise in Robotic Dynamic Analysis

- Failed capture analysis

- Release Analysis

- Berthing Analysis

Testing Facilities

Integrated Mobile Evaluation Testbed for Robotics Operations (iMETRO)

iMETRO is a NASA facility for functional testing of robotic hardware and software in realistic space exploration environments including simulation, indoor space vehicle and habitat mock-ups, and outdoor EVA proving grounds. Do you have a robotic or artificial intelligence (AI) technology that needs to be demonstrated in a relevant space environment? Are you looking for ways to advance the Technology Readiness Level (TRL) to level 4 and beyond for space exploration applications? If so, NASA JSC’s iMETRO facility has solutions for you. Whether you need to test a whole robot or a single hardware or software component, iMETRO has you covered with a variety of “house robots” to use for your test. Our JSC robotics engineers are ready to assist with any level of integration desired, for 1-hour consultations to extended test campaigns.

iMETRO Open-Source Software and Simulation

- The virtual facility includes open-source robot configurations (e.g., URDF) for iMETRO robots as well as models of mock-ups for space use cases, such as the crew access hatch and logistics stowage task trainer.

- ROS2 compatible software interfaces

You can check out the iMETRO open-source simulation assets, software, and documentation on Github at the link below. The iMETRO team is always making updates and adding new features:

https://github.com/NASA-JSC-Robotics/iMETRO

iMETRO Lab Facility Features

- The physical facility consists of many robots, space application mockups, and support instrumentation and computing. A variety of mock-ups and task trainers are available to use, and additional customized mockups can be designed and constructed by JSC staff for mission scenarios as needed.

- Overhead PTZ video cameras

- Remote operator situational awareness

- Optical tracking ground truth for pose estimation and navigation

- Isolated robot network with configurable latency and bandwidth restrictions (currently a future planned capability)

iMETRO Outdoor Rockyard Features

- Outdoor lunar and Mars yards

- Control station trailer

- Outdoor mobile dexterous robots

- Drone operations support

- Link to JSC Rock Yard maps: https://ntrs.nasa.gov/api/citations/20240002135/downloads/Rock_Yard_Map_Book.pdf

Robot Options

- Linear Rail-mounted Single Manipulator Arm

- Universal Robots UR10e

- Robotiq hand-E Gripper w/ Custom Fingers

- Vention horizontally mounted 2.0m linear rail

- Ewellix Telescoping Lift Kit with 700mm Stroke

- Intel® RealSense™ Wrist-Mounted Depth Camera

- Indoor Mobile Base with Dual Manipulator Arms

- Universal Robots UR5e (2x)

- Robotiq Hand-E Grippers with Custom Fingers

- Arms mounted to dual, independent lift-kits of 500mm Stroke

- Clearpath Ridgeback Wheeled Mobile Base

- Intel® RealSense™ Wrist-Mounted Depth Cameras

- Outdoor Mobile Base with Single Manipulator Arm (coming 2026)

- Universal Robots UR10e (Option for UR30)

- Robotiq hand-E Gripper w/ Custom Fingers

- Intel® RealSense™ Wrist-Mounted Depth Camera

- Bring Your Own Sensors and/or End Effectors

- Utilize standard interfaces

- Bring Your Own Robot

- Test custom configurations with space application mock-ups

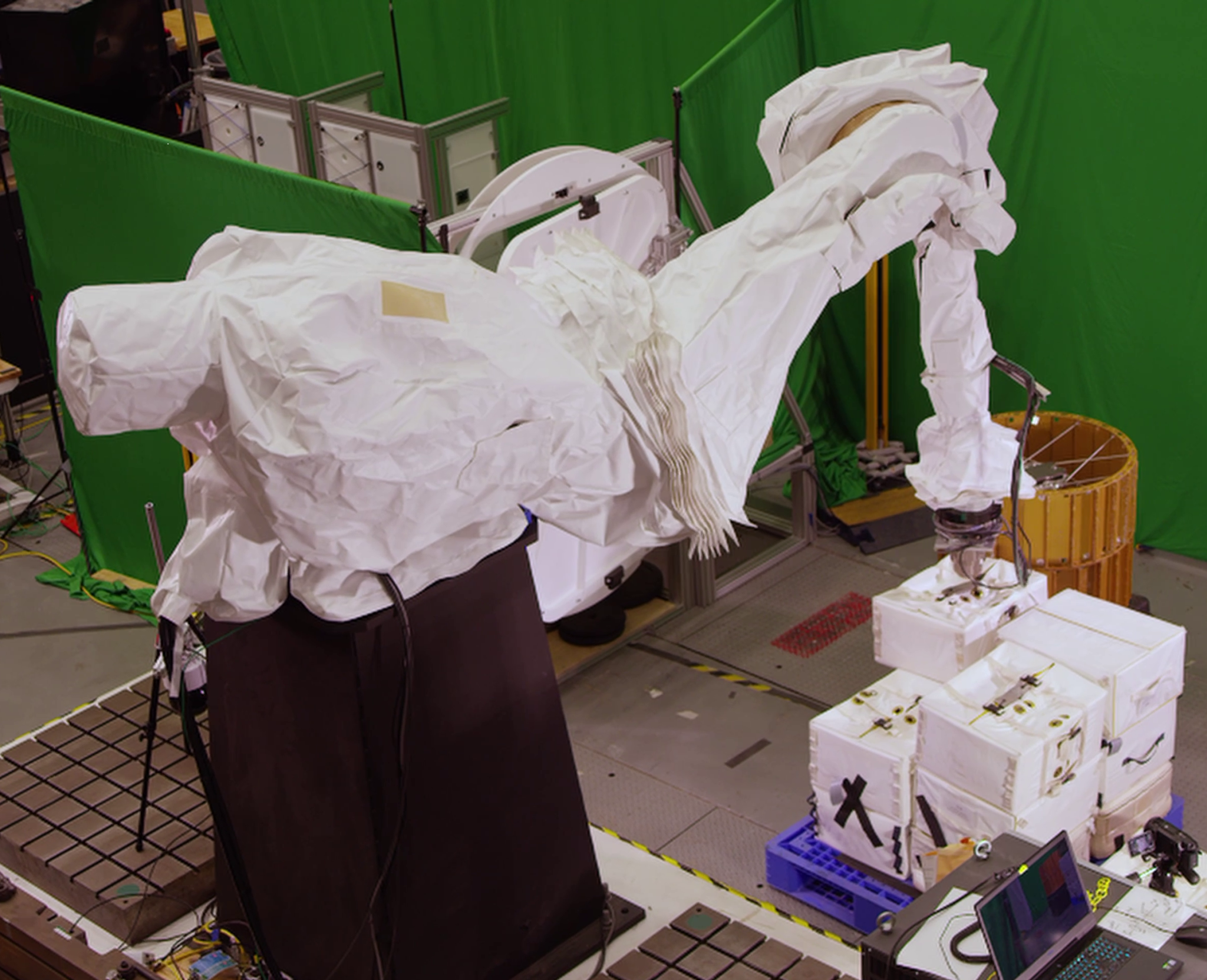

Electric Dexterous Manipulator Testbed (eDMT)

The Electric Dexterous Manipulator Testbed (eDMT) is used for testing space robotic payloads, interfaces, and concepts of operation for ISS and future Moon and Mars exploration missions. It consists of multiple Commercial Off-The-Shelf (COTS) serial manipulators. These manipulators can be used to perform a wide range of dynamic simulations and operational feasibility assessments. They range in size and payload capacity, so that smaller units can be relocated to other testing environments. Components have been designed to maximize compatibility in rugged, unstructured, and even vacuum environments.

Testbed Features:

- Closed-loop force and moment accommodation

- Detailed force and position metrology

- Mounted T-slot tables for mockup integration

- On-orbit Tool Change Mechanism Emulator (OTCME) end effector for grasping standard interfaces

- Optical motion tracking

Yaskawa Motoman ES165RD-II:

- 3 meter reach

- 165 kg payload capacity

- Permanent mount in facility

- ISS emulation end effector

Kuka KR70 R2100:

- 2.1 meter reach

- 70 kg payload capacity

- Fast response to sensor feedback, ideal for handling delicate payloads and testing autonomous operations

- Pedestal mounted in facility, but lightweight enough to transport via forklift for integrated testing

- Reconfigurable gripper interface

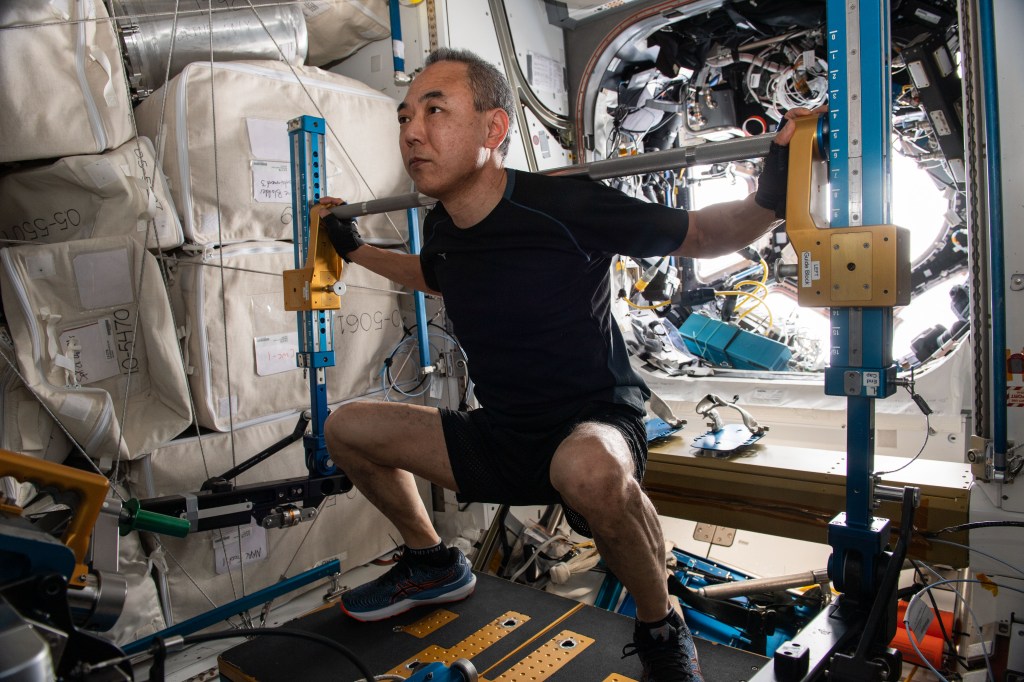

Active Response Gravity Offload System (ARGOS)

Active Response Gravity Offload System (ARGOS) is designed to simulate reduced gravity environments from earth gravity to microgravity. A continuous dynamic offload of a subject’s weight (or portion thereof) is maintained by a robotic motion control system that actively follows the subject’s motion within the system’s operational volume. ARGOS is capable of offloading humans (both in shirtsleeves and space suits), small rovers, and robots for testing, training, process development, and human research in simulated reduced gravity environments.

ARGOS 2 resembles an overhead bridge crane 41 x 24 x 25 feet in size. Sensors in the horizontal axes (X and Y) and vertical axis (Z) obtain displacement and force changes of the payload, allowing a computer-controlled winch to provide superimposed constant force offload above the payload’s center of mass.

ARGOS 2 Specifications

- 750lb offload capability

- 13’(X) x 30’(Y) x 15’(Z) workspace

- System wide communication for test subjects and support teams

- Motion tracking supported by AIBEL

- NASA Space suit support supported by Crew and Thermal Systems Division

- Pressurized breathing air

- Cooling water for suits

Motion capabilities

- Suited Configuration: 4 ft/s vertical, 6.5 ft/s horizontal

- Unsuited configuration: 11 ft/s vertical, 6.5 ft/s horizontal Variety of Gimbals (payload interfaces) to support suited, unsuited, and unmanned testing

Supported Test Types

- Suited or unsuited

- EVA in microgravity, Lunar, or Martian gravity environments

- EVA tools, process development

- Biometric studies in reduced gravity environments

- Robotic systems payloads

- New test types are possible

ARGOS technology is available in the NASA Patent Portfolio: https://technology.nasa.gov/patent/MSC-TOPS-60.

Related Patents

Advanced Humanoid Robotic Arm Technologies

Advanced Humanoid Robotic Hand Technologies

Advanced Humanoid Robotic Interface & Control

Advanced Robotic Sensing Technologies

Computer Vision Lends Precision to Robotic Grappling

Full-Size Reduced Gravity Simulator For Humans, Robots, and Test Objects

Precision Low Speed Motor Controller

Robonaut 2: Hazardous Environments

Robonaut 2: Industrial Opportunities

Robonaut 2: Logistics and Distribution

Robonaut 2: Medical Opportunities

Robotic Inspection System for Fluid Infrastructures

Upper Body Robotic Exoskeleton

Related Software

Approximate Cartesian Control for Robotic Tool Usage with Graceful Degradation

LAGER (Light-weight Accumulator Gathering Efficiently in Real-time)

Manipulator Analysis – Graphic, Interactive, Kinematic (MAGIK) Robotic Simulation Version 8.1

Connect With Us

Whether you are a public agency, private company, or academic institution, we look forward to hearing from you. Fill out the Statement of Interest form to submit your inquiry.