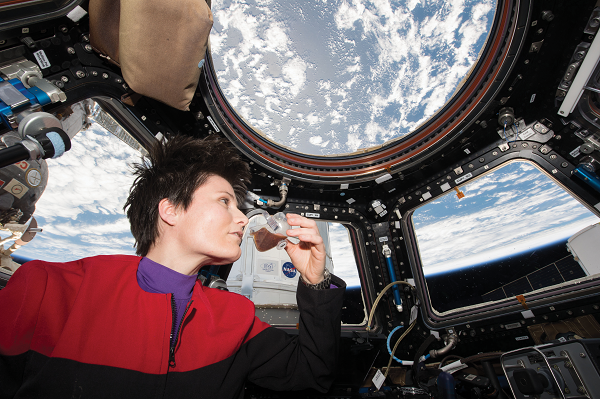

Studying fluids in microgravity is improving consumer products like shampoo and advancing technologies like life support systems

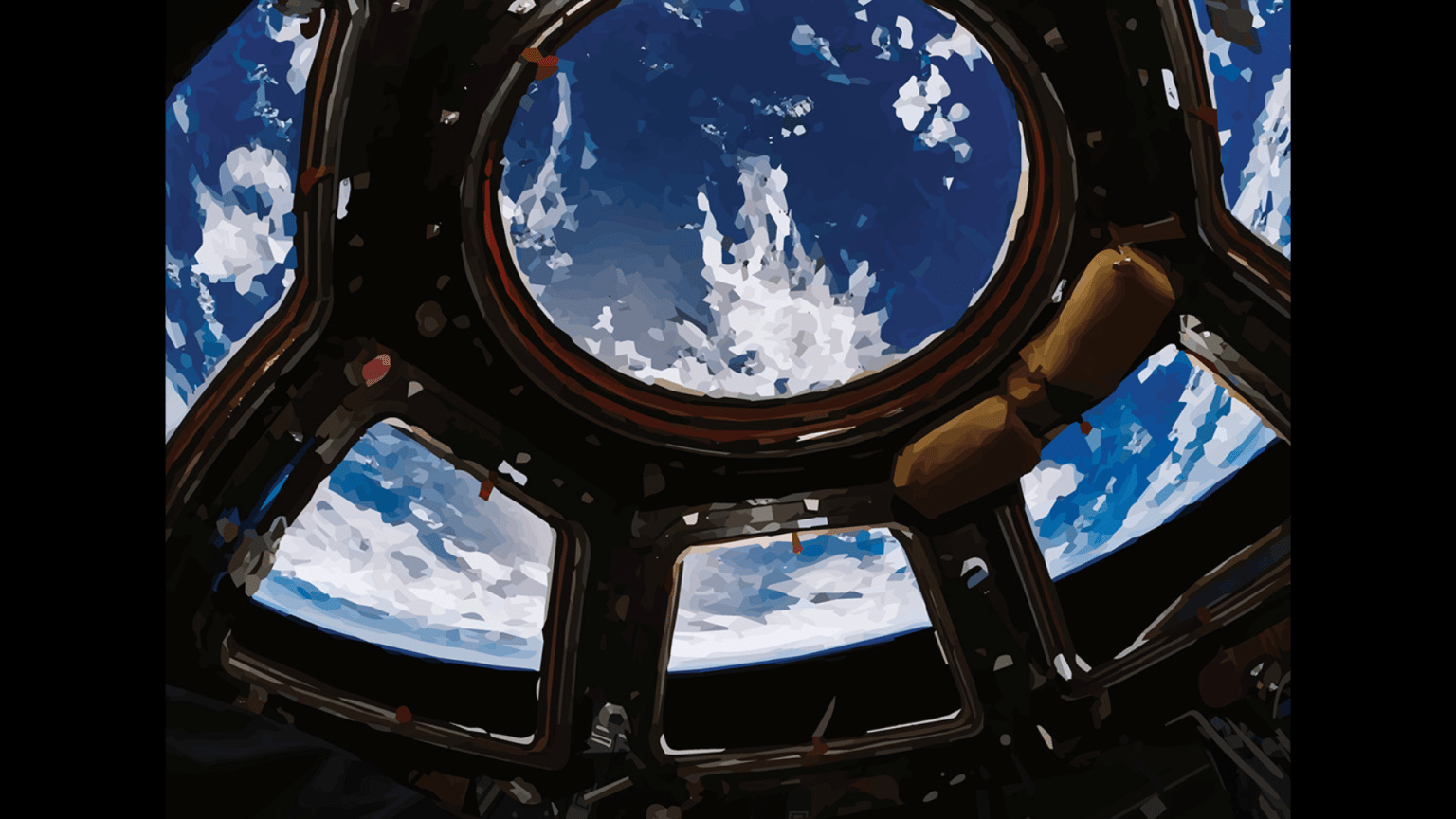

The fog of gravity is present in every experiment performed on Earth, clouding those observations and limiting our understanding. Heading to the International Space Station removes that fog.

Microgravity allows researchers to study the physics of our universe, from the properties of metals to atoms, through a completely new lens. Research on the space station is revealing fundamental science that can change our lives on Earth.

“Being in microgravity, you are in an environment where you can remove gravity. So, some processes that are masked on Earth you can study in this environment,” says ESA (European Space Agency) scientist Marco Braibanti.

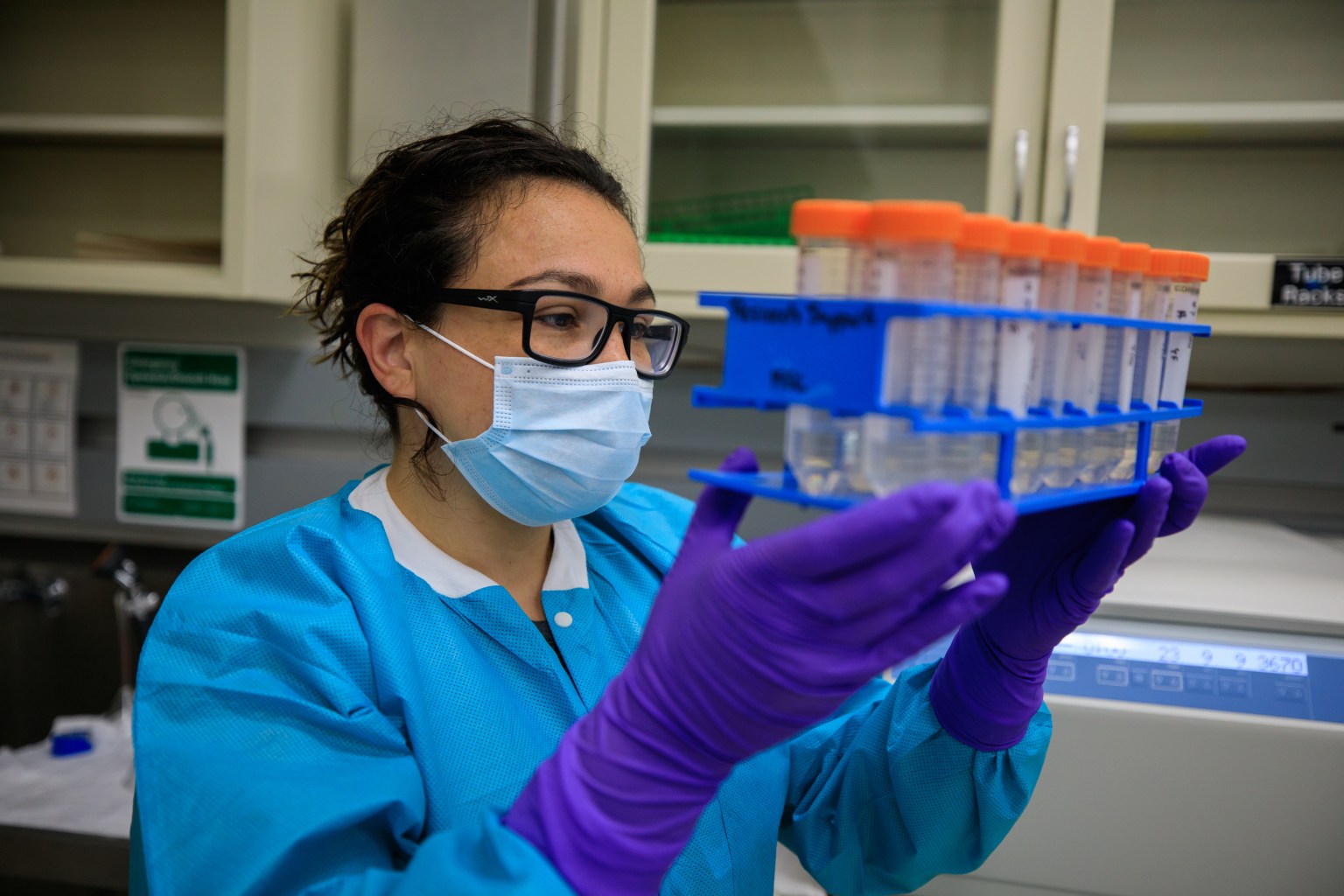

Colloids are mixtures of tiny particles suspended in a liquid. They include natural mixtures such as milk and muddy water as well as a range of manufactured products from shampoo to medicine to salad dressing. Studying colloids is complicated by the fact that gravity causes some particles to rise and others to sink. Microgravity removes that complication and makes possible research like the Advanced Colloids Experiments (ACE) conducted by NASA, the International Space Station (ISS) National Laboratory, and Procter & Gamble (P&G). This series of studies helps companies design better products used in our everyday lives and could inform the creation of entirely new ones, including some that could enable exploration farther into space.

The latest formulation of P&G’s Febreze Unstopables TOUCH Fabric Spray with touch-activated scent release technology is the first to incorporate materials based on this colloids research.

“It’s an amazing fluid that looks and feels like water,” says P&G researcher Matthew Lynch.

“The work on the station helped us envision and understand the formulation.”

Lynch says some two-thirds of P&G’s biggest brands could benefit from colloids research and in turn improve products for consumers. Space station research has contributed to three new patents for the company. Lynch points out that even a 1% savings in production costs or a slightly longer shelf life for household staples such as Downy fabric softener becomes significant. P&G products are used by an estimated 4.8 billion people every day—more than half of Earth’s population.

“The success of the P&G spaceflight experiments is more than just a compelling business impact,” Lynch said. “More importantly, what we learn here is going to help a lot of people.”

Other companies, including Delta Faucet, also have taken advantage of station physics research to improve their products. Their Droplet Formation experiment in collaboration with the ISS National Laboratory used microgravity to evaluate water drop formation and water flow from Delta Faucet’s H2Okinetic showerhead to create better performance, improve user experience, and conserve water and energy.

ESA also performed numerous microgravity fluids studies, contributing greatly to our understanding of boiling, heat transfer, and fluid flows. The FOAM experiment studied bubble size, rearrangement dynamics, and other properties of wet foams. Foams break down quickly in gravity, making them difficult to study on Earth.

“On Earth, liquid drains. That masks some other effects like coarsening, which is when gas passes between foam bubbles,” says Braibanti.

Solid and liquid foams are used across a variety of industries, from cleaning products to food and medicines. Gaining a better fundamental understanding of foams could help improve their control and process design in these industries.

“We can learn something new doing experiments that nobody has done before in a unique environment. You learn new things that you can then apply in novel applications on Earth and in space,” says Braibanti.

The ESA RUBI experiment analyzed a very different type of bubbles: those formed during boiling. Without gravity, boiling takes place in slow motion and produces larger bubbles. RUBI allows scientists to observe and measure effects that are too fast and too small on Earth, getting a more complete understanding of heat transfer during the boiling process. This information could be applied to help cool electronics such as laptops more efficiently.

“Scientists are in the process of analyzing all of RUBI’s data. Then we are planning to launch a new facility called Heat Transfer Host that hosts a number of different experiments in the field of heat transfer. The idea is to use the results that we have from RUBI in the design of the new experiments,” says ESA scientist Sebastien Vincent-Bonnieu.

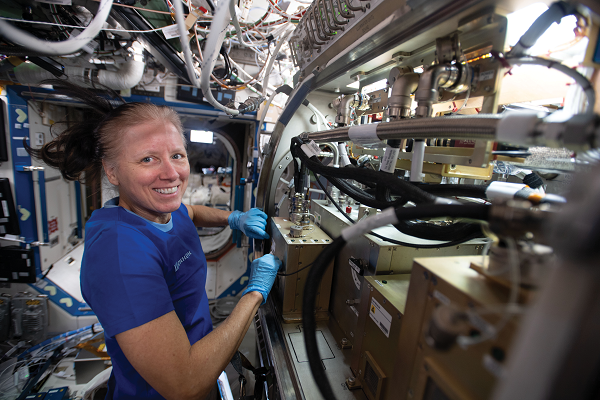

The changes that microgravity causes in fluid behavior also can present challenges for transitioning Earth technologies to space.

“We test reactor beds extensively on the ground, then fly the same thing and it underperforms in space,” said Packed Bed Reactor Experiment (PBRE) principal investigator Brian Motil of NASA’s Glenn Research Center in Cleveland, Ohio.

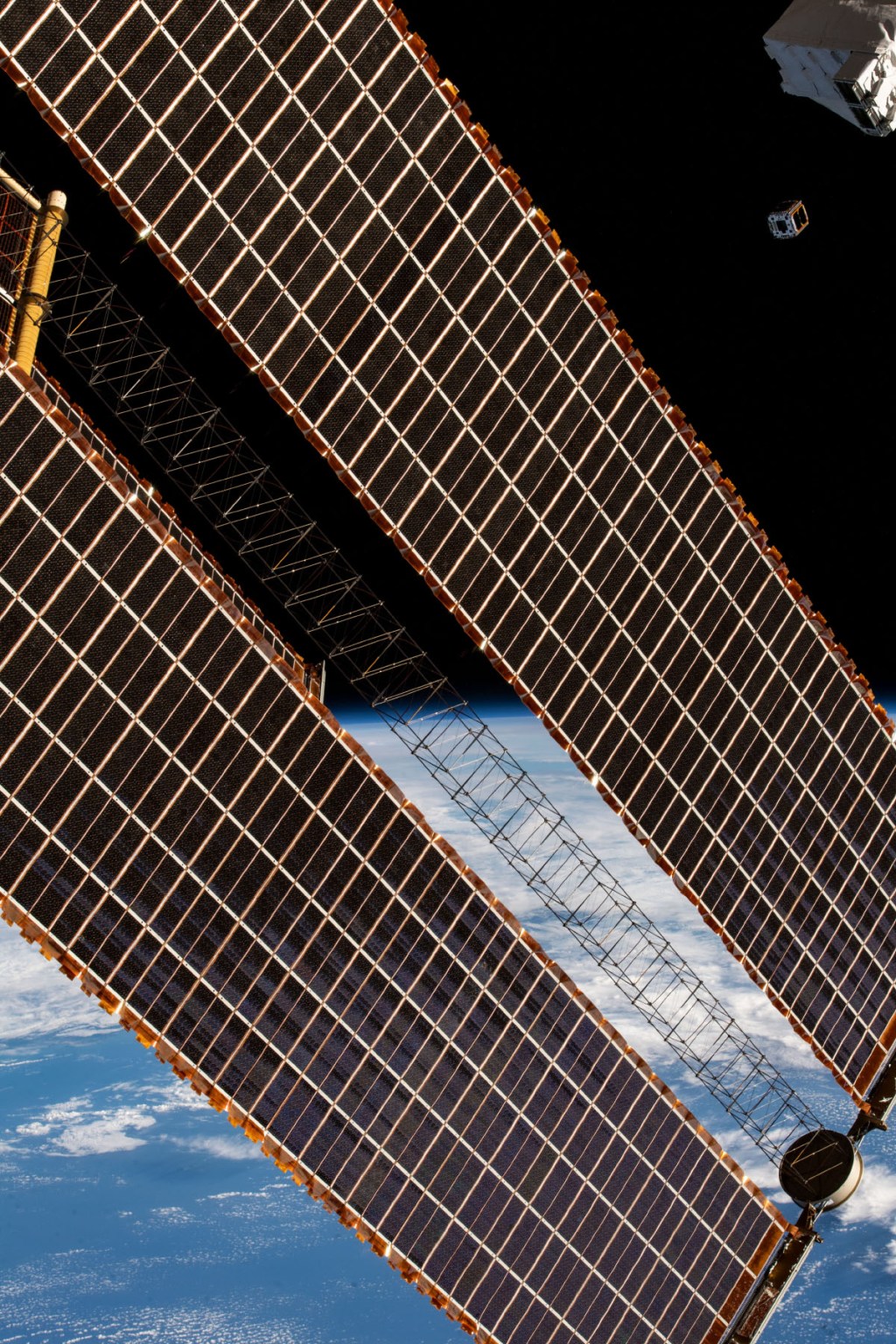

Reactors are critical to space exploration: they are used to reclaim and purify water, clean air, and provide many of the life-sustaining processes we take for granted on Earth. Because of the gap in our knowledge about how two-phase (i.e., between a gas and liquid, or between a liquid and solid) systems work in microgravity, reactor designers do not have the necessary tools to create more efficient systems. And as we travel farther into space, reactor efficiency must improve.

“The pressure drop in reactors in space is different than we expected,” said Motil. “Because of that, our focus has been to answer those fundamental questions of what is going on and what is the minimum flow rate we need to flush bubbles out of the system.”

The space station provides a tool for understanding this drop of performance and could enable scientists to increase the efficiency of life support systems.

“This research will enable us to do long-duration spaceflights, ones where astronauts will have to recycle most of their resources. Reactor beds are one of the many technologies that really need to be well tested prior to going to Mars,” said Motil. “Without the space station, we have no platform to validate what we have developed.”

Pressure drop calculations generated by the PBRE team so far have already been successfully applied to other station experiments at high flow rates. The IVGEN study, which tested the ability to generate water of sufficient quality for intravenous use in microgravity for medical emergencies, used these calculations to flush their system before the experiment. But high flow rates can damage reactor bed material, so research continues to conquer the low flow rate question.

Other space station fluids experiments also are providing actionable information and results. The ESA SODI-DCMIX study calculated how much certain mixtures of fluids and gas molecules move and collide, which could help us better understand the behaviors of these chemicals in underground oil reservoirs. Studies of capillary forces, the small pushes and pulls that move liquid through a narrow tube, have led to the development of a special cup that can be used in space and the testing of new life support systems that rely on shapes and fluid dynamics rather than complex pumps to move and store liquid.

“We have shown to the scientific community this can work and deliver interesting results,” said Vincent-Bonnieu. “And now that we are delivering a number of results, we are actually seeing growing interest in space station research. We are opening more doors than we are closing.”